Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Lean Manufacturing Financial Services

Caricato da

Durdana IrshadDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Lean Manufacturing Financial Services

Caricato da

Durdana IrshadCopyright:

Formati disponibili

Operations Council

Lean Manufacturing for Financial Services

Delivering Value by Eliminating Waste

Objective

Operations executives struggle to nd new ways to reduce cost while delivering high-quality service. Lean manufacturing concepts enable institutions to expand existing cost-reduction opportunities while simultaneously creating customer value. This study aims to help Operations executives: Identify at least 40% waste in their cost base; Apply Lean techniques and tools to reduce waste across Operations; Improve process ow by optimizing touch time and minimizing cycle time; and Embed Lean thinking in staff and the organization to drive sustainable transformation.

2006 Corporate Executive Board. All Rights Reserved.

Executive Summary

Understanding Leans Potential

Councils Denition of Lean Manufacturing

Lean Manufacturing is a production optimization methodology that relentlessly seeks out and eliminates activities that do not create value for customers (i.e., waste). Its outcomes are characterized by production systems that 1) minimize cycle times, 2) optimize touch times, and 3) generate continuous production ows.

40% of Operations Costs Are Wasteful Council research suggests that at least 40% of Operations expenses result from wasteful activities that add no value to the customer and therefore should be eliminated. The majority of these wasteful activities are caused by Operations executives managing increasingly complex service-fulllment processes that contain multiple handoffs and decision points. Work is more difcult to track and less tangible in a service environment, making hidden waste more prevalent. Furthermore, business stakeholders dene waste differently, resulting in institutions not measuring and reducing waste uniformly across the entire organization. Lean Adopters Identify More Waste and Operate More Efciently Lean institutions identify two times more cost-reduction opportunity than non-Lean adopters by seeking to eliminate non-value-added activities. Furthermore, Lean adopters operate more efciently, maintaining cost-efciency ratios that are considerably lower than the industry average. Lean Is Inexpensive and Generates Solid Returns Unlike other process improvement methodologies such as Six Sigma, Lean programs do not require signicant up-front capital investments or certication. Lean concepts are easy to apply given that they are, as one member stated, applied common sense. In addition, institutions leveraging Lean techniques report immediate results of 20% to 40% cost reduction in 12 to 18 months. Uncovering Customer Value by Challenging the Status Quo Lean empowers Operations executives and their staff to continuously challenge the status quo (e.g., reviewing legacy mandates and existing policies) to redene value according to customers. Rather than asking, How do I do this better? Lean adopters ask, Why do I do this at all? revealing unnecessary activities that should be removed to reduce cost and improve service. Lean Is Not a Fad While many nancial institutions remain skeptical about recent quality and process improvement methodologies, nancial institutions implementing Lean concepts demonstrate that Lean provides immediate and sizeable economic and service benets. A Council survey reveals that 38% of member institutions maintain formal Lean programs, many of which have been in place for at least two years.

vii

viii

Executive Summary (Continued)

Implementing Lean Manufacturing in Your Operations

Council research identies four core capabilities necessary to embed Lean in your organization

Capability #1: Value Skeptical Lens

Lean encourages Operations executives to identify and eliminate all activities that do not create value for the customer. Applying a value-skeptical lens to the internal process allows Operations executives to uncover hidden waste by challenging the status quo, and segmenting value and non-value-added activities as dened by the customer.

and leading institutions build these capabilities by establishing best practices that address four imperatives

Imperative #1: Take a Customers View of Waste

Precise Value Stream Mapping Page 65 To improve current processes quickly without sacricing quality, Merle Bank* leverages Lean tools including work study sheets and value stream maps to identify and quantify hidden waste. Merle prioritizes areas to reduce waste by ignoring legacy mandates and physical constraints.

Imperative #2: Run Operations Like a Factory Capability #2: Uninterrupted Operations Flow

Operations executives focus on making process activities ow efciently by optimizing touch time and minimizing cycle time. Making uninterrupted ow an operational goal embeds Lean efforts in day-to-day Operations and ensures they benet the customer and organization. Process Flow Visual Cues Page 87 Raven Bank* undertakes a Lean manufacturing initiative to remove paper-based waste and identify bottlenecks. Raven deploys visual cues to create a pull system to better manage capacity and balance workloads, ultimately reducing cycle times. Ofce to Factory Conversion Page 111 Akane Investments* deploys Lean/Six Sigma concepts to improve process ow by empowering employees and managers to proactively identify waste. Akane also collocates staff and improves capacity forecasting to reduce cycle time.

Imperative #3: Perfect Every Customer Interaction Capability #3: Link Customer Value to Employee Performance

Leading institutions understand the important link between customer value and employee behavior, and manage the variation of employee performance to drive customer satisfaction. Executives at these institutions strive to ensure that every customer interaction is performed awlessly and delivers precisely what the customer values. Automatic Contact Center Closed-Loop Process Page 145 By recording 100% of all customer interactions, Tima Insurance* uniquely understands the entire customer journey. Tima empowers each employee to self-assess and identify opportunities for improvement following customer interactions. Tima pinpoints discrete call representative behaviors that cause customer dissatisfaction and tailors coaching sessions to change individual staff behaviors and increase service quality.

Imperative #4: Make Change the Status Quo Capability #4: Sustainable Transformation

Leading institutions constantly adapt in response to changing customer needs. Establishing a culture where everyone, from the lowest level staff member to the CEO, is committed to the ideal of excellence and continuous improvement is a requisite to enable sustainable transformation efforts. Integrated Change Delivery Capability Page 171 Prudential plc embarks on a 1,000-day business transformation to rebuild its brand and regain customer trust. To drive its change efforts and ensure it delivers customer value, Prudential builds a dedicated business transformation capability driven by a QuarterMaster system and supported by a rigorous reporting structure.

* Pseudonym.

Executive Summary (Continued)

Tools to Implement Lean in Your Organization

This compilation of tools and frameworks aims to help Operations executives implement Lean concepts in their organizations. The tools on the left help eliminate process waste while the tools on the right aim to ensure sustainable transformation. It is our hope that Council members will reduce the need to reinvent the wheel by accessing each tool, template, or checklist needed, decreasing the time required to move a project from concept to completion.

Perfecting Processes Tools to reveal and reduce process waste

Perfecting People Tools to ensure sustainable transformation

Challenge

How do I assess my Lean status?

How do I see hidden waste?

How do I measure hidden waste?

How do I visually depict internal processes from a customers perspective?

How do I determine the best way to eliminate a non-valueadded activity?

How do I see impediments to process ow on the shop oor?

How do I ensure business units are prepared to execute change initiatives?

How do I ensure that business units implement change projects successfully?

How do I monitor and communicate change delivery progress?

How do I bring rigor to the project approval process?

Tool

Lean Diagnostic

Seven Wastes Table Label waste according to the seven waste categories.

Work Study Sheets Capture and measure the seven types of waste in each activity.

Value Stream Mapping Take a wingtipto-wingtip view of the process to uncover waste.

Waste Reduction Decision Tree Prioritize waste reduction tools to efciently and inexpensively eliminate waste.

Visual Cues Deploy inexpensive visual cues to make process ow visible.

Business Readiness Criteria Track core competencies to determine business units ability to successfully initiate change.

Change Absorption Assessment Take a forwardlooking view to evaluate business units ability to incorporate change initiatives.

Weekly Change Report Equip senior executives with actionable information and share it beyond the executive team.

Four-Step Governance Process Make trade-offs across project life cycle to ensure benets are realized.

Description

Determine areas to begin or extend Lean implementation.

Lean Manufacturing for Financial Services

60

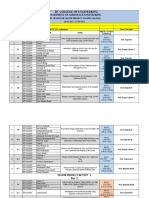

Overall BT Deliverables v Week Ending: 23/09/05

Lean Diagnostic : Perfecting Processes

Imperative #1 Take a Customers View of Waste

Complete Diagnostic Below 1. We distinguish between value and non-value-added activities. 2 . We maintain a library of wingtip-to-wingtip value stream maps for our core processes. 3. We expect to nd as much as 80 % waste in our processes. 4. We consistently challenge policy and external stakeholder requirements. 5. We employ metrics driven from the customers perspective. Total Score Suggested Action Steps Best Practice: Precise Value Stream Mapping

To label waste from a customers perspective, you should 1. Complete the Seven Wastes Table exercise with your team. p. 34 2. List 25 activities that customers do not value in a core process. p. 137 3. Use the Waste Reduction Tree to identify and eliminate waste. 4. Tour the shop oor of a manufacturing rm that has implemented Lean. To understand waste that is often neglected by traditional metrics, you should 5. Follow an item through a process from customer request to fulllment, and highlight non-value-added activities. 6. Organize a whiteboard exercise to map a wingtip-to-wingtip value stream. p. 77

Not a t All True A l wa y s True

Examples from Manufacturing

Scrap Rework Lost capacity due to mistakes

A l wa y s True

Type of Waste Defects

Examples from Financial Services

Errors and rework Work not meeting requirements Missing information Waiting for information, paperwork, and approval Equipment downtime Waiting time between batch processing Unnecessary steps Multiple hand offs Lack of standard procedures Walking to deliver paperwork Chasing needed information or data Lack of ergonomic work space design Doing more than is needed Too many reports, reviews, or approvals Batching paperwork Excessive backlog or work to be processed Too much paper to be handled, processed, and led Paper-based versus electronic data transfer Inefcient interofce mail systems Routing for unnecessary approvals and processing

Document Preparation Sort applications by complexity Distribute documents Scan documents Create loan document Create mortgage packet Collect documents from printer Take documents to checking bin Total Approve Term Loan Collect documents from in-box Audit buyer/seller agreements Complete transfer form Update document status Take documents to distribution box Total Packet Pulling Collect documents from in-box Search for documents Search for missing packet Take documents and packets to Quality Assurance Total

Distance Travelled (Yards)

Average Work Time (Mins)

Imperative # 2 Run Operations Like a Factory

Complete Diagnostic Below 1. We aim to optimize touch time and minimize cycle time for every process. 2 . We maintain visible workows by using visual cues that limit backlogs and bottlenecks. 3. We have empowered employees to proactively seek and reduce w a s te . 4. We successfully eliminate waste without signicant investment.

Not a t All True

Average Queue Time (Mins) 20 15

Summary

Go Live

Operational Considerations

Recruitment

Training

Partner Requirements

Management Information

Marketing

Mailing

IT

IT Support

Strategic Communication Operating Model

Programme

Finance

A List

Programme Status Last Weeks RAG AMBER AMBER AMBER AMBER AMBER AMBER AMBER GREEN

This Weeks RAG AMBER AMBER AMBER AMBER AMBER AMBER AMBER GREEN AMBER AMBER GREEN

Category Go Live Operational Considerations

Customer disbursement after solicitor review Customer disbursement if Customer solicitor not required

Criteria The implementation/go live date of the activity has been communicated and agreed between all interested parties. Business process manuals, disaster recovery, service support, and resource planning updated and signed off. Estimates for FTE, job descriptions, recruitment, built into long-term plan and can be met. Learning and development department aware of necessary training for new employees and upskilling training for current employees. A matrix reporting on all management information requirements by business area are established and the requirements agreed by the business reps as achievable. All brand values and business unit initiatives are communicated to Marketing. Marketing has full visibility into root causes of customer complaints. Agree on service-level agreements on work item tagging and imaging. The Technical Service Centre and On-Site Support have been updated. All e-mail addresses, log-in IDs, telephone service, and fax numbers are updated. The project has clearly articulated any changes to the standard operating model to the business area affected and end-to-end processes are documented. Communication plans have been formulated to ensure internal and external awareness of change activity. Deals which will require specic capital investment are agged to Finance at least four weeks prior to capital being required. Internal Audit and Compliance Monitoring are aware of the implementation of each deal and established process for ongoing measuring/monitoring.

Target Date Dec. 2005 Sept. 2005 July 2005 August 2005

Status Amber Red Green Green Amber Red Green Amber Amber Green Red Red Green Green

Owner Anderson Jackson White Harris Martin Thompson Garcia Clark Lee Walker Hall Allen King Young

Summary Adviser Service Voice Contact Corporate Customer Service Policyholder Customer PruDirect Partnerships Center Center Pensions Service Center Service Center Retention Executive Summary Overall, Customer Services and Distribution is poised to deliver signicant change across 2006. Caution is warranted as new product and service launches combined with technology upgrades and under resourcing bring various business units under pressure across 2006. Business Unit and Owner Adviser Service Center John Thomson Voice Contact Center Mary Davies Corporate Pensions Service Center Rita Lockhart Customer Service Center Michael Morris Policyholder Service Center Vince Gomez Customer Retention Contact Center Laura Smith PruDirect Isabel Williams Partnerships Tracy Perry

Programmes Require Exec Action or Attention

Regulatory AMBER GREEN AMBER B List

RAG Action Exec Action Program Name Issues / Risks

Machine cycle time Equipment downtime Waiting for materials and tools Waiting time between batch processing Poorly functioning machinery Inadequate tools Equipment with unbalanced ow Repetitive and unnecessary movement of parts Poor ergonomic design causing people to make unnecessary movement Producing more than is required to meet customer demand Running machines and/or making parts to keep people and machines busy High obsolescence and write-offs Producing what we can versus what the customer demands Long travel distances Unplanned premium freight Large batch containers

45 30

60 15

Waiting

Processing

6 9 15 Distance 5

1 10 12 0.5 23.5 Work Time 5 3 0.5 35 Queue Time

Activity Value Added (mins) Non-ValueAdded (mins) Location (Floor) Labor Hrs/FTE FTE

Recruitment Training Partner Requirements Management Information Marketing Mailing IT IT Support Strategic Operating Model Communication Finance Risk and Compliance

Jan Red Amber

Feb Red Amber

Mar Red Amber

Apr Red Amber

May Red Amber

June Amber Amber

July Amber Amber

Aug Amber Amber

Sept Amber Amber

Oct Green Amber

Nov Green Amber

Dec Green Amber

Summary Signicant understafng combined with anticipated new product launches in Q3 contributes to Red status across the rst half of 2006. The VCC has been simultaneously hit by a 10% increase in call volume and unanticipated backlogs. As a result, training and development activity has been deferred to later in the year and the area remains under pressure. Anticipated new product launch in Q2 combined with the PMS upgrade is expected to put the area under pressure beginning in Q2.

AMBER AMBER AMBER AMBER GREEN AMBER Resources Resource Type RAG Issue GREEN AMBER Deliverables Red/Amber in next 4 weeks (to 21/10/05) Exec Business Forecast Project / Sponsor Sponsor Date Workstream Name AMBER AMBER AMBER AMBER GREEN

Incoming Customer Claim Mail 20% Sort Mail 0.3 56.0 1 8 1 Fax 80% Upload to Workow and Quality Check 2.8 32.0 1 8 1

Send incorrect documents to front line

Key Deliverables Achieved / Highlights for this Reporting Period

Partners agree on processes, technology requirements, training, and service-level agreements. July 2005 Sept. 2005 Sept. 2005 Oct. 2005 Nov. 2005 Nov. 2005 April 2005 Sept. 2005 April 2005 June 2005

Green

Green

Green

Amber

Amber

Amber

Amber

Amber

Red

Red

Amber

Amber

1 1

2 2

3 3

4 4

5 5

Overall Status / Progress MadeDeliverable Progress Week Ending 23/09/05

Deliverable Description

Actions

Deliverable RAG Status AMBER AMBER AMBER AMBER AMBER AMBER AMBER AMBER AMBER AMBER

1 1

2 2

3 3

4 4

5 5

Motion

Complete Disbursement 2.0 1

Automated Quality Check 1.1 1 8 4

Green Amber Red Amber Green Amber

Green Amber Red Amber Green Amber

Green Amber Red Amber Green Red

Amber Green Amber Amber Green Red

Amber Green Amber Amber Green Red

Red Green Green Amber Green Green

Red Green Green Amber Green Green

Red Green Green Amber Green Green

Amber Green Amber Amber Green Green

Amber Green Red Amber Green Green

Amber Green Red Amber Green Green

Green Green Red Amber Green Green

Overall level of change absorption is currently manageable with no signicant resourcing issues. However, volume is expected to spike in Q2 following the introduction of new service standards. The area is working through some challenges due to the introduction of new telephony infrastructure and, once complete, is expected to green status. The next phase of Embedding Retention into Customer Service will have signicant impact on the area through the end of the year. Resources are tight and regular communication of status reports will occur across the coming months to keep all apprised of progress. PruDirect is currently undergoing a large change program and is unlikely to be able to absorb further change activity until this is completed. No signicant change is planned which will impact the area other than planned technology infrastructure upgrades which are unlikely to cause any signicant issues. Training requirements and planned holidays across Q1 and Q2 will result in under resourcing which will limit the units ability to absorb signicant change activity early in the year.

Variance Table

7 Slipped 76 Forecast Project / Deliverable Impact Reason / Action Days

97% of Deliverables Achieved 74 Achieved (inc. 5 delivered early)

Programme

5. We have internal Lean exper ts and resources. Total Score

10

Overproduction

12 17 Distance 4 35 15 54

Business Area impacted In Delivery

Change Calendar Impacts for period 19/09/0523/10/05 Key Impacts

L L

8.5 Work Time 4

10 Queue Time

Suggested Action Steps Best Practices: Process Flow Visual Cues and Ofce to Factory Conversion

To establish continuous ow with minimal investment, you should 1. For each process activity, ask why it cant be eliminated ve times. 2 . Inser t visual cues in every paper-intensive process. 3. Make exceptions and quality checks that require less than 10 minutes from everyones job. 4. Optimize existing equipment settings to expedite manual tasks.

L L Programme Change Control

Intermediaries Justin Cruz

Inventory

RAG AMBER GREEN GREEN GREEN GREEN GREEN GREEN GREEN GREEN GREEN AMBER GREEN GREEN GREEN GREEN GREEN GREEN GREEN GREEN AMBER

Impact H M M M M M M L L L H M M M M M M M L L

Programme / Project

Summary of Change Request (CR)

p. 9 9

Original CBRC Approved Date

Change request Amount Date

20

% increase Impact over CBRC on 1,000days

NWW

Commencing within next 4 weeks

Other change requests known to be in the pipeline, include:

Tool

L5. Position quality checks at the beginning of the process to ensure clean inputs.

6. Audit the applicable and leng th of all repor ts and forms every six months. 7. Make ow your operational goal across your depar tment .

p. 81

Transportation

C a se Stu d y

20

S o u r ce : O p e r a t i o n s C o u n c i l r e s e a r c h .

Page 59

Page 34

Page 71

Page 77 and 79

Page 137

Page 99

Page 185

Page 187

Page 191

Page 205

ix

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- ISBN Safe Work Method Statements 2022 03Documento8 pagineISBN Safe Work Method Statements 2022 03Tamo Kim ChowNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- of Thesis ProjectDocumento2 pagineof Thesis ProjectmoonNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Space Hulk - WDDocumento262 pagineSpace Hulk - WDIgor Baranenko100% (1)

- 18 June 2020 12:03: New Section 1 Page 1Documento4 pagine18 June 2020 12:03: New Section 1 Page 1KarthikNayakaNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Review1 ScheduleDocumento3 pagineReview1 Schedulejayasuryam.ae18Nessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Tetralogy of FallotDocumento8 pagineTetralogy of FallotHillary Faye FernandezNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Business Analytics Emphasis Course GuideDocumento3 pagineBusiness Analytics Emphasis Course Guidea30000496Nessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Azimuth Steueung - EngDocumento13 pagineAzimuth Steueung - EnglacothNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- My Personal Code of Ethics1Documento1 paginaMy Personal Code of Ethics1Princess Angel LucanasNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- LTE Networks Engineering Track Syllabus Overview - 23 - 24Documento4 pagineLTE Networks Engineering Track Syllabus Overview - 23 - 24Mohamed SamiNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Aptitude Number System PDFDocumento5 pagineAptitude Number System PDFharieswaranNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Assignment#10 Global Strategy and The Multinational CorporationDocumento1 paginaAssignment#10 Global Strategy and The Multinational CorporationAnjaneth A. VillegasNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- ReadmeDocumento3 pagineReadmedhgdhdjhsNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- AnticyclonesDocumento5 pagineAnticyclonescicileanaNessuna valutazione finora

- WEB DESIGN WITH AUSTINE-converted-1Documento9 pagineWEB DESIGN WITH AUSTINE-converted-1JayjayNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- 2SB817 - 2SD1047 PDFDocumento4 pagine2SB817 - 2SD1047 PDFisaiasvaNessuna valutazione finora

- Arnold Ventures Letter To Congressional Social Determinants of Health CaucusDocumento7 pagineArnold Ventures Letter To Congressional Social Determinants of Health CaucusArnold VenturesNessuna valutazione finora

- Analizador de Combustion Kigaz 310 Manual EngDocumento60 pagineAnalizador de Combustion Kigaz 310 Manual EngJully Milagros Rodriguez LaicheNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- SMC 2D CADLibrary English 1Documento590 pagineSMC 2D CADLibrary English 1Design IPGENessuna valutazione finora

- Functions in C++Documento23 pagineFunctions in C++Abhishek ModiNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Salads: 300 Salad Recipes For Rapid Weight Loss & Clean Eating (PDFDrive) PDFDocumento1.092 pagineSalads: 300 Salad Recipes For Rapid Weight Loss & Clean Eating (PDFDrive) PDFDebora PanzarellaNessuna valutazione finora

- CEE Annual Report 2018Documento100 pagineCEE Annual Report 2018BusinessTech100% (1)

- Classifications of AssessmentsDocumento11 pagineClassifications of AssessmentsClaire CatapangNessuna valutazione finora

- Log Building News - Issue No. 76Documento32 pagineLog Building News - Issue No. 76ursindNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- 5c3f1a8b262ec7a Ek PDFDocumento5 pagine5c3f1a8b262ec7a Ek PDFIsmet HizyoluNessuna valutazione finora

- 13 Adsorption of Congo Red A Basic Dye by ZnFe-CO3Documento10 pagine13 Adsorption of Congo Red A Basic Dye by ZnFe-CO3Jorellie PetalverNessuna valutazione finora

- Gemini Dollar WhitepaperDocumento7 pagineGemini Dollar WhitepaperdazeeeNessuna valutazione finora

- E0 UoE Unit 7Documento16 pagineE0 UoE Unit 7Patrick GutierrezNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Mixed Up MonstersDocumento33 pagineMixed Up MonstersjaneNessuna valutazione finora

- The Indonesia National Clean Development Mechanism Strategy StudyDocumento223 pagineThe Indonesia National Clean Development Mechanism Strategy StudyGedeBudiSuprayogaNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)