Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Lab 2

Caricato da

Damandeep SinghDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Lab 2

Caricato da

Damandeep SinghCopyright:

Formati disponibili

ENGI 10679

Lab #2 Cold Working & Annealing OBJECT: To evaluate the effect of cold working on the mechanical properties of steel. Bicycle Spoke UTS Tensile Tester Electric Furnace

EQUIPMENT:

THEORY:

During manufacturing the spoke is subjected to cold working, which tends to increase the tensile strength of the material. Annealing restores the material to its original properties. 1) Remove the bent end of the spoke and cut the spoke into two equal pieces. 2) Measure the diameter (required for the area calculation). 3) Take one piece and place it into the furnace at 950o C for 30 minutes, and then remove and place it on a ceramic tile to cool. 4) Turn on the United machine and the controller Run Datum program Load Sample #1 To jog the jaws > on main screen click operate > click jog The jog buttons on the machine are now ready to operate Jog machine up and down as needed to load the part properly Install Extensometer onto sample Zero force and extension > Operate >click Pos=0, Force=0 Create a new test sample > click new Under the templates tab select > Imperial or Metric Tensile Properties of round bars > Click Apply Under the Sample Info tab > Customer name "group x" > spec ID > name of sample cold worked or normalized > diameter of sample > Click apply > Click Test

METHOD:

Page 1 of 2

Lab #2

ENGI 10679

When the test is finished remove the sample then > click Okay Under the Reports tab select > most numerically recent report Under the Analysis tab ensure break point of material is at the end of the sample Return to Reports tab click > Reports button Microsoft Access will pop up select > most numerically recent test > click graph In the graph window click > Reports > print report 5) Perform a tensile test on both samples and print individual graphs of each for comparison. Be sure to keep track of which graph is for each sample.

CONCLUSION:

For both samples calculate: UTS (Ultimate Tensile Strength) = Maximum Load/Area Yield strength = Load at Yield/Area % Elongation = Extension(inches)/2(inch)gauge length X 100 Compare the results of your calculations for each material. What effect did cold work have on the material? Why would brazing be preferred to welding when joining two pieces of cold worked material?

NOTE:

For non-ductile materials, there will not be a dip at the yield point (Reference: Figure 3.5a on page 45 of the textbook). In the case of non-ductile materials, we use the 0.2% offset method to find the yield point. If you are using English units, the straight line which goes from the origin to the elastic limit is offset by 0.2% (0.002). The point where this offset line crosses the stress/strain graph is the Yield Point. (Reference: Figure 3.5b on page 45 and Yield Point on page 47).

Page 2 of 2

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Learn Thermal Analysis With Altair OptiStruct EbookDocumento120 pagineLearn Thermal Analysis With Altair OptiStruct EbookThapeloNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- C1499Documento10 pagineC1499Aleksei AvilaNessuna valutazione finora

- Design of Tension Circular Flange Joints in Tubular StructuresDocumento9 pagineDesign of Tension Circular Flange Joints in Tubular StructuresAnonymous tmRaHhNessuna valutazione finora

- Spaser Based On Fano Resonance in A Rod and Concentric Square Ring-Disk Nanostructure PDFDocumento4 pagineSpaser Based On Fano Resonance in A Rod and Concentric Square Ring-Disk Nanostructure PDFEngr NasrullahNessuna valutazione finora

- Free Downloads FileDocumento5 pagineFree Downloads FileJoJa JoJaNessuna valutazione finora

- Adsorption Technology in Water TreatmentDocumento6 pagineAdsorption Technology in Water Treatmenttgg666100% (1)

- Bimetallic Metal-Organic Frameworks and Their DeriDocumento35 pagineBimetallic Metal-Organic Frameworks and Their DeriHarshithNessuna valutazione finora

- WFC Gap AnalysisDocumento2 pagineWFC Gap AnalysisDilodilaver DilaverNessuna valutazione finora

- WiresDocumento140 pagineWiresRushabh ShahNessuna valutazione finora

- States of Matter PDFDocumento18 pagineStates of Matter PDFArnav AmbreNessuna valutazione finora

- Coupled Twotheta/ThetaDocumento5 pagineCoupled Twotheta/ThetaArya Bima PutraNessuna valutazione finora

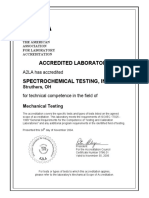

- Accredited Laboratory: A2LA Has AccreditedDocumento2 pagineAccredited Laboratory: A2LA Has AccreditedRene Alfonso BeltranNessuna valutazione finora

- Albodur 1055 HandoutDocumento1 paginaAlbodur 1055 HandoutВиктор ИсакNessuna valutazione finora

- Principal PlaneDocumento7 paginePrincipal Planesudharsanan c sNessuna valutazione finora

- Civalek 2021Documento17 pagineCivalek 2021Mehrshad GhasemabadiNessuna valutazione finora

- 4.stress Paths CSSM WEEK 4 5Documento29 pagine4.stress Paths CSSM WEEK 4 5ADNessuna valutazione finora

- Sulzer PLA TechnologyDocumento4 pagineSulzer PLA TechnologyHH KevinNessuna valutazione finora

- Mtech ThesisDocumento85 pagineMtech ThesisSuman BasakNessuna valutazione finora

- Double Layer Super CapacitorDocumento10 pagineDouble Layer Super CapacitorAlaa AhmedNessuna valutazione finora

- SP 6-2 (1962) - ISI Handbook For Structural Engineers - Part - 2 Steal Beams and Plate GirdersDocumento194 pagineSP 6-2 (1962) - ISI Handbook For Structural Engineers - Part - 2 Steal Beams and Plate GirdersKarthikKavuriNessuna valutazione finora

- Plugin CoursesDocumento3 paginePlugin CoursestiashbdNessuna valutazione finora

- AMPCO 18 SandDocumento1 paginaAMPCO 18 SandS BHATTACHARYYANessuna valutazione finora

- Coupler Tensile Strength TestDocumento1 paginaCoupler Tensile Strength TestShahril ZainulNessuna valutazione finora

- Material Science Solid Solutions: Chapter II - Phase DiagramsDocumento24 pagineMaterial Science Solid Solutions: Chapter II - Phase DiagramsPrakash KatdareNessuna valutazione finora

- Refrigeration Problem 1-2 SolvedDocumento4 pagineRefrigeration Problem 1-2 SolvedNorma FrancoNessuna valutazione finora

- Chapter 12Documento5 pagineChapter 12ramcharanneeli4Nessuna valutazione finora

- Bolted JointsDocumento20 pagineBolted JointsNurcahyo Djati WNessuna valutazione finora

- Machine Design Tutorials - Week 9Documento41 pagineMachine Design Tutorials - Week 9Yunsu LeeNessuna valutazione finora

- ISRM Rock Engineering Practice & Design Lecture 3 RMC and Emp Design E EberhardtDocumento0 pagineISRM Rock Engineering Practice & Design Lecture 3 RMC and Emp Design E EberhardtJohan Van Staveren100% (1)