Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

HRSG

Caricato da

bhp_4677Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

HRSG

Caricato da

bhp_4677Copyright:

Formati disponibili

HEAT RECOVERY STEAM GENERATOR (HRSG)

DESIGN, OPERATIONS & MAINTENANCE

21 - 23 May 2012, Kuala Lumpur

OFFER EXPIRES 30th MAR 2012 Send 2 team mates and the 3rd attends for free

Expert Course Trainer

James W. Malloy

Experienced HRSG Consultant with more than 50 plant inspections over the last six years Organised By

powerEDGE

Design, Operation and Maintenance of Heat Recovery Steam Generator (HRSG)

21 -23 May 2012, Kuala Lumpur Course Overview

The course is primarily intended for experienced Operations & Maintenance working in combined cycle power plants (CCPP), and it should also be of interest to engineers and managers involved in new CCPP project development. This 3 day course gives attendees a comprehensive and an in-depth survey of a broad range of topics relating to the design, operation and maintenance of the HRSG and associated steam cycle systems. Drawing on actual field experience from working in power plants throughout the world, the course will provide attendees with clear skills and knowledge on the operator actions and design issues that impact HRSG reliability, efficiency and its operating life.

3 day Course Learning Outcome

Gain a comprehensive understanding of the key systems and processes involved in the combined cycle power plant. Appreciate the key constraints and tradeoffs involved in designing an HRSG. Learn the water chemistry treatment options available for HRSG unit, their respective advantages and disadvantages. Get access to applied theory in real life situations through a series of worked case histories.

Who Should Attend

Engineers of all disciplines, managers, technicians, design, maintenance and operations personnel, and other technical individuals who need a comprehensive introduction to practical optimization, operation and design considerations of a major combined cycle power plant

You may also be interested in

Design and Operations of Circulating Fluidized Bed (CFB) Boilers

25th to 27th April, Kuala Lumpur, Malaysia

A Circulating Fluidized Bed (CFB) is an evolving technology that is very efficient in generating low-cost electricity with low emissions and environmental impact. As this is a new technology, in-depth knowledge on this technology is not been wide spread. This 3 day course is intended to provide detailed understanding on the concept of fluidized beds, operation of circulating fluidized bed boilers, operational problems in boilers, co-firing options and the environmental impact of the CFB boilers. DOWNLOAD BROCHURE HERE

Gas Turbines Operations Simulation Based

25th to 29th June, Kuala Lumpur, Malaysia

This 5 day simulation based training course covers the operations of a Gas Turbine. The course will introduce the student to the major components of a Gas Turbine and its associated systems. The use of a Gas Turbine simulator will allow students to view various operational problems and introduce the concepts of troubleshooting and fault finding. DOWNLOAD BROCHURE HERE

Combined Cycle Power Plant Operations

15th to 19th October, Kuala Lumpur, Malaysia

The course provides an overview of the processes and technology applied in a modern Combined Cycle Power Plant (CCPP) facility. A basic technical knowledge is assumed, but the trainer will explain the basic concepts behind the operation of plant items, in addition to their detailed function. Presentation of the course will be through a combination of lectures, presentations and group activities DOWNLOAD BROCHURE HERE

Design, Operation and Maintenance of Heat Recovery Steam Generator (HRSG)

21 -23 May 2012, Kuala Lumpur

3 day Course Outline

Introduction and Historical Perspective Comparison of Different Boilers & Cycles Materials Used in Boiler Construction HRSG Design Basics Thermodynamics & Heat Transfer Review Natural and Forced Circulation Supplemental Firing Basic Construction Details HRSG Design Variations Types of HRSG Variations Flow Path Descriptions Waterside Flow Paths Gas Side Flow Paths Key Components Feedwater: Preheaters, Recirculation, Deaerators, Economizers: Low, High Pressure Evaporators & Drums Relief and Safety Valves Superheaters, Reheaters, Attemperators Drains, Vents Casing/Setting Power Piping Codes and Standards Review of Design Criteria Examples of In-Service Degradation Standard Maintenance Activities Engineering Analysis Pipe Hanger Types and Specifications Control and Instrumentation Drum Level Pressure and Temperature Spray Systems Damage & Degradation Mechanisms Surface Corrosion & Pitting Flow Accelerated Corrosion Corrosion Fatigue Cold-End Deposition & Gas side Corrosion Creep & Thermal Effects Waterside Attack Water & Steam Chemistry Fundamentals Treatment Programs Steam Purity Requirements Carryover Operations and Maintenance Operating Modes Impact of Cycling Standard Maintenance Activities Boiler Preservation Inspection Practice Performance Tracking Life Assessment Case Histories Inspections Failure Analyses Design Modifications Performance Assessments

Design, Operation and Maintenance of Heat Recovery Steam Generator (HRSG)

21 -23 May 2012, Kuala Lumpur

Your Expert Faculty: James W. Malloy

Director, European Operations, leading engineering consultancy and inspection projects in the power generation sector . These activities are now concentrated on the steam cycle in combined cycle plants, but included projects for coal, oil, diesel and nuclear plants in the past. Areas of specialization are instrumentation and controls (I&C) as well as materials science. CRE S.A., Sophia Antipolis, France 1987-1991 Lead Engineer, worked on the design and development of real-time systems for controlling diesel generators and turbines. One application involved the development of a complete monitoring system under subcontract to a major European diesel manufacturer, which was subsequently installed on a new black start diesel at a US nuclear plant. Raytheon Company, Development Laboratory, Sudbury, MA. USA 1983-1987 Engineering and analyses to improve resistance of defense electronic systems to spatial environments and effects of nuclear radiation. This involved designing custom test circuitry and carrying out the tests at both Raytheon and US government facilities. Combustion Engineering Inc., Nuclear Division, Windsor CT. USA 1980-1982 Worked in the design group responsible for the nuclear fuel reloading (enriched uranium) for the St Lucie 1 and BG&E Calvert Cliffs plants. Used radiation transport programs for simulating the physics of the reactor during a cycle. Recent Project Experience HRSG Inspections ( more than 50 in last six years) Computer Simulation of Boiler and Steam Plant Performance API/ASME FFS-1 Fitness for Service Analysis on HRSG Components Coal Boiler Inspection and Life Assessments HRSG and Radiant Boiler Failure Analyses HRSG Training (annual public courses and closed session at client sites

Publications: "An Advanced Model for the Prediction of the Total Burnup-Dependent Self-Powered Rhodium Detector Response," T. G. Ober and J. W. Malloy, Proc. Int. Conf. on Mathematics and Computations, Reactor Physics and Environmental Analysis, vol. 2, p.22-31, Portland, Oregon (1995). "Cycling Experience of Large HRSG's in the New England ISO", D.S. Moelling, F.J. Berte, P. Jackson, J. Malloy. presented at POWERGEN Europe Brussels 2001. HRSG Inspection Planning Guide, 2nd edition; P. Jackson, D. Moelling, J. Malloy, M. Taylor, Tetra Engineering Group, Inc., 2006. "Computer Simulation of HRSGs Can Improve O&M", J.W. Malloy, C. Daublebsky, M. Taylor, Power Magazine, Jun 1 , 2009 Patents: US Patent 5,044,992, Sept 3, 1991, "Printed circuit injection molded connector with removable bifurcated contacts capable of high temperature exposure" (assigned to Raytheon Co.)

Design, Operation and Maintenance of Heat Recovery Steam Generator (HRSG)

21 -23 May 2012, Kuala Lumpur

REGISTRATION FORM Early Bird Ends 31 Mar2012 Normal Savings 4 ways to Register Online: www.poweredgeasia.com Email: info@poweredgeasia.com Phone: (65) 6741 9927 Fax: (65) 67478737

3 Day Programme

SGD $3900

SGD $4199

SGD $200

ATTENDEE DETAILS Name .................................................................................................. Job title ................................................................................................ Tel ....................................................................................................... Email ...................................................................................................

You may also be interested in

Introduction To Clean

Coal Technology

Name .................................................................................................. Job title ................................................................................................ Tel ....................................................................................................... Email .................................................................................................... . Name .................................................................................................. Job title ................................................................................................ Tel ....................................................................................................... Email ....................................................................................................

Circulating Fluidized

Bed Boiler

LNG Fundamentals Fundamentals of Power

Generation

Name .................................................................................................. Job title ................................................................................................ Tel ....................................................................................................... Email ....................................................................................................

OFFER EXPIRES 30th Mar 2012 Send 2 team mates and the 3rd attends for free

Name .................................................................................................. Job title ................................................................................................ Tel ....................................................................................................... Email .................................................................................................... COMPANY DETAILS Organisation name ...............................................................................Industry ................................................................................................ Address ............................................................................................................................................................................................................... Postcode ............................................................................................... Country ............................................................................................... Tel ..........................................................................................................Fax .......................................................................................................

PAYMENT METHODS By Cheque/ Bank Draft: Make Payable to Asia Edge Pte. Ltd. By Direct Transfer: Please quote AE1 with the remittance advise Account Name: Asia Edge Pte. Ltd. Bank Number: 508 Account Number: 762903-001Swift Code: OCBCSGSG All bank charges to be borne by payer. Please ensure that Asia Edge Pte Ltd receive the full invoiced amount. PAYMENT POLICY Payment is due in full at the time of registration. Full payment is mandatory for event attendance. I agree to Asia Edge Pte Ltd. payment terms CANCELLATIONS & SUBSTITUTIONS You may substitute delegates at any time. ASIA EDGE PTE LTD does not provide refunds for cancellations. For cancellations received in writing more than seven (7) days prior to the training course you will receive a 100% credit to be used at another ASIA EDGE PTE LTD training course for up to one year from the date of issuance. For cancellations received seven (7) days or less prior to an event (including day 7), no credits will be issued. In the event that ASIA EDGE PTE LTD cancels an event, delegate payments at the date of cancellation will be credited to a future ASIA EDGE PTE LTD event. This credit will be available for up to one year from the date of issuance. In the event that ASIA EDGE PTE LTD postpones an event, delegate payments at the postponement date will be credited towards the rescheduled date. If the delegate is unable to attend the rescheduled event, the delegate will receive a 100% credit

In House Solution

Save Up to 20% When you bring this training to your site. To find out more call 65791288

Potrebbero piacerti anche

- Thermal Power PlantsDocumento278 pagineThermal Power PlantskumarkaulNessuna valutazione finora

- Number of Units 1. HRSG System SummaryDocumento2 pagineNumber of Units 1. HRSG System SummaryShameer Majeed. ANessuna valutazione finora

- Hrsgs Behind FR 9E GTS: (123.4 MW Iso)Documento20 pagineHrsgs Behind FR 9E GTS: (123.4 MW Iso)api-19986783100% (1)

- Extending the Range of Single-Shaft Combined Cycle Power PlantsDocumento12 pagineExtending the Range of Single-Shaft Combined Cycle Power PlantsSrinivasa Rao PallelaNessuna valutazione finora

- HRSG 01 Basic DesignDocumento40 pagineHRSG 01 Basic DesignPremadi SetyokoNessuna valutazione finora

- Coal Based Power PlantDocumento41 pagineCoal Based Power Plant94gaurav100% (1)

- HRSG Cycle EfficiencyDocumento4 pagineHRSG Cycle EfficiencySuzaimi Safei50% (2)

- Improve Power Plant Efficiency with Combined Cycle TechnologyDocumento28 pagineImprove Power Plant Efficiency with Combined Cycle Technologyscribdhas2006100% (1)

- Heat Recovery Steam Generator 5Documento29 pagineHeat Recovery Steam Generator 5Hitesh SinglaNessuna valutazione finora

- TurboDocumento8 pagineTurboKorichiKarimNessuna valutazione finora

- Coal Fired Power Plant Heat Rate ReductionDocumento48 pagineCoal Fired Power Plant Heat Rate Reductionraharjoitb0% (1)

- ABB+Marine WHRS+infographicDocumento1 paginaABB+Marine WHRS+infographicBenjamin StricklandNessuna valutazione finora

- A Systematic Approach To Rehabilitations in Power PlantsDocumento35 pagineA Systematic Approach To Rehabilitations in Power PlantsalifacebNessuna valutazione finora

- Once Through BoilerDocumento9 pagineOnce Through Boilerbhuvi_patu12Nessuna valutazione finora

- CEP - SavingDocumento6 pagineCEP - SavingManoj UpadhyayNessuna valutazione finora

- 3.2 Big Block Assembly 3.2.1 Work Shop Assembly Pre-RequisitionsDocumento14 pagine3.2 Big Block Assembly 3.2.1 Work Shop Assembly Pre-RequisitionsEur-Ing Nicola GalluzziNessuna valutazione finora

- Power Plant Performance AnalyticsDocumento30 paginePower Plant Performance AnalyticsMunibNessuna valutazione finora

- CCGT Tender SpecDocumento162 pagineCCGT Tender Specmaverik29Nessuna valutazione finora

- 660 MW Sipat BoilerDocumento88 pagine660 MW Sipat BoilerTochi Krishna Abhishek100% (4)

- Thermal Power Plants IEE Checklist FormatDocumento17 pagineThermal Power Plants IEE Checklist FormatAlathea DonneNessuna valutazione finora

- An Overview of Combined Cycle Power Plant - EEPDocumento12 pagineAn Overview of Combined Cycle Power Plant - EEPrereilham100% (1)

- Shuaiba North HRSG ManualDocumento91 pagineShuaiba North HRSG Manualmartinp17171100% (7)

- HRSG StartupDocumento19 pagineHRSG Startuptpplant100% (1)

- Steam Line Blowing Procedure GeneralDocumento5 pagineSteam Line Blowing Procedure GenerallovegrkNessuna valutazione finora

- Gravimetric Feeder For Pulvurised FuelDocumento2 pagineGravimetric Feeder For Pulvurised FuelVijay KumarNessuna valutazione finora

- 3641-Ge Frame 9e Turbines PDFDocumento5 pagine3641-Ge Frame 9e Turbines PDFKorichiKarimNessuna valutazione finora

- SATIP-ME-2002 HRSG Installation Rev 5Documento6 pagineSATIP-ME-2002 HRSG Installation Rev 5zhang100% (1)

- Combined CycleDocumento34 pagineCombined Cycleatulsemilo100% (2)

- CEP SamalkotDocumento96 pagineCEP SamalkotkukugargNessuna valutazione finora

- Mechanical Engineering Project - Thermal Power Plant Study - WWW - Amie.nbcafe - inDocumento24 pagineMechanical Engineering Project - Thermal Power Plant Study - WWW - Amie.nbcafe - inbtdoss72100% (1)

- At M/S Jindal Steel &power Limited: For More ProjectsDocumento26 pagineAt M/S Jindal Steel &power Limited: For More ProjectsvasqueznvNessuna valutazione finora

- Introduction To Combined Cycle Power PlantDocumento4 pagineIntroduction To Combined Cycle Power PlantKelvin Liew100% (1)

- Heat Balance & Thermal Power Plant Performance (MDT)Documento44 pagineHeat Balance & Thermal Power Plant Performance (MDT)Anita BaitadeNessuna valutazione finora

- An Overview of Combined Cycle Power PlantDocumento71 pagineAn Overview of Combined Cycle Power PlantDreamie Blue100% (2)

- Energy Management System For Combined Cycle Power Plant TrainingDocumento4 pagineEnergy Management System For Combined Cycle Power Plant Trainingglenlcy100% (1)

- CCPP Plant Operating ProceduresDocumento123 pagineCCPP Plant Operating Proceduressprotkar100% (5)

- Power PlantDocumento42 paginePower Planthaitham1995Nessuna valutazione finora

- Duties & Responsibilities of Shift EngineerDocumento35 pagineDuties & Responsibilities of Shift EngineerNaveen ChodagiriNessuna valutazione finora

- Chemical Cleaning of Boiler Pressure Parts As TheDocumento57 pagineChemical Cleaning of Boiler Pressure Parts As TheAnonymous 1OmAQ0u3Nessuna valutazione finora

- Toshiba Power PlantDocumento24 pagineToshiba Power PlantMac Gerald Alindong100% (2)

- HRSG StartupDocumento20 pagineHRSG StartupKvvPrasad100% (1)

- Gas Turbine Performance CalculationDocumento7 pagineGas Turbine Performance CalculationAtiqur RahmanNessuna valutazione finora

- Thermax HRSGDocumento12 pagineThermax HRSGrevenk100% (1)

- Commissioning Steps Power Plant Under 40Documento3 pagineCommissioning Steps Power Plant Under 40ssheart_mind100% (1)

- How To Calculate Overall Thermal Efficiency of Combined Cycle Power PlantsDocumento10 pagineHow To Calculate Overall Thermal Efficiency of Combined Cycle Power PlantsManoj SharmaNessuna valutazione finora

- Power PlantDocumento11 paginePower Plantarvidkumar87060Nessuna valutazione finora

- How To Start Combined Cycle Power PlantDocumento37 pagineHow To Start Combined Cycle Power PlantBv Rao100% (1)

- BHEL Training Report on Mechanical Department ProjectsDocumento118 pagineBHEL Training Report on Mechanical Department ProjectsNitish KumarNessuna valutazione finora

- CCPP Operation ManualDocumento21 pagineCCPP Operation ManualEgit Bobyarta100% (5)

- Materials Report EPRI 2006 MANY Links NNBDocumento27 pagineMaterials Report EPRI 2006 MANY Links NNBAnonymous nw5AXJqjdNessuna valutazione finora

- Fire Ge Call2Documento7 pagineFire Ge Call2utsav mannuNessuna valutazione finora

- Energy Management Program Draft 10 01Documento7 pagineEnergy Management Program Draft 10 01job_openings4094Nessuna valutazione finora

- EpriDocumento15 pagineEprialkadyasNessuna valutazione finora

- Fundamentals of Supercritical Coal PowerDocumento7 pagineFundamentals of Supercritical Coal PowerEngr Imtiaz Hussain GilaniNessuna valutazione finora

- Grid Connected Converters: Modeling, Stability and ControlDa EverandGrid Connected Converters: Modeling, Stability and ControlNessuna valutazione finora

- Real-Time Simulation of More-Electric Aircraft Power SystemsDocumento11 pagineReal-Time Simulation of More-Electric Aircraft Power SystemscoralonsoNessuna valutazione finora

- Combined Cycle Power Plant Fundamentals: CourseDocumento7 pagineCombined Cycle Power Plant Fundamentals: CourseArun KumarNessuna valutazione finora

- Combined-Cycle Gas and Steam Turbine Power Plant Reliability AnalysisDocumento27 pagineCombined-Cycle Gas and Steam Turbine Power Plant Reliability Analysistwana najih hassanNessuna valutazione finora

- Polymer Electrolyte Fuel Cell DegradationDa EverandPolymer Electrolyte Fuel Cell DegradationMatthew M. MenchNessuna valutazione finora

- Energies 14 08521Documento14 pagineEnergies 14 08521PRASSAN SHAHNessuna valutazione finora

- Influence of Welding Procedure On Cast Steel Shackle PDFDocumento8 pagineInfluence of Welding Procedure On Cast Steel Shackle PDFbhp_4677Nessuna valutazione finora

- Exploring Temper Bead Welding TechniquesDocumento11 pagineExploring Temper Bead Welding TechniquesvaseaNessuna valutazione finora

- Thermal Degradation of Polymers at High TemperaturesDocumento8 pagineThermal Degradation of Polymers at High Temperaturesbhp_4677Nessuna valutazione finora

- Inclusions in SteelDocumento2 pagineInclusions in SteelJim ToddNessuna valutazione finora

- Dragline Maintenance PlanDocumento71 pagineDragline Maintenance Planbhp_467775% (4)

- Method Statement To Repair CrackDocumento11 pagineMethod Statement To Repair Cracklaz_kNessuna valutazione finora

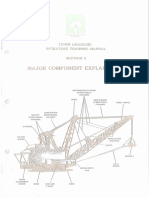

- Bucyrus 1370W Dragline Major ComponentsDocumento27 pagineBucyrus 1370W Dragline Major Componentsbhp_4677Nessuna valutazione finora

- The Control of Non-Metallic Inclusions in Cast SteelDocumento57 pagineThe Control of Non-Metallic Inclusions in Cast Steelbhp_4677Nessuna valutazione finora

- The Control of Non-Metallic Inclusions in Cast SteelDocumento57 pagineThe Control of Non-Metallic Inclusions in Cast Steelbhp_4677Nessuna valutazione finora

- Dragline Wire Rope InspectionDocumento12 pagineDragline Wire Rope Inspectionbhp_4677Nessuna valutazione finora

- Example BDocumento37 pagineExample Bbhp_4677Nessuna valutazione finora

- Narrative ThreeDocumento5 pagineNarrative Threebhp_4677Nessuna valutazione finora

- Elemental Map of Fe, C, Mn, O, Mg, Cl, S, ZnDocumento1 paginaElemental Map of Fe, C, Mn, O, Mg, Cl, S, Znbhp_4677Nessuna valutazione finora

- Maemo - I - Introduction To MaemoDocumento15 pagineMaemo - I - Introduction To MaemoCatalin ConstantinNessuna valutazione finora

- Mip-191bm72b Lab ManualDocumento51 pagineMip-191bm72b Lab ManualShay Patrick CormacNessuna valutazione finora

- Anson Ortigas FPS Sell-Out Report Week 2 JuneDocumento30 pagineAnson Ortigas FPS Sell-Out Report Week 2 JuneRevssor PeraltaNessuna valutazione finora

- Aethra BG1220Documento2 pagineAethra BG1220Priscila Vanegas100% (1)

- VLSI DESIGN Lab Manual Verilog+l-EditDocumento55 pagineVLSI DESIGN Lab Manual Verilog+l-Editmario sanchezNessuna valutazione finora

- DIGITUS DA-10287 Bluetooth Speaker ManualDocumento7 pagineDIGITUS DA-10287 Bluetooth Speaker Manualbuns301Nessuna valutazione finora

- Guidance Document Verification For TMHS ManufacturersDocumento25 pagineGuidance Document Verification For TMHS ManufacturersNurul amirahNessuna valutazione finora

- Real Time Operating Systems: Programme Elective - IIDocumento66 pagineReal Time Operating Systems: Programme Elective - IIDr D S Naga Malleswara RaoNessuna valutazione finora

- 1 Essay Tu Viet LaidocxDocumento2 pagine1 Essay Tu Viet LaidocxLy Ngoc Thanh B1906074Nessuna valutazione finora

- Public Health Engineering Department, Haryana Public Health Engineering Division No.2, Panipat Notice Inviting TenderDocumento17 paginePublic Health Engineering Department, Haryana Public Health Engineering Division No.2, Panipat Notice Inviting Tenderpmcmbharat264Nessuna valutazione finora

- Advanced Security Audit Policy Step-By-Step GuideDocumento19 pagineAdvanced Security Audit Policy Step-By-Step GuideVictor CastroNessuna valutazione finora

- Diesel Generator Set QSK60 Series Engine: 1760kVA - 2500kVA 50 HZ 1825kW - 2250kW 60 HZDocumento4 pagineDiesel Generator Set QSK60 Series Engine: 1760kVA - 2500kVA 50 HZ 1825kW - 2250kW 60 HZ3efooNessuna valutazione finora

- MiCOM P132 - TechnicalDataSheetDocumento44 pagineMiCOM P132 - TechnicalDataSheetcatalinccNessuna valutazione finora

- Bluetooth - Based Lamp ControllerDocumento59 pagineBluetooth - Based Lamp Controllerbvkarthik2711Nessuna valutazione finora

- Speed Control of Ac Motor Using TriacDocumento40 pagineSpeed Control of Ac Motor Using Triacchanchal2100% (2)

- Bim Contract IssuesDocumento9 pagineBim Contract IssuesEl ZharNessuna valutazione finora

- BORUDocumento1 paginaBORUAshesh MistryNessuna valutazione finora

- Manual Kubota Serie Ed1105 - 30Documento2 pagineManual Kubota Serie Ed1105 - 30Alvaro Escalona GtzNessuna valutazione finora

- Multiplex Ticket Booking SystemDocumento23 pagineMultiplex Ticket Booking SystemMohit Kumar Lal100% (1)

- BASDocumento178 pagineBASclayjr70Nessuna valutazione finora

- Advanced Encryption Standards AES PPT by Alljobs - Co .InDocumento11 pagineAdvanced Encryption Standards AES PPT by Alljobs - Co .In2145 RAFIQ ALINessuna valutazione finora

- CC770Documento85 pagineCC770essax_ltdNessuna valutazione finora

- FANUC CNC Maintenance Manual SectionsDocumento2 pagineFANUC CNC Maintenance Manual Sectionsmcantraks17Nessuna valutazione finora

- Experimental Performance RubricsDocumento3 pagineExperimental Performance RubricsAhmed AliNessuna valutazione finora

- DFN Mitteilungen 84 PDFDocumento54 pagineDFN Mitteilungen 84 PDFzasdfNessuna valutazione finora

- Checklist 1 After Recon - Beginner Friendly ChecklistDocumento2 pagineChecklist 1 After Recon - Beginner Friendly Checklistsidhant TechNessuna valutazione finora

- Xenta 511Documento86 pagineXenta 511Lucky Karunia Setyawan PratamaNessuna valutazione finora

- 1992 Toyota Previa Electrical DiagramDocumento175 pagine1992 Toyota Previa Electrical DiagramTam DominhNessuna valutazione finora

- Huaqin NB3029 (S560-16ACN)Documento89 pagineHuaqin NB3029 (S560-16ACN)Marko MatićNessuna valutazione finora

- Unit 2adtnotesDocumento74 pagineUnit 2adtnotesJobi VijayNessuna valutazione finora