Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

1412TP 204 204

Caricato da

Muhammad UmairDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

1412TP 204 204

Caricato da

Muhammad UmairCopyright:

Formati disponibili

1412 TRAKPACTOR SPECIFICATION

Above photograph features a 1412 Trakpactor fitted the with optional side conveyor and magnet.

IMPACT CRUSHER

Crusher type: Rotor Width: Rotor Diameter: Feed opening: Crusher frame: Hazemag AP-PH 1214/Q. 1340 mm. 1200 mm. (Over blowbars) 810 mm x 1360 mm. Fabricated in 20mm thick steel plate. Lined with 20mm thick Hardox 400 interchangeable bolt on wear plates. Runs in rugged spherical self aligning roller bearings and is fitted with four reversible and replaceable fixed blow bars. Two full size and two half size Martensitic steel blow bars are fitted as standard. Retractable vertically or horizontally. Two Manganese impact aprons locked in place hydraulically. Hydraulic overload protection system for both impact aprons. Through wedge belts with screw tension adjustment on engine. 0-600 x 500 x 500mm or slabs 1200 x 1000 x 250mnm edge length. 34 to 44 Metres per second. (Rotor tip speed) Different speed achieved by adjusting engine speed on throttle. Adjustment: Hydraulic Overload Protection: Maintenance: Inlet plate: Hydraulic assist with manually adjusted proximity switches. On overload, impact aprons retreat, then automatically return to pre-set position. Hydraulic case opening Hydraulically raising crusher inlet plate.

Rotor:

Blowbars:

Impact aprons:

Drive: Maximum feed size:

Impactor speeds:

APPLICATIONS This plant is designed for both demolition and quarrying applications. When fitted with manganese blow bars the crusher will tolerate small quantities of steel reinforcing bar in the feed. However, the machine is not designed to accept large pieces of steel or other uncrushable objects, and the feed material should be assessed / inspected for suitability prior to use. It is vitally important that large pieces of steel or similar uncrushable objects are not allowed to enter the crushing chamber as severe damage and injury may occur. When High Chrome bars are fitted, no steel should be allowed to enter the chamber, the machine should only be used on quarry applications, or clean materials such as asphalt.

1412 TRAKPACTOR SPECIFICATION

IMPACT CRUSHER - INTERNAL

VIBRATING GRIZZLY FEEDER

Type: Vibrating unit: Spring mounted vibrating. Twin heavy-duty cast eccentric shafts running in spherical roller bearings. Gears coupled at drive end. 4260mm. 1380mm. 12mm thick abrasion resistant steel bottom plate is included in the welded construction. Flange mounted hydraulic motor. 2000mm long double section of welded tapered finger bars at 48mm spaces fabricated in 20mm thick abrasion resistant steel. Removable rubber blanking mat fitted as standard. This can be substituted for various aperture wire meshes (available as optional extras) when used in conjunction with the optional side dirt conveyor. Variable speed control through a proportional flow control valve.

Length: Width: Pan:

Drive: Grizzly:

Underscreen:

Control:

1412 TRAKPACTOR SPECIFICATION

HOPPER

Hopper type: Hydraulic folding hopper with over centre struts and wedgelock system. 4400mm. 2735mm. Up to 6.6m3 dependent upon method of feed. Hardox wear resistant steel plate, suitably braced.

Hopper length: Hopper width: Hopper capacity: Hopper body:

PLANT CHUTEWORK

Impactor feed chute: Fabricated in 10mm mild steel plate with fully width single strand chain curtain and rubber curtain. Liners fitted at wear points. Grizzly fines/ bypass Fabricated in 6mm mild steel Chute: plates with two way flap door. Material passing over the blanking mat is discharged to the main product or the dirt chute via the bypass chute.

TRACK DRIVE

Heavy duty tracks fitted as standard. Pitch: 240mm. Longitudinal centres: 3800mm. Track width: 400mm. Climbing grade: 28 maximum. Track speed: 0.8 Km/h. Drive: Hydraulic integral motor. Control: Remote handset - dual speed. Track tensioning: Hydraulic adjuster, grease tensioning. Type:

1412 TRAKPACTOR SPECIFICATION

ON PLANT PRODUCT CONVEYOR

Conveyor Type: Shallow troughed belt conveyor. Design: Fully removable modular unit to aid access and maintenance. Conveyor is designed to lower for transport and the removal of trapped material. The conveyor can be lowered and raised whilst crushing. Belt Type: Ripstop EP500/3 with 7.5mm top and 1.5mm bottom rubber covers. Belt width: 1200mm. Max Disc Height: 3935mm Maximum Clearance: 840mm when belt lowered. Drive: Feedboot: Twin direct drive hydraulic motors. Fabricated in mild steel plate with abrasion resistant steel liners. Fully skirted wear resistant rubber sealing along the conveyor length. This is provided beneath the belt immediately below the impactor outlet. Belt tensioning is by use of screw adjustment at the head end Remote greasing to head/tail drum bearing blocks.

Skirting:

Impact cradle:

Belt adjustment:

Lubrication:

Above photographs feature a 1412 Trakpactor fitted with the optional magnet.

1412 TRAKPACTOR SPECIFICATION

POWERPACK

Powerpack type: Power: Engine speed: Caterpillar C-12. 438 Hp at 2100 rpm. Constant power from 1800 2100 rpm. Variable speed drive achieved by adjusting engine speed on throttle eliminating the need for pulley changes. The engine speed can be adjusted from 1600-2100rpm. Six cylinder, four stroke, direct injection. 594 Litres.

Engine: Fuel tank capacity:

CLUTCH

Clutch type: 21 KPTO fully automatic clutch.

GUARDS

Wire mesh or sheet metal guards are provided for all drives, flywheels, pulleys & couplings. The guards provided are designed and manufactured to CE & ANSI standards.

PLATFORMS

A steel grid maintenance platform is provided on one side of the feeder and impactor fitted with double row handrails and access ladders. Platforms are also included to gain access to the rear of the crusher and the powerpack.

TOOLBOX

A plant mounted lockable toolbox is provided containing the grease gun and operators manual.

1412 TRAKPACTOR SPECIFICATION

CHASSIS

Heavy duty steel fabricated I section of welded construction.

DUST SUPPRESSION SPRAYS

Sprays bars with atomiser nozzles are mounted over the impactor discharge point and the product conveyor head piped to an inlet manifold for clients pressured water supply. Type: Inlet: Pressure required: Water supply: Frost Protection: Pump: Clean water multi atomising nozzles. Single point. 2.8 bar (42 psi). 7 litres per minute. Via system drain valves. Optional extra.

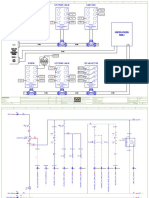

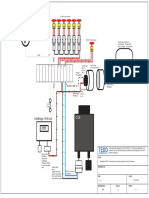

PLC CONTROLS

A CAN-bus PLC control system is fitted onto the plant to control operation the following items: Plant set-up. Impactor maintenance. Feeder (Start/Stop/Speed). Optional Dirt conveyor (Start/Stop/Raise/Lower). Product conveyor (Start/Stop/Raise/Lower). Engine power/temperature control. Crusher impact apron adjustment.

UMBILICAL CONTROL

An umbilical control unit is also supplied with the plant. This is fitted with controls for the track motion, feeder stop, start and a stop button for the plant.

1412 TRAKPACTOR SPECIFICATION

OPTIONAL EXTRAS

(For prices refer to BL-Pegson Limited) Re-Fuelling pump kit. Optional hydraulic folding hopper for shovel feed from rear 4.1 m wide. Single idler belt weigher with integrator and speed sensing wheel fitted to the main product conveyor. Overband magnetic separator Side/dirt conveyor. Wire meshes for feeder underscreen to separate scalpings at 10mm, 20mm, 30mm, 40mm or 50mm. Can only be used with optional dirt conveyor in situ. Radio remote control High Manganese blow bars. High Chrome blow bars (only for use when no steel is in the feed) Four full size blow bars in lieu of two full and two half.

RECOMMENDED OPTIONAL EXTRAS

Hydraulic driven water pump assembly to provide a pressurised water supply to the dust suppression sprays. Engine fire extinguisher system

REMOTE CONTROL (OPTIONAL EXTRA)

This remote radio control can be provided for the operating the tracking function and uses proportional joysticks for precise control. There are also facilities to start and stop the grizzly feeder, momentarily raise the impact-crusher inlet plate and shutdown the plant.This facility is only available in certain countries where type approval has been obtained. For a full list of countries please consult with BLP or your dealer.

MAGNET (OPTIONAL EXTRA)

Magnet Type: Magnet length: Drive: Control: Discharge chute: Power: Eriez CP20/125 suspended self cleaning overband. 2702mm. Direct drive hydraulic motor. Pre-set variable speed. Via stainless steel shredder plate. 570 Gauss at 200mm. 450 Gauss at 250mm.

1412 TRAKPACTOR SPECIFICATION

ON PLANT DIRT/SIDE CONVEYOR (OPTIONAL EXTRA)

Conveyor type: Belt Type: Troughed belt, hydraulically folding for transport. EP500/3 with 5mm top and 1.5mm bottom heavy duty rubber covers. 3980mm (head to tail drum centres). 600mm. 2418mm. Direct drive hydraulic motor. Remote greasing to tail drum bearings. Full length. Mounted to discharge on drive side of plant only.

Length: Width: Discharge height: Drive: Lubrication: Skirts: Position:

PLANT DIAGRAM

APPROXIMATE OVERALL PLANT WEIGHTS & DIMENSIONS

Operating Length: Operating Width: Operating Height: Transport Length: Transport Width: Transport Height: Total plant weight: 16597mm. 2800mm. 4214mm. 16885mm. 2800mm. 3750mm. 48.04 Tonnes

PAINTING

The plant is finish painted RAL 5015 Blue. The tracks and handrails are painted RAL 7012 Grey.

General

TEREX | Pegson equipment complies with CE requirements. Above line drawings feature a 1412 Trakpactor with optional magnet and side conveyor. Please consult TEREX | Pegson if you have any other specific requirements in respect of guarding, noise or vibration levels, dust emissions, or any other factors relevant to health and safety measures or environmental protection needs. However, on receipt of specific requests we will endeavour to ascertain the need for additional equipment and, if appropriate, quote extra to contract prices. Every endeavour will be made to supply equipment as specified, but we reserve the right, where necessary, to amend the specifications without prior notice as we operate a policy of continual product development. It is the importers responsibility to check that all equipment supplied complies with local legislation. 1412 Trakpactor specification 1412TP/204.

Potrebbero piacerti anche

- I-1312 ENGLISH Operation ManualDocumento184 pagineI-1312 ENGLISH Operation ManualНиколай Мамедов100% (1)

- Maxtrak Cone PartsDocumento39 pagineMaxtrak Cone PartsAshik Rahaman100% (1)

- Acert C27Documento46 pagineAcert C27Angela Allen100% (6)

- 1000 SR 07 Can Mk9pdfDocumento9 pagine1000 SR 07 Can Mk9pdfMarcelo Araoz ValdezNessuna valutazione finora

- Isuzu 4HK-1 Engine Service ManualDocumento121 pagineIsuzu 4HK-1 Engine Service ManualArtemio GutierrezNessuna valutazione finora

- C12 Manual PDFDocumento256 pagineC12 Manual PDFKrunoslav100% (3)

- Part 1 J44 Operations Manual REV002Documento95 paginePart 1 J44 Operations Manual REV002Serg100% (2)

- Extec C-12 Operation ManualDocumento43 pagineExtec C-12 Operation ManualΚΩΝΣΤΑΝΤΙΝΟΣ ΒΑΣΑΛΟΣ75% (4)

- Maxtrak+Dealer+Components+Manual+Issue+01 EngDocumento455 pagineMaxtrak+Dealer+Components+Manual+Issue+01 Engmarcelo100% (1)

- Extec Manual - OldDocumento187 pagineExtec Manual - OldSalAme75% (4)

- Powerscreen 1300 Maxtrak Tech Spec Rev 5-01-01-2013Documento12 paginePowerscreen 1300 Maxtrak Tech Spec Rev 5-01-01-2013baoyingNessuna valutazione finora

- Cat Inspect ModulesDocumento3 pagineCat Inspect ModulesDAnielNessuna valutazione finora

- I44 Technical SpecDocumento6 pagineI44 Technical SpecAnonymous K5m3Sa2kJW100% (1)

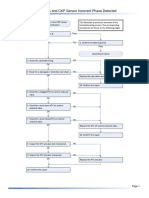

- DTC P0341: CMP Sensor A and CKP Sensor Incorrect Phase DetectedDocumento4 pagineDTC P0341: CMP Sensor A and CKP Sensor Incorrect Phase Detectedmzcz3866Nessuna valutazione finora

- Iampm Hpto12wDocumento19 pagineIampm Hpto12wvitoNessuna valutazione finora

- Chieftain 2200 3 DeckDocumento1 paginaChieftain 2200 3 DeckSrinivas NandikantiNessuna valutazione finora

- Cone Crushers: C-1540 C-1540RS C-1550Documento8 pagineCone Crushers: C-1540 C-1540RS C-1550brajesh123Nessuna valutazione finora

- Metrotrak 18 4 05Documento193 pagineMetrotrak 18 4 05PabloMatiasC100% (1)

- 002-Steam Turbines Basics For BeginnersDocumento10 pagine002-Steam Turbines Basics For BeginnersGeorge J AlukkalNessuna valutazione finora

- Presentation Slide showQJ341 QJ241..ppsxDocumento120 paginePresentation Slide showQJ341 QJ241..ppsxdaniel100% (1)

- Pegson Maxtrac 1300 Cone CrusherDocumento6 paginePegson Maxtrac 1300 Cone CrusherEndro Suhadi0% (2)

- Terex CrushingDocumento7 pagineTerex CrushingAndrey L'vovNessuna valutazione finora

- Qj340 ManualDocumento68 pagineQj340 Manualluis50% (2)

- 1000sr Spare Parts Manual (Elec. Dwg@AMTC) - Ilovepdf-Compressed PDFDocumento147 pagine1000sr Spare Parts Manual (Elec. Dwg@AMTC) - Ilovepdf-Compressed PDFS Sathish KumarNessuna valutazione finora

- XA750S Operations Manual Rev 1.0 (En)Documento292 pagineXA750S Operations Manual Rev 1.0 (En)PrekelNessuna valutazione finora

- General Spec Sheet Power Crusher PC 1270Documento2 pagineGeneral Spec Sheet Power Crusher PC 1270ion_zloteaNessuna valutazione finora

- McCloskey C44Documento5 pagineMcCloskey C44JesusFloresRodriguez100% (1)

- JMG Systems LTDDocumento34 pagineJMG Systems LTDWassiem Sayoun100% (1)

- Katalog - Finlay J-1175Documento195 pagineKatalog - Finlay J-1175Michał BujaraNessuna valutazione finora

- 1000 MaxtrackDocumento6 pagine1000 MaxtrackJaimeAguilar0% (1)

- Symbols For Pipe FittingsDocumento5 pagineSymbols For Pipe FittingsPhoolPhool100% (2)

- Caterpillar 992K PDFDocumento28 pagineCaterpillar 992K PDFvfierr001100% (2)

- Finlay I-130 Engine Fault ReportedDocumento4 pagineFinlay I-130 Engine Fault ReportedLuis Antonio Vega ParangueoNessuna valutazione finora

- QJ340Documento11 pagineQJ340defiunikasungti100% (2)

- Kotler Pom15 Im 08Documento28 pagineKotler Pom15 Im 08Muhammad Umair100% (1)

- QH Red Fault CodesDocumento1 paginaQH Red Fault CodesJuan Guzmán100% (1)

- Maxtrak 1000 Manual AX857-901-8EN-02c PDFDocumento386 pagineMaxtrak 1000 Manual AX857-901-8EN-02c PDFjulio60% (5)

- (نسخة) JB-WD-DSE 6120 MKIII - 12.5-200 (1106)Documento1 pagina(نسخة) JB-WD-DSE 6120 MKIII - 12.5-200 (1106)Mahmood NabilNessuna valutazione finora

- XA400 - TerexPegson Specs PDFDocumento14 pagineXA400 - TerexPegson Specs PDFjet snake100% (4)

- The Extec C-12: Features and Benefits BookDocumento21 pagineThe Extec C-12: Features and Benefits BookReyna CoaquiraNessuna valutazione finora

- Kotler Pom15 Im 09Documento26 pagineKotler Pom15 Im 09Muhammad UmairNessuna valutazione finora

- Kotler POM 15e IM Notes Appendix MarketingByTheNumbersDocumento49 pagineKotler POM 15e IM Notes Appendix MarketingByTheNumbersMuhammad UmairNessuna valutazione finora

- 1412TP 204 204Documento8 pagine1412TP 204 204alfredNessuna valutazione finora

- Powerscreen Chieftain 2100X: 3 Deck Incline ScreenDocumento16 paginePowerscreen Chieftain 2100X: 3 Deck Incline Screenfranco avilaNessuna valutazione finora

- Premiertrak 300 & R300 Operations Manual 1.0 (En)Documento17 paginePremiertrak 300 & R300 Operations Manual 1.0 (En)Luis Paladines BravoNessuna valutazione finora

- 1100 X 650 HR 20 4 05 PDFDocumento245 pagine1100 X 650 HR 20 4 05 PDFandres100% (4)

- Repuestos Kleemann CribadoDocumento94 pagineRepuestos Kleemann CribadoJano Parra100% (1)

- QH331 F&B 26-09-11 (Rev 4)Documento34 pagineQH331 F&B 26-09-11 (Rev 4)danielNessuna valutazione finora

- Kotler Pom15 Im 18Documento29 pagineKotler Pom15 Im 18Muhammad Umair100% (1)

- IC Parameters Rev5.4may2009Documento80 pagineIC Parameters Rev5.4may2009William Reyes MedinaNessuna valutazione finora

- Tesab 1012t Parts Manual 2003 PDFDocumento81 pagineTesab 1012t Parts Manual 2003 PDFMiroslav MomchilovNessuna valutazione finora

- Code C On Extec Jaw CrusherDocumento6 pagineCode C On Extec Jaw CrusherAdal Vera100% (1)

- Mobile Crusher 900x600Documento7 pagineMobile Crusher 900x600macross086100% (7)

- SICK SENSORUM30-213112 - en - 20100308 - 1431Documento4 pagineSICK SENSORUM30-213112 - en - 20100308 - 1431danielNessuna valutazione finora

- Kotler Pom15 Im 20Documento26 pagineKotler Pom15 Im 20Muhammad Umair100% (1)

- Chieftain 1600 PartsDocumento79 pagineChieftain 1600 PartsGiuro Kralev100% (2)

- QH330 F&BDocumento38 pagineQH330 F&BSaša Slavić100% (2)

- Sandvik Mobiles: Scalper Key Sales PointsDocumento42 pagineSandvik Mobiles: Scalper Key Sales PointsDyego GarciaNessuna valutazione finora

- Video Case Teaching NotesDocumento39 pagineVideo Case Teaching NotesMuhammad UmairNessuna valutazione finora

- Dokumen - Tips - Powerscreen Premiertrak 400 r400 Jaw Crusher Jaw Crusher Crusher TypeDocumento14 pagineDokumen - Tips - Powerscreen Premiertrak 400 r400 Jaw Crusher Jaw Crusher Crusher TypeManuel dlHNessuna valutazione finora

- Kotler Pom15 Im 07Documento27 pagineKotler Pom15 Im 07Muhammad Umair80% (5)

- Premiertrak 400 r400 Crushing Brochure en 2014Documento1 paginaPremiertrak 400 r400 Crushing Brochure en 2014anon_728840059Nessuna valutazione finora

- Operation Manual 683 V 11 PDFDocumento170 pagineOperation Manual 683 V 11 PDFEricson ViaNessuna valutazione finora

- 623CT Sales Specification NewDocumento19 pagine623CT Sales Specification NewDaniel Alejandro Navarro Jara100% (1)

- J-1175 Spare Parts Manual - 29082018-192-193Documento2 pagineJ-1175 Spare Parts Manual - 29082018-192-193Kilton BiswasNessuna valutazione finora

- BROCHURE PEGSON 4242SR - TerexPegson+SpecsDocumento9 pagineBROCHURE PEGSON 4242SR - TerexPegson+SpecsGoran Erakovic100% (1)

- Extec C12 - Sandvik QJ341 Parts List PDFDocumento4 pagineExtec C12 - Sandvik QJ341 Parts List PDFghitaNessuna valutazione finora

- 1000SR Plant Manual 2004 (U) PDFDocumento412 pagine1000SR Plant Manual 2004 (U) PDFJimmy Xon100% (6)

- Diesel Engines 8V/12V/16V 4000 M60R: For Vessels With Unrestricted Continuous Operation (1A)Documento2 pagineDiesel Engines 8V/12V/16V 4000 M60R: For Vessels With Unrestricted Continuous Operation (1A)Jorge Bellido100% (1)

- Kotler Pom15 Im 17Documento27 pagineKotler Pom15 Im 17Muhammad Umair50% (2)

- AAR Manual of Standards and Recommended Practices Brakes and Brake EquipmentDocumento38 pagineAAR Manual of Standards and Recommended Practices Brakes and Brake EquipmentDaniel SantacruzNessuna valutazione finora

- Triturador de Entulho Rubble-Master-Rm60Documento12 pagineTriturador de Entulho Rubble-Master-Rm60João Santiago0% (1)

- Lokotrack LT110C S N 76814Documento613 pagineLokotrack LT110C S N 76814Luis Pimentel100% (6)

- Powerscreen Chieftain 1700 2 Deck Technical Specification Rev 9-01-01 2017Documento16 paginePowerscreen Chieftain 1700 2 Deck Technical Specification Rev 9-01-01 2017Mahmoud Abd El MonemNessuna valutazione finora

- E7 Hydraulic Diagram-ESDocumento2 pagineE7 Hydraulic Diagram-ESCésar A. Chacón100% (1)

- PVG ValveDocumento1 paginaPVG Valvedaniel100% (1)

- S175Documento7 pagineS175FD2027Nessuna valutazione finora

- 428 Trakpactor SpecificationDocumento7 pagine428 Trakpactor SpecificationYeco MachineryNessuna valutazione finora

- Kotler Pom 15 Im 11Documento28 pagineKotler Pom 15 Im 11Muhammad Umair100% (1)

- Kotler Pom15 Im 10Documento23 pagineKotler Pom15 Im 10Muhammad Umair100% (1)

- Kotler Pom15 Im 06Documento27 pagineKotler Pom15 Im 06Muhammad Umair100% (1)

- Kotler Pom15 Im 04Documento27 pagineKotler Pom15 Im 04Muhammad Umair67% (3)

- Kotler Pom15 Im 03Documento26 pagineKotler Pom15 Im 03Muhammad Umair100% (2)

- Kotler POM 15e IM IntroductionDocumento8 pagineKotler POM 15e IM IntroductionMuhammad UmairNessuna valutazione finora

- Kotler Pom15 Im 16Documento32 pagineKotler Pom15 Im 16Muhammad Umair100% (1)

- Kotler Pom15 Im 13Documento26 pagineKotler Pom15 Im 13Muhammad Umair100% (1)

- Model Profile - 61Documento2 pagineModel Profile - 61ar dseNessuna valutazione finora

- Washer Repair SchematicDocumento11 pagineWasher Repair SchematicJason MackiewiczNessuna valutazione finora

- Motor Xoay NgángDocumento14 pagineMotor Xoay NgángNguyễn Văn Hùng100% (1)

- RC60 - 72H Kubota 60" Deck Parts BookDocumento17 pagineRC60 - 72H Kubota 60" Deck Parts Bookbrja73gmailNessuna valutazione finora

- PERKINS Genset MODELDocumento96 paginePERKINS Genset MODELGRAND SOLARNessuna valutazione finora

- DTSeals CatalogDocumento12 pagineDTSeals Cataloggume pesaNessuna valutazione finora

- Turbines, Compressors and Fans - S. M. YahyaDocumento170 pagineTurbines, Compressors and Fans - S. M. YahyaHarsh Bhavsar0% (3)

- GrooverAutomation Production Systems and CIM Chapeter 7 Solutions PDFDocumento25 pagineGrooverAutomation Production Systems and CIM Chapeter 7 Solutions PDFMustafaSert100% (1)

- R0223 Hi Wall Inverter 17seerDocumento1 paginaR0223 Hi Wall Inverter 17seerPrimero Valencia LuisNessuna valutazione finora

- Orca Share Media1569922103234 PDFDocumento45 pagineOrca Share Media1569922103234 PDFArnel SisonNessuna valutazione finora

- Chapter 6 GearDocumento13 pagineChapter 6 GearMEWAEL MIZANNessuna valutazione finora

- The History of Small EngineDocumento12 pagineThe History of Small EngineJastine Mico benedictoNessuna valutazione finora

- Hotchkiss Drive - WikipediaDocumento1 paginaHotchkiss Drive - Wikipediasrushti hippargiNessuna valutazione finora

- DTC P0028Documento2 pagineDTC P0028Willie AustineNessuna valutazione finora

- Spherical Plain Bearings, Plain Bushes, Rod Ends: Catalogue 238Documento181 pagineSpherical Plain Bearings, Plain Bushes, Rod Ends: Catalogue 238durvalmedinasNessuna valutazione finora

- Datasheet Motor Generador Cummins Onan 30MCGBADocumento4 pagineDatasheet Motor Generador Cummins Onan 30MCGBABam BANessuna valutazione finora

- 0332 v11 T6Documento38 pagine0332 v11 T6sumitNessuna valutazione finora

- Ball Bearing UnitsDocumento416 pagineBall Bearing UnitsilusimataNessuna valutazione finora

- Mechanical Design Engineering Handbook - (Chapter 11 - Worm Gears)Documento20 pagineMechanical Design Engineering Handbook - (Chapter 11 - Worm Gears)Lee DonoghueNessuna valutazione finora