Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Workbench Apdaptive Mesh

Caricato da

ypcadDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Workbench Apdaptive Mesh

Caricato da

ypcadCopyright:

Formati disponibili

FULLY AUTOMATIC ADAPTIVE MESH REFINEMENT INTEGRATED INTO THE SOLUTION PROCESS

Joseph R. Tristano, Zhijan Chen, D. Alfred Hancq, Wa Kwok

ANSYS Incorporated, Canonsburg, PA U.S.A. {joe.tristano,james.chen,al.hancq,wa.kwok } @ansys.com ABSTRACT

Finite element analysts and designers need to feel confident in the results of their analyses before sending a product to prototype or production. Mesh discretization can greatly influence the desired results. In this paper we present framework for adaptive mesh refinement to obtain FEA results with a desired accuracy. The process involves adaptively refining the mesh based on solution error norms until the result desired converges to certain accuracy. The adaptive refinement/meshing process must be fully automatic and very robust. We present an exhaustive method to create a fully automatic and integrated process that takes advantage of many of the mesh refinement and mesh optimization algorithms found in literature. The results of the process provide the user with the desired accuracy in the smallest number of iterations possible. Keywords: h-adaptivity, adaptive mesh refinement, adaptive finite element

1. INTRODUCTION

Finite element analysts and designers need to feel confident in the results of their analyses before sending a product to prototyping or production in order to save their companys time and money. This is is especially true for users who are not experts in FEA. The discretization of the model intended for analysis can greatly influence the outcome of their desired results. In order to feel confident with the desired results we have developed a fully automatic adaptive mesh refinement process that is integrated into the solution process. The mesh is refined based upon error norms and other information output by the solver. In order to make the process reliable and robust, multiple methods for refining the mesh have been implemented. The process also needs to be efficient, i.e., the process needs to mark enough nodes for refinement such that the iterations are not wasted in the solver. The importance of this work lies in the method to integrate the tools and procedures found in literature into a fully embedded automatic and robust adaptive solution process. The remainder of this paper will first discuss the overall framework of the process. We will then discuss the previous work in the area on which the building blocks for the process were built. We will then go into detail of the sub processes within the process such as methodology for selecting nodes and elements for refinement and the refinement process itself. We will finally show some examples and discuss areas for future work. This paper will focus on refinement of tetrahedral meshes. However, the method can easily be extended to other element types.

SOLVER COMPONENT DRIVER COMPONENT

solve

YES

converged or num iterations met

stop

get nodelist to be marked and nodelist to exclude from refinement

REFINE COMPONENT

NO

nodes marked > % of total or PGR key is set

YES

unmark nodes that may cause problems

delete tetrahedron

template refinement

Preprocess surface mesh

SET PGR KEY

refine surface mesh using templates

mesh interior with tetrahedron and refine interior nodes using templates

conventional mesh optimization methods

YES

quality ok

NO

quadratic tetrahedron improvement

NO

quality ok

YES

Figure 1 Overview of Adaptive Solution Process

1.1 Process Overview

The adaptive solution process is an iterative process illustrated Figure 1. It is clearly seen that this adaptive solution process does not lend itself to failure. Various techniques are used to protect the refine process from producing poorly shaped elements. It is imperative that the mesh generated from the refinement process is of adequate quality. The process is as follows. The initial solve takes place. The solver driver then determines which nodes must be refined and which nodes must be excluded from refinement (to prevent refinement of singularities). Depending on the amount of nodes marked, two paths may be taken. The first path is the template based tetrahedron refinement based on Statens work. The second path uses a Pseudo Global Refinement (PGR) method that: deletes the tetrahedron, refines the surface mesh and performs some optimization of the surface mesh, re-meshes with tetrahedron and refines any marked interior nodes using templates. Extensive tetrahedron optimization is performed using conventional methods of B.Joe [1] for each method of refinement. If the conventional optimization methods fail, more specialized quadratic tetrahedron optimization methods are called (Kwok et al. [2]). This process iterates until the solution has converged or the number of adaptive iterations has been met. If either method fails, various styles of the PGR algorithm work to refine the model to create a high quality tetrahedron mesh. The processes communicate via data passed through COM Interfaces. These interfaces allow us to maintain each procedure of the process independently. The interfaces are implemented in several components (DLLs). The solver component solves the FE model. The driver component determines what elements should be refined based on analysis type specific criterion. This component communicates between the solver and mesh refiner and determines when the adaptive loop should stop. This component also charts the progress of adaptivity for the user, which enables the user to track the convergence of the result per refinement iteration along with displaying the number of nodes and elements for each iteration. The mesh refiner asks the driver for a mesh object and the nodes and elements to be refined and excluded from refinement. This component is self-encapsulated and determines whether templates or PGR refinement should be executed. If the quality of the output mesh is not adequate, more refinement and mesh optimization are performed to increase the quality to acceptable levels. This componentization also enables quick prototyping and implementation of new refinement algorithms, solvers, and error estimators.

complex real world geometry and quadratic tetrahedron, this process is never trivial.

1.2.1 Adaptive Refinement

Diaz-Morcillo [7] presented an adaptive mesh refinement process for electromagnetic problems. Since the elements are usually linear and the geometry is usually simple for this class of problems, the framework for the algorithm is allowed to be quite simple: solve, estimate error, refine. Jones [8] also describes a method very similar to Diazs. His work also concentrates more on the refinement algorithms than creating a fail-safe process that can run on real world geometry.

1.2.2 Template Based Refinement

We have chosen to use Statens [6] (Figure 2) template based refinement over existing methods of refinement. This method was chosen over Delaunay[5] refinement because it has shown the ability to maintain overall mesh quality after successive refinements.

Figure 2 Statens Template Based Refinement

2. ADAPTIVE REFINEMENT SUBPROCSESES 2.1 Methodology for Choosing Candidates for Adaptive Refinement

Adaptive H refinement is supported for structural, thermal, and modal analysis. The result quantity , the expected accuracy E (expressed as a percentage), and the region R on the geometry that is being subjected (scoped) to adaptive analysis may be selected. The user-specified accuracy is achieved when convergence is satisfied as follows:

i +1 i < E , i = 1,2,3, K n (in R) 100 1 ( + ) i +1 i 2

(1)

1.2 Previous Work

The literature contains many works regarding error estimates [3],[4] and refinement methods[5],[6], however, the methods used to fully automate and integrate these tools into a robust failsafe algorithm have been trivialized. When dealing with

Elements will be flagged for refinement on some basis measure. The criterion for which elements and nodes are selected for adaptive refinement depends on analysis type and on what results quantities are requested. In addition, depending on analysis type and the requested result type of , nodes may be flagged for refinement to augment the element list. This is done to help ensure that true convergence is achieved on the result .

2.1.1 Element Selection Methodology, Structural and Thermal Analysis

A basis measure must be employed to identify poorly shaped elements that are causing analysis inaccuracies. The procedure to select the elements for refinement, aside from the error calculation itself, is the same for both structural and thermal analysis and will be discussed first. For structural analysis, a displacement based error measure developed by Zienkiewicz-Zhu[3] is used as this basis. Essentially an elemental stress error is calculated from the difference between the average nodal stress and the element nodal stress. This stress error is then integrated over the element volume to calculate an energy error that is then used as the structural error basis. This calculation is performed over the element set and can be seen mathematically by [9]:

i a i { n } = { n } { n }

element error throughout the element set. Although highly dependent on the loading and geometry, typical percentages of elements flagged for refinement range from 5 to 20 percent.

2.1.2 Element Selection Methodology, Modal Analysis

In selecting elements for modal refinement, a different basis mechanism as well as different cutoff technique is employed. The basis function is simply largest element volume. The element set is sorted on that basis and then a cutoff element technique is employed so that a set percentage of the largest elements are flagged for refinement. Typically, 25 percent of the elements will be flagged for refinement but this value is controllable by the user.

where:

i { n } = stress error vectorat node n of elementi

a n

} = averaged stress vectorat node n =

n Ne

2.1.3 Node Augmentation Selection methodology

Although the element selection methods described above perform well in obtaining an accurate global solution, node augmentation based on the result may be required to ensure that a local converged result is achieved. This is applicable to results where local refined meshes are required to achieve an accurate solution. Consider the case where is based on equivalent stress and a stress concentration exists. Consider also that in that region the element error is low enough compared to another region such that the other region in the model is flagged for refinement. Thus, as a result, the change in will be likely small enough to satisfy the requested accuracy E, although true convergence has not been reached. To aid in this, a list of nodes on the region R will be flagged for refinement that have values near and thus ensures that a false convergence will not occur. This is node augmentation is only applicable to certain type of results where this false convergence can occur and includes: Structural stresses and strains Structural post tools based on stress and/or strain Structural contact results Thermal heat fluxes

i =1

i { n }

N en

N en = numberof elementsconnectedto node n

i { n } = stress vectorof node n of elementi

Then for eachelement: 1 ei = { }T [ D]1{ }d (vol) 2 vol where: ei = energy error for elementi vol = elementvolume [ D] = stress strain matrixof the element { } = stress error vector

(2)

A similar calculation for temperature-based problems using elemental heat flux was given by Huang and Lewis[4] and is used a basis for thermal energy error. After all the element errors are collected, a cutoff range technique is employed where the elements with the largest error are flagged for refinement. A critical value is calculated and elements with an error above this value will be flagged for refinement according to the equation:

e crit = e max (e max e min ) where : e crit = minimum element error required t o be flagged for refinement e max = maximum element error in element set e min = minimum element error in element set

(3)

Nodes are selected for refinement based on a cutoff range technique. However, since convergence may be applied to either the minimum or maximum of , and in addition, may be positive or negative, logic is required to handle each permutation. Each node in the set will test the following logic statement and will be flagged for refinement if the statement is true:

Converging on max

= cutoff factor, 1 default of .75 0

As can be seen from the equation above, a cutoff factor of zero would cause only elements with the highest error to be flagged while a factor of one would flag all elements for refinement. At first glance, the default of .75 would seem to allow a disproportionately large number of elements to be flagged but experience has shown this value to be valid. This is due to a typically large gradient in the distribution of

< 0 (n > ) 0 (n > )

Converging on min

< 0 (n < ) 0 (n < )

where :

(4)

= result quantity to be converged upon n = result quantity at node n = cutoff factor, 1 , default of .8 0

Care must be taken when compiling this node list. Artificial singularities may exist in the model due to the applied loads that could cause a divergent refinement series. A list of boundary conditions known to cause these singularities is compiled and any nodes in the region R that exist on these boundaries are excluded as candidates for node augmentation. Note that geometric singularities may exist in model that the program cannot detect and thus care must be taken by the user to ensure that a proper region R is selected for the result quantity where convergence is of interest.

2.2 Refinement Process 2.2.1 Refinement Driver

After the nodes and elements are marked for refinement, the refinement driver loads the refine component. Data, such as the previous mesh, marked and excluded nodes and elements, and the BRep are passed into the refine component via a COM Interface (Figure3). Figure 4 Bending Interior Edges There may be cases where there is not enough room on the interior of the model to bend an interior element edge to create an acceptable quality element (Figure 4). In this case, we determine if the tetrahedron is a poor element that lies on the boundary of the topological body. If this poor element lies on the boundary, a few operations may be performed to either modify the tetrahedron or simply delete it. Some of these operators include: Figure 3 COM Interface for Refinement Component Splitting the longest edge to create better-shaped elements Swapping element edges to create a better configuration Moving interior corner nodes to improve resulting element shapes Deleting the element if it is a kite or cap on the boundary Modifying a mid-side node of the elements on the boundary.

2.2.2 Node Marking and Element Improvement

The mesh is converted into a local data structure and the appropriate nodes are marked. During the node marking leg, the algorithm may determine that some quadratic tetrahedron may invert during the refinement process. At this time a few things may happen: Mid-side nodes on element edges interior to the topological body are perturbed, poor boundary elements may be deleted, nodes may be unmarked. When bending interior edges, we examine the diagonal of the tetrahedron that is chosen to be refined that will invert the children tetrahedron. The mid-side node is perturbed until the children elements will have an acceptable shape.

If all of these methods fail to produce a valid configuration, the nodes marked on the poor element will be unmarked for refinement. Although the driver component wanted the nodes to be refined, the unmarking of nodes has been proven to be an acceptable practice via empirical studies.

2.2.2 Template Based Refinement

The template base refinement follows Statens work with slight modifications. There are cases where after some refinement that the diagonal to refine the tetrahedron upon will create invalid elements. In this case, we again try to bend interior mid-side nodes to create an acceptable quality element.

2.2.3 Pseudo Global Refinement (PGR)

In the cases where template based refinement fails, we try a new method called Pseudo Global Refinement (PGR). The PGR method is an innovative technique that utilizes template based surface mesh refinement and local remeshing techniques to perform mesh refinement during an adaptive solution process.

The PGR method is comprised of the following steps. 1. 2. Remember marked interior node locations (memory nodes) and delete tetrahedron Split boundary edges that have very high transitions as to improve the quality of the resultant mesh Improve quality of surface mesh via triangle quality swapping Refine marked nodes on surface using template refinement and clean surface mesh Fill body with tetrahedron Refine Interior Nodes closest to memory nodes Optimize Mesh Figure 6 Acceptable Linear Element Becomes Invalid with the Addition of Mid-Side Nodes

3. 4. 5. 6. 7.

2.2.3.3 PGR Template Surface Mesh Refinement

2.2.3.1 PGR Surface Mesh Aspect Ratio Adjustment

To obtain a successful refinement using the PGR method, the surface mesh is massaged to prevent poor element quality later in the process (Figure 5). This preventative method reduces high transitions in the mesh by looping through marked nodes and determining if any edge, Ei @ node M, with length, Li @ node M, exceeds the ratio when compared to the smallest edge length at the node, Lmin @ node M. If this edge ratio exceeds , the edge is split to reduce the high transition. In practice, we have found that =10.0 is a suitable number. Figure 7 Template Triangle Refinement PGR Template triangle refinement uses Statens method [6] of refinement to refine the marked nodes (Figure 7). This refinement is then followed by topological optimization of the triangles [10] and mixed Laplacian/Optimization smoothing[11] of the refined surface mesh.

2.3 Tetrahedron Optimization Methods

After the topological body bound by the refined surface mesh is filled with tetrahedron, mesh optimization is performed on the mesh. B. Joes [1] tetrahedron optimization techniques have been implemented for the initial optimization leg of the code. For cases where the mesh cannot be improved by Joes techniques, more advanced and specialized tetrahedron optimization operators are used. These methods consist of the same methods used to improve tetrahedron quality during the node marking leg of the process. Improving poor boundary element tetrahedron by reposition their mid-side nodes is one of the most common specialized tetrahedron operators called in the process (Figure 8). The operator is quite simple. The smallest or inverted angle is found on the boundary face. The unconstrained edge is determined, i.e., the edge that does not lie on a topological edge is found. The direction of the edge, E , is crossed with the surface normal, N surface , to determine the direction, Vmove , in which the mid-side node of the moving edge should move. This process moves the node a small based on the distance between the mid-side nodes of the adjacent edges until the quality of the tetrahedron adjacent to the edge are acceptable.

Figure 5 Splitting High Transition Edges

2.2.3.2 PGR Surface Mesh Optimization

We perform topological optimization of the mesh along with quality optimization of the mesh. The quality optimization of the mesh is required for quadratic elements. An element may have acceptable quality when it is linear but adding mid-side nodes to the element may invalidate it (Figure 6). Therefore, the quality swap is extremely important. A quality swap is one in which a swap is performed if the quality of the elements will improve in the new configuration. This step provides a high quality surface mesh to send to the template based surface mesh refinement.

8a bad configuration

8b corrected configuration

8c correcting configuration

Figure 9 Improving Bad Boundary Element

3. EXAMPLES AND FUTURE WORK

Figure 10 Pressure Vessel Initial Mesh

3.1 Example 3.1.1 Pressure Vessel

The following example illustrates our process on a moderate complexity CAD geometry of a pressure vessel. The intersections of the fillets in the model contain many sliver surfaces, which have been defeatured via Mesh Based Defeaturing [12]. The loading condition is shown in Figure 8. The initial mesh (Figure 10) was intentionally set to the coarsest setting possible to show the robustness of the refinement process. It is clearly seen that the initial mesh contains many high aspect ratio tetrahedron. The model was set to adapt on the maximum normal stress of the whole model with a convergence criterion of 7% allowable change in the maximum normal stress (Figure 11). After four iterations, the model converged to .5% change in maximum normal stress (Figure 12, Table 1). The large increase in the number of nodes is due to the massaging of the surface mesh during PGR. PGR allows the complex fillets to be refined while maintaining the overall quality of the mesh.

Figure 11 Convergence Control on Solution

Figure 12 Pressure Vessel Convergence

Figure 8 Pressure Vessel Loading Condition

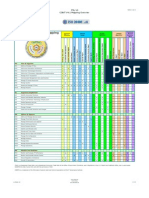

Table 1 Pressure Vessel Convergence

Solution Number Normal Stress (Pa) Change (%) 1 1.3980E+07 2 1.9378E+07 32.062 3 2.0886E+07 7.8 4 2.0994E+07 0.51585 Nodes Elements 2080 1056 13099 4643 35255 22418 123451 83988

Figure 15 Plate with Hole Initial Mesh

Figure 13 Pressure Vessel Converged Normal Stress

3.1.2 Plate with Hole

The next example illustrates an academic problem of a plate with a hole. The interesting item with this model is the scoping of results to the top surface (region R as discussed above). As stated above, the scoping control limits the marking of nodes to nodes lying on the scoped surface (Figure 17). The model converges to 1.88 % change in maximum equivalent stress in four iterations (Figure 16, Table2).

Figure 16 Plate with Hole Convergence Table 2 Plate with Hole Convergence

Solution Number Equivalent Stress (psi) Change (%) Nodes Elements 1 2 3 4 1088.4 1430.5 1502.9 1531.6 27.161 4.9363 1.8895 438 2388 12494 35341 174 1183 7543 22925

Figure 14 Plate with Hole Loading Condition

Figure 17 Plate with Hole Scoped Equivalent Stress Result

3.2 Future Work

This paper presented a framework for successfully integrating fully automatic adaptive refinement into the solution process.

This process is quite robust. However, as with any process, there is always room for improvement. Future work in this area may consist of: Determining better heuristics for when to choose PGR over Template refinement Using an optimization method to place the mid-side nodes when bending interior edges or moving the mid-side node of a poor surface tetrahedron Developing new specialized tetrahedron cleanup operators Improve refinement for thin models when the aspect ratio of the opposite side of the model is much larger than the side being refined (Figure 18)

International Meshing Roundtable, Sandia National Laboratories, pp.147-155, (2000 ) [8] Mark T. Jones and Paul E. Plassmann, Adaptive Refinement of Unstructured Finite-Element Meshes, Finite Elements in Analysis and Design, Num 25 pp. 41-60, (1997) [9] ANSYS Inc, Theory Manual [10] Scott A. Canann, S. N. Muthukrishnan and R. K. Phillips, Topological Refinement Procedures for Triangular Finite Element Meshes, Engineering with Computers, Springer-Verlag, Vol 12, pp.243-255, (December 1996) [11] Zhijian Chen, J. Tristano, W Kwok, Combined laplacian and optimization-based smoothing for quadratic mixed surface meshes, Submitted to 12th International Meshing Roundtable [12] Anton V. Mobley, M. P. Carroll, and S. A. Canann, An object oriented approach to geometry defeaturing for finite element meshing, In Proc. 7th Intl Meshing Roundtable '98, Sandia National Laboratories, (1998)

Figure 18 Cross-section of thin model with high aspect ratio tetrahedron

REFERENCES

[1] Barry Joe, Construction of Three-Dimensional Improved-Quality Triangulations Using Local Transformations Siam J. Sci. Comput., Vol 16, pp.1292-1307 (1995) Wa Kwok, Z. Chen, J. Tristano, Quadratic Tetrahedral Mesh Improvements, Submitted to 12th International Meshing Roundtable O. C Zienkiewicz,., and J. Z Zhu, "A Simple Error Estimator and Adaptive Procedure for Practical Engineering Analysis", International Journal for Numerical Methods in Engineering, Vol. 24, pp. 337357 (1987). H.C. Huang and R.W. Lewis, Adaptive Analysis for Heat Flow Problems Using Error Estimation Techniques, Paper presented at the 6th International Conference on Numerical Methods in Thermal Problems. Also University of Wales, University College of Swansea Internal Report CR/635/89 (April 1989) Maria-Cecilia Rivara, Local Modification of Meshes for Adaptive and/or MultiGrid Finite-Element Methods, Journal of Computational and Applied Mathematics, Elsevier, Num 36, pp.79-89, (1991) Matthew Staten, Selective Refinement of Two and Three-Dimensional Finite Element Meshes, Master's Thesis, Department of Civil and Environmental Engineering, Brigham Young University, (1996 ) Alejandro Diaz-Morcillo, L. Nuo, J. V. Balbastre and D. Snchez-Hernndez, Adaptive Mesh Refinement in Electromagnetic Problems, Proceedings, 9th

[2] [3]

[4]

[5]

[6]

[7]

Potrebbero piacerti anche

- Finite Element MethodDocumento9 pagineFinite Element MethodSriram Anil Kumar GandhamNessuna valutazione finora

- Layout Oriented Synthesis of High Performance Analog CircuitsDocumento5 pagineLayout Oriented Synthesis of High Performance Analog CircuitsOana MitaNessuna valutazione finora

- 15 PDFDocumento28 pagine15 PDFwearplayNessuna valutazione finora

- A Verification Procedure For MSC/NASTRAN Finite Element ModelsDocumento22 pagineA Verification Procedure For MSC/NASTRAN Finite Element ModelsTomaspockNessuna valutazione finora

- Some Recent Advances For Practical Finite Element AnalysisDocumento11 pagineSome Recent Advances For Practical Finite Element AnalysismariomatoNessuna valutazione finora

- Discretization ErrorDocumento11 pagineDiscretization Errorசுஜித் குமார்Nessuna valutazione finora

- A Verification Procedure For MSC/NASTRAN Finite Element ModelsDocumento22 pagineA Verification Procedure For MSC/NASTRAN Finite Element Modelsdumi_userNessuna valutazione finora

- Mesh Discretization Error and Criteria For Accuracy of Finite Element SolutionsDocumento12 pagineMesh Discretization Error and Criteria For Accuracy of Finite Element Solutionsglassw380Nessuna valutazione finora

- Stopping Criteria For A Constrained Single-Objective Particle Swarm Optimization AlgorithmDocumento10 pagineStopping Criteria For A Constrained Single-Objective Particle Swarm Optimization AlgorithmLittle PrincessNessuna valutazione finora

- Ansys ExercisesDocumento20 pagineAnsys Exerciseskpvraj100% (1)

- Analog Circuit Optimization System Based On Hybrid Evolutionary AlgorithmsDocumento12 pagineAnalog Circuit Optimization System Based On Hybrid Evolutionary AlgorithmsashishmanyanNessuna valutazione finora

- Vahidnia, Arash Ledwich, Gerard Ghosh, Arindam Palmer, EdwardDocumento8 pagineVahidnia, Arash Ledwich, Gerard Ghosh, Arindam Palmer, EdwardMarioTresićNessuna valutazione finora

- Feature Selection For A Real-World Learning TaskDocumento12 pagineFeature Selection For A Real-World Learning TaskkolldirNessuna valutazione finora

- Fixtures - FEADocumento5 pagineFixtures - FEAMohammedRafficNessuna valutazione finora

- Global Optimization MethodDocumento32 pagineGlobal Optimization MethodHeather WinNessuna valutazione finora

- Afmc16 Dfo CFD PDFDocumento4 pagineAfmc16 Dfo CFD PDFdatam38Nessuna valutazione finora

- Improvement in Power Transformer Intelligent Dissolved Gas Analysis MethodDocumento4 pagineImprovement in Power Transformer Intelligent Dissolved Gas Analysis MethodsueleninhaNessuna valutazione finora

- Optimization of Machining Parameters Using Fuzzy Based Principal Component Analysis During Dry Turning Operation of Inconel 625 - A Hybrid ApproachDocumento9 pagineOptimization of Machining Parameters Using Fuzzy Based Principal Component Analysis During Dry Turning Operation of Inconel 625 - A Hybrid Approachsuneel kumar rathoreNessuna valutazione finora

- Adaptive Reproducing Kernel Particle Method Using Gradient Indicator For Elasto-Plastic DeformationDocumento13 pagineAdaptive Reproducing Kernel Particle Method Using Gradient Indicator For Elasto-Plastic DeformationDesmondd MondNessuna valutazione finora

- 1801 07114 PDFDocumento39 pagine1801 07114 PDFhamidrezaee008Nessuna valutazione finora

- Workpackage 4: Optimization: Distributed Modelling ApproachDocumento4 pagineWorkpackage 4: Optimization: Distributed Modelling ApproachMelissa MillerNessuna valutazione finora

- AIAA20025539 StanderDocumento10 pagineAIAA20025539 Standerger5555kingNessuna valutazione finora

- Optimum Coordination of Overcurrent Relays Using SADE AlgorithmDocumento10 pagineOptimum Coordination of Overcurrent Relays Using SADE AlgorithmJamile_P_NNessuna valutazione finora

- Design of Experiments Via Taguchi Methods - Orthogonal Arrays - ControlsWikiDocumento11 pagineDesign of Experiments Via Taguchi Methods - Orthogonal Arrays - ControlsWikiRachel HillNessuna valutazione finora

- Optimized Extraction of MOS Model ParametersDocumento6 pagineOptimized Extraction of MOS Model ParametersTâm NguyễnNessuna valutazione finora

- Taguchi APPDocumento14 pagineTaguchi APPAmey VidvansNessuna valutazione finora

- Integrating Theory, Experiments, and FEA To Solve Challenging Nonlinear Mechanics ProblemsDocumento17 pagineIntegrating Theory, Experiments, and FEA To Solve Challenging Nonlinear Mechanics ProblemsBodieTechNessuna valutazione finora

- Stope Boundary Optimization Using A 3D Approximate Hybrid AlgorithmDocumento14 pagineStope Boundary Optimization Using A 3D Approximate Hybrid AlgorithmKENNY BRANDON MAWODZWANessuna valutazione finora

- J Fen Um AccuracyDocumento9 pagineJ Fen Um Accuracyhamed12077Nessuna valutazione finora

- Chapter - 1: Another Problem During The Time of Optimizing Any Objective FunctionsDocumento14 pagineChapter - 1: Another Problem During The Time of Optimizing Any Objective FunctionsHossein HosseinNessuna valutazione finora

- Optimization in Design of Electric MachinesDocumento10 pagineOptimization in Design of Electric MachinesRituvic PandeyNessuna valutazione finora

- Of Final BookDocumento197 pagineOf Final BookSachinNessuna valutazione finora

- Industrial Applications Using Neural NetworksDocumento11 pagineIndustrial Applications Using Neural Networksapi-26172869Nessuna valutazione finora

- Comparison and SelectionDocumento10 pagineComparison and SelectioncruzreyeslauraNessuna valutazione finora

- Straightness and Flatness Evaluation Using Data Envelopment AnalysisDocumento10 pagineStraightness and Flatness Evaluation Using Data Envelopment Analysisakjeevanantham79Nessuna valutazione finora

- Stewart 2004Documento6 pagineStewart 2004Hanan MouchtakiriNessuna valutazione finora

- Nassaj, Lienig Et Al. 2009 - A New Methodology For Constraint-DrivenDocumento4 pagineNassaj, Lienig Et Al. 2009 - A New Methodology For Constraint-DrivensimNessuna valutazione finora

- Comparing Efficiency of Integration Methods For Cloth SimulationDocumento8 pagineComparing Efficiency of Integration Methods For Cloth SimulationCyrille LamasséNessuna valutazione finora

- Exploiting A Workstation Network For Automatic Generation of Test Patterns For Digital CircuitsDocumento17 pagineExploiting A Workstation Network For Automatic Generation of Test Patterns For Digital CircuitsDhwal MehtaNessuna valutazione finora

- An Optimization Framework To Computer-Aided DesignDocumento7 pagineAn Optimization Framework To Computer-Aided DesignYaqoob AliNessuna valutazione finora

- Design of Experiments Via Taguchi Methods Orthogonal ArraysDocumento21 pagineDesign of Experiments Via Taguchi Methods Orthogonal ArraysRohan ViswanathNessuna valutazione finora

- Final Project ReportDocumento18 pagineFinal Project ReportjstpallavNessuna valutazione finora

- Electricity Load Forecasting - IntelligentDocumento10 pagineElectricity Load Forecasting - IntelligentkarthikbolluNessuna valutazione finora

- 1979 Efficient Solution of Design Problems Using A Sequential-Modular Flowsheeting ProgrammeDocumento7 pagine1979 Efficient Solution of Design Problems Using A Sequential-Modular Flowsheeting Programmelvjiaze12Nessuna valutazione finora

- Pillay Application GeneticDocumento10 paginePillay Application GenetickfaliNessuna valutazione finora

- Multi-Objective Optimal Placement of Recloser and Sectionalizer in Electricity Distribution FeedersDocumento4 pagineMulti-Objective Optimal Placement of Recloser and Sectionalizer in Electricity Distribution Feedersabera alemayehuNessuna valutazione finora

- Validation and Updating Ansys Model Using Expt Modal DataDocumento10 pagineValidation and Updating Ansys Model Using Expt Modal DataKiran KolluruNessuna valutazione finora

- FEA SummaryDocumento4 pagineFEA Summarysharma_ankur_jecNessuna valutazione finora

- Introduction To ANSYS7842679769Documento21 pagineIntroduction To ANSYS7842679769Julie RochaNessuna valutazione finora

- Zeina L Zadeh 2019Documento4 pagineZeina L Zadeh 2019Gustavo FloresNessuna valutazione finora

- Solving Ode by Ann PDFDocumento14 pagineSolving Ode by Ann PDFDeep SinghaNessuna valutazione finora

- PolyTop PDFDocumento29 paginePolyTop PDFahmed_shaheebNessuna valutazione finora

- Sari WESIC2003 PaperDocumento8 pagineSari WESIC2003 PaperSalehNessuna valutazione finora

- 101 Ways Extract Modal Parameters Which Is One Me PDFDocumento13 pagine101 Ways Extract Modal Parameters Which Is One Me PDFValentino de GeorgeNessuna valutazione finora

- Integer Optimization and its Computation in Emergency ManagementDa EverandInteger Optimization and its Computation in Emergency ManagementNessuna valutazione finora

- Affine Arithmetic-Based Methods for Uncertain Power System AnalysisDa EverandAffine Arithmetic-Based Methods for Uncertain Power System AnalysisNessuna valutazione finora

- Apdl ExampleDocumento7 pagineApdl ExampleypcadNessuna valutazione finora

- Ansys Capabilities ChartDocumento8 pagineAnsys Capabilities ChartypcadNessuna valutazione finora

- Surface Solution On Solid FaceDocumento9 pagineSurface Solution On Solid FaceypcadNessuna valutazione finora

- Mechanical Intro 14.5 L10 ThermalDocumento27 pagineMechanical Intro 14.5 L10 ThermalypcadNessuna valutazione finora

- Customize Legend MechanicalDocumento12 pagineCustomize Legend Mechanicalypcad0% (1)

- Offshore-Combin39 Vs SplinterDocumento12 pagineOffshore-Combin39 Vs SplinterypcadNessuna valutazione finora

- Ansys UpfDocumento57 pagineAnsys Upfypcad100% (1)

- Ansys UpfDocumento57 pagineAnsys Upfypcad100% (1)

- Civil Combining Ansys CivilfemDocumento24 pagineCivil Combining Ansys CivilfemypcadNessuna valutazione finora

- Ansys UpfDocumento57 pagineAnsys Upfypcad100% (1)

- Fatigue DemoDocumento17 pagineFatigue DemoypcadNessuna valutazione finora

- Fatigue ANSYSDocumento22 pagineFatigue ANSYSapi-3717939100% (2)

- Custom Is Ing Mechanical in WorkbenchxDocumento1 paginaCustom Is Ing Mechanical in WorkbenchxypcadNessuna valutazione finora

- How To Install WordPressDocumento11 pagineHow To Install WordPressmetaouiNessuna valutazione finora

- Application of Graph Theory in Web 2Documento9 pagineApplication of Graph Theory in Web 2Maria Benedetta VitalesNessuna valutazione finora

- Programming LanguagesDocumento27 pagineProgramming LanguagesziggatronNessuna valutazione finora

- Time & Work - Part-03Documento9 pagineTime & Work - Part-03shuhal AhmedNessuna valutazione finora

- 01 Crash CourseDocumento23 pagine01 Crash CourseahmetakdoganNessuna valutazione finora

- Brosur Dan Spek BT-350Documento3 pagineBrosur Dan Spek BT-350dr novi kurniasariNessuna valutazione finora

- Itil Cobit Mapping TemplateDocumento6 pagineItil Cobit Mapping Templategobits100% (3)

- Manual GLDDocumento126 pagineManual GLDIna Rodica PricăNessuna valutazione finora

- Cmlexch PDFDocumento7.952 pagineCmlexch PDFtumbledoor100% (1)

- AREVA Directional Over Current Relay MiCOM P12x en TechDataDocumento28 pagineAREVA Directional Over Current Relay MiCOM P12x en TechDatadeccanelecNessuna valutazione finora

- Management Presentation 1Documento10 pagineManagement Presentation 1clizardoNessuna valutazione finora

- Sample Test Paper Duet PDFDocumento3 pagineSample Test Paper Duet PDFhasnain ghazalaNessuna valutazione finora

- Shankar - Fundood Data - G To LDocumento16 pagineShankar - Fundood Data - G To LBuvanesh RajagopalNessuna valutazione finora

- TC TRK 2p Brochure Eng 210x297mm Rev7 17072021 Lrs Single PagesDocumento8 pagineTC TRK 2p Brochure Eng 210x297mm Rev7 17072021 Lrs Single Pagesneophantom00Nessuna valutazione finora

- AVI Eehal: E-Mail: Mobile: 312.451.8811Documento5 pagineAVI Eehal: E-Mail: Mobile: 312.451.8811CHAVAMOHITHBALAJI SchoolNessuna valutazione finora

- UserManual Coding VCM v1.4.Documento51 pagineUserManual Coding VCM v1.4.ImSW1100% (2)

- Normalization Vs DeNormalizationDocumento26 pagineNormalization Vs DeNormalizationamolgavaliNessuna valutazione finora

- Ximble Biometric Information PolicyDocumento3 pagineXimble Biometric Information PolicychapungutNessuna valutazione finora

- PRO II 8.0 Component and Thermophysical Properties - Reference ManualDocumento207 paginePRO II 8.0 Component and Thermophysical Properties - Reference ManualLuis Carlos Ayllón EscobarNessuna valutazione finora

- HP Service Manager Tailoring and CustomizationDocumento5 pagineHP Service Manager Tailoring and Customizationfrom_jimNessuna valutazione finora

- Installation Guide For Windows: Section 1 - Create An Account at Udaan Translation Web InterfaceDocumento15 pagineInstallation Guide For Windows: Section 1 - Create An Account at Udaan Translation Web Interfacekamarajme2006Nessuna valutazione finora

- Linux SchedulingDocumento28 pagineLinux SchedulingKoushik AkkinapalliNessuna valutazione finora

- The Hanging Tree - Jennifer LawrenceDocumento6 pagineThe Hanging Tree - Jennifer LawrenceChan Sek Yeong100% (1)

- New Brunswick Enterprise Architecture ManualDocumento108 pagineNew Brunswick Enterprise Architecture ManualMichael DavidsonNessuna valutazione finora

- Installed Base ErrorsDocumento5 pagineInstalled Base ErrorsManmohan KulkarniNessuna valutazione finora

- Introduction To Plant SimulationlDocumento16 pagineIntroduction To Plant SimulationlLeon SakiNessuna valutazione finora

- Real Python PDFDocumento209 pagineReal Python PDFIvanov Ilya100% (1)

- COBOL Basics Questions and Answers - SanfoundryDocumento2 pagineCOBOL Basics Questions and Answers - SanfoundryHarshu PatilNessuna valutazione finora

- Surface Water Modeling System: A Comprehensive Software Environment For Creating Hydrodynamic ModelsDocumento11 pagineSurface Water Modeling System: A Comprehensive Software Environment For Creating Hydrodynamic ModelsMajhic AryonoNessuna valutazione finora

- Text Processing (Complete)Documento100 pagineText Processing (Complete)WeiYewHuongNessuna valutazione finora