Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

PSV Guidance Notes

Caricato da

carr007Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

PSV Guidance Notes

Caricato da

carr007Copyright:

Formati disponibili

Plant Integrity Management Ltd, Company Guideline- PSV documentation (Draft)

PSV DOCUMENTATION

1.0 PURPOSE 1.1 To establish a procedure for the data gathering and validation of PSV data for use in an upload template for Plant Integrity Managements PSV database, to ensure integrity of raw data and efficient upload time.

2.0

SCOPE 2.1 This procedure applies to all PSV data being prepared for upload to Plant integrity managements PSV database.

2.2 3.0

This procedure applies to all employees preparing PSV data for Plant integrity managements PSV database.

RESPONSIBILITIES 3.1 3.2 The Project Manager has responsibility and authority to ensure this procedure is followed. He may delegate tasks to qualified personnel as needed. All employees involved with PSV RBIs are responsible for knowing and following this procedure.

4.0

REFERENCES 4.1 None

5.0

DEFINITIONS 5.1 RBI Risk Based Inspection P+ID Piping and instrument diagram PSV Pressure Safety Valve

6.0

PROCEDURE 6.1 Guidance Notes 6.1.1 All information being used for PSV data gathering must be kept in the working documents folder relating to each site excluding PSV certificates which will be organised within the received documents folder.

Plant Integrity Management Ltd 2011 Issue. 1 (Draft) 29 August 2011 Originated by: Reviewed by:

Page 1 of 3 Approved by:

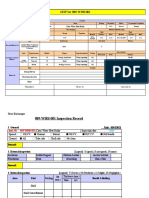

Plant Integrity Management Ltd, Company Guideline- PSV documentation (Draft) 6.1.2 Print out all associated P+IDs for each site and file in order of (XX), platform (Field-Platform-Module), drawing number (xxxxx), sheet number (xxxx) HDBY-XX-XXXXX-XXXX 6.1.3 P+ID registers will be provided by the client and must be cross checked with available P+Ds. Any missing P+IDs must be highlighted in the missing documents spreadsheet. Highlight all PSVs witnessed on P+IDs whilst updating the PSV register with PSV location, PSV system and service on line associated with PSV. Using database import template located in 03_MaerskOilDenmark/00_General/03_PSVProjectGenericdata/WorkingDocu ments, certificate information must be imported to the template for upload to the Plant integrity management PSV database. Manual data entry will be required at this step and rules must be followed to ensure a simple upload to the PSV database. Three worksheets are available in the data import template: Certification all certificate data must be inserted into this worksheet. A unique number must be assigned to each certificate (RowID). Association must be established between certificates and their corresponding valve (ID_ValveRowID) using the unique number from tblTagandValveData worksheet (RowID). When applying safety codes to certificate details on the worksheet they must be input as TRUE or FALSE. No cell may be left blank in the safety code section of the worksheet. All Pre-pop, Leak and Actual leak test results must be input as either a PASS or FAIL. Valve data all valve data must be inserted to this worksheet. Valve data should only be extracted from the latest certificate available. As before, a unique number must be assigned to each valve (RowID) RBI data For purposes of upload this worksheet will largely be left blank. Only the first 5 columns must be completed to allow upload to the PSV database. Within the worksheet RowID corresponds to the unique number applied to each RBI. HistoryID corresponds to the certificate RowID and the Valve ID corresponds to the Valve RowID. 6.1.6 Certificate data must be organised within the document received folder using a hierarchy of Site System Valve.

6.1.4 6.1.5

Issue. 1 (Draft) 29 August 2011

Page 2 of 3

Plant Integrity Management Ltd, Company Guideline- PSV documentation (Draft) 6.1.7 As two certificates are required for each valve RBI a check needs to be performed against the PSV register highlighting which valves have 0/1/2 certificates. For completeness, a missing documents register must be created highlighting gaps in the available documentation. This must include: Missing P+IDs, PSV on register but not witnessed on P+ID, PSVs witnessed on P+ID but considered to be removed, number of valves missing one or more certificates.

6.1.8

7.0

DOCUMENTATION Examples of the PSV documentation process may be found under MaerskOilDenmark/01_TyraEast/00_PSV RBI/WORKING DOCUMENTS/ Tyra East Template MaerskOilDenmark/01_TyraEast/00_PSV RBI/WORKING DOCUMENTS/ East Tyra PID Register

Issue. 1 (Draft) 29 August 2011

Page 3 of 3

Potrebbero piacerti anche

- Off Shore Piping Design, Layout and Stress Analysis (Project Standards and Specifications)Documento5 pagineOff Shore Piping Design, Layout and Stress Analysis (Project Standards and Specifications)sachin nagavkarNessuna valutazione finora

- Site Acceptance Test Contract No.: 537856: 863013-VPS-PQM-E-DS-0002Documento16 pagineSite Acceptance Test Contract No.: 537856: 863013-VPS-PQM-E-DS-0002Andry YanuarNessuna valutazione finora

- 4.30 PM / Calibration Procedure For Fire & Gas Detection System Installed at Different Plant Location Across The ComplexDocumento5 pagine4.30 PM / Calibration Procedure For Fire & Gas Detection System Installed at Different Plant Location Across The Complexkirandevi1981Nessuna valutazione finora

- Coral FLNG SA Is The Special Purpose Entity Responsible To Develop and Operate Coral South Floating Platform (FLNG)Documento4 pagineCoral FLNG SA Is The Special Purpose Entity Responsible To Develop and Operate Coral South Floating Platform (FLNG)MateusPauloNessuna valutazione finora

- Bath Heater ChecklistDocumento4 pagineBath Heater ChecklistThiruppathirajanNessuna valutazione finora

- EIL Shedule of Rates ENQ - REV0Documento20 pagineEIL Shedule of Rates ENQ - REV0kotiNessuna valutazione finora

- ITP InstrumentationDocumento9 pagineITP InstrumentationzhangyiliNessuna valutazione finora

- SEIP For 089-WHB-001: Claus Waste Heat BoilerDocumento6 pagineSEIP For 089-WHB-001: Claus Waste Heat BoilerThinh NguyenNessuna valutazione finora

- Doha North Sewerage Treatment & Associated WorksDocumento67 pagineDoha North Sewerage Treatment & Associated WorksLito MendozaNessuna valutazione finora

- BE-WI-248-01-F25 Datasheet Solenoid ValveDocumento3 pagineBE-WI-248-01-F25 Datasheet Solenoid Valvemika cabelloNessuna valutazione finora

- Safety Analysis Function Evaluation (S.A.F.E.) Chart: Project Document No. RevisionDocumento19 pagineSafety Analysis Function Evaluation (S.A.F.E.) Chart: Project Document No. RevisionCandraNessuna valutazione finora

- API 14C TablesDocumento10 pagineAPI 14C TablessegunoyesNessuna valutazione finora

- 01-01-1865-D ELDS Technical Manual Iss13Documento221 pagine01-01-1865-D ELDS Technical Manual Iss13Alberyt099Nessuna valutazione finora

- Cathodic Protection SystemDocumento11 pagineCathodic Protection SystemphuongNessuna valutazione finora

- New SSIV InstallationDocumento12 pagineNew SSIV InstallationDidiNessuna valutazione finora

- TRHT SP Te 86 Oo 203 - 0Documento28 pagineTRHT SP Te 86 Oo 203 - 0belhaska100% (1)

- National Oil Corporation: Rev Date Description Checked ApprovedDocumento14 pagineNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliNessuna valutazione finora

- Atmos LDS and Batch For Pertamina UPMS CY3 Multiproduct PipelineDocumento19 pagineAtmos LDS and Batch For Pertamina UPMS CY3 Multiproduct PipelineMario SitorusNessuna valutazione finora

- Annex 17 - Induction Nawara ProjDocumento18 pagineAnnex 17 - Induction Nawara ProjMajdiSahnounNessuna valutazione finora

- Shutdown Panel Functional SpecDocumento17 pagineShutdown Panel Functional SpecCandice Williams100% (1)

- Nuflo Mc-III Exp DatasheetDocumento4 pagineNuflo Mc-III Exp DatasheetJerrydawangNessuna valutazione finora

- Layouts For CGDDocumento21 pagineLayouts For CGDShyam Prasad K SNessuna valutazione finora

- E002 For Instrument Acceptance StandardsDocumento14 pagineE002 For Instrument Acceptance StandardsSuresh Kumar RanaNessuna valutazione finora

- FEP3546-AEL-IC-SPC-0002 Rev 2.0Documento47 pagineFEP3546-AEL-IC-SPC-0002 Rev 2.0Mohammed Saleem Syed KhaderNessuna valutazione finora

- NPL-NG-P140001-BM-752 Pipe Material Class Summary - Rev 2.0Documento38 pagineNPL-NG-P140001-BM-752 Pipe Material Class Summary - Rev 2.0Kehinde AdebayoNessuna valutazione finora

- Analyser Sample SystemsDocumento19 pagineAnalyser Sample Systemsaslam.amb100% (1)

- Pipeline Depth of CoverDocumento18 paginePipeline Depth of Coverallouche_abdNessuna valutazione finora

- Field Instrument Installation ChecklistDocumento1 paginaField Instrument Installation ChecklistAbarajithan RajendranNessuna valutazione finora

- ESD ValveDocumento4 pagineESD ValveKyrie Abaya100% (1)

- Ed Temporary Refuge IntegrityDocumento27 pagineEd Temporary Refuge Integrityliamo88880Nessuna valutazione finora

- NGP 006 PCS 15.03 0012-10-00 Specification For Loading ArmsDocumento9 pagineNGP 006 PCS 15.03 0012-10-00 Specification For Loading Armsm.shehreyar.khanNessuna valutazione finora

- PEGS-01015-SAF-005 Rev.1-0Documento35 paginePEGS-01015-SAF-005 Rev.1-0Monkey The LuffyNessuna valutazione finora

- Simops V3 I3 03 PDFDocumento5 pagineSimops V3 I3 03 PDFravikrssNessuna valutazione finora

- ROHR2 Tutorial eDocumento86 pagineROHR2 Tutorial eZoran100% (1)

- Motor Standard, IP55, (Ah 180 - 315) - ENDocumento60 pagineMotor Standard, IP55, (Ah 180 - 315) - ENkfathi55Nessuna valutazione finora

- Iooc Idhc BPD Ins Mto 032 03Documento9 pagineIooc Idhc BPD Ins Mto 032 03Fatholla SalehiNessuna valutazione finora

- Blanking and Blinding PracticeDocumento8 pagineBlanking and Blinding PracticeBabyface888100% (1)

- ES-30.99.37.0017 - External Pipeline Coatings - Part 1Documento63 pagineES-30.99.37.0017 - External Pipeline Coatings - Part 1maheshNessuna valutazione finora

- Hydrostatic Test ProcedureDocumento7 pagineHydrostatic Test Procedurelaleye_olumideNessuna valutazione finora

- Offshore Containers: Standard For Certification No. 2.7-1Documento30 pagineOffshore Containers: Standard For Certification No. 2.7-1Teknik MarinaNessuna valutazione finora

- ATEXDocumento1 paginaATEXselvan110663Nessuna valutazione finora

- Donghong Pipe Industry BrochureDocumento34 pagineDonghong Pipe Industry BrochuredonghongguanyeNessuna valutazione finora

- Sa 1141 PDFDocumento66 pagineSa 1141 PDFAwais Tariq100% (2)

- Maintenance and User Manual: Borehole TV Camera Inspection System Setting Up InstructionsDocumento21 pagineMaintenance and User Manual: Borehole TV Camera Inspection System Setting Up InstructionsFranklin L SilvaNessuna valutazione finora

- API 2000 5th Vs 6th FinalDocumento21 pagineAPI 2000 5th Vs 6th FinalCepopaky CangkrukanNessuna valutazione finora

- Mokveld Test Unit VTU-1Documento1 paginaMokveld Test Unit VTU-1eng_moh04Nessuna valutazione finora

- Risk Based Verification of Offshore Structures: DNV-OSS-304Documento35 pagineRisk Based Verification of Offshore Structures: DNV-OSS-304Youn Seok ChoiNessuna valutazione finora

- Comment Resolution Sheet 19009 Welding DossierDocumento1 paginaComment Resolution Sheet 19009 Welding DossierDheeraj E MohananNessuna valutazione finora

- Oil and Gas Offshore Pipeline Leak Detection System: A Feasibility StudyDocumento8 pagineOil and Gas Offshore Pipeline Leak Detection System: A Feasibility StudycbqucbquNessuna valutazione finora

- Power Point Fiber Optic Distributed Strain and Temperature SensorsDocumento63 paginePower Point Fiber Optic Distributed Strain and Temperature SensorsjovinosubidoNessuna valutazione finora

- Satr W 2012Documento1 paginaSatr W 2012Mohammed Hamed BaganNessuna valutazione finora

- High-Integrity Pressure Protection System: Traditional SystemsDocumento4 pagineHigh-Integrity Pressure Protection System: Traditional SystemsgowtemdmNessuna valutazione finora

- Piping and Vessels Preparation For Commissioning - Part 2Documento12 paginePiping and Vessels Preparation For Commissioning - Part 2MohamedNessuna valutazione finora

- Metering SystemDocumento21 pagineMetering Systemaadianvi0% (1)

- UMS-IMC-F07-0011 - Terms of Reference (ToR) For SIL ClassificationDocumento20 pagineUMS-IMC-F07-0011 - Terms of Reference (ToR) For SIL ClassificationRichard Ikwubute100% (1)

- Results Flowcontrol 2-2015 PDFDocumento36 pagineResults Flowcontrol 2-2015 PDFpredic1Nessuna valutazione finora

- Technical Doc 1 - Technical Scope of Work Drs Eac181Documento25 pagineTechnical Doc 1 - Technical Scope of Work Drs Eac181bhargavpansuria09Nessuna valutazione finora

- 7-11 Putaway Project Post With Clearing Ap in Sap 4.0B: Functional SpecificationDocumento6 pagine7-11 Putaway Project Post With Clearing Ap in Sap 4.0B: Functional SpecificationBlahNessuna valutazione finora

- The Production Data Management Platform For Reservoir Management and Optimisation: A Case StudyDocumento13 pagineThe Production Data Management Platform For Reservoir Management and Optimisation: A Case StudyVignesh KumarNessuna valutazione finora

- Pci Evidence Reference v1Documento192 paginePci Evidence Reference v1mani karthikNessuna valutazione finora

- IGMP Multicast WebinarDocumento35 pagineIGMP Multicast Webinaredonat0894Nessuna valutazione finora

- Ec Case Study (22,44)Documento11 pagineEc Case Study (22,44)Aditya KanojiyaNessuna valutazione finora

- CCSF Student Gmail Accounts:: What Instructors Need To KnowDocumento3 pagineCCSF Student Gmail Accounts:: What Instructors Need To KnowHelloNessuna valutazione finora

- Zippo Manufacturing Co. v. Zippo Dot Com, IncDocumento2 pagineZippo Manufacturing Co. v. Zippo Dot Com, Incron22Nessuna valutazione finora

- Application Submitted Status: Right To Public ServicesDocumento1 paginaApplication Submitted Status: Right To Public ServicesUjjawal RanjanNessuna valutazione finora

- Mini Project 2 Report Mba 2nd Semester 2Documento51 pagineMini Project 2 Report Mba 2nd Semester 2Saurav KumarNessuna valutazione finora

- (GUIDE) Unbrick A Hard Bricked L90 All Varia - LG Optimus L90 PDFDocumento1 pagina(GUIDE) Unbrick A Hard Bricked L90 All Varia - LG Optimus L90 PDFpartidasluisNessuna valutazione finora

- CBE Tactic Hybrid Instructions WEBDocumento2 pagineCBE Tactic Hybrid Instructions WEBMario Gallardo CaballeroNessuna valutazione finora

- June 2019 (IAL) QP - S1 EdexcelDocumento24 pagineJune 2019 (IAL) QP - S1 EdexcelDummy ETHNessuna valutazione finora

- MC Email SPDocumento36 pagineMC Email SPMarkus Suritsch (AT)Nessuna valutazione finora

- SF S4 EC EE Data HCI en-USDocumento248 pagineSF S4 EC EE Data HCI en-USSky MoviesNessuna valutazione finora

- Amethyst State of Survival (SOS)Documento9 pagineAmethyst State of Survival (SOS)Virnawati FarahNessuna valutazione finora

- MNG3702 Study Guide 2023Documento128 pagineMNG3702 Study Guide 2023Neferu MadzTwalNessuna valutazione finora

- Js CodeDocumento25 pagineJs CodeOm BhandareNessuna valutazione finora

- Competitive Analysis Tutorial 69 PDFDocumento3 pagineCompetitive Analysis Tutorial 69 PDFFerdinand MangaoangNessuna valutazione finora

- Rlu210 SiemensDocumento34 pagineRlu210 SiemensTechnical DeptNessuna valutazione finora

- 2023 NAT G10 Examiner's Handbook - 05.16.2023Documento18 pagine2023 NAT G10 Examiner's Handbook - 05.16.2023Francis Joshua MorenoNessuna valutazione finora

- CV PDFDocumento6 pagineCV PDFPromy VaiNessuna valutazione finora

- 10.27 - Pricelist ElectricalDocumento12 pagine10.27 - Pricelist ElectricalAsaph AdigueNessuna valutazione finora

- Project of FMDocumento18 pagineProject of FMmamaru bantieNessuna valutazione finora

- Epson Command Code For ProgrammingDocumento131 pagineEpson Command Code For ProgrammingSudarno SilabanNessuna valutazione finora

- 2022 20231008BP4117Documento114 pagine2022 20231008BP4117AnkitNessuna valutazione finora

- Fortisiem External Systems Configuration Guide PDFDocumento622 pagineFortisiem External Systems Configuration Guide PDFaykargilNessuna valutazione finora

- SQL Mid Term Part 1Documento17 pagineSQL Mid Term Part 1Ioana Toader0% (1)

- BCSL056Documento25 pagineBCSL056r06677624Nessuna valutazione finora

- CICA CraneSafetyBulletin292useDocumento2 pagineCICA CraneSafetyBulletin292useColin TanNessuna valutazione finora

- SQL Injection VulnerabilityDocumento5 pagineSQL Injection VulnerabilityMeduzagyzaNessuna valutazione finora

- Maruthi Technologies: CCTV, Computer, Laptop, Ups - Sales, Service, Installation, Amc'S & SparesDocumento4 pagineMaruthi Technologies: CCTV, Computer, Laptop, Ups - Sales, Service, Installation, Amc'S & SparesMadhu EnterprisesNessuna valutazione finora

- DWR-M921 User ManualDocumento66 pagineDWR-M921 User ManualAdministrador AngloNessuna valutazione finora

- ICICI Bank PO Previous Year Papers Computer MinDocumento7 pagineICICI Bank PO Previous Year Papers Computer MinPhilip GeorgeNessuna valutazione finora