Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

51 Matrix Quality Manual Jan 2010

Caricato da

Rehan RaufDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

51 Matrix Quality Manual Jan 2010

Caricato da

Rehan RaufCopyright:

Formati disponibili

113

QUALITY OPERATIONS MANUAL

BY NATURE WE ARE RESTLESS, ALWAYS SEEKING IMPROVEMENTS, AND WILL REMAIN THIS WAY, ITS PART OF OUR DNA

Copyright 2010 Matrix Sourcing. All Rights Reserved.

www.apparelco.com

TABLE OF CONTENTS

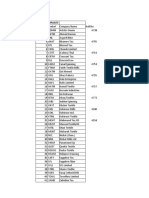

SR# 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 PREFACE COMPANY OVERVIEW QUALITY PROCESS FLOW CHART GARMENT ENGINEERING BULK FABRIC LOT APPROVAL PROCEDURE LAB TEST PROCEDURE INHOUSE PRE-PRODUCTION MEETING VENDOR PRE-PRODUCITON MEETING QUALITY ONLINE DATA (QUONDA) TYPES OF INSPECTION FINAL INSPECTION REQUIREMENTS FINAL INSPECTION PROCEDURE GARMENT INSPECTION METHOD GARMENT MEASUREMENT METHODS DEFECTS CLASSIFICATION PRODUCT SAFETY OVERVIEW SYSTEM AUDIT TRAINING (GENERIC) MATRIX CODE OF CONDUCT EMPLOYEES ETHICAL CODE ACKKNOWLEDGEMENT SUPPLIER MANUAL APPENDIX LIST (A THROUGH Z) CONTENTS PAGE # 2 3 5 6 11 12 13 16 20 21 25 26 35 52 81 103 106 107 108 110 111 112

Updated: January, 2010

www.apparelco.com

PREFACE

Quality is an integral part of services that Matrix Sourcing provides to its valued customers. Although this manual describes Matrixs quality requirements and expectations, Matrix also expects its partner suppliers to develop a positive culture of quality. This culture must begin with management commitment to prevention based & continuous improvement based quality systems including; x x x x Allocate appropriate resources to ensure quality systems are effective Encourage participation of all workers in improvement plans Ensure that processes are stable & capable Document systems, processes, procedures etc. as necessary to maintain effective operations

This manual offers step by step instructions to conduct inspections and thus serves the purpose of training team members. Many procedures included in this manual have been carefully adopted from our customers. Where necessary, some procedures have been standardized after carefully studying the standards and procedures supplied by our customers and any exceptions have been clearly marked. Although every possible effort has been employed to make this manual error free, if you find any errors, please feel free to contact the quality assurance department. This manual will be updated on continuous basis and latest update will always be available at Matrix portal database.

Updated: January, 2010.

www.apparelco.com

COMPANY OVERVIEW

Matrix is a progressive and ethical buying office. It caters to select clientele linking them with reliable suppliers. Matrix develops a strategy as unique as the client, and then ensures that the linkages and relationships are not only monitored to meet and exceed expectations, but also keep evolving to higher levels of performance over time. Apart from core services that are specific to orders placed, Matrix also invests it's time and resources in nurturing continuous improvement in process, people and product. This is why relationships developed by Matrix last a lifetime. The company has been in business for over 20 years, and is considered a leader in region.

QUALITY CONTROL:

The Quality Control teams at Matrix perform pre-shipment audits. Resources are intelligently allocated to reflect priorities. Inspectors are regularly evaluated and certified to ensure transparency and homogeneity of the process. The QM (Quality Assurance + Quality Control) systems have been developed through years of successful business with the leading knitwear and woven brands of the US such as Nike, Adidas, MTAR, Van Heusen, BTX etc. Having done extensive work for the factories doing business with these buyers, the people at Matrix have gained a lot of valuable experience.

QUALITY ASSURANCE:

Assurance and Control are equal functions in our quality management program. Our assurance programs help identify areas of improvement, and lead to training programs at the vendors end. They are designed to build quality into the process and product. Assurance teams use many tools such as troubleshooting, monitoring of learning curves and fit products to process capability.

COMPLIANCE:

Ethics are the fundamental business principle at Matrix Sourcing. At Matrix, ethical business practices do not stop in-house, but also extends into various interconnected facilities for vendors. We make every possible effort to ensure our business partners are ethically responsible down the chain. All our vendors have to pass our stringent criteria of corporate and social responsibility. We keep ourselves abreast with customs and security compliance standards of all importing countries and ensure that the supply chain is fully secure and compliant. Some of our vendors are now ISO 14001 certified. All major vendors are compliant to WRAP and FLA standards, many already approved by these independent bodies.

Updated: January, 2010

www.apparelco.com

IT & HRD:

The IT department at Matrix takes care of all the needs of a global organization that needs to stay WELL INFORMED. It is equipped with the best hardware and software facilities specifically geared to the sourcing environment. The extranet takes care of the data collection and dissemination needs of the organization and ensures a smooth workflow throughout the office. This IT department also works in close relation with the Quality department so that realtime tracking of quality issues is possible through our in-house developed Quality Management System namely QUONDA. The information tracking module is built with a centralized database server that stores the entire companys information in one efficient database server.

PRODUCT DEVELOPMENT AND MATERIALS:

The product development section at Matrix is a window for new buyers in terms of pricing, sampling and information collection. It serves as the initial phase in catering to new buyers, acclimatizing them to the industry / Matrixs way of working. We serve as a buffer to make sure that the buyer only walks away with the best possible image in his mind regarding leadtimes, quality of samples, the quality of production and pricing issues. The department provides assistance on a micro level, something that is essential to the growth of any account. From a broader perspective, Business development provides buyers with services that can foster bulk business, after we get the ground work done in pricing and sampling.

TRAFFIC:

In the logistics area, globalization is creating even more complex supply chains. We manage shipments rapidly, safely and on-time all across the globe. The basis for this is our comprehensive network: combining air and ground transport for optimal delivery performance. On one hand this gives us worldwide reach, and on the other, a strong local presence and unique understanding of international markets and customers. The logistics department at Matrix has a combination of global reach and local knowledge which gives our buyers a competitive edge.

CORE OPERATIONS:

Our core operations are divided into two categories- Pre production / Approvals, and Production Monitoring & Management. Effective management of the pre-production approvals process is critical to delivering great quality product on time. Our pre production team works with well articulated and well thought out timing and action calendars ensuring that each product is ready for production in the true sense before it gets handed over to production departments for manufacturing. Timely approvals results in hassle free production without any stoppages. Each production activity is monitored closely for adherence to the start and end dates specified in the initial timing and action calendars.

Updated: January, 2010.

www.apparelco.com

QUALITY PROCESS FLOW CHART

Garment Engineering

Approve Bulk Fabric Lots Conduct In-house PP Meeting

Conduct Vendor PP Meeting

UPDATE INSPECTION REPORT ON MATRIX PORTAL DATABASE

Conduct Trial Run Inspection

Conduct Operation Inline Inspection

Conduct Offline Inline Inspection

Take TOP Samples

Conduct Finishing Inline Inspection

Conduct Batch Audit

Conduct Pre-final Inspection

Conduct Final Inspection

Take Shipment Samples

Updated: January, 2010

www.apparelco.com

GARMENT ENGINEERING

The garment engineering plays integral roll in overall garment manufacturing. Before start of bulk production it is very essential to verify garment for measurements, aesthetic and garment manufacturability. Garment engineering also confirms the garment shrinkage and wash look etc. We can verify all these aspects through garment engineering to avoid production losses. To make garment before start bulk production to confirm following according to the requirement of customer.

x x x x x x

Fabrication Garment Aesthetics Garment Stitching Garment Accessories Garment wash and appearance testing Garment Specs

The following are the steps of garment engineering

PROTO SAMPLE I & II

SALESMAN SAMPLE / DEVELOPMENT SAMPLE

SIZE SET

QRS / PPS

PRODUCTION

Updated: January, 2010.

www.apparelco.com

PROTO / FIT SAMPLE EVALUATION

x Matrix Sourcing Merchandiser forward sample request to vendor for proto / fit sample along with the required information i.e. Style sheet , construction details , fabrication , accessories etc. Vendor Merchandiser submits proto / fit sample to the Matrix Sourcing sampling department for proto / fit sample evaluation.

x x x

Matrix Sourcing sampling executive verifies garment construction, styling and garment measurement comply with given standards. After proto / fit approval, proto sample will send to the buyer and after buyer approval sales man sample procedure will start. In case of rejection of proto / fit sample, vender will re-submit the entire sample for proto / fit sample approval.

SALES SAMPLE

x Matrix Sourcing merchandiser will submit request to the vendor for sales samples along with style, fabrication and accessories details. x The sales sample will be made in actual fabric and accessories. x Pre-production meeting held in the presence of Matrix merchandising, vendor merchandising and production team. x All fabric, embellishment and accessories are signed by the Matrix Sourcing merchandising before start of sales sample production. x Matrix Sourcing sampling department conducts in line audits during sale sample production. x Matrix Sourcing sampling department will conduct final audit after completion of sales sample production.

Updated: January, 2010

www.apparelco.com

SIZE SET

x

After proto / fit approval, Matrix Sourcing merchandising forwards request to vendor for size set along with specs / grading. Matrix Sourcing sampling department verifies garment measurement and Construction according to the required standard and make its report. Matrix sampling also verifies proto / fit comments(if any) during size set evaluation.

QRS / PP SAMPLE

x

After size set approval Matrix merchandiser will forward request to vendor for Preproduction samples / Qualified reference sample along with previous samples comments. Matrix sampling verifies QRS / PP sample for fabrication, construction, measurement and accessories. After sample evaluation as per customer standards, Matrix sampling technition seal the QRS / PP sample for production reference. In case of sample rejection factory resubmits sample to Matrix Sourcing for evaluation.

QRS / PP sample is a physical sample that represents an acceptable product. The purpose of QRS / PP sample is to demonstrate manufacturing capability prior to start of production, and ensure product conformance in production. The sample is kept in the production line, so that it is available for tailors and other production staff for quick review. For any change in QRS / PP sample a new sample is sealed to avoid any mistakes.

ROLE CLARIFICATION

Sample Type Proto Sales Sample Development Sample Size set QRS / PP TOP Owner Factory + Matrix Merchandiser Factory + Matrix Merchandiser Factory + Matrix Merchandiser Factory + Matrix Merchandiser Factory + Matrix Merchandiser Factory + Matrix Merchandiser Responsible Sampling Sampling Sampling Sampling Sampling QC In loop QC QC QC QC QC Sampling

Updated: January, 2010.

www.apparelco.com

MATRIX DAILY SAMPLE LOG SHEET

SAMPLE EVALUATION SPECS SHEET

Updated: January, 2010

www.apparelco.com

SAMPLE COMMENT SHEET

SAMPLING PACKAGE & TIMELINES REQUIREMENT

Every buyer has different timeline for sample approvals. Garment engineering process should be executed by concerned stakeholders in a manner to achieve timeline for sample approval. Always consult customer quality manual for sampling package requirements and timelines for approval because criteria of every customer is different. Sampling package normally includes unwashed garments, washed garments, wash test reports, product safety checklist, proto / sample comments etc

Updated: January, 2010.

10

www.apparelco.com

BULK FABRIC LOT APPROVAL PROCEDURE

Once lab dips are approved by the customer, vendor dyes bulk fabric and sends two swatches for shade approval to Matrix. This should also include any other fabric materials being dyed with body fabric. Pre-production merchandiser / fabric development team gives original color standards or approved lab dips to Matrix QC, so that QCs are well versed with buyer standards while inspecting or approving fabric shade. If bulk lot is well matched with approved lab dip and previously approved lots, Matrix QC signs both swatches and marks OK on swatch. One swatch is returned to vendor and second is kept in Bulk Fabric Lots File of respective style for future reference. If bulk lot is not a good match with approved lab dip or previously approved lots, Matrix QC marks Reject on both swatches and writes remarks for improvement. Vendor must resubmit all rejected lots to Matrix QC for approval.

HOW TO COMMENT ON SHADE? Use one or more of shade dimensions from below. Only use one from the slashed options at a time.

+a* Redd

Depth: Go Light / Go Dark Tone: Go Red / Go Green / Go Blue / Go Yellow Chroma: Go Bright / Go Dull

Updated: January, 2010

11

www.apparelco.com

MATRIX SOURCING LAB TESTING PROCEDURE

Before bulk production starts, Matrix QC randomly picks fabric for testing. Factory may start cutting based on its internal pass test report. Testing in garment form is a must. Garment from bulk production (all colorways) is randomly selected and submitted for testing to customer approved third party lab. Following are some test requirements from our customers;

x

Physical properties tests e.g. cuttable width, GSM, fabric count, dimensional stability, skewness, pilling resistance, pH, flammability, UV transmittance etc Colorfastness properties tests e.g. colorfastness to laundering, perspiration, water, crocking etc Stretch and strength properties e.g bursting strength, snagging, abrasion resistance, seam slippage, tear test, tensile test etc Water resistance properties e.g water repellency, rain test, hydrostatic pressure test, waterproofness etc Moisture management properties e.g absorbency test, wicking test etc Garment durability and appearance retention tests Graphic and print durability tests

x x x

Note: All tests are conducted based on customers testing requirements / methods therefore customer manual is always consulted prior to testing. QC must evaluate the tested specimen by himself for following;

x

Compare test report number with the number mentioned on tested specimen to ensure that the report is of tested specimen Compare tested specimen with its approved standard Check tested specimen for any color bleeding, shrinkage, pilling, damage, print durability etc

x x

Updated: January, 2010.

12

www.apparelco.com

IN-HOUSE PRE-PRODUCTION MEETING

Where:

Conference Room / Quality Room

When:

After PP sample has been sealed by sampling department.

PARTICIPANTS:

x x x x x x Sampling Executive Pre-production Merchandiser Production merchandiser Quality Control Manager Quality Controller Product Safety Analyst

Sampling Briefing:

Sampling executive gives comprehensive briefing about styling according to customer fit comments. He identifies vital concerns in the style and also mentions its technical aspects.

Pre-Production Merchandising Briefing:

Pre-production merchandiser hands over the following to Manager QC; x x x x Style Sheet, Measurement Sheet BOM if available from customer Proto / Fit / Counter samples comments, PPS comments, Size set comments Approved Sealed sample

Note: In-house PP meeting cannot be held in absence of any of the above.

Production Merchandising Briefing:

Production merchandiser hands over the following to Manager QC; x x x x x x x x Purchase order(s), Order spread sheet(s) Fabric, rib and other trim approvals in all colors Main label, size label, care label, ID/Time and other label approval in all sizes & colors Sewing threads, Fusing, Buttons, Zippers and other accessory approvals in all sizes & colors Embellishment approvals in all sizes & colors Packing Instructions Garment fold size, Pollybag quality & size, Carton quality & size approvals Packing accessories approvals Updated: January, 2010 13

www.apparelco.com

Note: The concerned production merchandiser should sign all approvals before handing over to QC. In case of non-availability of any of the above approvals, production merchandiser must mention the date for handing over missing approvals. This date should be prior to start of production.

Quality Controller Responsibility:

Quality controller receives all approvals and records them on In-house PP Meeting checklist. QC also records expected date of receiving non-available approvals and follows up accordingly with production merchandiser. The QC marks NA (not available) in case of anything not being used for the particular style.

Quality Control File Contents:

1. Bill of materials (BOM) if available 2. Purchase order sheet / Spread sheet 3. Style sheet / Measurements sheet 4. Packing instructions / Directive 5. Sample comments 6. Approved bulk fabric card 7. Approved embellishment card 8. Approved garment accessories 9. Approved packing accessories 9. Lab testing requirements about particular order 10. In line / Pre final / Final inspection reports

Updated: January, 2010.

14

www.apparelco.com

Updated: January, 2010

15

www.apparelco.com

VENDOR PRE-PRODUCTION MEETING

Conducted by: Matrix Quality Controller Where: Vendor production facility When: After conducting Matrix In-house Pre-Production meeting, before vendor starts cutting.

PARTICIPANTS:

1. Matrix Quality Control Manager 2. Matrix Quality Controller 3. Matrix Merchandisers. 4. Vendor Quality Control Manager 5. Vendor Quality Inspectors 6. Vendor Cutting Manager 7. Vendor Sampling Manager 8. Vendor Production Manager 9. Vendor Production Supervisors 10. Vendor Rowing Inspectors 11. Vendor Merchandisers Matrix QC leads Vendor pre-production meeting and discusses potential concerns in production as below.

Fabrication Issues:

x x x All expected fabrication issues especially those highlighted by the customer during sampling process. Potential production problems according to fabric behavior i.e. pilling in fleece fabric, holes and contrast seeds in thermal fabric etc. Fabric GSM, Shrinkage, Shade & Cross staining.

Cutting issues:

x x All cutting related issues highlighted by the customer during sampling process i.e. measurements, stripe matching, pattern adjustment and fabric wales positioning etc. Grading of pocket, panels, inserts etc

Updated: January, 2010.

16

www.apparelco.com

Embellishment issues:

x

All potential issues in application of embellishment i.e. print, embroidery, flock, heat transfer, decorative patches etc are discussed.

Construction & Stitching issues:

x Sample comments regarding sewing issues and every operation of concerned style is discussed. Emphasis is on critical operations. All out of routine operations are discussed with sampling master and finalized in vendor pre production meeting. Difficult operations are highlighted and displayed for every style. Difficult operations checklist is maintained and verified during production.

x x

Finishing issues:

x All expected finishing and packing issues specially those highlighted by the customer are discussed with vendor. This includes garment shape, fold size, carton size and printing etc. After conducting Vendor pre-production meeting, Matrix QC distributes pre production comments to all participants through e-mail. Matrix QC emphasizes on vendor pre-production meeting points during sewing inline, pre final and final inspections. The vendor representative gives production time and action plan (T.N.A) to Matrix QC in vendor pre-production meeting. Pressing instructions are placed and clearly demonstrated. Factory specs men are advised to measure first batch after pressing to ensure that pressing instructions are properly followed.

x x x x

Updated: January, 2010

17

www.apparelco.com

VENDOR PRE PRODUCTION REVIEW MEETING FORMAT

Buyer Vendor Style # BOM Date Garment Description Accessories Description Main Label PO ID CNC Interfacing Elastic Width Hang tag UPC QRS Approval Date Specs Date Fabric Description & GSM Cary over from

IM #

Pre- Shrink

Other Garment Particulars Body color Embellishment Zipper Snaps

/ Draw cord

Panels

Ribs

Twill tape

Updated: January, 2010.

18

www.apparelco.com

VENDOR PRE-PRODUCTION MEETING CHECK LIST

Sr # 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 Contents Fabric in which trial run has been done? Size in which trial run has been done and number of pieces? What sorts of fabric previously were in these lines? What type of needle brand previously been used for that fabric? Specs Accuracy Which area needs adjustment? Who has checked and verified the specs? Do we need to adjust the paper pattern and which area? Does pattern check against the specs by sample room Machine needs adjustment if previously had different fabrication? What needle brand and number will be suitable for such fabric? Sewing thread Quality being used? Do we need to change any operation to have better Quality and production? What work aid do we require for this style. Does embellishment card and test report in production file? Does trial run being done with embellishment? Has Fabric, rib, twill tape and accessories been inspected and tested? Remarks

DIFFICULT OPERATION CHECK LIST

Sr # Area Operation Remarks

QUONDA

Updated: January, 2010 19

www.apparelco.com

(QUALITY ONLINE DATA ANALYSIS)

Quality can be improved only if accurate, reliable & real time data can be provided to line management. To achieve this objective Matrix Sourcing has developed a system of quality online data analysis named as QUONDA. Matrix quality assurance department conducts different types of inspections at vendors premises. The reports & record of all these inspections is entered in QUONDA database on hourly basis. QUONDA system operational procedure is as under;

x

QUONDA analyst plans audit schedule considering number of audits at different locations. Audit code is generated for every audit to be conducted, system generated SMS is sent to all QCs about their audit schedule and audit codes.

QCs perform their inspections in factories according to the given schedule. After completion of each inspection QCs make their reports, take defectives pictures and send SMS of audit findings to system. The entered report appears in QUONDA database within few seconds and SMS alert is sent to all key personnel at factory and matrix about audit findings. QUONDA analyst at Matrix continuously monitor inspection reports from all sources and takes immediate action in case of any problem.

QCs upload defective pictures (every inspection) and carton pictures (final inspection) in QUONDA database at the end of the day or very next day. The record of inspections entered in QUONDA is later used as a tool for conducting different types of quality analysis. This system has ability to spot trends and resolve issues as they occur. Time reduced between audit conducted & results being delivered to stakeholders to take corrective & preventive actions. QUONDA provides optimal allocation of resources based on individual skills, proximity & availability

Updated: January, 2010.

20

www.apparelco.com

TYPES OF INSPECTIONS

Matrix quality department conducts different types of inspections in fabric and garment form. Quality manual of every customer is consulted before starting inspection of any brand. All inspection reports are prepared on formats designed by Matrix Sourcing and entered in Matrix database by Matrix QC. Production status should be noted on the appropriate box on this format.

FABRIC INSPECTION

This inspection is performed in facilities offering fabric as final finished prouduct. The purpose of this inspection is to assure that fabric produced is as per customer requirements. Customer manual for quality standards, test requirements and auditing procedures must be consulted. Fabric inspection is conducted at two different stages; 1. Off loom fabric inspection 2. Final fabric inspection

OFF LOOM FABRIC INSPECTION

WHY: Off loom inspection is conducted on regular basis to ensure prevention of defect at grass root level and that given customer standards are being followed in production of fabric. WHEN: During fabric production. HOW: About 100-150 yards or 10% of every lot is inspected. Any issue regarding fabrication is brought to the knowledge of all concerned personnel.

FINAL FABRIC INSPECTION

WHY: To quantify defect rate and to ensure that finishing requirements are met. WHEN: Once complete shipment is packed and shipping documentation are ready. HOW: This inspection is conducted following international fabric inspection methods. Four point inspection system is followed. The sample size is 10 % of shipment quantity. QC makes report of inspection, discuss with all key personnel and enter report and defect images on portal database.

Updated: January, 2010

21

www.apparelco.com

GARMENT INSPECTION TYPES

The below mentioned inspections are conducted in factories offering garment as finished product.

TRIAL RUN INSPECTION

WHY: To streamline production line according to customers requirements and to make any necessary changes to pattern for achieving required measurements of garment. WHEN: After vendor pre-production meeting & before start of bulk cutting. HOW: About 20 garments in each size are stitched (washed if required) & finished. These garments are checked for measurements. Any issues regarding pattern adjustment and cutting are brought to the knowledge of sampling and cutting department respectively.

CUT PANEL INSPECTION

WHY: To assure that cut panels being forwarded to sewing lines are defect free and have no negative impact on apparel product integrity. WHEN: Before induction of panels in sewing lines. When bulk cutting starts. HOW: QC randomly picks sample of 20 cut panels from cutting bundles. Any nonconformance in cut panels i.e. uneven cut panels, fabric defects on panels, pattern adjustment etc is brought to the knowledge of cutting department.

OPERATIONAL INLINE INSPECTION

WHY: To ensure no sewing mistakes are reflected in production garments. This inspection is the most critical one and can help a long way in achieving low defect rate goals. WHEN: As soon as sewing starts in production line HOW: Each sewing operation is checked stepwise by Matrix QC on all sewing machines. Problems are identified and corrective action is suggested / demonstrated to vendor. QC inspects 5 to 10 garments from each machine. Matrix QC keeps special focus on any issue until issue is permanently resolved.

Updated: January, 2010.

22

www.apparelco.com

FIRST 32 GARMENTS INSPECTION

WHY: To verify whatever discussed during pre-production meeting and operational inlines stage has been followed or not. WHEN: This inspection will be carried out at first off product. This inspection will always be carried out whenever factory will induct new or carryover style in sewing lines. HOW: Sample of first off 32 garments is selected and sample is thoroughly checked for measurement and garment compliance.

OFFLINE INLINE / OUT PUT INSPECTION

WHY: To quantify the defect rate of production line and identify major problems, so that measures can be taken to control them. WHEN: When garment starts to come off the sewing line. HOW: Garments are randomly selected and checked for quality and measurements. This inspection is based upon customers Acceptance Quality Level (AQL) requirement.

FINISHING INLINE INSPECTION

WHY: To quantify defect rate and to ensure that all finishing requirements are met. WHEN: Once garments have been pressed. HOW: Garments are randomly selected and checked for quality and measurements. This inspection is also based upon customers Acceptance Quality Level (AQL) requirement.

INTERIM AUDIT / BATCH AUDITS

WHY: To ensure that every batch being passed by finishing inspectors is as per customers requirement. WHEN: At least 100 pcs packed in each style. HOW: Procedure of conducting interim audit is same as final audit. Reject batch is reaudited and OK batch is forwarded to packing section. All passed cartons are kept in warehouse with passing date of batch marked on each carton.

Updated: January, 2010

23

www.apparelco.com

PRE-FINAL INSPECTION

WHY: To check the quality of shipment expected to be presented for final inspection. It is a chance to make any necessary correction, as at final inspection stage time for correction may be limited. WHEN: At least 80% of shipment is packed in cartons. HOW: Garments are randomly selected and checked for quality and measurements. This inspection is also based upon customers Acceptance Quality Level (AQL) requirement.

FINAL INSPECTION

WHY: To check the outgoing quality of garments & measure the defect rate. WHEN: Once complete shipment is packed and shipping documentation are ready. HOW: Garments are randomly selected and checked for quality and measurements. This inspection is also based upon customers Acceptance Quality Level (AQL) requirement. An Inspection certificate is issued to vendor upon completion of this inspection.

PRODUCTION SAMPLE REQUIREMENTS

WHY: Main purpose of customers requirement of TOP, Ad or Inline samples is to make sure

that production quality is the same as pre-production samples and it incorporates all desired improvements.

WHEN: After inline inspection, garments must be washed if required, pressed and packed as

bulk.

HOW: Every customer has its own requirement for shipment samples. Customers quality

standards are strictly followed while inspection. Please note that some customers do not require TOP or inline samples.

Updated: January, 2010.

24

www.apparelco.com

MATRIX SOURCING FINAL INSPECTION REQUIREMENTS

x

Vendor must inform Matrix 24 hours prior to presenting final audit. This request is made through e-mail. Vendor will also give weekly audit plan on prescribed format. For late night and off day audits, vendor must inform Senior Management (COO) 48 hours prior to presenting final audit. Note: If any of the above is missing, QC is bound to not conduct Final audit.

IMPORTANT

x

All third time failed audits are considered b-grades and matrix sourcing notifies to buyer. Matrix auditing policy requires all QCs / QAs to takes pictures of the nonconformances found during their audits. This applies to all inspection levels and factories must endorse this practice.

FINAL AUDIT PRE-REQUEST FORMAT (24 HOURS BEFORE INTIMATION)

Vendor Name: Unit # GT / WO # STYLE # PO # COLOR DATE: QTY TIME REMARKS

FINAL AUDIT PRE-REQUEST FORMAT (WEEKLY)

Vendor Name: Unit # GT / WO # DATE STYLE # PO # FROM COLOR QTY TO TIME REMARKS

Updated: January, 2010

25

www.apparelco.com

FINAL INSPECTION PROCEDURE (GENERIC)

Matrix Sourcing has developed its own procedures for conducting audits. The auditing procedure explained below is for all customers. Any additional requirement by any customer is also fulfilled by adding that requirement in our generic procedure.

WORKSPACE REQUIREMENTS:

A. The work area should be well organized at all times. Environment clean, dry and quiet. B. Work space should be clean and clear. C. Appropriate room temperature and light level should be maintained in inspection area.

AUDITING TOOLS:

All auditing tools should be well organized and accessible. A. Steel or reinforced fiberglass tape. B. Box Knife. C. Defect stickers.

Updated: January, 2010.

26

www.apparelco.com

PAPER WORK:

Paper work should be located. This includes; Brand information: Quality manual, Measurement manual. Audit information: AQL chart, audit reports, wash test reports, additional reports if required. Style information: Specification sheet, PO, PP sample, approved trim cards, size specification, embellishment artwork etc.

BRAND QUALITY MANUAL

ADDITIONAL REQUIREMENTS:

Following additional requirements should be followed;

x x x x x

Pre- final pass report Packing list Deviation Chart QRS (Qualified reference sample) / Color wise QRS Product safety report and Metal detection (If applicable)

Updated: January, 2010

27

www.apparelco.com

PACKING LIST VERIFICATION

Packing list should be in the following or similar computerized format preferably on vendors letter head, Packing List Customer Style # Vendor Name Carton Number 1-18 19 20-34 35 36-57 58 59-73 74 NIke 190183 Style Textile Color Name Red Red Blue Blue Black Black Yello w Yello w Color Code 218 218 278 278 213 213 124 124 Date PO # Vendor ID # Quantity S 24 18 5-Jan-2010 450146666 STY Total Units 432 16 360 19 528 22 360 23

# of Cartons 18 1 15 1 22 1 15 1

M 24 19 24 23

L 24 22 -

XL -

2XL -

Total

74

42 S

90 M 5. 4 5. 2 18

46 L 5.6 5.4 Wid th:

XL -

2XL -

1762 Average 5.4 5.2

Carton (Kgs)

Weight

Gross Weight Net Weight

5.2 5.0

Carton size (Inches) Country of Origin:

Length: Pakistan

12

Height:

Sign (Packing Incharge)

Updated: January, 2010.

28

www.apparelco.com

DEVIATION CHART

Deviation chart should be in the following or similar computerized format preferably on vendor letter head. Make sure that the deviation is within acceptable percentage, size wise, Color wise and in total as allowed by the customer. If deviation is out of tolerance then inform Manager QC and Merchandiser. Deviation is always preferred to be on plus side. Deviation Chart Customer Style # PVH D1242332 Date PO # Vendor ID # M 432 0 430 -2 -0.46% M 432 0 430 -2 -0.46% M 864 0 860 -4 -0.46% L 605 0 615 +10 +0.02% L 605 0 615 +10 +0.02% L 1210 0 1230 +20 +0.02% XL 537 0 537 0 0% XL 537 0 537 0 0% XL 0 20-Jan-2005 E0231334-0003 8706 XXL 173 0 190 +17 +0.1% XXL 173 0 190 +17 +0.1% XXL 0 Total 1,855 0 1,882 +27 +0.01% Total 1,855 0 1,882 +27 +0.01% Total 3710 0 3764 +54 +0.01%

Vendor Name D.S . Textiles Color: RED S 108 0 110 +2 +1.85% S 108 0 110 +2 +1.85% S 216 0 220 +4 +1.85%

Order Quantity Pre-Shipped Packed Quantity Deviation (+/-) Deviation (+/-%) Color: NAVY

Order Quantity Pre-Shipped Packed Quantity Deviation (+/-) Deviation (+/-%) Grand Total Order Quantity Pre-Shipped Packed Quantity Deviation (+/-) Deviation (+/-%)

1074 346 1074 380 0 +34 0% +0.1%

Updated: January, 2010

29

www.apparelco.com

USE OF SAMPLING PLAN (AQL)

Acceptable Quality Level (AQL) is defined as the maximum number of defects per unit of product, that for the purpose of sampling inspection can be considered satisfactory acceptable. The sampling plans most frequently used by the military standard are based on the AQL system. The basic concept of using AQL is to give inspection teams the means of measuring faults within a consignment of merchandize without 100% inspection. Matrix Sourcing follows AQL given by our customers at all inspection stages. Sample size is selected based on AQL chart.

AQL CHART

Updated: January, 2010.

30

www.apparelco.com

SKU CALCULATION PROCEDURE

The SKU selection procedure is to determine number of cartons and garments in each size and color according to required AQL level. QC calculates sample size per store keeping unit with the help of following formula; A. SKU = No of sizes * No of colors. B. PCS / SKU = Sample size / SKU. PCS / SKU C. 1-19 20-31 32-49 CTN / SKU 2 3 4

D. Total cartons = CTN / SKU * SKU. E. PCS/CTN = Sample size / total cartons. QC prepares a table of SKU calculation and take sample size accordingly.

CARTON QUANTITY AND CARTON LABELS

A. Total cartons are counted against packing list and carton numbers are compared. B. Carton marking and carton stickers placement is checked. C. All carton labels are checked with the information provided on purchase order and ESI sheet. This includes PO #, PO Material, Diamond mark, UCC sticker placement. D. Carton dimensions are measured physically (L+W+H) and verified with the size provided in packing list. E. Physical condition of all shipping cartons is checked. All shipping cartons must meet customer quality standards. F. Cartons must be properly sealed with a security tape. G. Cartons must not be damaged, over packed or under packed.

Updated: January, 2010

31

www.apparelco.com

PACKING INSPECTION

Once cartons are marked for sample, QC checks following in the selected cartons;

x

Carton labels are compared with carton contents. Whatever is mentioned on the carton should be inside carton. Embellishment along with other packing accessories is checked while checking carton contents accuracy. Hangtag & UPC is checked for correct IM#, correct style, correct color, and polybag orientation etc. Packing Assortment / Ratio. Polybag size, polybag print, ventilation holes etc. Garment fold size. Packing accessories are checked e.g. Hangtags, Clips, Pins, Tissue Paper etc. If required by the customer garments are passed through metal detector machine.

x x x x x

Updated: January, 2010.

32

www.apparelco.com

GARMENT COMPLIANCE INSPECTION PROCEDURE

The purpose of checking garment compliance is to assure that all customer requirements and expectations are met. Matrix Sourcing has standardized its garment compliance inspection procedure which all QCs are bound to follow. Garment compliance is checked in the following manner;

x

Garment folding, garment orientation, hang tags, stickers placements, ploy bag printing etc is checked with approved standards. QC checks consistency of color, embellishment shade and stickers placement for all contents of carton. QC checks all colors used on garment body with color standards / fabric approvals. Color combinations of all items are checked with color specification sheet. Specification and placement of all items used on garment is checked. If bill of materials is provided by the buyer then garment is compared thoroughly checked with BOM. Color combination and embellishment size is checked with embellishment colored artwork, sample and embellishment approvals. All stitching details are checked with QRS and Style sheet. All labels, UPC, Polybag and other packing accessories are checked with PP sample and approved trim card. Three garments in each size are checked for measurements i.e. one garment is checked for complete measurements and two garments are checked for key measurements. If any measurement falls out of tolerance then all sample size is checked for that specific measurement.

x x x

x x

Updated: January, 2010

33

www.apparelco.com

INSPECTION & REPORTING PROCEDURE

Garment inspection is conducted in clockwise manner. This method is consistently used throughout inspection. OK and defective garments are kept separate and findings are shared with all concerned personnel. QC takes decision about shipment based on AQL provided by customer. All audit findings are recorded in Matrix inspection report form. Matrix QC, production merchandiser and vendor representative signs inspection report. Inspection report form contains three copies, QC give one copy to merchandiser, one copy to factory representative and one copy is kept with him for record. Defects pictures are taken and audit status is updated on Matrix portal database. As soon as the report is entered in database a system generated SMS about audit findings is sent to all concerned personnel. Reports entered in portal database can be reviewed and analyzed by all concerned personnel at Matrix. Concerned personnel at vendors have right to access their reports on portal but that access is limited up to vendor related reports only. The data on portal can be later used as a tool for different analysis. Note: Inspection reports format are attached in appendix A, B, C & D.

SHIPMENT SAMPLES

Matrix QC picks shipment samples after each final inspection. Quantity of shipment samples taken varies from customer to customer. Normally it is preferred to have shipment samples available in all colors and sizes for a single style. The main purpose of shipment sample is to assure product quality of concerned shipment to customer and In case of any complaint from customer, Matrix can verify with their reference shipment sample.

Updated: January, 2010.

34

www.apparelco.com

GARMENT INSPECTION METHOD

All types of garments are inspected using clockwise method. Clockwise garment inspection is a systematic procedure of inspecting garments to ensure that the garment conforms to customers specifications. Inspectors are bound to follow a check list therefore it is highly unlikely that he/she might miss an irregularity.

CLOCKWISE INSPECTION KNITTED TOP

1. References to Right and Left are AS WORN. Garment inspection should be done in clockwise direction as shown below:

2. Pick up by shoulder points. Check front & back appearance & presentation is correct.

Updated: January, 2010

35

www.apparelco.com

3. Lie flat on table. Examine styling details.

4. Open & check any center front opening

5. Examine inside and outside of collar / neck. Examine inside shoulder seam

Updated: January, 2010.

36

www.apparelco.com

6. Fold top forward at shoulders. Examine back neck.

7. Examine left shoulder and armhole seam.

8. Fold sleeve across front of garment, examine back left armhole. Check for shading.

Updated: January, 2010

37

www.apparelco.com

9. Examine left sleeve cuff inside & out.

10. Examine left underarm seam & left side seam. Check C&C label.

11. Examine bottom hem inside and out, front & back.

Updated: January, 2010.

38

www.apparelco.com

12. Examine right side seam & right underarm.

13. Examine right sleeve cuff inside and out.

14. Fold sleeve across front of garment. Examine back right armhole, check for shading.

Updated: January, 2010

39

www.apparelco.com

15. Examine right armhole seam and shoulder seam.

16. Turn garment over. Examine styling details & any unchecked seams on back.

17. A-Grade & B/C-Grade should be kept separate.

Updated: January, 2010.

40

www.apparelco.com

CLOCKWISE INSPECTION BOTTOM / PANT

1. Pick up by waist. Check front and back appearance & presentation are correct.

2. Lie flat on table. Examine styling details, logos etc.

3. Examine front rise seam.

Updated: January, 2010

41

www.apparelco.com

4. Check front outside waistband. If elasticized stretch out to full extent.

5. Turn waistband back. Examine styling details, labels, drawcords etc.

6. Turn waistband inside out.

Updated: January, 2010.

42

www.apparelco.com

7. Fold waistband over. Examine back waist.

8. Fold front rise towards auditor, outseam to inseam. Examine styling details. Examine left outseam, including side pocket. Check for shading.

9. Examine left leg opening. If elasticized stretch out to full extent.

Updated: January, 2010

43

www.apparelco.com

10. Fold front leg out.

11. Examine back rise and front rise.

12. Examine total inseam.

13. Return leg to original position. Turn pant over, back rise to auditor. Examine right out seam.

Updated: January, 2010.

44

www.apparelco.com

14. Examine right leg opening. If elasticized stretch out to full extent.

15. Turn over garment. Examine styling details. Examine other unchecked seams.

16. A-Grade & B/C-Grade should be kept separate.

Updated: January, 2010

45

www.apparelco.com

CLOCKWISE INSPECTION JACKETS

Clockwise inspection of jackets is conducted in the following manner. 1. Pick up by shoulder points. Check front and back appearance & presentation is correct.

2. Lie flat on table. Examine styling details.

3. Open & check center front opening. Check appearance and presentation. Examine styling details facings, labels, pockets etc.

Updated: January, 2010.

46

www.apparelco.com

4. Examine inside collar. Starting with left shoulder seam examine all liner seams in a clockwise direction.

5. Examine bottom hem inside & out, front & back. If elasticized, stretch out to full extent.

6. Examine outside collar.

Updated: January, 2010

47

www.apparelco.com

7. Fold forward at shoulders. Examine back neck. Examine inside and outside of hood.

8. Examine left shoulder seam & armhole seam.

9. Fold sleeve across front of garment, examine back left armhole. Check for shading.

Updated: January, 2010.

48

www.apparelco.com

10. Examine left cuff inside & out.

11. Examine left side seam & underarm seam.

12. Examine right side seam & underarm seam.

Updated: January, 2010

49

www.apparelco.com

13. Examine right sleeve cuff inside and out.

14. Fold sleeve across front of garment. Examine back right armhole, check for shading.

15. Examine right armhole seam and shoulder seam.

Updated: January, 2010.

50

www.apparelco.com

16. Turn jacket over. Examine styling details & any unchecked seams.

17. A-Grade & B/C-Grade should be kept separate.

Updated: January, 2010

51

www.apparelco.com

GARMENT MEASUREMENT

Size specifications provided by the customer, are critical and must be followed. It is vital to ensure that all garments conform to these specifications. Please note that the measurement method may vary from buyer to buyer therefore buyer measurement manual must be consulted for measurement compliance check.

How to Measure?

The measurement methods of different areas on different garment types are shown below;

Knitted Top

CHEST (1 INCH BELOW ARMHOLE)

Measure 1 inch below armhole, straight across from edge to edge.

CHEST (ARMPIT TO ARMPIT)

Measure armpit to armpit, straight across from edge to edge.

Updated: January, 2010.

52

www.apparelco.com

HIGH CHEST (AS SPECIFIED FROM HPS)

Measure specified point from hps, measure straight across from edge to edge.

ACROSS BACK

At specified point below high point shoulder, measure straight across armhole seam to armhole seam.

ACROSS FRONT

At specified point below high point shoulder, measure straight across armhole seam to armhole seam.

Updated: January, 2010

53

www.apparelco.com

BOTTOM HEM

Continuous Hem: Measure at bottom across from edge to edge. Vented Hem: Measure just above the vent opening across from edge to edge.

BOTTOM HEM (RELAXED)

With garment lying flat, in relaxed position, measure from side to side at the middle of the hem / trim.

BOTTOM HEM (STRETCHED)

Measure from side to side at the middle of the rib with the hem / trim fully extended.

Updated: January, 2010.

54

www.apparelco.com

BOTTOM HEM / TRIM HEIGHT

Self Hem: Measure from bottom edge of hem to top flat lock stitch line. Trim Hem: Measure from bottom edge of trim to over lock join seam of trim.

ACROSS SHOULDER

Measure from left shoulder point (top most point of sleeve/body overlock seam) to right shoulder point straight across.

SHOULDER SLOPE (FROM ARMHOLE )

Measure from imaginary line, connecting high point of shoulder seam to highest point of armhole seam.

Updated: January, 2010

55

www.apparelco.com

SHOULDER SLOPE (AS SPECIFIED)

Measure specified point away from HPS towards armhole, measure imaginary line down to shoulder.

FRONT LENGTH (FROM HPS)

Measure from HPS (high point shoulder) to bottom edge of front body. (If garment has a rib bottom, include rib in front length measurement.)

Front Length (From CF)

Measure from highest point of neck to bottom edge of front body. (If garment has a rib bottom, include rib in front length measurement.)

Updated: January, 2010.

56

www.apparelco.com

BACK LENGTH (FROM HPS)

Measure from high point shoulder to bottom edge of front. If garment has a rib bottom, include rib in front length measurement.

BACK LENGTH (FROM CF)

Measure from highest point of neck to bottom edge of front. If garment has a rib bottom, include rib in front length measurement.

SIDE SEAM LENGTH

Measure from armpit to bottom edge of hem / trim.

Updated: January, 2010

57

www.apparelco.com

SIDE VENT LENGTH (FRONT)

Measure from bottom edge of vent to opening

Side Vent Length (Back)

Measure from bottom edge of vent to opening.

Sleeve length (From Center Back)

Measure straight from center back to edge of sleeve / cuff / rib.

Updated: January, 2010.

58

www.apparelco.com

SLEEVE LENGTH (THREE POINT METHOD)

Measure straight from center back neck seam to sleeve attach seam, pivot, measure straight from sleeve attach seam to bottom of sleeve.

SLEEVE CAP

Measure straight from center cap to farthest end of cuff or hem with garment laid flat and at a natural angle.

UNDER ARM LENGTH

Measure from armpit to sleeve/cuff/rib edge.

Updated: January, 2010

59

www.apparelco.com

MUSCLE / BICEPS (1 INCH BELOW ARMHOLE)

Measure straight across at right angle to sleeve fold, 1 below armpit.

MUSCLE / BICEPS (FROM ARMPIT)

Measure at armpit straight across at right angle to sleeve fold.

ELBOW (AS SPECIFIED)

Mark specified point up from cuff edge, then measure straight across at a right angle to sleeve fold.

Updated: January, 2010.

60

www.apparelco.com

ELBOW (CENTERED)

Fold cuff edge to high point of armhole, measure straight across folded line.

FOREARM

Mark specified point up from cuff edge, then measure straight across at a right angle to sleeve fold.

CUFF HEM / TRIM HEIGHT

Measure from bottom edge of sleeve to farthest top stitch line of hem.

Updated: January, 2010

61

www.apparelco.com

CUFF OPENING

Measure cuff opening at center.

ARM HOLE (STRAIGHT)

Measure from high point of armhole seam to lowest point of armhole seam straight.

ARMHOLE (CURVED)

Measure from high point of armhole seam to lowest point of armhole seam along the seam.

Updated: January, 2010.

62

www.apparelco.com

RAGLAN DEPTH

Measure from HPS to imaginary line at under arm seam.

NECK WIDTH (SEAM TO SEAM)

Measure from overlock seam to overlock seam at high points of shoulder.

NECK OPENING (RELAXED)

Measured on the half. Fold neck line along center front and center back keeping neck seams even. Measure along seam line.

Updated: January, 2010

63

www.apparelco.com

NECK OPENING (STRETCH)

Extend neck to maximum stretch and measure neck width point to point.

Updated: January, 2010.

64

www.apparelco.com

TOP EDGE COLLAR LENGTH

Measure collar length at outer edge from left collar point to right collar point.

NECK CIRCUMFERENCE

Measure from center of collar band button to outer corner of buttonhole along the neck over lock seam.

NECK HEM / TRIM HEIGHT

Measure from edge of neck trim to its joining seam.

Updated: January, 2010

65

www.apparelco.com

COLLAR HEIGHT (FROM CENTER BACK)

Measure height from out side edge of collar to the neck over lock join seam at center back.

COLLAR BAND HEIGHT

At center back, measure height of collar band seam to seam.

COLLAR POINT LENGTH

Measure from collar point to collar join seam.

Updated: January, 2010.

66

www.apparelco.com

COLLAR SPREAD

Fasten CF Collar band button. Fold collar naturally. Measure distance between the two collar points.

TIE SPACE

Fasten CF Collar band button. Fold collar naturally. Measure space at center front neck.

FRONT NECK DROP

Binding / Hem: Measure from edge Collar: Measure from collar/body join seam. Trim: Measure from trim/body join seam.

Updated: January, 2010

67

www.apparelco.com

BACK NECK DROP

Measure from imaginary line (Right HPS to Left HPS) to over lock seam of neck at CB. Binding / Hem: Measure from edge

Collar: Measure from collar/body join seam. Trim: Measure from trim / body join seam.

PLACKET WIDTH

Measure from edge to edge of placket.

Updated: January, 2010.

68

www.apparelco.com

PLACKET LENGTH

Measure from top of placket to the bottom stitching line of placket box. *Do not include the placket box if specially instructed.

PLACKET BOX HEIGHT

HOOD HEIGHT / OPENING

Measure straight from neck seam to top edge of hood opening.

Updated: January, 2010

69

www.apparelco.com

HOOD LENGTH

Measure from back neck seam to front edge along seam.

HOOD WIDTH

Measure straight across hood from edge of opening to center back edge.

SWEAT PATCH WIDTH

Measure from outer stitch line to outer stitch line straight across at highest point.

Updated: January, 2010.

70

www.apparelco.com

SWEAT PATCH HEIGHT

Measure from neck join seam down to outer stitch line of sweat patch.

POCKET WIDTH

Measure across top edge of pocket from edge to edge.

POCKET HEIGHT

At Side: Measure at side of pocket from top edge to bottom edge At Center: Measure at center of pocket from top edge to bottom edge.

Updated: January, 2010

71

www.apparelco.com

POCKET OPENING

PLACEMENT (FROM HPS)

Measure from HPS down to top edge of pocket.

POCKET PLACEMENT (FROM CF)

Measure from CF across to closer side edge of pocket.

Updated: January, 2010.

72

www.apparelco.com

FRONT ZIPPER LENGTH

Measure from top teeth of zipper to the bottom edge of zipper.

POCKET ZIPPER LENGTH

KNITTED BOTTOMS

Waist (Relaxed) Measure from side to side along the middle of the waistband without applying pressure.

Updated: January, 2010

73

www.apparelco.com

WAIST (STRETCHED)

Extend waistband just enough to remove all gathering. Measure from side to side along the middle of the waistband.

WAISTBAND HEIGHT

Measured from the waistband joining seam to the top of waistband.

SEAT FROM CROTCH

Measure specified distance from crotch, measure straight from side seam to side seam .

Updated: January, 2010.

74

www.apparelco.com

SEAT (FROM WAIST BAND) / HIGH HIP

Measured specified distance down from top of waistband or up from crotch point as specified. Mark distance from top of waistband at CF and both side seams. Measure straight from left SS marked point to CF marked point to right SS marked point.

FRONT RISE

Measured from below waistband to crotch along the natural counter of front seam. * Measure from top of waist band if specified.

BACK RISE

Measured from below waist band to crotch along the natural counter of back seam. *Measure from top of waist band if buyer required.

Updated: January, 2010

75

www.apparelco.com

THIGH

Measured 1 below crotch from inseam joining seam across to the out side of leg parallel to bottom edge of leg opening.

KNEE (AT )

Fold the leg so that bottom is touching crotch. Measure the fold line parallel to bottom.

KNEE (AT SPECIFIED)

Measure specified point from crotch towards bottom. Measure the marked line parallel to bottom.

Updated: January, 2010.

76

www.apparelco.com

BOTTOM OPENING

With the garment lying flat, measure straight across from side to side at the leg opening edge.

ELASTIC LEG OPENING (RELAXED)

Measure from side to side straight across the bottom edge without applying pressure.

ELASTIC LEG OPENING (STRETCHED)

Stretch just enough to remove all gathering. Measure from side to side straight across the elastic.

Updated: January, 2010

77

www.apparelco.com

INSEAM

Measure from crotch to bottom edge of hem.

OUT SEAM

Measure along side seam from below the waistband to the bottom of leg. *Include waistband if specified.

BOTTOM HEM TRIM HEIGHT

Measure from the bottom edge of the trim to the top edge of the trim.

Updated: January, 2010.

78

www.apparelco.com

FRONT POCKET PLACEMENT (FROM WAIST BAND)

Measure straight from top of waistband down to top of pocket opening.

POCKET OPENING

Measure pocket opening seam to seam.

POCKET BAG WIDTH

Take widest point of pocket bag and measure across from stitch line to stitch line.

Updated: January, 2010

79

www.apparelco.com

FRONT POCKET BAG LENGTH

Measure pocket bag length from stitch line to stitch line.

ZIPPER LENGTH

Measure from outside edge of zipper stopper to outside edge of zipper slider.

FLY LENGTH

Measured straight from top of waistband to bottom of fly

Updated: January, 2010.

80

www.apparelco.com

DEFECTS CLASSIFICATION (GENERIC)

Matrix Sourcing has established its own defects classification guidelines. All QCs are bound to follow these guidelines while inspecting garments and making reports. Purpose of establishing guidelines is to standardize defects recording on inspection reports, so that everyone at Matrix Sourcing is aware about the nature of defect by looking at inspection reports. Furthermore process of data generation and its analysis is expedited. General classification guidelines are as under;

FABRIC DEFECTS

This category should be used for defects found within the fabrics used to make a garment.

106 SLUB / KNOT / SNAG

SLUB / KNOT: Thick uneven spot(s) in the fabric caused by lint or small lengths of yarn adhering to it, or where two yarn ends are tied together. SNAG: A pulled thread in the fabric. All snags should be considered defective.

SLUB

KNOT

SNAG

107 MISPICK / DOUBLE PICKS OR ENDS

This category is used when inspecting woven fabric.

Updated: January, 2010

81

www.apparelco.com

108 COLOR CONTAMINATION

A transfer of color from one fabric to another. All bleeding and color migration should be considered defective.

109 - SHADING

Noticeable color difference between the same color. GMT-GMT Noticeable color difference between the same color. Panel-Panel. Finishing streaks. Shading that can be seen during visual inspection should be viewed with light box. If shading is visible under CWF lighting or daylight, product should be considered defective.

112 FABRIC PERFORMANCE

This includes appearance, texture, feel etc. That is different from the approved fabric or with discrepancies between garment.

Updated: January, 2010.

82

www.apparelco.com

113 FABRIC HOLE

Includes holes in the fabric and needle holes. All fabric holes should be considered defective

114 FABRIC RUN

A break in the yarn of a fabric that causes the stitch to run along the needle line or a void caused by a missing warp yarn. All fabric runs should be considered defective.

115 YARN CONTAMINATION

Foreign fibers or soil knitted into the fabric. Contamination which is a 1/8 (0.3cm) or greater in a critical area of a garment, which can be easily seen should be considered defective. Contamination greater than (0.6cm) in non critical area should be considered defective.

Updated: January, 2010

83

www.apparelco.com

111 YELLOWING OF FABRIC

This is a phenomenon which causes light colored fabric to yellow over time. All yellowing should be considered defective.

199 MISCELLANEOUS FABRIC DEFECTS

This code includes all other fabric defects that are not captured by the previous fabric codes.

Updated: January, 2010.

84

www.apparelco.com

CONSTRUCTION & STITCHING DEFECTS

This category should be used for defects made by operations performed on a garment that brings together different materials.

201 BROKEN / DROP / SKIP STITCH

Broken / drop / skip stitch is damaged or irregularities along the stitch line.

202 RAW EDGE / FRAYED SEAM

Raw edge is slipping or raveling edges. Frayed seam is seam with yarn ends. Any frayed seam that affects the appearance and function of the garment should be considered defective.

203 OPEN / DELAMINATED SEAM

A seam which appears to be open is called open seam. A seam that starts to delaminate from edges is called delaminated seam. All open and delaminated seams should be considered as defective.

Updated: January, 2010

85

www.apparelco.com

204 OVERRUN STITCH

Overrun stitch is any stitching on a seam or hem that has overrun into the garment, or into an area that is not supposed to be stitched. Any overrun stitch that affect the appearance or function of the garment should be considered defective.

206 UNEVEN / WAVY STITCHING

Stitching that is wavy, not straight, or loose. When the stitching affects the garment appearance or function it should be considered defective.

208 PUCKERING / PLEATING

Undesirable uneven surface or gathering of fabric on a garment. Any puckering that affects appearance and function of the garment should be considered defective.

Updated: January, 2010.

86

www.apparelco.com

211 TWISTED / ROPING / UNEVEN HEM

Twisted / Roping describes hem or seam that does not lie flat and has a twisted appearance. Any twisted / roping that affects appearance and function of the garment should be considered defective. Uneven hem refers to wide and narrow or uneven hem. When viewing a garment keep its shoulders even or pant leg flat. If the hem is exposed from opposite side of the garment around the bottom hem or leg opening, the garment should be considered defective. Any unevenness that affects the garments appearance may be a reason for considering garment defective.

Roping

Twisted

Uneven hem

216 CONSTRUCTION NOT AS SPECIFIED

When the construction of a garment differs from given specifications i.e specification request v neck, garment has crew neck, incorrect color combination, high/low pocket or shoulder, incorrect placement etc. Any deviation from construction specification should be considered defective.

Updated: January, 2010

87

www.apparelco.com

299 MISCELLANEOUS CONSTRUCTION DEFECT

Defects that are not captured by previous construction codes. Defects that are not covered by previous construction codes, that appear appearance and performance of the garment should be considered defective.

Updated: January, 2010.

88

www.apparelco.com

TRIMS DEFECTS

This category should be used for defects in assemblies / sub-components that are not fabric materials that may or may not serve a mechanical function or operation in a garment.

301 TRIM BROKEN / INOPERABLE / INSECURE

Trim components that have been damaged, but may still function below the expected level are called broken trims. i.e. broken snap, zipper puller, damaged drawcord etc. Trim components that do not function properly are called inoperable trims. i.e. faulty zippers, pullers, snaps, etc. Trim components that are not properly secured to garment. All broken / inoperable / insecure trim items should be considered defective.

305 TRIM NOT AS SPECIFIED

When a trim item differs from specifications i.e. incorrect color, incorrect size, missing trim item etc Any deviation from specification that was not approved by the appropriate stakeholders prior to production should be considered defective.

Updated: January, 2010

89

www.apparelco.com

306 TRIM BLEEDING / COLOR MIGRATION

Transferring of trim color onto another component or onto the fabric of the garment. All trim bleeding and color migration should be considered defective.

390 MISCELLANEOUS TRIM DEFECTS

Other defects pertaining to a trim item that are not captured by previous codes but affects the trim. Defects that are not covered by previous codes that would affect the performance or appearance of the garment should be considered defective.

Updated: January, 2010.

90

www.apparelco.com

EMBELLISHMENTS DEFECTS

This category should be used for defects related to application of an image, graphic, embroidery etc. that is of a decorative nature.

401 UNRAVELLING EMBELLISHMENT

Embroidery that has started to unravel i.e. thread hanging from embroidery. Unraveling threads in the embroidery should be considered defective.

402 PEELING / DELAMINATION

Peeling is patches or heat transfers where the embellishment has begun to peel from the garment or the layer. When layers of a patch or heat transfer separates from itself it is called delamination. All heat transfers / appliques / patches where the embellishment has begun to peel from the garment or delaminate from itself should be considered defective.

Updated: January, 2010

91

www.apparelco.com

403 POOR COVERAGE / REGISTERATION / CRACKING

x

Poor coverage is prints with light ink coverage resulting in the fabric color bleeding through the print, or too much ink where the ink builds up is too heavy often resulting in a blurry print or varying color intensity within a heat transfer.

Poor registration is poorly aligned image where details appear out of place.

Cracking is link that is cracked or cracks when garment is stretched.

410 IMPROPER BACKING REMOVAL

Excess backing used in the embroidery and other applications that are not properly removed prior to packing. All excess tear away backing (used for embroideries and other applications) not removed from garments should be considered defective.

Updated: January, 2010.

92

www.apparelco.com

412 HOOP / PLATE / SCREEN MARK

Hoop marks appear as light ring around embroidery. Plate marks appear as a light area around heat transfers. Screen marks appear as two lines in the fabric along the edge of the print. Hoop / plate / screen marks effecting the overall appearance of the garment could be considered defective. It should be compared with the approved standard if available.

415 EMBELLISHMENT NOT AS SPECIFIED

When an embellishment differs from the specifications i.e. incorrect color, incorrect size, missing embellishment, wrong placement etc. Any embellishment that differs from specifications but not approved by appropriate stakeholders prior to production should be considered defective. Approved standard may be needed.

416 EMB BLEEDING / COLOR MIGRARTION

The transfer of dye from embellishment onto fabric of garment or other colors within embellishment. All embellishment bleeding or color migration onto the garment or other colors within embellishment should be considered defective.

Updated: January, 2010

93

www.apparelco.com

499 MISCELLANEOUS EMBELLISHMENT DEFECT

Embellishment defects that are not covered by the previous codes but affects embellishment of a garment. Any defect pertaining to embellishments that are not covered by previous codes, that affects appearance of the garment should be considered defective.

Updated: January, 2010.

94

www.apparelco.com

LABELING DEFECTS

This category should be used when defects are related to labels that are functional and not decorative in nature e.g. care and content label, PO ID, Corporate loop label etc.

501- MISSING / INCORRECT / INCOMPLETE LABEL

Missing label is when a label in not applied. Incorrect label is when label doesnt match approved standard. Incomplete label is when a part of label is missing. Missing / incorrect / incomplete labels are considered as defective.

502 PEELING / CRACKING

Peeling is when a label peeling away from a garment. Cracking label is label / heat transfer that cracks on stretching. All labels must be securely attached. Any peeling should be considered defective. Any cracking should be considered defective. Heat transfers can be tested for cracking using Nikes heat transfer stretch standards.

Updated: January, 2010

95

www.apparelco.com

503 COLOR BLEEDING / MIGRATION / SHADING

Labels with visual appearance of color bleeding, color migration or shading onto garment or itself. Any bleeding / color migration or shading of heat transfer / label should be considered defective.

590 MISCELLANEOUS LABELING DEFECT

Any labeling issue not captured by the previous labeling defect codes. Any labeling defect that affects the appearance, function and salability of the garment should be considered defective.

Updated: January, 2010.

96

www.apparelco.com

CLEANLINESS / APPEARANCE

This category is used when any foreign contaminant or substance is found on a garment or in its packaging.

601 - SOIL

Soiling is a generic term used to describe any type of stain caused by dirt, dust, soil, oil, grease marks, ink smears etc. Any soil that affects appearance of a garment shall be considered defective.

603 UNATTACHED / UNTRIMMED THREAD

Threads that have been trimmed but not removed from garments are called unattached threads. Threads that were not trimmed from garments are called untrimmed threads.

604 FOREIGN OBJECTS / INSPECTION STICKERS

Any foreign object left on the garment that should have been removed prior to packaging i.e. stickers, melted plastic, sand, stone, etc. All foreign objects that is found on garment should be considered defective. If the sticker is small and in an inconspicuous place and doesnt cause any stain or damage to the garment when removed, it will not be considered as defective.

Updated: January, 2010

97

www.apparelco.com

605 PRESSING / HEAT DEFECTS

Affects from pressing / heat such as shine, color change, schorching etc. Pressing / heat defects that affects appearance and salability of garment should be considered defective.

690 MISCELLANEOUS CLEANLINESS DEFECTS

Other cleanliness / appearance defects that are not captured by previous cleanliness defect codes. Any defect that affects appearance and cleanliness of the garment should be considered defective.

Updated: January, 2010.

98

www.apparelco.com

PACKAGING DEFECTS

This category should be used when discrepancies are found in carton labeling information, pack quantities or methods of packaging.

703 PRODUCT IN CARTON INCORRECT

Mixed sizes in same carton, mixed sizes within same garment i.e. warmups, incorrect carton count, incorrect style / size / color etc. Any mis-packed cartons should be considered defective and replaced.

704 POLYBAG NOT AS SPECIFIED

Incorrect polybag size, ventilation holes, missing / incorrect recycle info, incorrect material etc. Polybags that are not to specification should be considered defective and repackaged.

Polybag too small

Polybag too big

Polybag misprinted

Updated: January, 2010

99

www.apparelco.com

706 STICKERS / HANGTAGS / CARTON LABELS

Missing / incorrect carton labels, UPC labels, price tickets, hangtags, hangtags bleeding etc.

799 MISCELLANEOUS PACKAGING

Includes other packaging defects that are not captured by previous packaging codes. Any defect that affect accuracy of packaging should be considered defective.

Updated: January, 2010.

100

www.apparelco.com

WASHING DEFECTS (WOVENS)

This category should be used when discripancies are found in washing of garment.

901 BRUSHING / SPRAY EFFECT / MOUSTACHES

x

Includes non-conformances related to brushing, spray effect, moustaches etc of garment.

902 GRINDING / RIPPING(uneven / missing / incorrect)

x

Includes defects related with grinding and ripping of a product.

903 SAND BLAST(uneven / missing / incorrect)

x

Includes all defects related with sand blast of a product.

Updated: January, 2010

101

www.apparelco.com

904 IMPROPER SELVAGE

All defects related to selvage are included in this category.

905 WASHING NOT AS SPECIFIED

This category should be used when washing of a product is not upto standards. Any deviation from wash specification should be considered defective.

999 MISCELLANEOUS WASHING DEFECTS

Includes other washing defects that are not captured by previous wash defect codes. Any defect that affect accuracy of washing should be considered defective.

Updated: January, 2010.

102

www.apparelco.com

PRODUCT SAFETY OVERVIEW

Product safety is basic requirement for some customers of Matrix. Special attention is given to Kids category because any small part, Draw card, snaps etc may affect the child during use and it may cause minor / serious injury or it may cause death. To manufacture garment and implement product safety measures customer product safety protocol is followed. Matrix Sourcing and vendor works together to make sure product safety requirements are met. Matrix PS analyst ensures that following basic product safety elements are met as per buyers requirement;

x x x x x x x x

Drawcord Metal Detection Metal contamination prevention Sharp points Small parts Torque and tension Flammability Neck stretch

DRAWCORD

Drawstrings, functional cords and decorative cords are considered as an important element of product safety. Some customers prefer not to use drawstrings on infants and toddler product or may have exposed drawcord length requirements for different product categories. Matrix PS analyst is involved in development process and he must assure that cords are exactly used and applied as per customer safety protocol.

METAL DETECTION

Some customers and destinations (Japan) have requirement of passing products or items through metal detector machines. Matrix has worked with its vendors to develop metal detection procedures as per customers requirements. PS analyst ensures that the MD premises are designed and maintained as per customer standards. Normally customers require conveyer detector and hand held metal detector as MD equipment. The MD equipment must be calibrated before use and is also calibrated by third party after a specific time period given by customer. Monthly PS audits are conducted at vendor premises to check compliance with procedures. Metal detection reports are maintained as per procedures outlined by customers.

Updated: January, 2010

103

www.apparelco.com

METAL CONTAMINATION PREVENTION

Metal contamination prevention is a system of control for preventing any metal contamination in a product. This procedure applies to all areas of production environment including sample rooms. PS Analyst closely monitors MCP process at factory and conduct monthly system audit to assure that all MCP requirements are met. Suppliers may have additional procedures and controls to accompany the requirements of this procedure. Some important requirements are as under;

x x x x

Embroidery, sewing, hand sewing and tag gun needles should be controlled. All broken needle fragments should be located. Follow needle replacement procedure set by buyer. Control metallic tools and components e.g. nails, scissors, clippers, machine parts etc. Record of metallic tools and needles should be maintained as per customer requirement.

SHARP POINTS

Sharp points on product may result in injury or discomfort to user. Sharp points are not acceptable by some customers and must be eliminated. Matrix PS analyst identifies small parts during garment engineering process and ensures testing and elimination of sharp points as per customer product safety protocol.

SMALL PARTS

Any small part that can detach from garment contains risk of choking or suffocation if swallowed by a child. Matrix PS analyst is responsible to identify and test small parts as per customer product safety protocol.

Updated: January, 2010.

104

www.apparelco.com

TORQUE AND TENSION

Some customers have established requirements for Torque (twist) and Tension (pull) testing to ensure that components sustain desired force (twist or pull) during its use. Customers safety protocol must be consulted for test criteria and equipment. PS analyst identifies components to be tested during product development / engineering process.

FLAMMABILITY