Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Tool Rack 1

Caricato da

David KammerDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Tool Rack 1

Caricato da

David KammerCopyright:

Formati disponibili

i

c a n

d o

t h a t

by christopher schwarz

Tool Rack

Swiped from a French engraving, this rack works in the shop or even in your kitchen.

ts good to keep your tools protected (think: tool chest). But its also good to keep them handy (think: at arms reach). My favorite way to accomplish both goals is a stout tool rack. Ive made many tool racks since I became a woodworker, most of them crude affairs that were cobbled together in a few minutes. Ive always wanted a rack that both looks good and is easy to build. Then, while browsing a French book on vintage handplanes, I saw it. In a 19th-century engraving of a French workshop, the back wall was covered with a rack very much like this one. Finding it and drawing it to scale were the hard parts. Building it took just a few hours.

Hang one. A quick afternoon and a few boards are all that is needed to build this handy tool rack with a shelf above.

ing (available for free on our web site) to create a full-size paper template. I stuck the paper to one of the end pieces using 3M spray adhesive. Then I cut the ogee shape using a jigsaw and cleaned up my curves with a rasp and sandpaper. Then I used the finished end piece as a pattern to make the second end.

take a close look at the tools you are going to store on your rack before you imitate me. Use my drawing (or your own modified drawing) to mark a line where this front piece will join the ends. Clamp the front piece in position and screw

You Know the Drill The project is assembled using pocket screws, dimensional pine and some Shaker pegs I found at our home center (will wonders never cease?). You are going to need at least 12' of 1x12 and 4' of 1x4 pine to build this rack. Once you have the wood in hand, the first step is to cut all the parts to length. Then rip the back and top pieces to width. Use a circular saw with an edge guide to make the rips, or use a jigsaw to make the rips then remove the saw blade marks with your block plane. Next work on the ends with their ogee shape. I used the SketchUp draw26

Everything is in Pocket All the joinery for this rack is screws. Bore three pocket holes on each end of the 1x4, which is the front of the tool rack. Then drill five pocket holes on each end of the back piece of the rack. You are just about ready to assemble the bulk of the rack, but first clean off all the tool marks using a block plane or sandpaper. You have to assemble the racks parts in a certain way for everything to go together. The first job is to screw the front 1x4 to the end pieces. The position of this part is critical because it will determine how much of a gap you will have between the front and the back of your rack. And this gap is what holds your tools. After much experimentation, I have found that a 1 2" gap is ideal for handling about 99 percent of my tools. However, you should

Screw this. The entire project is assembled with pocket screws. Here Im boring five pocket holes on one end of the back piece.

popular woodworking magazine April 2011

LEAD PHOTO BY AL PARRISH; STEP PHOTOS BY THE AUTHOR; ILLUSTRATIONS BY ROBERT W. LANG

it down. Screw the other end in place using the same procedure. Now you can screw the back piece in place. You should be able to squeeze it between the two ends, tap it gently in place, then screw it tightly to the ends. Now you can turn your attention to the top piece. I cut a 1 4" x 1 4" chamfer on the underside of the top using a block plane. This is easy to do freehand just use your combination square to lay out the pencil lines for the chamfer and plane the corner down to them. A little irregularity is OK. The top of the rack is screwed to the ends. Its not done with pocket holes just six simple countersunk No. 8 x 11 4" wood screws.

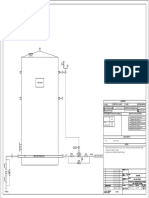

501 2"

11 2"

53 4" 23" 21 4"

46" 10" 9" 33 8"

1 2"

ELEVATION

3 4"

Ive Got You Pegged The Shaker pegs on the front of the rack give you more places to hang your tools. The seven pegs are spaced every 53 4" across the front of the rack. The center of each hole is 21 4" down from the top edge of the front of the rack. The pegs I bought needed 1 2"-diameter and 1 2"-deep holes. Drill the holes, dab in some glue and knock them home. I had an extra peg left over from the package from the home center and put it on one of the ends to hold my shop apron (our photographer hung a backsaw on it for the photo at left). Finishing & Hanging My first instinct was to paint this rack, but the pine I found was clear enough to use without paint. So the finish for this rack is the same I use for all my shop furniture. I thin down satin spar varnish with paint thinner at 3:1. I wipe on three

Tool Rack

No. item dimeNsioNs (iNches) t W l material

r=8" r=16" 33 4" 101 4" 57 8"

1 2" 1 2"

233 4"

2 1 1 1

Ends Back Front Top

3 4 3 4

9 23 1014 46 34 334 46 3 4 10 5012

Pine Pine Pine Pine

u Go Online for more

For links to all these online extras, go to: u popularwoodworking.com/apr11

video: Watch a free video tour of the

3"

PROFILE

authors shop at home. plan: Download the free SketchUp plan for this tool rack.

articles: All the "I Can Do That" articles

coats, sanding between each coat with a #320-grit sanding sponge. Hanging the rack is simple. Find the studs in your shop wall. Drive No. 8 x 3" screws through the back of the rack and into your studs. Then purchase two simple L-brackets. Screw them to the underside of the top and into your studs. That should do the trick. Though this rack is intended for the shop, several people who have seen it insist they are going to build one for the kitchen and put their knives in the rack, hang pots on the pegs and put cookbooks on the top shelf. As the French are both expert craftsmen and chefs, this is entirely appropriate. PWM

Chris is the editor of this magazine and doesnt have a drop of French blood in him, despite his love of French benches, tool racks, wine and food.

are free online. Download the complete I Can Do That manual: u popularwoodworking.com/ icandothat Our products are available online at: u ShopWoodworking.com

About This Column

Our I Can Do That column features projects that can be completed by any woodworker with a modest (but decent) kit of tools in less than two days of shop time, and using raw materials that are available at any home center. We offer a free online manual in PDF format that explains all the tools and shows you how to perform the basic operations in a step-by-step format. Visit ICanDoThatExtras. com to download the free manual.

Stops sagging. Dont forget the little L-brackets under the top. These prevent the top piece from sagging.

popularwoodworking .com

27

Potrebbero piacerti anche

- Filehost - The Art of Woodworking - Handbook of JoineryDocumento147 pagineFilehost - The Art of Woodworking - Handbook of JoineryAlbinuta1100% (26)

- Making A Wooden MalletDocumento11 pagineMaking A Wooden MalletKoki MostafaNessuna valutazione finora

- A Manual of Carpentry and JoineryDocumento505 pagineA Manual of Carpentry and Joineryfullmoonfarm113100% (2)

- American Woodworker - Giant Shop CabinetDocumento9 pagineAmerican Woodworker - Giant Shop CabinetJosé Narcelio Sampaio Ferreira100% (1)

- Woodcraft Magazine 016 (May - 2007)Documento84 pagineWoodcraft Magazine 016 (May - 2007)Anonymous MwulYRw2L100% (2)

- The Art of Woodworking - Cabinetmaking 1992Documento148 pagineThe Art of Woodworking - Cabinetmaking 1992ghimpe--100% (13)

- The Woodwright’s Guide: Working Wood with Wedge and EdgeDa EverandThe Woodwright’s Guide: Working Wood with Wedge and EdgeValutazione: 4 su 5 stelle4/5 (6)

- Japanese Shoji Cabinet Inspired BookcaseDocumento17 pagineJapanese Shoji Cabinet Inspired BookcaseRicardo Salcido67% (15)

- Popular Woodworking - Essential Guide To Routers PDFDocumento95 paginePopular Woodworking - Essential Guide To Routers PDFkeatz100% (4)

- Complete Table Saw Book, Revised Edition: Step-by-Step Illustrated Guide to Essential Table Saw Skills, Techniques, Tools and TipsDa EverandComplete Table Saw Book, Revised Edition: Step-by-Step Illustrated Guide to Essential Table Saw Skills, Techniques, Tools and TipsValutazione: 3.5 su 5 stelle3.5/5 (2)

- Woodworking Plans - Stylish CredenzaDocumento6 pagineWoodworking Plans - Stylish CredenzaBob Kowalski100% (2)

- Traditional Wooden Handplanes: How to Restore, Modify & Use Antique PlanesDa EverandTraditional Wooden Handplanes: How to Restore, Modify & Use Antique PlanesValutazione: 5 su 5 stelle5/5 (1)

- Building A Traditional Workbench - Frank Klausz - Woodworkers JounalDocumento13 pagineBuilding A Traditional Workbench - Frank Klausz - Woodworkers Jounallehigh1979100% (5)

- Handwork Issue3Documento92 pagineHandwork Issue3Joel Turner67% (3)

- Make Woodwork Tools PDFDocumento0 pagineMake Woodwork Tools PDFstolar2007100% (3)

- Furniture and Cabinet-Making - With Instructions and Illustrations on Constructing Household Furniture, Including Various Cabinet Designs for Different Uses - The Handyman's Book of WoodworkingDa EverandFurniture and Cabinet-Making - With Instructions and Illustrations on Constructing Household Furniture, Including Various Cabinet Designs for Different Uses - The Handyman's Book of WoodworkingValutazione: 5 su 5 stelle5/5 (2)

- Intermediate Guide to Japanese Joinery: The Secret to Making Complex Japanese Joints and Furniture Using Affordable ToolsDa EverandIntermediate Guide to Japanese Joinery: The Secret to Making Complex Japanese Joints and Furniture Using Affordable ToolsNessuna valutazione finora

- The Shel L Game: Ti Ps For Ca Rvi NG A Classic Newpo RT Shel LDocumento4 pagineThe Shel L Game: Ti Ps For Ca Rvi NG A Classic Newpo RT Shel LTAANGTAWAN007Nessuna valutazione finora

- Woodworking For Am 00 Gri FialaDocumento136 pagineWoodworking For Am 00 Gri FialaIvan BaićNessuna valutazione finora

- The Handplane Book - G. Hack - Taunton Press - 1999Documento273 pagineThe Handplane Book - G. Hack - Taunton Press - 1999M8ow6f100% (7)

- Rob Cosman - The Great Hand Plane Revival SupportDocumento8 pagineRob Cosman - The Great Hand Plane Revival Supportmartyj19631100% (4)

- Roy Underhill's The Woodwright's Shop Classic Collection, Omnibus E-book: Includes The Woodwright's Shop, The Woodwright's Companion, and The Woodwright's WorkbookDa EverandRoy Underhill's The Woodwright's Shop Classic Collection, Omnibus E-book: Includes The Woodwright's Shop, The Woodwright's Companion, and The Woodwright's WorkbookValutazione: 4 su 5 stelle4/5 (1)

- Build a wooden hand plane in under 2 hoursDocumento10 pagineBuild a wooden hand plane in under 2 hoursFred171717100% (1)

- (Art of Woodworking 16) Time-Life Books-Classic American Furniture - Time Life Education (1995)Documento148 pagine(Art of Woodworking 16) Time-Life Books-Classic American Furniture - Time Life Education (1995)cosmelli100% (2)

- Basic Marquetry and Beyond: Expert Techniques for Crafting Beautiful Images with Veneer and InlayDa EverandBasic Marquetry and Beyond: Expert Techniques for Crafting Beautiful Images with Veneer and InlayValutazione: 4.5 su 5 stelle4.5/5 (3)

- LEADING SUPPLIER OF LUMBER AND WOOD PRODUCTSDocumento12 pagineLEADING SUPPLIER OF LUMBER AND WOOD PRODUCTSerleosNessuna valutazione finora

- The Wood Turner's Handybook: A Practical Manual for Workers at the Lathe: Embracing Information on the Tools, Appliances and Processes Employed in Wood TurningDa EverandThe Wood Turner's Handybook: A Practical Manual for Workers at the Lathe: Embracing Information on the Tools, Appliances and Processes Employed in Wood TurningNessuna valutazione finora

- End Table: MahoganyDocumento3 pagineEnd Table: Mahoganyrherdez100% (1)

- 1997 Jeep Cherokee Country 4.0Documento11 pagine1997 Jeep Cherokee Country 4.0LuissUlsrNessuna valutazione finora

- The Art of Woodworking Sharpening and Tool CareDocumento147 pagineThe Art of Woodworking Sharpening and Tool Caredemo1967100% (1)

- The Woodwright's Workbook: Further Explorations in Traditional WoodcraftDa EverandThe Woodwright's Workbook: Further Explorations in Traditional WoodcraftValutazione: 4.5 su 5 stelle4.5/5 (4)

- Table Saw BowlDocumento5 pagineTable Saw BowlJustJack38100% (1)

- Woodworker's Guide to Handplanes: How to Choose, Setup and Master the Most Useful Planes for Today's WorkshopDa EverandWoodworker's Guide to Handplanes: How to Choose, Setup and Master the Most Useful Planes for Today's WorkshopValutazione: 5 su 5 stelle5/5 (3)

- Basic Mobile WorkbenchDocumento10 pagineBasic Mobile Workbenchfarcasiun50% (4)

- Essential Cabinetmaking TechniquesDocumento19 pagineEssential Cabinetmaking TechniquesJeroen Matthee Jay100% (1)

- Book Case (Mission Style)Documento8 pagineBook Case (Mission Style)khunchaiyai100% (3)

- Woodwork Joints How they are Set Out, How Made and Where Used.Da EverandWoodwork Joints How they are Set Out, How Made and Where Used.Valutazione: 5 su 5 stelle5/5 (1)

- Router LiftDocumento27 pagineRouter Liftmrivero1983100% (2)

- The Essential Handsaw Book: Projects & Techniques for Mastering a Timeless Hand ToolDa EverandThe Essential Handsaw Book: Projects & Techniques for Mastering a Timeless Hand ToolNessuna valutazione finora

- Leg Tapering Jig: Project 14585EZDocumento5 pagineLeg Tapering Jig: Project 14585EZBSulliNessuna valutazione finora

- Technique Series #6 - Rob Cosman - Hand-Cut Dovetails Shop PDFDocumento88 pagineTechnique Series #6 - Rob Cosman - Hand-Cut Dovetails Shop PDFsesostrisserbius100% (3)

- PWW 233 Derevyannoe KruzhevoDocumento68 paginePWW 233 Derevyannoe KruzhevoSergio Larraguibel100% (2)

- American Woodworker - 123 (September 2006)Documento65 pagineAmerican Woodworker - 123 (September 2006)Emilian Baluta100% (3)

- The Complete Guide to Woodworking and 40 ProjectsDocumento440 pagineThe Complete Guide to Woodworking and 40 ProjectsLuis Raul Diaz Aviña100% (2)

- Kitchen Projects for the Woodworker: Plans and Instructions for Over 65 Useful Kitchen ItemsDa EverandKitchen Projects for the Woodworker: Plans and Instructions for Over 65 Useful Kitchen ItemsValutazione: 4 su 5 stelle4/5 (2)

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersDa EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersValutazione: 3.5 su 5 stelle3.5/5 (2)

- SpokeshaveDocumento6 pagineSpokeshavestuckinthestudioNessuna valutazione finora

- A Little Book of Vintage Designs and Instructions for Making Dainty Gifts from Wood. Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box: Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box.Da EverandA Little Book of Vintage Designs and Instructions for Making Dainty Gifts from Wood. Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box: Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box.Nessuna valutazione finora

- Woodwork JointsDocumento5 pagineWoodwork JointsAbdul Sukur Kamsir100% (3)

- More of Roy Underhill’s The Woodwright’s Shop Classic Collection, Omnibus Ebook: Includes The Woodwright's Apprentice, The Woodwright's Eclectic Workshop, and The Woodwright's GuideDa EverandMore of Roy Underhill’s The Woodwright’s Shop Classic Collection, Omnibus Ebook: Includes The Woodwright's Apprentice, The Woodwright's Eclectic Workshop, and The Woodwright's GuideNessuna valutazione finora

- Pre-Commissioning Formats for TransformerDocumento19 paginePre-Commissioning Formats for TransformerBalaji DevathaNessuna valutazione finora

- Discovering Japanese Handplanes: Why This Traditional Tool Belongs in Your Modern WorkshopDa EverandDiscovering Japanese Handplanes: Why This Traditional Tool Belongs in Your Modern WorkshopValutazione: 5 su 5 stelle5/5 (2)

- Many Forms of - KANNA - Japan Woodworking and Blade Tools DescriptionDocumento23 pagineMany Forms of - KANNA - Japan Woodworking and Blade Tools DescriptionMiralia BenciuNessuna valutazione finora

- M.V Arabian Sea Electrical Repairs For Lay Up 2017: RS No. Work Specification QTY RemarksDocumento3 pagineM.V Arabian Sea Electrical Repairs For Lay Up 2017: RS No. Work Specification QTY RemarksMariyath Muraleedharan KiranNessuna valutazione finora

- Wire Gauge and Current Limits PDFDocumento3 pagineWire Gauge and Current Limits PDFShahbazNessuna valutazione finora

- LOADALL - 533-105: Static DimensionsDocumento4 pagineLOADALL - 533-105: Static DimensionsCesar QuintanillaNessuna valutazione finora

- Pneumatic Actuator CatalogueDocumento12 paginePneumatic Actuator Cataloguekumar.arunk6784Nessuna valutazione finora

- 1 212bft Test JusteringDocumento85 pagine1 212bft Test JusteringUputstva Za TraktoreNessuna valutazione finora

- Techn Data Sheet Port ElevatorDocumento1 paginaTechn Data Sheet Port ElevatorFikret DavudovNessuna valutazione finora

- TM1115 - STM32F103ZE - Chapter 6 (I2C - LCD)Documento23 pagineTM1115 - STM32F103ZE - Chapter 6 (I2C - LCD)Safwat KhairNessuna valutazione finora

- Steiner Belt Chart for Agricultural EquipmentDocumento2 pagineSteiner Belt Chart for Agricultural EquipmentVM Elliott IINessuna valutazione finora

- Broadcom Bcm2046 BluetoothDocumento2 pagineBroadcom Bcm2046 BluetoothMishaCveleNessuna valutazione finora

- Tensor-GO Battery Column Array v1.2Documento2 pagineTensor-GO Battery Column Array v1.2RaulNessuna valutazione finora

- ELEC 344 - Module 2 Lecture NotesDocumento45 pagineELEC 344 - Module 2 Lecture NotesMax HornerNessuna valutazione finora

- BP Hardware 2016Documento228 pagineBP Hardware 2016Artemis ChristofiloggianisNessuna valutazione finora

- LM2480NADocumento5 pagineLM2480NAFranklin JimenezNessuna valutazione finora

- Catalog PLC GuideDocumento38 pagineCatalog PLC GuideOsama MohammedNessuna valutazione finora

- Ra605 Software User ManualDocumento141 pagineRa605 Software User ManualRAPHAEL PACIULLO RAMALHONessuna valutazione finora

- Combining Two HackRF SDR To See More - Oleg Kutkov Personal BlogDocumento7 pagineCombining Two HackRF SDR To See More - Oleg Kutkov Personal BlogEkaterina HoffmannNessuna valutazione finora

- 2021 Multi Split Catalogue Final MayDocumento24 pagine2021 Multi Split Catalogue Final MayMinh Phát Điều HoàNessuna valutazione finora

- HLX PlusDocumento44 pagineHLX PlusAmantino Ricker de FreitasNessuna valutazione finora

- Manual de Check Point PumpsDocumento14 pagineManual de Check Point PumpsEdwin060990Nessuna valutazione finora

- Industrial MechanicsDocumento9 pagineIndustrial MechanicsLucas veasNessuna valutazione finora

- Vortex Wireless User Guide v1.1Documento52 pagineVortex Wireless User Guide v1.1RamitNessuna valutazione finora

- GTU Bachelor of Engineering Industrial Electrical SystemsDocumento2 pagineGTU Bachelor of Engineering Industrial Electrical SystemsDarshit KotadiyaNessuna valutazione finora

- BelimoDocumento4 pagineBelimoAnjana2893Nessuna valutazione finora

- 3000 Series Indicators Instruction Manual: T32ME IndicatorDocumento48 pagine3000 Series Indicators Instruction Manual: T32ME IndicatorGerardo EspinozaNessuna valutazione finora

- 227 - COMM - Manual - Eng - Mitsubishi MELSEC SeriesDocumento29 pagine227 - COMM - Manual - Eng - Mitsubishi MELSEC SeriesPhuocauto CncNessuna valutazione finora

- Summary of SPLN D3.009-1:2010: 1 Phase Prepayment Active Energy Meter - Standard Transfer SpecificationDocumento7 pagineSummary of SPLN D3.009-1:2010: 1 Phase Prepayment Active Energy Meter - Standard Transfer SpecificationabbotNessuna valutazione finora

- Hfo Heating System P&idDocumento1 paginaHfo Heating System P&idAbdur RehmanNessuna valutazione finora

- Electrical & Instrumentation Punch List S.No DescriptionDocumento6 pagineElectrical & Instrumentation Punch List S.No DescriptionNisar AhmedNessuna valutazione finora