Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Deped K To 12 Technology and Livelihood Education - Tile Setting

Caricato da

yachiru121Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Deped K To 12 Technology and Livelihood Education - Tile Setting

Caricato da

yachiru121Copyright:

Formati disponibili

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION INDUSTRIAL ARTS TILE SETTING (Exploratory)

Learning Competencies

Content Standard

Performance Standard

Project / Activities

Assessment

Duration

LESSON 1: PREPARING CONSTRUCTION MATERIALS AND TOOLS Demonstrate understanding of/on: Identifying and classifying 1. Tools and materials are identified per job requirements construction materials Identifying and describing 2. Tools are classified according to their functions per job tools per job requirements. requirements 3. Materials are classified according to their uses for specific construction projects. 4. Tools and materials are selected per job requirement. Accomplishing different forms like job order slips, tools and materials requisition slips, and borrowers slips Following accurate requisition procedures 1. Needed materials and tools are listed per job requirement. 2. Materials and tools are requested according to the prepared list. 3. Requests are done per companys standard operating procedures (SOP). 4. Materials and tools are provided and unavailable ones substituted without sacrificing cost and quality of work. Identify materials and tools appropriate to a specific job 1. Listing down the tools needed in tile setting. 2. Using tools properly 3. Making a list of materials per company standards Direct observation Written test/questioning 3 hours

Request appropriate materials and tools

1. Making a list of different sizes of tiles.

Oral questioning Direct observation Written test

2 hours

*TWG on K to 12 Curriculum Guide version January 31, 2012

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION INDUSTRIAL ARTS TILE SETTING (Exploratory)

Learning Competencies LO3. Receive and inspect materials

Content Standard Following procedures in receiving tools and materials Observing proper handling of tools and materials

Performance Standard 1. Receiving and inspected materials and tools per quantity and specifications based on requisition. 2. Tools and materials are checked for damages and manufacturing defects. 3. Materials and tools received are handled with appropriate safety devices. 4. Materials and tools are stored in an appropriate location nearest the workplace.

Project / Activities 1. Enumeration of some common defects and/or damages of tools and materials used for tile setting.

Assessment Oral questioning Direct observation Written test

Duration 3 hours

*TWG on K to 12 Curriculum Guide version January 31, 2012

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION INDUSTRIAL ARTS TILE SETTING (Exploratory)

Learning Competencies

Content Standard LESSON 2:

Performance Standard

Project / Activities

Assessment

Duration

PERFORMING MENSURATIONS AND CALCULATIONS

Demonstrate understanding of/on: Making calculations and computations using the four fundamental operations, ration and proportion, algebra and trigonometry 1. Calculation needed to complete work tasks are performed using the four basic processes of addition (+), subtraction(-), multiplication (x) and division (/) including but not limited to: Trigonometric functions and Algebraic computations. 2. Calculations involving fractions, percentages, and mixed numbers are used to complete workplace tasks. 3. Numerical computations are self-checked and corrected for accuracy. 4. Accurate measurements are obtained according to job requirements. 5. Systems of measurements are identified and converted according to job requirements 6. Work pieces are measured according to job requirements. LO1.Carry out measurements and calculations 1. Making simple computations using the four fundamental operations Oral questioning Direct observation Written test 4 hours

*TWG on K to 12 Curriculum Guide version January 31, 2012

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION INDUSTRIAL ARTS TILE SETTING (Exploratory)

Learning Competencies LO2. Select Measuring Instrument

Content Standard Visualizing objects and shapes specifically geometric shapes. Interpreting formulas for volume, areas, and perimeters of plane and geometric figures. Measuring Instruments/Measuring Tools Proper handling of measuring instruments

Performance Standard 1. Objects or components to be measured are identified, classified, and interpreted according to the appropriate regular geometric shapes. 2. Measuring tools are selected/identified per object to be measured or according to job requirements 3. Correct specifications are obtained from relevant sources. 4. Measuring instruments are selected according to job requirements. 5. Alternative measuring tools are used without sacrificing cost and quality of work. 6. Measurements are obtained according to job requirements.

Project / Activities 2. Measuring the lengths, width and thickness of some pieces of wood which will be presented in the class. 3. Computing the area of some geometric figures

Assessment Actual demonstration Direct observation Written test/ questioning

Duration 4 hours

*TWG on K to 12 Curriculum Guide version January 31, 2012

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION INDUSTRIAL ARTS TILE SETTING (Exploratory)

Learning Competencies

Content Standard LESSON 3:

Performance Standard

Project / Activities

Assessment

Duration

INTERPRETING TECHNICAL DRAWINGS AND PLANS 3 hours 2. Demonstration 3. Direct observation 4. Written test/questioning

Demonstrate understanding of/on: Drawing symbols and signs according to job specifications Drawing lines Trade mathematics 1. Signs, symbols, and data are identified according to job specifications. 2. Signs, symbols and data are determined according to classification or as appropriateness in drawing. 1. Necessary tools, materials and equipment are identified according to the plan. 2. Components, assemblies or objects are recognized per job requirement. 3. Dimensions and specifications are identified according to job requirements. 4. Freehand sketch is produced in accordance with job requirements. LO1 Read/Interpret blueprints and plans 1. Enumerate the lines necessary in making working drawing.

Basic technical drawing Technical plans and schematic diagram Symbols and abbreviations

LO2. Perform freehand sketching

1. Make a sketch of an area of four feet long and four feet wide to be tiled with 4 by 4 tiles.

Practical application/ performance test Written test/ questioning

3 hours

*TWG on K to 12 Curriculum Guide version January 31, 2012

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION INDUSTRIAL ARTS TILE SETTING (Exploratory)

Learning Competencies

Content Standard

Performance Standard

Project / Activities

Assessment

Duration

LESSON 4: MAINTAINING TOOLS AND EQUIPMENT Demonstrate understanding of/on: Types of Tools and Equipment Classification of functional and nonfunctional tools Uses of Personal Protective Equipment (PPE). 1. Tools and equipment are identified according to classification/specification and job requirements. 2. Functional and non-functional tools and equipment are segregated and labeled according to classification. 3. Safety of tools and equipment are observed in accordance with manufacturers instructions. 4. Conditions of PPE are checked in accordance with manufacturers instructions. 1. Lubricants are identified according to types of equipment. 2. Tools and equipment are lubricated according to preventive maintenance schedule or manufacturers specifications. 3. Measuring instruments are checked and calibrated in accordance with LO1. Check condition of tools and equipment 1. Enumerate the conditions of tools and equipment that needs maintenance or repair. Oral questioning Direct observation Written test 6 hours

Types and uses of lubricants Types and uses of cleaning materials/solvent Types and uses of measuring instruments and equipment. Preventive maintenance techniques and procedures.

LO2. Perform basic preventive maintenance.

1. Explain the importance of lubricants in tool and equipment maintenance.

Oral questioning Direct observation Written test

3 hours

*TWG on K to 12 Curriculum Guide version January 31, 2012

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION INDUSTRIAL ARTS TILE SETTING (Exploratory)

Learning Competencies

Content Standard OSHC workplace regulations

Performance Standard manufacturers instructions. 4. Tools are cleaned and lubricated according to standard procedures. 5. Defective equipment and tools are inspected and replaced according to manufacturers specification. 6. Work place is cleaned and kept in safe state in line with OSHC regulations. 1. Inventory of tools, instruments, and equipment are conducted and recorded per company practices. Tools are inspected and stored after use. Tools and equipment are stored safely in accordance with manufacturers specifications or company procedures.

Project / Activities

Assessment

Duration

Inventory of tools and equipment Tools and equipment handling Tool safekeeping/storage

LO3. Store tools and equipment.

1. Explaining the disadvantages of improper storing of tools and equipment.

2. 3.

Practical examination Direct observation Written test/questioning

2 hours

*TWG on K to 12 Curriculum Guide version January 31, 2012

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION INDUSTRIAL ARTS TILE SETTING (Exploratory)

Learning Competencies

Content Standard LESSON 5:

Performance Standard

Project / Activities

Assessment

Duration

PRACTICING OCCUPATIONAL HEALTH AND SAFETY PROCEDURES

Demonstrate understanding of/on: TLV table Philippine OHS standards Effects of hazards in the workplace Ergonomics ECC regulations 1. Terms of maximum tolerable limits are identified based on threshold limit value (TLV). 2. Effects of hazards are determined. 3. OHS issues and concerns are identified in accordance with workplace requirements. 4. Requirements and relevant workplace OHS legislation. 1. OHS procedures for controlling hazards and risks are strictly followed. 2. Procedures in dealing with workplace accidents, fire and emergencies are followed in accordance with the organizations OHS policies. 3. Personal protective equipment (PPE) is correctly used in accordance with organizations OHS procedures and practices. 4. Procedures in providing appropriate assistance in the event of workplace LO1. Evaluate hazards and risks 1. Making a list of known hazards and risks in the workplace. Interview Written examination Simulation 2 hours

Safety regulations Clean air act Electrical and fire safety code Waste management Disaster preparedness and management Contingency measures and procedures

LO2.

Control hazards and risks.

1.

Demonstrating or illustrating the proper use of PPEs.

Written examination Interview

2 hours

*TWG on K to 12 Curriculum Guide version January 31, 2012

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION INDUSTRIAL ARTS TILE SETTING (Exploratory)

Learning Competencies

Content Standard

Performance Standard emergencies are identified in line with the established organizational protocol.

Project / Activities

Assessment

Duration

Operational health and safety procedure, practices and regulations Emergency-related drills and training

Procedures in emergency related drill are strictly followed in line with the established organizational guidelines and procedures. OHS personal records are filled up in accordance with workplace requirements. PPE are maintained in line with organization guidelines and procedures.

LO3. Maintain 1. occupational health and safety awareness

Commenting about the emergency drills undertaken in the schools such as fire drill and earthquake drill

Demonstration Interview Written examination

4 hours

40 hrs.

*TWG on K to 12 Curriculum Guide version January 31, 2012

Potrebbero piacerti anche

- Laboratory Quality/Management: A Workbook with an Eye on AccreditationDa EverandLaboratory Quality/Management: A Workbook with an Eye on AccreditationValutazione: 5 su 5 stelle5/5 (1)

- L1 Introduction To Media and Information Literacy MELC1Documento28 pagineL1 Introduction To Media and Information Literacy MELC1Christine JacobNessuna valutazione finora

- Sender - Channel - ReceiverDocumento2 pagineSender - Channel - ReceiverKristine Sheila AmorosoNessuna valutazione finora

- 10.MIL 9. Current and Future Trends in Media and InformationDocumento45 pagine10.MIL 9. Current and Future Trends in Media and InformationHeli Senn VentenillaNessuna valutazione finora

- AbcDocumento77 pagineAbcDON ORIDONessuna valutazione finora

- Abstract Design Circle Bubble PowerPoint Templates StandardDocumento3 pagineAbstract Design Circle Bubble PowerPoint Templates StandardschaNessuna valutazione finora

- Test in MILDocumento3 pagineTest in MILGIRLIE CAONessuna valutazione finora

- Philosophy of Classroom Management 18413306Documento13 paginePhilosophy of Classroom Management 18413306api-408430724Nessuna valutazione finora

- Lesson 8 MilDocumento28 pagineLesson 8 MilJOHN MICHAEL IGNACIONessuna valutazione finora

- Budgeted Outlay in Oral CommunicationDocumento3 pagineBudgeted Outlay in Oral CommunicationKristine May QuisayNessuna valutazione finora

- Oral Comm - Handout 1Documento12 pagineOral Comm - Handout 1Teresa Borja0% (1)

- Mil L7 MoocDocumento55 pagineMil L7 MoocSherry GonzagaNessuna valutazione finora

- Prac Res 1 Week 3Documento7 paginePrac Res 1 Week 3Jethro Leo AlmadenNessuna valutazione finora

- 2 Intonation and StressDocumento27 pagine2 Intonation and StressdiwiyanaNessuna valutazione finora

- The Functions, Nature, and Process of CommunicationDocumento22 pagineThe Functions, Nature, and Process of CommunicationArmie SalayogNessuna valutazione finora

- Word CV TemplateDocumento2 pagineWord CV Templatebima saktiNessuna valutazione finora

- CareerDocumento7 pagineCareersiopaupaoNessuna valutazione finora

- Concepcion National High School-MainDocumento3 pagineConcepcion National High School-MainClarissa Mae Fajanilan FirmalanNessuna valutazione finora

- Content Content Standard Performance Standard Learning CompetenciesDocumento3 pagineContent Content Standard Performance Standard Learning CompetenciesCyrielNessuna valutazione finora

- L8 Digital Divide Cyber Bullying and Computer Addiction 1Documento33 pagineL8 Digital Divide Cyber Bullying and Computer Addiction 1Joyceee CabulayNessuna valutazione finora

- Commonly Misused Words and Confusingly Related WordsDocumento13 pagineCommonly Misused Words and Confusingly Related WordsAnnisNessuna valutazione finora

- Tile Setting NC II CGDocumento13 pagineTile Setting NC II CGBryan Borje0% (1)

- Setting of ExpectationsDocumento17 pagineSetting of ExpectationsRobert DechosNessuna valutazione finora

- Ii. Content: CS - ICT11/12-ICTPT-Ia b-2 CS - ICT11/12-ICTPT-Ia b-2 CS - ICT11/12-ICTPT-Ia-b-3 CS - ICT11/12-ICTPT-Ia-b-3Documento11 pagineIi. Content: CS - ICT11/12-ICTPT-Ia b-2 CS - ICT11/12-ICTPT-Ia b-2 CS - ICT11/12-ICTPT-Ia-b-3 CS - ICT11/12-ICTPT-Ia-b-3EMMALYN PASIONNessuna valutazione finora

- 200 Syllabus 2020Documento4 pagine200 Syllabus 2020Chanon AdsanathamNessuna valutazione finora

- Ict Benefits and IssuesDocumento5 pagineIct Benefits and IssuesJonel PagalilauanNessuna valutazione finora

- ORAL COMMUNICATION ELEMENTS AND BENEFITSDocumento6 pagineORAL COMMUNICATION ELEMENTS AND BENEFITSKat PingolNessuna valutazione finora

- Media and Information LiteracyDocumento36 pagineMedia and Information LiteracyNics AlionNessuna valutazione finora

- LP Demo FinalDocumento3 pagineLP Demo FinalJerrahMaeEnanoriaNessuna valutazione finora

- Types of MediaDocumento7 pagineTypes of MediaZhiel Nangit Abordo0% (1)

- Work Immersion Portfolio ExamplesDocumento14 pagineWork Immersion Portfolio ExamplesPegafi ToledoNessuna valutazione finora

- 1 Earthquake Hazards LPDocumento3 pagine1 Earthquake Hazards LPKonrad Dela CruzNessuna valutazione finora

- Resume and Application LetterDocumento27 pagineResume and Application LetterCharlyn DavidNessuna valutazione finora

- Exam Midterm Structure of English LanguageDocumento1 paginaExam Midterm Structure of English LanguageMaureen Taguba Sta Ana100% (1)

- Types of Speech ContextDocumento9 pagineTypes of Speech ContextAngela MendozaNessuna valutazione finora

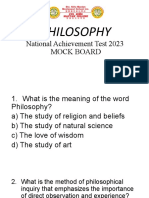

- Nat PhiloDocumento51 pagineNat PhiloRuby Ann GarciaNessuna valutazione finora

- CompositionDocumento12 pagineCompositionapi-208041294100% (1)

- Oral ComDocumento191 pagineOral ComjaishenneNessuna valutazione finora

- Orca Share Media1576550898808Documento22 pagineOrca Share Media1576550898808Christine Malibiran100% (1)

- The Evolution of Traditional To New MediaDocumento6 pagineThe Evolution of Traditional To New MediaSheally TalisaysayNessuna valutazione finora

- Introduction To MIL (Part 5) - Media Habits and Performance Task - ProjectDocumento23 pagineIntroduction To MIL (Part 5) - Media Habits and Performance Task - ProjectCharissa QuitorasNessuna valutazione finora

- Learn Key Multimedia ConceptsSynthesized media refers to information types generated bycomputer Examples: Text, graphics, animationDocumento24 pagineLearn Key Multimedia ConceptsSynthesized media refers to information types generated bycomputer Examples: Text, graphics, animationPalaKhartikeyanNessuna valutazione finora

- Keys To School Success - 9th GradeDocumento29 pagineKeys To School Success - 9th GradeSanjay SheoranNessuna valutazione finora

- Effective Communication Skills LectureDocumento48 pagineEffective Communication Skills LectureBabar Hussain100% (1)

- Overview of The Question Formulation TechniqueDocumento1 paginaOverview of The Question Formulation Techniqueapi-416923934Nessuna valutazione finora

- Types of Speeches: Persuasive SpeechDocumento7 pagineTypes of Speeches: Persuasive SpeechKarl CodasteNessuna valutazione finora

- Good Morning Welcome To This Subject Media and Information LiteracyDocumento41 pagineGood Morning Welcome To This Subject Media and Information LiteracyRhea Mae SumalpongNessuna valutazione finora

- Text Information and MediaDocumento9 pagineText Information and MediaBless100% (1)

- Parent Handbook 2020-21 PDFDocumento32 pagineParent Handbook 2020-21 PDFAndy S100% (1)

- CV Resume Word Template 906Documento1 paginaCV Resume Word Template 906Linky DooNessuna valutazione finora

- MOTION MEDIA ESSENTIALSDocumento48 pagineMOTION MEDIA ESSENTIALSSophia AbatayNessuna valutazione finora

- LP - Practical Research 2Documento8 pagineLP - Practical Research 2Fredinel Malsi Arellano100% (1)

- Reading ComprehensionDocumento2 pagineReading ComprehensionJani Arizky100% (2)

- Quarter 2 Lesson 2Documento19 pagineQuarter 2 Lesson 2glencurit44Nessuna valutazione finora

- First Quarterly Exam in Oral Communication in Context Answer KeyDocumento4 pagineFirst Quarterly Exam in Oral Communication in Context Answer KeyM3xobNessuna valutazione finora

- Evolution of Traditional To New MediaDocumento48 pagineEvolution of Traditional To New MediaKayle CombisNessuna valutazione finora

- 5 Media and Information LanguagesDocumento40 pagine5 Media and Information LanguagesLeah Mae GarciaNessuna valutazione finora

- IMPROMPTU SPEAKING - Speaking Without Preparation: Techniques To Delivering A Better Impromptu SpeechDocumento4 pagineIMPROMPTU SPEAKING - Speaking Without Preparation: Techniques To Delivering A Better Impromptu SpeechDhiren RanaNessuna valutazione finora

- Deped K To 12 Technology and Livelihood Education - MasonryDocumento8 pagineDeped K To 12 Technology and Livelihood Education - Masonryyachiru121Nessuna valutazione finora

- Deped K To 12 Technology and Livelihood Education - CarpentryDocumento8 pagineDeped K To 12 Technology and Livelihood Education - Carpentryyachiru121Nessuna valutazione finora

- Anatomy and Physiology I Fall 2009 Exam I Study GuideDocumento1 paginaAnatomy and Physiology I Fall 2009 Exam I Study Guideyachiru121Nessuna valutazione finora

- Bones of The Upper LimbDocumento14 pagineBones of The Upper Limbyachiru121Nessuna valutazione finora

- Bacteriology ReviewDocumento47 pagineBacteriology ReviewDeti ParidlahNessuna valutazione finora

- Assess Notes Nursing AssessmentDocumento206 pagineAssess Notes Nursing Assessmenttostc100% (7)

- Anatomy Tables - Bones of The Thorax: Bone Structure Description Notes RibDocumento3 pagineAnatomy Tables - Bones of The Thorax: Bone Structure Description Notes Ribyachiru121Nessuna valutazione finora

- Anatomy Head ReviewDocumento34 pagineAnatomy Head ReviewJordan BrooksNessuna valutazione finora

- Anatomy Thorax ReviewDocumento18 pagineAnatomy Thorax Reviewyachiru121Nessuna valutazione finora

- API Review Muscles f2009Documento1 paginaAPI Review Muscles f2009yachiru121Nessuna valutazione finora

- AP Review NotesDocumento15 pagineAP Review Notesyachiru121Nessuna valutazione finora

- Anatomy Abdomin ReviewDocumento24 pagineAnatomy Abdomin Reviewmooni2009Nessuna valutazione finora

- Anatomy Lower Extr ReviewDocumento12 pagineAnatomy Lower Extr Reviewabuzeid5Nessuna valutazione finora

- Bones of The Pelvis and PerineumDocumento6 pagineBones of The Pelvis and Perineumyachiru121Nessuna valutazione finora

- Anatomy Pelvis ReviewDocumento20 pagineAnatomy Pelvis Reviewyachiru121Nessuna valutazione finora

- Anatomy Levels and Planes ReviewDocumento3 pagineAnatomy Levels and Planes Revieware4erNessuna valutazione finora

- Anatomy and Physiology Unit III: Objectives/RationaleDocumento16 pagineAnatomy and Physiology Unit III: Objectives/Rationaleyachiru121Nessuna valutazione finora

- First Aid ManualDocumento225 pagineFirst Aid ManualHugo MartinsNessuna valutazione finora

- Bones and Cartilages of The Head and NeckDocumento27 pagineBones and Cartilages of The Head and Neckyachiru121100% (1)

- A P1 Review Test 4Documento1 paginaA P1 Review Test 4yachiru121Nessuna valutazione finora

- DEPED 2012 - K TO 12 - MTB RationaleDocumento30 pagineDEPED 2012 - K TO 12 - MTB Rationaleyachiru121100% (3)

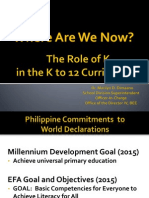

- DEPED 2012 - K TO 12 - Where Are We Now, K in K To 12Documento21 pagineDEPED 2012 - K TO 12 - Where Are We Now, K in K To 12yachiru121100% (1)

- Bones of The Back RegionDocumento9 pagineBones of The Back Regionyachiru121Nessuna valutazione finora

- Bones of The Lower LimbDocumento15 pagineBones of The Lower Limbyachiru121Nessuna valutazione finora

- Bones of The Abdominal RegionDocumento7 pagineBones of The Abdominal Regionyachiru121Nessuna valutazione finora

- DEPED 2012 - K TO 12 - Learning DR VillanezaDocumento32 pagineDEPED 2012 - K TO 12 - Learning DR Villanezayachiru121100% (1)

- DEPED 2012 - Classroom DR VillanezaDocumento17 pagineDEPED 2012 - Classroom DR Villanezayachiru121100% (1)

- DEPED 2012 - K TO 12 - L1-L2-L3-Dr. GironDocumento56 pagineDEPED 2012 - K TO 12 - L1-L2-L3-Dr. Gironyachiru121Nessuna valutazione finora

- DEPED 2012 - Assessment in Kinder Mam VioletaDocumento54 pagineDEPED 2012 - Assessment in Kinder Mam Violetayachiru121Nessuna valutazione finora

- DEPED - K To 12 Assessment & Rating - 2012Documento44 pagineDEPED - K To 12 Assessment & Rating - 2012yachiru121Nessuna valutazione finora

- DEPED - The K To 12 Basic Education Programv2 - 2012Documento38 pagineDEPED - The K To 12 Basic Education Programv2 - 2012yachiru121100% (1)

- HandbookDocumento53 pagineHandbookyachiru121Nessuna valutazione finora

- MecE 360 Mechanical Design II Course SyllabusDocumento3 pagineMecE 360 Mechanical Design II Course SyllabusJames MoodyNessuna valutazione finora

- Detailed Lesson Plan (Resistor Color Coding)Documento11 pagineDetailed Lesson Plan (Resistor Color Coding)Jessa Bahi-an100% (3)

- Business Personal StatementDocumento2 pagineBusiness Personal StatementBojan Ivanović50% (2)

- Nature of Performance-Based AssessmentDocumento3 pagineNature of Performance-Based AssessmentDarel GarzNessuna valutazione finora

- Derek Smits Resume NurseDocumento3 pagineDerek Smits Resume Nurseapi-305752422Nessuna valutazione finora

- Zuhaib Ashfaq Khan: Curriculum VitaeDocumento6 pagineZuhaib Ashfaq Khan: Curriculum VitaeRanaDanishRajpootNessuna valutazione finora

- The Master's Hand: AnecdoteDocumento6 pagineThe Master's Hand: AnecdoteNiday DimalawangNessuna valutazione finora

- Effects of Module Shortage on Student PerformanceDocumento18 pagineEffects of Module Shortage on Student PerformanceSESENessuna valutazione finora

- Indian Forest Service Exam Cut-Off Marks 2018Documento1 paginaIndian Forest Service Exam Cut-Off Marks 2018surajcool999Nessuna valutazione finora

- Department of Education: Grade & Section Advanced StrugllingDocumento4 pagineDepartment of Education: Grade & Section Advanced StrugllingEvangeline San JoseNessuna valutazione finora

- Name: Fajar Abimanyu Ananda NIM: I2J022009 Class: Teaching English For Young Learners (TEYL)Documento3 pagineName: Fajar Abimanyu Ananda NIM: I2J022009 Class: Teaching English For Young Learners (TEYL)Fajar Abimanyu ANessuna valutazione finora

- Use Your Shoe!: Suggested Grade Range: 6-8 Approximate Time: 2 Hours State of California Content StandardsDocumento12 pagineUse Your Shoe!: Suggested Grade Range: 6-8 Approximate Time: 2 Hours State of California Content StandardsGlenda HernandezNessuna valutazione finora

- Revised RMS AVID HandbookDocumento15 pagineRevised RMS AVID HandbookAllison BallardNessuna valutazione finora

- FY 2023 Gender IssuesDocumento12 pagineFY 2023 Gender IssuesCATALINA DE TOBIONessuna valutazione finora

- Course File Format For 2015-2016Documento37 pagineCourse File Format For 2015-2016civil hodNessuna valutazione finora

- Eng 149 - Language Learning Materials Development HandoutDocumento45 pagineEng 149 - Language Learning Materials Development HandoutHanifa PaloNessuna valutazione finora

- Math Fall ScoresDocumento1 paginaMath Fall Scoresapi-373663973Nessuna valutazione finora

- MOOC 4 Negotiation GameDocumento1 paginaMOOC 4 Negotiation GameRoberto MorenoNessuna valutazione finora

- Preserving Historic Buildings and MonumentsDocumento261 paginePreserving Historic Buildings and MonumentsYoungjk KimNessuna valutazione finora

- Freedom WritersDocumento8 pagineFreedom WritersRacquel JohnsonNessuna valutazione finora

- Curriculum ProposalDocumento38 pagineCurriculum ProposalMailyne Ventura Bacongco100% (3)

- Me Enuc5112 Aw1 To Aw12 Sem 1Documento12 pagineMe Enuc5112 Aw1 To Aw12 Sem 1api-256758604Nessuna valutazione finora

- Clinical Reasoning Strategies in PTDocumento19 pagineClinical Reasoning Strategies in PTamitesh_mpthNessuna valutazione finora

- "A Product Is Frozen Information" Jay Doblin (1978) : by Dr. Aukje Thomassen Associate ProfessorDocumento12 pagine"A Product Is Frozen Information" Jay Doblin (1978) : by Dr. Aukje Thomassen Associate Professorapi-25885843Nessuna valutazione finora

- ISM MBA Admission Results 2014Documento7 pagineISM MBA Admission Results 2014SanaNessuna valutazione finora

- CHN - NCPDocumento2 pagineCHN - NCPfhengNessuna valutazione finora

- CV Julian Cardenas 170612 EnglishDocumento21 pagineCV Julian Cardenas 170612 Englishjulian.cardenasNessuna valutazione finora

- Literary AnalysisDocumento3 pagineLiterary Analysisapi-298524875Nessuna valutazione finora

- How To Draw Portraits (Beginner Starting Point) - Leveling ArtistDocumento10 pagineHow To Draw Portraits (Beginner Starting Point) - Leveling Artistluiz costa guitarNessuna valutazione finora