Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Unit3 Binary Rectification 1

Caricato da

Sem FilioDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Unit3 Binary Rectification 1

Caricato da

Sem FilioCopyright:

Formati disponibili

8/15/2011

Whats Showing?

The McCabe-Thiele Graphical Method

Episode 1

Application to Binary Rectification

Rewind of the McCabe Thiele Method Special Clip on Binary Rectification Rectification and Stripping in Plates Drama of the Rectifying and Stripping Sections Intrigues of the Feed Plate Putting our Act Together to Determine the Number of Ideal Plates

The McCabe-Thiele Method A Rewind

It is a graphical method for solving

Binary Rectification

This is a distillation application to a

multistage applications. It assumes constant molal overflow from each stage. Like the Kremser Equation, the M-T Method assumes that some constant rates exist in the flow. However, the equilibrium relation for the system is not linear.

binary system where a fractionating column is used. A Reflux Rate from a Condenser and a Boil-up Rate from a Reboiler generate the liquid and vapor flows through several contact plates. The Feed is introduced in a proper plate; the section above the feed is called the Rectifying Section; below it is the Stripping Section.

8/15/2011

TC Reflux Rectifying Section Feed

Total Condenser

Visualization of the Column

Distillate

xD

xF

Stripping Section

A Simple Fractionating Column

V L

Boil-up

PR Partial Reboiler

Bottoms

B xB

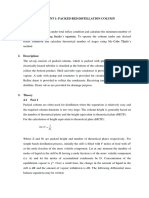

Plate Analysis

Plates are numbered serially from

Plate Analysis

n-1 n n+1

top to bottom.

The McCabe-Thiele Method

assumes that the liquid and vapor flows from each plate are constant in each section. For Rectifying Section: L & V For Stripping Section: L & V

8/15/2011

Plate Analysis

As contact between liquid and vapor

Plate Analysis

This means that the MVC fraction in

occurs in each plate, the vapor becomes richer in MVC; while MVC is removed from the liquid. Rectification - enrichment of the vapor with MVC Stripping- removal of MVC from the liquid

the vapor (y) increases from bottom to top and the MVC fraction in the liquid (x) decreases from top to bottom. The plate temperature (T) increases from top to bottom.

Plate Analysis

n-1

yn xn-1

Equilibrium Data

Binary Equilibrium Data Sources Handbook Distillation Section Ideal System A plot of y versus x equilibrium data is needed. A diagonal (x = y) plot is also drawn for use in the McCabe-Thiele Method.

T T

yn+1 xn

n-1

n n+1

n+1

8/15/2011

Methanol -Water Equilibrium Data

1 1

Analysis of the Rectifying Section

V TC Reflux L Total Condenser

0.8

Distillate

xD

0.6

n V L x n Material Balances: Stream Balance: V = L + D

0.4

y n+1

0.2

MVC Balance: V y = L x + D x n D n+1 y n+1 = L V x n + D V x D Rectifying Line Equation

0 0 0 0.2 0.4

0.6

0.8

1 1

Analysis of the Rectifying Section

y n+1 = L V x n + D V x D L V But: V = L + D L V R D R + D 1 R D R + D 1 Let: RD D V = L D Reflux Ratio 1 = R + D x x n + D 1 1 Rectifying Line Equation

Analysis of the Rectifying Section

y n+1 = R D R + D 1 R D R + D 1 x x n + D 1

The RLE is a straight line with slope:

R + D x D 1

Slope =

Y-Intercept =

R + D

Diagonal (x=y) Analysis: If x = y , then x = x D This means that the RL will intersect the diagonal when x = x D

y n+1 =

R + D

Another Form of the RLE

8/15/2011

Analysis of the Rectifying Section

Procedure To Plot the Rectifying Line:

0.8

RL

1. Given the Reflux Ratio and Distillate Composition, calculate the y-intercept of the RL. 2. Plot xD in the diagonal. 3. Connect xD in the diagonal with the y-intercept.

0.6 y d

Y-int

i 0.4

Example: Given a Distillate with 90 mole% Methanol, 10 mole% Water and a Reflux Ratio of 0.8. x x R = 0.8 D D = 0.9 D = 0.5 R + 1 D

0.2

0 0

0.2

0.4 x i

0.6

0.8

xD

1 1

Analysis of the Stripping Section

y m m V L V L x m-1 Material Balances: Stream Balance: L = V + B B

Analysis of the Stripping Section

y m = L V x B m-1 V L V Note that the Y-intercept of the SLE is negative. x B

V = L -

The SLE is a straight line with slope:

PR

Bottoms

Partial Reboiler MVC Balance: L V L x m-1 = V y + m B m-1 V x

B xB

B x B

Diagonal (x=y) Analysis: If x = y , then x = x B This means that the SL will intersect the diagonal when x = xB

y m

Stripping Line Equation

To plot easier the SL, another straight line equation may be derived by combining the RLE and SLE. This is the Feed Line Equation (FLE).

8/15/2011

Analysis of the Feed Plate

Analysis of the Feed Plate

Feed

L Feed

Let q = mole of liquid contributed by 1 mole of feed to the Stripping Section 1 - q = mole of vapor contributed by 1 mole of feed to the Rectifying Section

Therefore:

L V

= =

L + q F V + (1 - q) F

Derivation of the Feed Line Equation

From the RLE: From the SLE: Subtracting: V y = L x + D xD V y = L x - B xB Eqn A

Derivation of the Feed Line Equation

y = q (q - 1) x + xF (1- q) q (q - 1)

(V - V) y = (L - L) x + D xD + B xB

The FLE is also a straight line with slope: Diagonal (x=y) Analysis: If x = y , then x = xF

Also the Over-all MVC Balance is:

F xF = D xD + B xB

From the Analysis of the Feed Plate: (V - V) = (1 - q) F Eqn A therefore becomes: y = q (q - 1) -q (1- q) x + and (L - L) = -q F (1 - q) F y = -q F x + F xF x + xF (1- q) xF (1- q) Feed Line Equation

This means that the FL will intersect the diagonal when x = xF

Since the FLE is derived from the RLE and SLE, this means that the three lines intersect. Thus the SL should pass the intersection of the RL and FL. NOTE: THE VALUE OF q DEPENDS ON THE TYPE OF FEED.

8/15/2011

Types of Feed

Saturated Liquid F V L

Types of Feed

Saturated Vapor F V L

Feed q=1

Feed V L q=0

+ F

V + F

Slope of the Feed Line is Infinity.

Slope of the Feed Line is Zero.

Types of Feed

Wet Mixture F V L

Types of Feed

Subcooled Liquid F V L

Feed

Feed V L q>1

0<q<1

V =

V + (1 - q) F

= L +qF

V <

L +qF

Slope of the Feed Line is Negative.

Slope of the Feed Line is Positive.

8/15/2011

Types of Feed

Superheated Vapor F V L

Plotting of the Feed Line

1. Plot xF in the Diagonal. 2. Knowing the type of feed, calculate the Slope of the Feed Line = q (q - 1)

Feed q<0

L 3. From xF in the Diagonal, draw a straight line with the calculated slope.

V =

V + (1 - q) F

<

Slope of the Feed Line is Positive.

0.8

Feed Line for Subcooled Liquid

Feed Line for Saturated Liquid

0.8

0.6 y d i i 0.4 y d i i

0.6

0.4

0.2

0.2

0 0 0 0.2 0.4

xF

x i

0 0 0 0.2 0.4

0.6

0.8

1 1

xF

x i

0.6

0.8

1 1

8/15/2011

0.8

Feed Line for Wet Mixture

0.8

Feed Line for Saturated Vapor

0.6 y d i i 0.4 y d i i

0.6

0.4

0.2

0.2

0 0 0 0.2 0.4

xF

x i

0 0 0 0.2 0.4

0.6

0.8

1 1

xF

x i

0.6

0.8

1 1

Feed Line for Superheated Vapor

0.8

Plotting of the Stripping Line

0.6 y d i i 0.4

1. Plot the Rectifying Line. 2. Plot the Feed Line. 3. Plot xB in the Diagonal. 4. From xB in the Diagonal, draw a straight line passing through the intersection of the Rectifying and Feed Lines.

0.2

0 0 0 0.2 0.4

xF

x i

0.6

0.8

1 1

8/15/2011

Determination of the Number of Ideal Stages

0.8

0.6 y d i i 0.4

Example: A saturated liquid mixture of 50% methanol, 50% water by mole will be distilled in a column using a total condenser and partial reboiler. The distillate is to contain 90 mole% methanol while the bottoms shall have 5 mole% methanol. Reflux Ratio is 0.8. Using a Feed Rate of 100 Moles/hr and the McCabe-Thiele Method, determine: a) Molal Rates of Liquid and Vapor in RS and SS b) Number of Ideal Plates Needed c) Mole % Methanol in L & V from each plate d) Location of the Feed Plate

0.2

0 0 0

xB

0.2

0.4

xF

x i

0.6

0.8

xD

1 1

Determination of the Number of Ideal Stages

Given: F = 100 moles/hr xF = 0.5 q = 1 xD = 0.9 xB = 0.05 Rd = 0.8 Required: a) L, V in RS & SS b) No. of ideal plates c) y and x from each plate Solution: V = L + D Rd = L/D = 0.8 V = (Rd + 1)D F = D + B = 100 F xF = D xD + B xB D = 52.9412 L = 42.3529 V = 95.2941 = V L = L + F = 142.3529

Determination of the Number of Ideal Stages

Procedure to Get No. of Ideal Stages: 1. Plot the RL, FL, and SL. 2. From xD in the diagonal, draw triangular steps using the EL and RL alternately. 3. Shift to the SL once the intersection of the RL and FL is reached or passed by. 4. Continue drawing the triangular steps until xB is reached or passed by. 5. Number of Ideal Stages = No. of Steps Number of Ideal Plates = No. of Steps - 1 since the Partial Reboiler is an Ideal Stage

10

8/15/2011

Determination of the Number of Ideal Stages

0.8

TC V y1 Reflux

Total Condenser

0.6 y d i i 0.4

1 y2 x1

L xo

D

y1 = xo = xD

xD

(X1, y1) - equilibrium composition

0.2

Analysis of the First Plate

0 0 0 0

xB

0.2

0.4

xF

x i

0.6

0.8

xD

1 1

Drawing the First Plate

1 1 1 1

Locating the Feed Plate

y1 y2

0.8

0.8

0.6 y d y i d i 0.4 i i

0.6

0.4

0.2

0.2

0 0 0 0

0 0 0

xB

0.2

0.4

xF

x i

0.6

x1

0.8

1 1

xD

xB

0.2

0.4

xF

x i

0.6

0.8

1 1

xD

11

8/15/2011

Shifting to the Stripping Section

1 1 1 1

Completing All the Ideal Stages

0.8 0.8

0.6 y d i i 0.4 y d i i 0.4 0.6

0.2 0.2

0 0 0

xB

0.2

0.4

xF

x i

0.6

0.8

1 1

xD

0 0 0 0

xB

0.2

0.4

xF

x i

0.6

0.8

1 1

xD

Determination of Plate Compositions and Feed Plate Location

To Get the Liquid and Vapor Compositions from Each Plate: Using the EL, read the x and y values for each step corresponding to a plate. To Locate the Feed Plate: Locate the step that crosses over the intersection of the RL and FL. This corresponds to the feed plate.

1 2

0.8

3 4

0.6 y d i i 0.4

0.2

PR

0 0 0

xB

0.2

0.4

xF

x i

0.6

0.8

xD

1 1

12

Potrebbero piacerti anche

- Distillation PresentationDocumento61 pagineDistillation PresentationAli AmjadNessuna valutazione finora

- The Mccabe-Thiele Method: Stream Total Molar Flowrate Composition (Mole Fraction MVC) V YDocumento10 pagineThe Mccabe-Thiele Method: Stream Total Molar Flowrate Composition (Mole Fraction MVC) V YRose Dane Escobedo DiestaNessuna valutazione finora

- CH3802 Formal DistillationDocumento33 pagineCH3802 Formal DistillationAldi StefanusNessuna valutazione finora

- McCabe-Thiele Method 1Documento37 pagineMcCabe-Thiele Method 1HariKrishnaBushi100% (2)

- Types DistillationDocumento81 pagineTypes Distillationhet sevakNessuna valutazione finora

- Mccabe ThieleDocumento15 pagineMccabe ThieleChintan ModiNessuna valutazione finora

- MC CabeDocumento18 pagineMC CabeSata AjjamNessuna valutazione finora

- Continuous DistillationDocumento29 pagineContinuous DistillationSAI P HARIHARAN 19BCM0030Nessuna valutazione finora

- Distillation L5Documento25 pagineDistillation L5Shiavm PatelNessuna valutazione finora

- Mc-Cabe Thiele MethodDocumento23 pagineMc-Cabe Thiele MethodSyauqi Subri100% (2)

- Distillation Problem 4: Fig. 1: Flow Sheet For Distillation ColumnDocumento2 pagineDistillation Problem 4: Fig. 1: Flow Sheet For Distillation Columnshan02140% (1)

- Jawaharlal Nehru Technological University Kakinada: III Year B. Tech. Petrochemical Engineering II SemDocumento37 pagineJawaharlal Nehru Technological University Kakinada: III Year B. Tech. Petrochemical Engineering II SemHashmi AshmalNessuna valutazione finora

- Chap4 4 PDFDocumento8 pagineChap4 4 PDFroxetteNessuna valutazione finora

- Mass and Energy Balances - Stripping Section and Partial ReboilerDocumento45 pagineMass and Energy Balances - Stripping Section and Partial ReboilerShamsMohd100% (1)

- Ch4 DesignDocumento72 pagineCh4 DesignGebrekiros ArayaNessuna valutazione finora

- TutorialDocumento40 pagineTutorialShamsMohd100% (1)

- Cab2054 L1 Absorption and StrippingDocumento61 pagineCab2054 L1 Absorption and StrippingAzmi Musa100% (1)

- Distillation Design The Mccabe-Thiele MethodDocumento24 pagineDistillation Design The Mccabe-Thiele MethodNagwa MansyNessuna valutazione finora

- Distillation Continued: V Moles Per HourDocumento12 pagineDistillation Continued: V Moles Per HourronaldNessuna valutazione finora

- Continuous Column DistillationDocumento58 pagineContinuous Column DistillationDavion StewartNessuna valutazione finora

- 3G4 Distillation CalculationsDocumento22 pagine3G4 Distillation CalculationsMahmoud Nasr0% (1)

- Total Reflux. in Design Problems, The Desired Separation Is Specified and A Column IsDocumento8 pagineTotal Reflux. in Design Problems, The Desired Separation Is Specified and A Column IsmantascitaNessuna valutazione finora

- 221 06Documento25 pagine221 06Fransiscus Leo ChandraNessuna valutazione finora

- 120712ChE128 7 LiqLiq ExtractDocumento39 pagine120712ChE128 7 LiqLiq ExtractPhuong PhamNessuna valutazione finora

- Mccabe Thiele MethodDocumento3 pagineMccabe Thiele Methodmusmanzafar100% (1)

- Unit Operation Ii: Operations, Prentice Hall, 1993Documento40 pagineUnit Operation Ii: Operations, Prentice Hall, 1993esiri aluyaNessuna valutazione finora

- Continous Distillation ColumnDocumento58 pagineContinous Distillation ColumnGeorge MarkasNessuna valutazione finora

- Mccabe ThieleDocumento63 pagineMccabe ThieleAshlesh MangrulkarNessuna valutazione finora

- 120712ChE128 4 ColumnDistDocumento58 pagine120712ChE128 4 ColumnDistJunaid AhmadNessuna valutazione finora

- Lab ManualDocumento59 pagineLab ManualmarkNessuna valutazione finora

- DistillationTheory 1Documento21 pagineDistillationTheory 1Prashant KumarNessuna valutazione finora

- Ideal LeachingDocumento15 pagineIdeal LeachingSata AjjamNessuna valutazione finora

- DistillationDocumento29 pagineDistillationgebremichaelNessuna valutazione finora

- Chapter 3Documento26 pagineChapter 3Zahoor Hussain Rana73% (11)

- Distillation Course Notes 2021Documento17 pagineDistillation Course Notes 2021SNessuna valutazione finora

- Menghitung Jumlah Plate PDFDocumento12 pagineMenghitung Jumlah Plate PDFUtari NuravifahNessuna valutazione finora

- Distillation: By: In. Nurul Hasyimah Mohd AminDocumento60 pagineDistillation: By: In. Nurul Hasyimah Mohd Aminmsa_adonNessuna valutazione finora

- Continuous Distillation Practice 1Documento35 pagineContinuous Distillation Practice 1Najmul Puda PappadamNessuna valutazione finora

- Liquid Liquid ExtractionDocumento40 pagineLiquid Liquid ExtractionMahder Seifu100% (1)

- CHEE 310 Distillation 2020 Side StreamDocumento26 pagineCHEE 310 Distillation 2020 Side StreamTSHEGOFATSO GOTSILENGNessuna valutazione finora

- McCabe Thiele MethodDocumento58 pagineMcCabe Thiele MethodABPNessuna valutazione finora

- Sieve Tray ColumnDocumento18 pagineSieve Tray ColumnDonsius MarbunNessuna valutazione finora

- Con Duc To Me TryDocumento5 pagineCon Duc To Me TryNareshmurty NareshNessuna valutazione finora

- Chapter 1 IntroductionDocumento32 pagineChapter 1 IntroductionaradayNessuna valutazione finora

- Lab ManualDocumento58 pagineLab ManualAkhil KumarNessuna valutazione finora

- Chemical Engineering - Separations 5 Residue Curve Maps: ξ, suchDocumento4 pagineChemical Engineering - Separations 5 Residue Curve Maps: ξ, suchchikukotwal100% (1)

- AbsorptionStripping PDFDocumento25 pagineAbsorptionStripping PDFJuan Camilo HenaoNessuna valutazione finora

- 4444444Documento11 pagine4444444jayesh newalNessuna valutazione finora

- Operational Calculus in Two Variables and Its ApplicationsDa EverandOperational Calculus in Two Variables and Its ApplicationsNessuna valutazione finora

- Hypoelliptic Laplacian and Orbital Integrals (AM-177)Da EverandHypoelliptic Laplacian and Orbital Integrals (AM-177)Nessuna valutazione finora

- The Spectral Theory of Toeplitz Operators. (AM-99), Volume 99Da EverandThe Spectral Theory of Toeplitz Operators. (AM-99), Volume 99Nessuna valutazione finora

- Working Guide to Vapor-Liquid Phase Equilibria CalculationsDa EverandWorking Guide to Vapor-Liquid Phase Equilibria CalculationsValutazione: 5 su 5 stelle5/5 (1)

- Discrete Mechanics: Concepts and ApplicationsDa EverandDiscrete Mechanics: Concepts and ApplicationsNessuna valutazione finora

- Analysis and Design of Multicell DC/DC Converters Using Vectorized ModelsDa EverandAnalysis and Design of Multicell DC/DC Converters Using Vectorized ModelsNessuna valutazione finora

- Applications of Derivatives Rate of Change (Calculus) Mathematics Question BankDa EverandApplications of Derivatives Rate of Change (Calculus) Mathematics Question BankNessuna valutazione finora

- Use of Logarithmic Strains To Evaluate "True" Cauchy Stresses in Finite Deformation ProblemsDocumento14 pagineUse of Logarithmic Strains To Evaluate "True" Cauchy Stresses in Finite Deformation ProblemsIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNessuna valutazione finora

- Math Olympiad Reviewer Grade 6Documento7 pagineMath Olympiad Reviewer Grade 6Benz DyNessuna valutazione finora

- A Comparing Collaborative Filtering and Hybrid Recommender System For E-CommerceDocumento6 pagineA Comparing Collaborative Filtering and Hybrid Recommender System For E-CommerceIJRASETPublicationsNessuna valutazione finora

- Electric Field and Potential Lab ReportDocumento6 pagineElectric Field and Potential Lab ReportAudio books LibraryNessuna valutazione finora

- Pipe-Soil Interaction On A Normally Consolidated Clay SeabedDocumento24 paginePipe-Soil Interaction On A Normally Consolidated Clay SeabedJacob PhilipNessuna valutazione finora

- LabVIEW ExercisesDocumento188 pagineLabVIEW Exercisesgurhan100% (1)

- 3D Spiral Staircase Calculator - Building Materials & Spiral Staircase Dimensions Calculator Online - Perpendicular - ProDocumento2 pagine3D Spiral Staircase Calculator - Building Materials & Spiral Staircase Dimensions Calculator Online - Perpendicular - Probharatheeeyudu100% (2)

- Exp 13 Unsteady Heat Transfer UnitDocumento12 pagineExp 13 Unsteady Heat Transfer UnitShounak Bhattacharya100% (1)

- Commutators in Quantum Mechanics PDFDocumento2 pagineCommutators in Quantum Mechanics PDFIsraelNessuna valutazione finora

- Class X English Maths Chapter17Documento16 pagineClass X English Maths Chapter17Deena SNessuna valutazione finora

- The Sine Rule Worksheet #01, Shape & Space Revision From GCSE Maths TutorDocumento2 pagineThe Sine Rule Worksheet #01, Shape & Space Revision From GCSE Maths TutorgcsemathstutorNessuna valutazione finora

- MATH 4 3rd Quarter Week 3 Day 1Documento14 pagineMATH 4 3rd Quarter Week 3 Day 1Fritz BalasabasNessuna valutazione finora

- Bs Math Thesis TopicDocumento8 pagineBs Math Thesis Topicafknjdsta100% (2)

- Notes For Students Xi (Programming and Computational Thinking) PDFDocumento106 pagineNotes For Students Xi (Programming and Computational Thinking) PDFsuryansh tyagi0% (2)

- Intro ML For QuantsDocumento51 pagineIntro ML For QuantsCoralieNessuna valutazione finora

- Duhok Polytechnic University Technical College of Engineering Highway and Bridge Subject: Calculus II Lecturer's Name: Abdulaziz RASHIDDocumento27 pagineDuhok Polytechnic University Technical College of Engineering Highway and Bridge Subject: Calculus II Lecturer's Name: Abdulaziz RASHIDJayHatNessuna valutazione finora

- Soldier Pile and Lagging Caltan 1990 Tedds CalcDocumento2 pagineSoldier Pile and Lagging Caltan 1990 Tedds CalcRJSQNessuna valutazione finora

- Investigation of Prediction Accuracy, Sensitivity, and Parameter Stability of Large-Scale Propagation Path Loss Models For 5G Wireless CommunicationsDocumento19 pagineInvestigation of Prediction Accuracy, Sensitivity, and Parameter Stability of Large-Scale Propagation Path Loss Models For 5G Wireless CommunicationsTommy AsselinNessuna valutazione finora

- Math Solution ManualDocumento46 pagineMath Solution ManualEdzae LilioNessuna valutazione finora

- Economic Growth (Weil - 2E) Solutions (Ch.1&3&8)Documento17 pagineEconomic Growth (Weil - 2E) Solutions (Ch.1&3&8)Hoo Suk HaNessuna valutazione finora

- Various A-Level Economics NotesDocumento7 pagineVarious A-Level Economics NotesYasheelNessuna valutazione finora

- G-Sonique Ultrabass MX44 VSTi v1.0 MERRY XMAS ASSiGN International Software Crack DownloadDocumento1 paginaG-Sonique Ultrabass MX44 VSTi v1.0 MERRY XMAS ASSiGN International Software Crack DownloadMegatore0% (1)

- Probability and Statistics Dr. Ishapathik Das, IIT TirupatiDocumento37 pagineProbability and Statistics Dr. Ishapathik Das, IIT TirupatiCS21B007 ASHU TIWARINessuna valutazione finora

- Production Forecasting For Unconventional ResourcesDocumento22 pagineProduction Forecasting For Unconventional Resourcessaladinayubi1234Nessuna valutazione finora

- Kubo Formulae For Second-Order Hydrodynamic CoefficientsDocumento4 pagineKubo Formulae For Second-Order Hydrodynamic CoefficientskayNessuna valutazione finora

- CE50P-2: Numerical Solution To Engineering ProblemsDocumento21 pagineCE50P-2: Numerical Solution To Engineering ProblemshgfhfghfghgNessuna valutazione finora

- 84 Picon NunezDocumento6 pagine84 Picon Nunez1940LaSalleNessuna valutazione finora

- Sanskrit Sample Paper For PHD at IIT BDocumento2 pagineSanskrit Sample Paper For PHD at IIT BShashankNessuna valutazione finora

- Mathematics in The Modern WorldDocumento24 pagineMathematics in The Modern WorldCadillac Cain80% (5)