Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

CAD CAM Syllabus

Caricato da

Deepak AwasthiDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

CAD CAM Syllabus

Caricato da

Deepak AwasthiCopyright:

Formati disponibili

MEE307 Version No.

Prerequisite Objectives:

CAD/CAM

2 0 4

1.01 MEE302 Design of Machine Elements 1. To understand the basics of CAD/CAM. 2. To gain exposure over the concepts of computer graphics. 3. To learn about the geometric issues concerned to the manufacturing and its related areas. 4. To understand the latest advances in the manufacturing perspectives. Expected Student will be able to Outcome: 1. Understand the importance of CAD/CAM principles in the Product development. 2. Develop programs related to manufacturing using codes. 3. Analyze the importance of networking in manufacturing environment. Unit I Computer Hardware Product Development Cycle Introduction to CAD/CAM Graphics input devices- cursor control devices, Digitizers, Scanners, speech oriented devices and touch panels, Graphics display devices CRT, color CRT monitors, DVST, Flat- panel display, Graphics output Devices Printers and Plotters Graphics Standards Neutral File formats IGES, STEP Unit II Principles of Computer Graphics Geometric Modeling Wireframe, Surface and Solid CSG and B-Rep- World/device coordinate representations, 2D and 3D geometric transformations, Matrix representationtranslation, scaling, shearing, rotation and reflection, composite transformations, concatenation Graphics software, Graphics functions, output primitives- Bresenhams Algorithm and DDA Unit III CNC Machine Tools Introduction to NC, CNC, DNC- Manual part Programming Computer Assisted Part Programming Examples using NC codes- Adaptive Control Canned cycles and subroutines CAD / CAM approach to NC part programming APT language, machining from 3D models Unit IV Group Technology, CAPP and FMS Introduction to part families-parts classification and cooling group technology machine cells-benefits of group technology Process Planning CAPP & types of CAPP Flexible manufacturing systems (FMS) the FMS concept-transfer systems head changing FMS Introduction to Rapid prototyping, Knowledge Based Engineering. Unit V CIM CIM wheel CIM Database- CIM-OSI Model Networking Standards in CIM Environment Network structure Network architecture TCP/IP, MAP Virtual Reality, Augmented Reality- Artificial Intelligence and Expert system in CIM. Text Books Mikell P. Groover and Emory W. Zimmers, CAD/CAM Computer Aided Design and Manufacturing, Prentice Hall Edition, 2004 References 1. Mikell P. Groover, Automation, Production Systems and Computer Integrated Manufacturing, Pearson Education, 2005 2. James A. Rehg, Henry W. Kraebber, Computer Integrated Manufacturing, Pearson Education. 2002 3. Ibrahim Zeid, Mastering CAD/CAM, Tata McGraw Hill International Edition, 2005 4. Donald Hearn and M.Pauline Baker Computer Graphics Prentice Hall, International., 1992

5. Ranky, Paul G., Computer Integrated Manufacturing, Prentice Hall, International., 1986 Mode of Evaluation Quiz/Assignment/ Seminar/Written Examination Recommended by the Board of Studies on: 31-10-2009 Date of Approval by the Academic Council: 27-11-2009

MEE307L

CAD/CAM LAB

CAD EXPERIMENTS 1. Structural analysis of Trusses 2. Structural analysis of Beams 3. Structural analysis of Frames 4. Plane stress/Plane strain analysis 5. Model analysis of different structures 6. Steady state thermal analysis 7. Transient thermal analysis 8. Flow analysis 9. Thermo-mechanical analysis CAM EXPERIMENTS 1. Manual part programming using G and M codes for Turning, Step turning, Taper turning, multiple turning, Facing, Multiple facing, thread cutting and radius turning on cylindrical components. 2. CNC Milling program involving linear motion and circular interpolation. 3. CNC Milling program involving contour motion and canned cycles. 4. CNC Milling program involving Pocket milling 5. Diagnosis and trouble shooting in CNC machine 6. CNC code generation using any CAM software. 7. Simulation of machining operations using any CAM software. 8. Route sheet generation using CAM software. 9. Study and practical demonstration on Wire-Cut EDM, 10. Study and practical demonstration on Coordinate measuring machine, 11. Study and practical demonstration on Vertical Machining center and Horizontal Machining center 12. Study on Rapid Prototyping Technologies, Student shall submit team work in the form of project /assignments with neat documentation. References Lab Manual prepared by VIT faculty Mode of Evaluation Experiments/Record work/Oral/ Practical Examination Recommended by the Board of Studies on: 31-10-2009 Date of Approval by the Academic Council: 27-11-2009

Potrebbero piacerti anche

- Mee2007 Cad CamDocumento2 pagineMee2007 Cad CamSrivathson EswaranNessuna valutazione finora

- CADCAM-minDocumento91 pagineCADCAM-minBandi KumarreddyNessuna valutazione finora

- Me8691 Cad&m UpdatedDocumento70 pagineMe8691 Cad&m UpdatedkipseyNessuna valutazione finora

- 161ME51 Cad/Cam/Cae: L-T-P C 3-0-0 3 Programme: Sem: 5 Category: PC Aim: Course OutcomesDocumento2 pagine161ME51 Cad/Cam/Cae: L-T-P C 3-0-0 3 Programme: Sem: 5 Category: PC Aim: Course OutcomeskganesanNessuna valutazione finora

- CADCAMDocumento50 pagineCADCAMPrem Chander100% (5)

- Lecture01 - CAD CAM - CAE - Introduction of The CourseDocumento21 pagineLecture01 - CAD CAM - CAE - Introduction of The CourseSameer shaikhNessuna valutazione finora

- Mechanical - VI. Sem Syllabus GtuDocumento115 pagineMechanical - VI. Sem Syllabus GtukishormechNessuna valutazione finora

- ME1355-CAD / CAM Laboratory: Lab ManualDocumento42 pagineME1355-CAD / CAM Laboratory: Lab ManualVeeria Chandran S100% (1)

- Modeling and Problem Solving Techniques for EngineersDa EverandModeling and Problem Solving Techniques for EngineersNessuna valutazione finora

- Course Outline CIM 14Documento3 pagineCourse Outline CIM 14Bizuayehu TadesseNessuna valutazione finora

- Me8691-Computer Aided Design and ManufacturingDocumento2 pagineMe8691-Computer Aided Design and ManufacturingGeorge Oliver100% (3)

- PG Diploma in CAD/CAM: Short Term Courses - NIELITDocumento2 paginePG Diploma in CAD/CAM: Short Term Courses - NIELITInder Jeet KoriNessuna valutazione finora

- CD5291 Computer Aided Tools for Manufacturing Detailed SyllabusDocumento2 pagineCD5291 Computer Aided Tools for Manufacturing Detailed SyllabusKamalakkannan RadhakrishnanNessuna valutazione finora

- Mechanical Engg 19Documento115 pagineMechanical Engg 19Harshul BrahmbhattNessuna valutazione finora

- Up and Running with AutoCAD 2012: 2D Drawing and ModelingDa EverandUp and Running with AutoCAD 2012: 2D Drawing and ModelingValutazione: 3.5 su 5 stelle3.5/5 (3)

- CAD/CAM/CIM Course OverviewDocumento126 pagineCAD/CAM/CIM Course OverviewA. I. RehmanNessuna valutazione finora

- New Cad&m Mtech SyllabusDocumento3 pagineNew Cad&m Mtech SyllabusupenderNessuna valutazione finora

- CIM Subject Guide for Mechanical Engineering StudentsDocumento7 pagineCIM Subject Guide for Mechanical Engineering StudentsKeerthe VaasanNessuna valutazione finora

- Me704 Cim (Cad)Documento25 pagineMe704 Cim (Cad)ASHU KNessuna valutazione finora

- Cim (English)Documento320 pagineCim (English)DaRkSouLNessuna valutazione finora

- Evolution of CAD/CAM: Mit, UsaDocumento63 pagineEvolution of CAD/CAM: Mit, UsaNaveenNessuna valutazione finora

- CAD Graphics TechniquesDocumento18 pagineCAD Graphics TechniquesNeeraj GuptaNessuna valutazione finora

- CAD CAM AutomationDocumento4 pagineCAD CAM AutomationTiago LopesNessuna valutazione finora

- Mf5102 Computer Integrated Manufacturing Systems: For Syllabus, Question Papers, Notes & Many MoreDocumento2 pagineMf5102 Computer Integrated Manufacturing Systems: For Syllabus, Question Papers, Notes & Many MoreNandha Gopal SenthilnathanNessuna valutazione finora

- Cadcam Lab ManualDocumento71 pagineCadcam Lab ManualBrahmaiah BonthaNessuna valutazione finora

- CAD COMPUTER AIDED DESIGNDocumento2 pagineCAD COMPUTER AIDED DESIGNmuru0105Nessuna valutazione finora

- Computer Integrated Manufacturing CourseDocumento3 pagineComputer Integrated Manufacturing CoursesatheeshNessuna valutazione finora

- Introduction to CAD/CAM Lecture 1Documento22 pagineIntroduction to CAD/CAM Lecture 1Pankaj ChhabraNessuna valutazione finora

- CAD&MDocumento2 pagineCAD&MVarun ANessuna valutazione finora

- ME8691 Syllabus Edubuzz360Documento2 pagineME8691 Syllabus Edubuzz360Johnson PaulNessuna valutazione finora

- Engineering Cad Unit 1 PDFDocumento256 pagineEngineering Cad Unit 1 PDFShri Vignesh KNessuna valutazione finora

- SyllabusDocumento3 pagineSyllabusAnonymous 4h9p1EIQYSNessuna valutazione finora

- MODIFIED CAD CAM - 4year 1sem PDFDocumento56 pagineMODIFIED CAD CAM - 4year 1sem PDFSatya AruntejaNessuna valutazione finora

- Upgraded Technology and Application in Die CastingDocumento12 pagineUpgraded Technology and Application in Die CastingSaurabhNessuna valutazione finora

- Cadcam LabDocumento83 pagineCadcam LabRachit VemulaNessuna valutazione finora

- 4.32 & 4.33 TE & BE - Mech Engg 40Documento1 pagina4.32 & 4.33 TE & BE - Mech Engg 40Honey SinghNessuna valutazione finora

- Cim SyllabusDocumento2 pagineCim SyllabusHarish HNessuna valutazione finora

- Question Bank - Cad Cam CaeDocumento12 pagineQuestion Bank - Cad Cam CaePravin DahalkeNessuna valutazione finora

- RGPV Syllabus Grading Me 804 Cad Cam CimDocumento1 paginaRGPV Syllabus Grading Me 804 Cad Cam Cimabhinavgiri17Nessuna valutazione finora

- Cad Cam PDFDocumento2 pagineCad Cam PDFRanjit SinghNessuna valutazione finora

- Computer Aided Design (CAD) : DR Janardhan VDocumento206 pagineComputer Aided Design (CAD) : DR Janardhan Vk pNessuna valutazione finora

- 15AE308J - Design Lab Manual New 2020Documento43 pagine15AE308J - Design Lab Manual New 2020rushan ahmedNessuna valutazione finora

- CAD CAM Micro SyllabusDocumento2 pagineCAD CAM Micro Syllabusrajya lakshmiNessuna valutazione finora

- Industry Uses of CADD: Student Learning ObjectivesDocumento11 pagineIndustry Uses of CADD: Student Learning ObjectivesMphilipTNessuna valutazione finora

- CAD CAM and CAE Course OutlineDocumento3 pagineCAD CAM and CAE Course Outlinedejenem398Nessuna valutazione finora

- Intro to CAD/CAM SystemsDocumento31 pagineIntro to CAD/CAM SystemsJOHN RICHMOND DIZONNessuna valutazione finora

- University of Mumbai Scheme of Instruction and Evaluation for B.E. Mechanical EngineeringDocumento82 pagineUniversity of Mumbai Scheme of Instruction and Evaluation for B.E. Mechanical EngineeringJayesh NavareNessuna valutazione finora

- Introduction To CAM - Pdfud Abdul Majeed - 1 - Introduction To CAMDocumento12 pagineIntroduction To CAM - Pdfud Abdul Majeed - 1 - Introduction To CAMKiranRao BiradarNessuna valutazione finora

- Me2402 - CimDocumento1 paginaMe2402 - CimhariccetNessuna valutazione finora

- Cad Cam PDFDocumento96 pagineCad Cam PDFABHISHEKMISHRA100% (1)

- Me8691 Computer Aided Design and Manufacturing SyllabusDocumento2 pagineMe8691 Computer Aided Design and Manufacturing SyllabusGanapathy TNessuna valutazione finora

- Advanced Manufacturing SystemsDocumento23 pagineAdvanced Manufacturing SystemsDhanish KumarNessuna valutazione finora

- CNC LAB MANUAL AND RECORDDocumento33 pagineCNC LAB MANUAL AND RECORDrajee10133% (3)

- Course ObjectivesDocumento4 pagineCourse Objectivesmkumar_234155Nessuna valutazione finora

- The CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0Da EverandThe CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0Valutazione: 5 su 5 stelle5/5 (1)

- Engineering Applications: A Project Resource BookDa EverandEngineering Applications: A Project Resource BookValutazione: 2.5 su 5 stelle2.5/5 (1)

- Interactive Computing in BASIC: An Introduction to Interactive Computing and a Practical Course in the BASIC LanguageDa EverandInteractive Computing in BASIC: An Introduction to Interactive Computing and a Practical Course in the BASIC LanguageValutazione: 5 su 5 stelle5/5 (1)

- Up and Running with AutoCAD 2020: 2D Drafting and DesignDa EverandUp and Running with AutoCAD 2020: 2D Drafting and DesignNessuna valutazione finora

- GPH TorqueDocumento2 pagineGPH TorqueDeepak AwasthiNessuna valutazione finora

- Hydraulic Cylinder and PistonDocumento1 paginaHydraulic Cylinder and PistonDeepak AwasthiNessuna valutazione finora

- Cad/Cam: Rasterisation Scan Conversion of LinesDocumento34 pagineCad/Cam: Rasterisation Scan Conversion of LinesDeepak AwasthiNessuna valutazione finora

- CP1034 07-Oct-2011 RM01Documento2 pagineCP1034 07-Oct-2011 RM01Deepak AwasthiNessuna valutazione finora

- Common Application Form For Ues22 and Tgc115 Jul 2012and Ssctech Men and Women Oct 2012 Course - 30-Jun-2011 - Ues22Documento3 pagineCommon Application Form For Ues22 and Tgc115 Jul 2012and Ssctech Men and Women Oct 2012 Course - 30-Jun-2011 - Ues22Karan KhandelwalNessuna valutazione finora

- Using Simulator in AVR StudioDocumento10 pagineUsing Simulator in AVR StudioNadar Dinakaran SankaravelNessuna valutazione finora

- A Case Study To Bottle The Biogas in Cylinders As Source ofDocumento4 pagineA Case Study To Bottle The Biogas in Cylinders As Source ofSamir VahoraNessuna valutazione finora

- 04-87RA9001-01 Installation Junction Box Main Field Signals 9000 SeriesDocumento1 pagina04-87RA9001-01 Installation Junction Box Main Field Signals 9000 SeriesRonaldNessuna valutazione finora

- Cold Lime Soda Softening ProcessDocumento10 pagineCold Lime Soda Softening ProcessSaurabh JadhavNessuna valutazione finora

- Specification Ball ValveDocumento7 pagineSpecification Ball ValveJoshua HernandezNessuna valutazione finora

- 15 151905 Machine Design IDocumento3 pagine15 151905 Machine Design IPeeka Prabhakara RaoNessuna valutazione finora

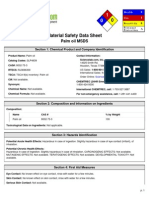

- Palm Oil MSDSDocumento5 paginePalm Oil MSDSCaliche Omn100% (1)

- Operation PhilosophyDocumento29 pagineOperation PhilosophyMashiur RahmanNessuna valutazione finora

- Corrapol Clear Corrugated Sheet Ranges Technical GuideDocumento8 pagineCorrapol Clear Corrugated Sheet Ranges Technical GuideDavid Galvis VelozaNessuna valutazione finora

- Flexible grid coupling selection guideDocumento18 pagineFlexible grid coupling selection guidechavico113Nessuna valutazione finora

- Geopolymer Paver Blocks: Aaron Darius Vaz, Donal Nixon D'Souza, Noothan Kaliveer, Satish K.T and Amar S.MDocumento6 pagineGeopolymer Paver Blocks: Aaron Darius Vaz, Donal Nixon D'Souza, Noothan Kaliveer, Satish K.T and Amar S.MRodrigo RamosNessuna valutazione finora

- Roof Truss Design LoadsDocumento51 pagineRoof Truss Design LoadsFeigyl Miro100% (4)

- Saturn Engine CoolingDocumento5 pagineSaturn Engine Coolinglamping_apNessuna valutazione finora

- General Service Solenoid Valves: NC NO UDocumento4 pagineGeneral Service Solenoid Valves: NC NO UDevinNessuna valutazione finora

- Cement Additives Improve High-Performance BindersDocumento7 pagineCement Additives Improve High-Performance Bindersimsurender87Nessuna valutazione finora

- AURORA KN95 Face Mask Introduction 2020Documento23 pagineAURORA KN95 Face Mask Introduction 2020victorcamposNessuna valutazione finora

- What To Do When Service Is Needed: C Cu Ua An ND Do o N Ne Ec Ce Es Siitta A S Se Errv Viic Ciio oDocumento48 pagineWhat To Do When Service Is Needed: C Cu Ua An ND Do o N Ne Ec Ce Es Siitta A S Se Errv Viic Ciio oJANessuna valutazione finora

- A Comparative Investigation On The Effects of Nanocellulose From BacteriaDocumento13 pagineA Comparative Investigation On The Effects of Nanocellulose From BacteriaPaloma GuardeziNessuna valutazione finora

- QB 5 - Basic NDT - LT QBDocumento5 pagineQB 5 - Basic NDT - LT QBprabhakaran.SNessuna valutazione finora

- Madpenguin - Ca-Tutorial Use An Old Inkjet Printer To Learn Servo Motor Control With EMC2 Part 2Documento7 pagineMadpenguin - Ca-Tutorial Use An Old Inkjet Printer To Learn Servo Motor Control With EMC2 Part 2Rudi AribowoNessuna valutazione finora

- Storing and Sanitation TechniquesDocumento27 pagineStoring and Sanitation TechniquesMarjory Alga Omale100% (1)

- Potato Plastic Lab ModuleDocumento4 paginePotato Plastic Lab ModuleAnoif Naputo AidnamNessuna valutazione finora

- Ammonium Polyphosphate SpecificationDocumento3 pagineAmmonium Polyphosphate SpecificationMaggie VillacortaNessuna valutazione finora

- Canopy Glass Thickness PDFDocumento1 paginaCanopy Glass Thickness PDFRufus ChengNessuna valutazione finora

- Objective: Experiment 2: Determination of Ash ContentDocumento2 pagineObjective: Experiment 2: Determination of Ash ContentRaj Kumar Purkayastha100% (2)

- AIGOSTAR 300000HFA Panini Maker NoticeDocumento9 pagineAIGOSTAR 300000HFA Panini Maker NoticeSYLVIENessuna valutazione finora

- Integrated LabDocumento36 pagineIntegrated LabBeki WalkerNessuna valutazione finora

- Johnson Controls Automotive Experience Global Supplier Standards Manual Tooling and Equipment Chapter 2 Metals Stamping DiesDocumento40 pagineJohnson Controls Automotive Experience Global Supplier Standards Manual Tooling and Equipment Chapter 2 Metals Stamping DiesMostafa Abd El AlemNessuna valutazione finora

- Utilization of Waste Plastic in Manufacturing of Paver BlocksDocumento4 pagineUtilization of Waste Plastic in Manufacturing of Paver BlocksAragorn RingsNessuna valutazione finora

- Chemistry ProjectDocumento16 pagineChemistry Projectgaganshishodia2Nessuna valutazione finora

- Raven 2350 Ultra Carbon Black Technical Data SheetDocumento2 pagineRaven 2350 Ultra Carbon Black Technical Data SheetCoopertiva PlastcooperNessuna valutazione finora