Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Training Ver7.1 Calculate Flange - General Example

Caricato da

vantayusdDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Training Ver7.1 Calculate Flange - General Example

Caricato da

vantayusdCopyright:

Formati disponibili

Training: Calculate Flange (General Example)

Calculate Flange (General Example)

Description

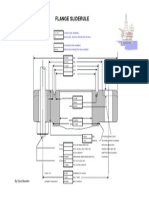

The following describes the calculation method for in situ flange survey. Also see AutoFix Site Survey for Flange Capture. Laser Flange Capture and Calculate Flange (Bolt Minimum Distance Example) For a successful flange survey the following must be determined: Flange type rating and size.

Flange work point position within a known co-ordinate system.

Copyright Mike Lloyd Technical Services Ltd. 1998~2008 Page 1

Updated 07/04/08

Training: Calculate Flange (General Example) Flange orientation based on a consistent frame of reference (see Bolt Hole Orientation Standard for a full description of flange orientation)

Flange centre-line direction (Horizontal)

Copyright Mike Lloyd Technical Services Ltd. 1998~2008 Page 2

Updated 07/04/08

Training: Calculate Flange (General Example) Flange centre-line direction (Vertical)

Flange Pitch Circle Diameter (PCD) and number of bolts.

Copyright Mike Lloyd Technical Services Ltd. 1998~2008 Page 3

Updated 07/04/08

Training: Calculate Flange (General Example) Flange Outside Diameter (OD) and flange Thickness.

For a full flange position and identity ten pieces of information are required. Easting(X), Northing(Y), Height(Z) of work point. Azimuth(Horizontal), Zenith (Vertical) direction of flange centre-line. Bolt-hole orientation and number of bolt-holes. Flange Pitch Circle Diameter, Outside Diameter and Thickness. Flange face type.

Copyright Mike Lloyd Technical Services Ltd. 1998~2008 Page 4

Updated 07/04/08

Training: Calculate Flange (General Example)

Survey of a single flange using the contact method

This survey is of one flange, named flange 4. The points prefixed with DAT will be used to orientate the survey results to a plane and the given north.

The design file for this survey must be None Pipe Spool Type, and contain a flange number 4. The initial design flange identity should be the surveyors best guess, but the number of bolts must be the same.

Copyright Mike Lloyd Technical Services Ltd. 1998~2008 Page 5

Updated 07/04/08

Training: Calculate Flange (General Example)

Copyright Mike Lloyd Technical Services Ltd. 1998~2008 Page 6

Updated 07/04/08

Training: Calculate Flange (General Example) Options for size of prism ball used with type4 device.

Note for this example the smaller ball was used. The large prism ball is preferred as this gives a better rotation of the prism face. To start the calculation process press Calculate Button.

Copyright Mike Lloyd Technical Services Ltd. 1998~2008 Page 7

Updated 07/04/08

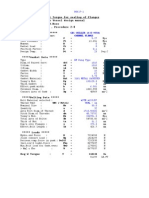

Training: Calculate Flange (General Example)

After pressing the calculate button once the above results will be shown. Several options and considerations can now be made. Do not be too hasty in deciding to drop any individual observation. If there is an obvious error then check the box to remove from the calculation process. When continue 04 button is pressed and no changes have been made then the results screen with be displayed. Otherwise a recalculated set of values will be shown. If further changes are made then the new recalculated results will be shown. When no changes are made and the continue button is pressed then the next flange or the result screen will be displayed.

Copyright Mike Lloyd Technical Services Ltd. 1998~2008 Page 8

Updated 07/04/08

Training: Calculate Flange (General Example)

Then press Continue 04.

Copyright Mike Lloyd Technical Services Ltd. 1998~2008 Page 9

Updated 07/04/08

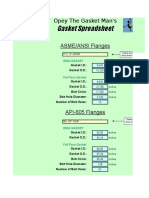

Training: Calculate Flange (General Example) Results screen is displayed. The values at this stage have very little meaning. To complete the survey process we must orientate the file.

To orientate this file use the Auto Orientate routine.

Copyright Mike Lloyd Technical Services Ltd. 1998~2008 Page 10

Updated 07/04/08

Training: Calculate Flange (General Example)

Copyright Mike Lloyd Technical Services Ltd. 1998~2008 Page 11

Updated 07/04/08

Training: Calculate Flange (General Example) Final Results

The only element that cannot be found using this survey system is the type of flange face. This must be determined correctly, usually by a query to the relevant engineer.

Copyright Mike Lloyd Technical Services Ltd. 1998~2008 Page 12

Updated 07/04/08

Potrebbero piacerti anche

- Ms 192 Service ManualDocumento98 pagineMs 192 Service ManualJOSEALBERICH67% (3)

- PT6C-67C MM Chap 4-5Documento39 paginePT6C-67C MM Chap 4-5anony810388% (8)

- Bolt Torque ASME B16.5 Flanges - Sheet Gaskets 02Documento26 pagineBolt Torque ASME B16.5 Flanges - Sheet Gaskets 02bakelly100% (7)

- 10P87-D0003-046-R0-WHRU by TEPLDocumento23 pagine10P87-D0003-046-R0-WHRU by TEPLjigarNessuna valutazione finora

- 015 DH 1003 Rectangular TanksDocumento12 pagine015 DH 1003 Rectangular TanksAndrew PopeNessuna valutazione finora

- Loads On FlangesDocumento16 pagineLoads On Flangesccoollest100% (3)

- Sample 8D ReportDocumento2 pagineSample 8D ReportLndIngenieriaNessuna valutazione finora

- Boundary Layer Thickness and Heat Transfer CalculationsDocumento9 pagineBoundary Layer Thickness and Heat Transfer Calculationsannie100% (1)

- AB 520 Finite Element Analysis FEA Requirements PDFDocumento4 pagineAB 520 Finite Element Analysis FEA Requirements PDFbello imamNessuna valutazione finora

- Bolt Torq. (Moss+Farr)Documento9 pagineBolt Torq. (Moss+Farr)Bahtiar Anak LaNang100% (1)

- Mean Metal Temperature For Fixed Heat Exchanger - Intergraph CADWorx & AnalysisDocumento3 pagineMean Metal Temperature For Fixed Heat Exchanger - Intergraph CADWorx & Analysisisrar khanNessuna valutazione finora

- Bolt Torque Calculation For FlangeDocumento1 paginaBolt Torque Calculation For Flangevishnudno1Nessuna valutazione finora

- Girth Flange Load Calculation Using by FEA TechniquesDocumento12 pagineGirth Flange Load Calculation Using by FEA TechniqueskingstonNessuna valutazione finora

- FLANGEDocumento1 paginaFLANGEscrbdgharavi50% (2)

- Sec. VIII Div 1 Apen 1Documento16 pagineSec. VIII Div 1 Apen 1ADRIANNessuna valutazione finora

- Pulsating Heat Pipe ReportDocumento65 paginePulsating Heat Pipe ReportIdul Azharul HoqueNessuna valutazione finora

- PV Elite WebinarDocumento24 paginePV Elite WebinarAndrea Hank LattanzioNessuna valutazione finora

- Pressure Vessel FormulaDocumento9 paginePressure Vessel FormulaNasir Khan JadoonNessuna valutazione finora

- ASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound GasketsDocumento5 pagineASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound Gasketserik aranaNessuna valutazione finora

- Checking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumberDocumento1 paginaChecking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumbershazanNessuna valutazione finora

- Trunnion Calculation SheetDocumento2 pagineTrunnion Calculation Sheetnirga100% (1)

- EJMA Calculation Report For Cryostat DNB 7HL9UC v1 3Documento25 pagineEJMA Calculation Report For Cryostat DNB 7HL9UC v1 3zstNessuna valutazione finora

- Pipe Expansion & FlexibilityDocumento92 paginePipe Expansion & Flexibilityfileseeker100% (1)

- Compress EvaluateDocumento23 pagineCompress EvaluateVishalDhiman100% (1)

- Allowable Nozzle Loading for Carbon Steel and Stainless Steel PipesDocumento1 paginaAllowable Nozzle Loading for Carbon Steel and Stainless Steel PipesoberaiNessuna valutazione finora

- FEA Check List For Expansion BellowDocumento3 pagineFEA Check List For Expansion BellowRyan FisherNessuna valutazione finora

- Pressure & Temperature ClassificationDocumento1 paginaPressure & Temperature Classificationkeo85100% (1)

- CNC Lathe Fanuc Tamil Acme Thread ChartDocumento16 pagineCNC Lathe Fanuc Tamil Acme Thread ChartDhanraj VasanthNessuna valutazione finora

- Gasket Dimension (ASME B16.5 & B16.47)Documento4 pagineGasket Dimension (ASME B16.5 & B16.47)amaNessuna valutazione finora

- Design by AnalysisDocumento22 pagineDesign by AnalysisJEELE77Nessuna valutazione finora

- PADT ANSYS Fastener Simulation Part1Documento22 paginePADT ANSYS Fastener Simulation Part1isma_nashNessuna valutazione finora

- Flange Loading CheckDocumento48 pagineFlange Loading CheckrefuzerNessuna valutazione finora

- Blind Flange Design CalculationsDocumento4 pagineBlind Flange Design CalculationsamaNessuna valutazione finora

- Shaft Alignment - Vibration Analysis - OutlineDocumento4 pagineShaft Alignment - Vibration Analysis - OutlineElias RizkNessuna valutazione finora

- Design Calculations For Pressure VesselsDocumento54 pagineDesign Calculations For Pressure VesselsEdgar A. Arredondo QuirozNessuna valutazione finora

- ASCE 7-05 Table 15-4-2Documento1 paginaASCE 7-05 Table 15-4-2barouniamineNessuna valutazione finora

- Manufacturing Data ReportDocumento14 pagineManufacturing Data Reportfuransu777Nessuna valutazione finora

- Design Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeDocumento8 pagineDesign Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeAndres Rodriguez HerreraNessuna valutazione finora

- Saddle 1Documento3 pagineSaddle 1RUDHRA DHANASEKARNessuna valutazione finora

- Body Flange Bolt TorqueDocumento1 paginaBody Flange Bolt TorqueLcm Tnl100% (1)

- Pipe SupportDocumento8 paginePipe SupportVignesh GandhirajNessuna valutazione finora

- Welding SymbolsDocumento12 pagineWelding SymbolsrsrtnjNessuna valutazione finora

- TBE-Pressure Vessel Standard TemplateDocumento4 pagineTBE-Pressure Vessel Standard TemplateSiva baalanNessuna valutazione finora

- PV Elite Transport A Vertical Vessel in The Horizontal Position PDFDocumento3 paginePV Elite Transport A Vertical Vessel in The Horizontal Position PDFnodyyy100% (1)

- Bolt TorqueDocumento3 pagineBolt TorqueHeri KurniawanNessuna valutazione finora

- PV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Documento32 paginePV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Priyo Jati WahyonoNessuna valutazione finora

- Pipe Load CalculationDocumento6 paginePipe Load CalculationSuthan SelvarajNessuna valutazione finora

- 2015 FSAE - Design IC Spec Sheet - 2015 - Template - 2015!03!10 VerDocumento10 pagine2015 FSAE - Design IC Spec Sheet - 2015 - Template - 2015!03!10 VerAnirudh25895Nessuna valutazione finora

- 1.9L TDI Timing Belt How ToDocumento120 pagine1.9L TDI Timing Belt How Tonbjmiller100% (1)

- 08 Surface HT Volumic VWeld InstructionsDocumento10 pagine08 Surface HT Volumic VWeld Instructionsjdial9664Nessuna valutazione finora

- Search - Subjects - Titles - Courses - Illustrations - Topics - E-Course BuilderDocumento39 pagineSearch - Subjects - Titles - Courses - Illustrations - Topics - E-Course BuilderNJPACofCCNessuna valutazione finora

- Bearing Failure Query Sheet AnalysisDocumento3 pagineBearing Failure Query Sheet AnalysismahaveenNessuna valutazione finora

- JH Step 1-4: Autonomous Maintenance Training at Birla TyresDocumento13 pagineJH Step 1-4: Autonomous Maintenance Training at Birla Tyresperu1975Nessuna valutazione finora

- Strengthening Stamping Capability Through Continuous ImprovementDocumento56 pagineStrengthening Stamping Capability Through Continuous ImprovementraajmrkNessuna valutazione finora

- Lean Manufacturin and Six SegmaDocumento9 pagineLean Manufacturin and Six Segmashahid_ali21Nessuna valutazione finora

- 07a Scrutineering FSG Workshop Conti Hanover 20141018Documento26 pagine07a Scrutineering FSG Workshop Conti Hanover 20141018mc-andybroeker5182Nessuna valutazione finora

- Tata Motors Case StudyDocumento35 pagineTata Motors Case StudyGokulraju Rangasamy100% (2)

- Apqp FormsDocumento25 pagineApqp FormsgkspNessuna valutazione finora

- Chemical Plants - Stages: Basic DesignDocumento35 pagineChemical Plants - Stages: Basic DesignMauricio AlvaradoNessuna valutazione finora

- OpenPlant Modeler CONNECT Edition Routing Pipelines Metric TRNC03238-10001Documento52 pagineOpenPlant Modeler CONNECT Edition Routing Pipelines Metric TRNC03238-10001ingecon.erwanpsNessuna valutazione finora

- The 3rd Generation: CAT - NO.B1004EDocumento7 pagineThe 3rd Generation: CAT - NO.B1004E3bparticipationsNessuna valutazione finora

- Boundy8e PPT Ch04Documento32 pagineBoundy8e PPT Ch04AndrewNessuna valutazione finora

- D2143 15Documento4 pagineD2143 15vantayusdNessuna valutazione finora

- A311A311M-04 (2015) Standard Specification For Cold-Drawn, Stress-Relieved Carbon Steel Bars Subject To Mechanical Property RequirementsDocumento4 pagineA311A311M-04 (2015) Standard Specification For Cold-Drawn, Stress-Relieved Carbon Steel Bars Subject To Mechanical Property RequirementsvantayusdNessuna valutazione finora

- A 753 PDFDocumento28 pagineA 753 PDFvantayusdNessuna valutazione finora

- Astm B363Documento4 pagineAstm B363vantayusdNessuna valutazione finora

- Viar Lock Inglese High Res PDFDocumento40 pagineViar Lock Inglese High Res PDFvantayusdNessuna valutazione finora

- +trelleborg Elastopipe 2014 BrochureDocumento8 pagine+trelleborg Elastopipe 2014 BrochurevantayusdNessuna valutazione finora

- NORSOK Standard-Compact Flanged ConnectionsDocumento93 pagineNORSOK Standard-Compact Flanged Connectionsകന്നിമേൽ ആശിഷ് നായർNessuna valutazione finora

- A 753 PDFDocumento28 pagineA 753 PDFvantayusdNessuna valutazione finora

- ASTM D2992-06 Standard Practice For Obtaining Hydrostatic Pressure Design Basis For Fiberglass Pipe & Fittings PDFDocumento11 pagineASTM D2992-06 Standard Practice For Obtaining Hydrostatic Pressure Design Basis For Fiberglass Pipe & Fittings PDFChengkc2014100% (1)

- ELASTOPIPE Deluge System: Personal Handbook ForDocumento48 pagineELASTOPIPE Deluge System: Personal Handbook ForvantayusdNessuna valutazione finora

- Norsok L-004-CR Ror OgDocumento29 pagineNorsok L-004-CR Ror OgWissam Jarmak100% (2)

- M CR 601r1Documento14 pagineM CR 601r1nazari123Nessuna valutazione finora

- Engineering Management WorkshopDocumento20 pagineEngineering Management Workshopvantayusd0% (1)

- Axial Flow Check Valve for Non-Slam Non Return API 6D 6A SubseaDocumento1 paginaAxial Flow Check Valve for Non-Slam Non Return API 6D 6A SubseavantayusdNessuna valutazione finora

- M CR 601r1Documento14 pagineM CR 601r1nazari123Nessuna valutazione finora

- Api 602 AjDocumento7 pagineApi 602 AjvantayusdNessuna valutazione finora

- Stainless Steel Bs en EquivalentsDocumento3 pagineStainless Steel Bs en EquivalentsSantiago VayasNessuna valutazione finora

- Material Data Sheets and Element Data Sheets For PipingDocumento133 pagineMaterial Data Sheets and Element Data Sheets For PipingJorge Durão100% (1)

- CAD1 AssignmentDocumento11 pagineCAD1 AssignmentJohn2jNessuna valutazione finora

- FG - BDER-78 Technical Catalogue - Technical - UNDocumento8 pagineFG - BDER-78 Technical Catalogue - Technical - UNAnh Le NgocNessuna valutazione finora

- Pull Test Procedure - Chile Cabildo & Villa Seca 3MW-SkyLineDocumento7 paginePull Test Procedure - Chile Cabildo & Villa Seca 3MW-SkyLinecnuneza4Nessuna valutazione finora

- Sinusverteiler Multivalent SolutionsDocumento13 pagineSinusverteiler Multivalent SolutionsIon ZabetNessuna valutazione finora

- DMD Documentation Error - Freetronics ForumDocumento3 pagineDMD Documentation Error - Freetronics ForumapofviewNessuna valutazione finora

- Java Topics To Cover in InterviewsDocumento5 pagineJava Topics To Cover in InterviewsHemanth KumarNessuna valutazione finora

- Seminar ReportDocumento30 pagineSeminar Reportshashank_gowda_7Nessuna valutazione finora

- 2014-6-2 PCED South Hill Coalition Proposed Elements MatrixDocumento2 pagine2014-6-2 PCED South Hill Coalition Proposed Elements MatrixSpokane City CouncilNessuna valutazione finora

- Power and Simplicity: Pace ScientificDocumento16 paginePower and Simplicity: Pace ScientificAnonymous mNQq7ojNessuna valutazione finora

- Technical Publications: Direction 2190775 100Documento21 pagineTechnical Publications: Direction 2190775 100zakaria alhosinyNessuna valutazione finora

- BS 1400 - 1973Documento38 pagineBS 1400 - 1973Metal dept100% (1)

- Unit-I: Introduction To J2EEDocumento29 pagineUnit-I: Introduction To J2EEsurakshaNessuna valutazione finora

- Ea80 Series PDFDocumento82 pagineEa80 Series PDFAnca MunteanuNessuna valutazione finora

- 01 4G64S4M & 4G69S4N Engine-2Documento38 pagine01 4G64S4M & 4G69S4N Engine-2vitor santosNessuna valutazione finora

- 2014 Solder Joint ReliabilityDocumento18 pagine2014 Solder Joint ReliabilitychoprahariNessuna valutazione finora

- Achievements Under EpiraDocumento6 pagineAchievements Under EpiraLyn Dela Cruz DumoNessuna valutazione finora

- Customize ADFS sign-in page brandingDocumento4 pagineCustomize ADFS sign-in page brandingmicu0% (1)

- Strength of Pressure Vessels With Ellipsoidal HeadsDocumento8 pagineStrength of Pressure Vessels With Ellipsoidal Headsنصرالدين ادريسNessuna valutazione finora

- A Report On Workability of Fresh Concrete by Slump TestDocumento5 pagineA Report On Workability of Fresh Concrete by Slump TestRishabhJain100% (1)

- Devoir 2 Arsalan 2SM BIOFDocumento3 pagineDevoir 2 Arsalan 2SM BIOFphytanjaNessuna valutazione finora

- As ISO 128.23-2005 Technical Drawings - General Principles of Presentation Lines On Construction DrawingsDocumento9 pagineAs ISO 128.23-2005 Technical Drawings - General Principles of Presentation Lines On Construction DrawingsSAI Global - APAC0% (3)

- Amphenol Musician Range PDFDocumento8 pagineAmphenol Musician Range PDFtrc_wmNessuna valutazione finora

- List of Linkages2016Documento74 pagineList of Linkages2016engrwho0% (1)

- Timing Chain Tensioner ResetDocumento4 pagineTiming Chain Tensioner ResetHybrid RacingNessuna valutazione finora

- Loading Equipment For Amsco Evolution™ Steam Sterilizers: ApplicationDocumento4 pagineLoading Equipment For Amsco Evolution™ Steam Sterilizers: ApplicationniNessuna valutazione finora

- Physics Lab ReportDocumento2 paginePhysics Lab ReportFelix SonsunNessuna valutazione finora

- Microsoft Word - Transistor Models and The Feedback Amp - Docmicrosoft Word - Transistor Models and The Feedback Amp - Doctransistor - Models - and - The - FbaDocumento14 pagineMicrosoft Word - Transistor Models and The Feedback Amp - Docmicrosoft Word - Transistor Models and The Feedback Amp - Doctransistor - Models - and - The - FbashubhamformeNessuna valutazione finora