Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Resume Sample

Caricato da

datastageDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Resume Sample

Caricato da

datastageCopyright:

Formati disponibili

RESUME

NAME: NAZISH QURESHI FATHER'S NAME: M. T. QURESHI DATE OF BIRTH: 2nd January, 1968 B-51, GHARONDA APARTMENTS, SHRESTHA VIHAR,DELHI -110092. INDIA Telephone: 22144789

ADDRESS:

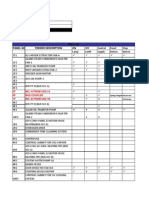

EDUCATIONAL QUALIFICATIONS:

S. No. Examination Passed 1. School/ University Year of Passing 1983 %age of marks 78%

2. 3.

Ramjas School, R.K. AISSE(Class X), CBSE, Puram, New Delhi New Delhi Ramjas School, R.K. AISSCE(Class XII), Puram, CBSE, New Delhi New Delhi BSc Engg (Mechanical) AMU, Aligarh

1985 1989

79% 88% (2nd position)

WORK EXPERIENCE:

S. No. Period From September, 1989 September, 1990 January, 1995 April, 1998 To August, 1990 December, 1994 March, 1998 March, 2001

Name of the Organisation National Thermal Power Corporation Ltd. (A Government of India Enterprise) - do - do - do -

Designation/Grade

1.

Engg Executive Trainee

2. 3. 4.

Engineer Sr. Engineer Asstt. Chief Design Engineer (Mech)

5.

- do -

April, 2001

Till Date

Dy. Chief Design Engineer (Mech)

Details of Experience

September 1989 - May 1990 Power Plant Familiarisation at Power Engineers Training Society, Durgapur, West Bengal, India. May 1990 - December, 1993 Worked as a commissioning engineer incharge of 4 X 210MW Turbine Generator package and associated auxiliary systems at the National Capital Power Project (NTPC) 4 X 210MW coal-based Thermal Power Station, Dadri, Distt. Ghaziabad (U.P.) India. Successfully commissioned the following systems of 4 units of 210MW each:

Steam Turbine (210MW KWU design) - Turbine oil system and hydraulic turning gear; Turbine Governing system; Turbine seal steam system, Turbine extraction steam system; Generator seal oil system, Generator Stator cooling water system, Generator gas cooling system; Condenser evacuation & vacuum system; HP/LP Bypass control system; Bolier feed pumps and feedwater system; Condensate extraction pumps & condensate system; Auxiliary Equipment cooling water system; Central air conditioning plants and package air conditioning plants.

Worked as commissioning engineer incharge of Fire Fighting, Fire Protection & Alarm systems at National Capital Power Project (NTPC) 4 X 210MW coal-based Thermal Power Station, Dadri, Distt. Ghaziabad (U.P.) India. Successfully commissioned the folowing systems:

Fire hydrant system; Fire sprinkler systems for oil units, fuel storage, transformers etc.; Fire annunciation systems for control rooms & switchyard.

Also assisted in the following commissioning activities in addition to the above:

Boiler hydro-test; Boiler acid cleaning; Boiler alkali boil-out; Steam blowing; Alkali flushing of feed & condensate lines.

January 1994 - May, 1997 Operations of National Capital Power Project (NTPC) 4 X 210MW coalbased Thermal Power Station, Dadri, Distt. Ghaziabad (U.P.) India from unit control board with the most advanced control & instrumentation (DDCMIS); Worked as unit control engineer incharge of operations of Boiler Turbine, associated auxiliary systems, electrical systems, control & instrumentation and unit control board.

Boiler: BHEL make (Combustion Engg. USA design); pulverised coal/oil fired with tilting tangential firing; also operated the boilers on 100% oil firing upto full load i.e., 210MW. TURBINE: BHEL make (Kraftwerke Union, Germany design); tandem compounded. regenerative, reheat, condensing, 3-cylinder.

June, 1997 - Till date Evaluation of advanced technologies for adoption by NTPC with special reference to Clean Coal Technologies and renewable energy areas.

Feasibility study for IGCC Urea fertilizer coproduction along with M/s Toyo Engg, Japan. Feasibility study for setting up an Integrated Gasification Combined Cycle (IGCC) demonstration plant along with Council for Scientific & Industrial Research (CSIR). Study & evaluation of refuelling project for NTPC's Combined Cycle Gas Turbine Plants, using synthesis gas generated from refinery residue, along with Texaco Corporation,USA. Feasibility study and project engineering of 20MW capacity NTPC Wind Power Project in Tamil Nadu, India. Design & Engineering of 4 X 4000 lpd solar water heating system for the residential complex at NTPC's Power Management Institute at NOIDA (U.P.) India Evaluation of Technology Options for refinery residue based power plant considering Conventional Boiler, Circulating Fluidised Bed Combustion (CFBC) and Integrated Gasification Combined Cycle (IGCC).

Technologies evaluated:

Clean Coal Technologies: Integrated Gasification Combined Cycle (IGCC), Circulating Fluidised Bed Combustion (CFBC, Pressurised Fluidised Bed Combustion (PFBC), Fuel Cells etc. Renewable Energy & Distributed Generation: Rural electrification thru Distributed Generation, Wind Power Generation, Solar Thermal Power Generation systems, Geothermal Power Generation, Biomass gasification etc.

Significant Achievements:

The Dadri Thermal Power Station of NTPC where I was engaged in commissioning & operations of the power plant from 1990-1997, has achieved remarkable performance in terms of availability, efficiency, make-up water consumption, oil consumption & auxiliary power consumption. The Dadri Thermal Power plants are being operated with the minimum manpower amongst all power stations in India. The Dadri Thermal Power Station became the 1st power station in India, to modify & operate the existing 210MW coal-fired boilers of BHEL-make, at 100% oil firing. All the modifications were carried out in-house. BACK TO MY HOMEPAGE

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Date Totalgen U1 (MWH) Total Gen U2 (MWH) Total Generation (MW) PLF (%)Documento5 pagineDate Totalgen U1 (MWH) Total Gen U2 (MWH) Total Generation (MW) PLF (%)datastageNessuna valutazione finora

- Odisha BOE-2014 NotificationDocumento10 pagineOdisha BOE-2014 NotificationdatastageNessuna valutazione finora

- WoodwardDocumento4 pagineWoodwarddatastageNessuna valutazione finora

- Cost of SteamDocumento13 pagineCost of SteamAlouis MutimboNessuna valutazione finora

- Boilers: 27 Bureau of Energy EfficiencyDocumento28 pagineBoilers: 27 Bureau of Energy EfficiencyVikas Saini100% (1)

- Module Shifted: ON TMCC U#1Documento2 pagineModule Shifted: ON TMCC U#1datastageNessuna valutazione finora

- HP BypassDocumento14 pagineHP BypassdatastageNessuna valutazione finora

- Career PlanDocumento4 pagineCareer PlandatastageNessuna valutazione finora

- Generator Protection ClassDocumento1 paginaGenerator Protection Classdatastage100% (1)

- Shree Jagannatha Sahasranama (Odia) 1/11Documento11 pagineShree Jagannatha Sahasranama (Odia) 1/11datastageNessuna valutazione finora

- Power2GO UGDocumento54 paginePower2GO UGdatastageNessuna valutazione finora

- EiietcrkgenDocumento53 pagineEiietcrkgendatastageNessuna valutazione finora

- Turbine Bypass SystemDocumento20 pagineTurbine Bypass Systemamer_arauf100% (17)

- Digital Automatic Voltage RegulatorDocumento3 pagineDigital Automatic Voltage RegulatordatastageNessuna valutazione finora

- Generator Capability CurveDocumento2 pagineGenerator Capability CurvedatastageNessuna valutazione finora

- 1.35046!CHRISGAS - Final Publishable Results - Web - November 2010Documento33 pagine1.35046!CHRISGAS - Final Publishable Results - Web - November 2010RicardoEscaladaCuadrado1301Nessuna valutazione finora

- Oxy Coal Combustion by Munawar HussainDocumento24 pagineOxy Coal Combustion by Munawar HussainMunawar HussainNessuna valutazione finora

- M2 IGCC HRSG Enhanced Modeling and Simulation in Power Plant DR R R JoshiDocumento32 pagineM2 IGCC HRSG Enhanced Modeling and Simulation in Power Plant DR R R JoshiAkshat RawatNessuna valutazione finora

- Curriculum: M.Sc. Chemical EngineeringDocumento39 pagineCurriculum: M.Sc. Chemical EngineeringPICS FarhanNessuna valutazione finora

- The Role of Carbon Capture and Storage in The Energy TransitionDocumento23 pagineThe Role of Carbon Capture and Storage in The Energy TransitionEsperanza MorenoNessuna valutazione finora

- Equity Investment Cia 3: Reliance PowersDocumento27 pagineEquity Investment Cia 3: Reliance PowersananyaNessuna valutazione finora

- QGESSSec 2Documento37 pagineQGESSSec 2Onnuri WonNessuna valutazione finora

- Dar Presentation Dubai JTDocumento36 pagineDar Presentation Dubai JTSudhir RavipudiNessuna valutazione finora

- Hydrogen For Power Gen Gea34805Documento18 pagineHydrogen For Power Gen Gea34805Siddhant DhallNessuna valutazione finora

- 2-Jan Kollmus-Siemens Carbon Capture Technologies - Successful Technology Development From Pilot Scale To Application in Mega Plant ScaleDocumento39 pagine2-Jan Kollmus-Siemens Carbon Capture Technologies - Successful Technology Development From Pilot Scale To Application in Mega Plant ScaleIsmar AdrianNessuna valutazione finora

- Final Report On Mill ModellingDocumento193 pagineFinal Report On Mill ModellingLigang WangNessuna valutazione finora

- University Institute of Technology (UIT), RGPV, Bhopal, Faculty-2005Documento26 pagineUniversity Institute of Technology (UIT), RGPV, Bhopal, Faculty-2005Santosh KumarNessuna valutazione finora

- Table 1. Updated Estimates of Power Plant Capital and Operating CostsDocumento2 pagineTable 1. Updated Estimates of Power Plant Capital and Operating CostsWahyoe DamaiNessuna valutazione finora

- 10 1 1 177 6477 PDFDocumento444 pagine10 1 1 177 6477 PDFNugiNessuna valutazione finora

- Chemical ProjectsDocumento10 pagineChemical ProjectsZahoor Hussain RanaNessuna valutazione finora

- WinklerDocumento24 pagineWinklerRashveenaNessuna valutazione finora

- PPD Coal CompleteDocumento34 paginePPD Coal CompletemyravganacNessuna valutazione finora

- Development of Gas Turbine Combustors For Fuel Flexibility 3Documento9 pagineDevelopment of Gas Turbine Combustors For Fuel Flexibility 3John KellyNessuna valutazione finora

- Organisational Study of BHEL Electronics DivisionDocumento68 pagineOrganisational Study of BHEL Electronics Divisionnarendranovi70% (10)

- Siemens IGCC PlantDocumento32 pagineSiemens IGCC PlantDeepak GehlotNessuna valutazione finora

- Assessing The Effectiveness and Sustainability of Carbon Capture and StorageDocumento27 pagineAssessing The Effectiveness and Sustainability of Carbon Capture and StorageSanuja Samadith PanagodaNessuna valutazione finora

- 2008 Abstract Booklet 9-12-08.FINALDocumento63 pagine2008 Abstract Booklet 9-12-08.FINALgladiolus86Nessuna valutazione finora

- SelexolDocumento2 pagineSelexolandrez627Nessuna valutazione finora

- Biomass Gasification Country Reports Oct 2004Documento178 pagineBiomass Gasification Country Reports Oct 2004Yiannis AntonopoulosNessuna valutazione finora

- Frey Akunuri 2001Documento265 pagineFrey Akunuri 2001Anonymous UT0gI7Nessuna valutazione finora

- Indicadores Economicos Ei - 200912Documento2 pagineIndicadores Economicos Ei - 200912Mari Luz Hermoza MamaniNessuna valutazione finora

- ME 8792 PPE Unit - 2Documento71 pagineME 8792 PPE Unit - 2UdamanNessuna valutazione finora

- Greenhouse Gases - Capturing Utilization and ReductionDocumento348 pagineGreenhouse Gases - Capturing Utilization and ReductionrjoliveirNessuna valutazione finora

- EPRI IGCC Design and RAM Analysis For Zero EmissionsDocumento68 pagineEPRI IGCC Design and RAM Analysis For Zero EmissionsRaden MasNessuna valutazione finora

- Psa Fullreport PDFDocumento297 paginePsa Fullreport PDFHarshaNessuna valutazione finora