Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

KS-19557 ATT Bell Telephone Nuclear Blast Detector

Caricato da

c126358Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

KS-19557 ATT Bell Telephone Nuclear Blast Detector

Caricato da

c126358Copyright:

Formati disponibili

0

0

'

0

0

f.Ell SYSH.:.'-.\

Plant Series

SECTICN 01

3, Nove:mber 1968

AT 8.. I Co Standard

KS-19557 DETECTOR

{NUClEAR BlAST)

DeSCRIPTiON

CONTENTS PAGE

1. GENERAL .-

2. DESCRIPTION

3. OPERATION 3

4. TROUBLESHOOTING 6

S. MAINTENANCE OF ENVIRONMENTAL SHIELD

7

6. PROCEDURE FOR DETECTION UNIT

'REPLACEMENT 7

REMOVING THE DETECTION UNIT 8

REPLACING THE DETECTION UNIT 8

THE HIGH VOlTAGE CONVERTER

9

7. CABLE ASSEMBLY 10

8. SCHEMA TiC AND WIRING DIAGRAM 12

1. GEI\:ERAL

1.01 This section describes the KS-19557 detector

ir.wnded for use at any hardened communications

facility to provide warning of the detonation of a

nuclear device prior to the arrival of the associated

shock wave.

1.02 This section is reissued to change list numbers

in 1.04, operating voltages in 1.05, test

procedure in 4.02(2)(a) and (b), to add Part 7,

Fig. 5, 7, and 8, and to revise Fig. 9 and 10.

1.03 The detector basically consists of a radiation

sensitive detection unit installed in a blastproof

above ground level with the associated

cll't:tronic equipment installed in a hardened facility

below ground level. The detection unit and

associated electronic cquipm<.:nt are c()nnccted hy

signal lines and de Pf!Wer lines emlnsd in one

spt>cial!y dc;.;igned cable, one end of which is

terminated at time of installation (see Part 7).t

1.04 The detector is designated list

numbers 1 through and 2S through 40.t

The list number to be used at any given facility

is determined by the available de supply voltage,

whether the electrical equipment cabinet is to be

wall or rack mounted, whether the facility is

manned or unmanned, and whether the facility is

situated ahove or below an elevation of 4500 feet.

Each of the list numbers 'i through 13 and 28

through identifies a cbmplete detection system.

List numbers 17 through 27 and 44 through 47

identify the components of the system. List

numbers H through 13 are for use at facilities

located below 4500 feet in elevation and Jist numbers

28 through 40 are for use at facilities located

above 4500 feet in elevation. List numbers 44

through 47 are special electrical equipment cabinets

that are used in the high elevation detection systems

of list numbers through 40.. All other

components are interchangeable for high or low

elevation systems.

1.05 The detector operates on pov>er supplied by

the facility batteries wr.ich p:-event loss of

protection provided by the deteecor shodd comrr:ercial

power fail. The detection system is designed to

operate on +24Vdc or -24\'dc .

1.06 The electrical equipment cabinet can be

mounted either in a 19-inch or larger

equipment bay or on a wall. If mounted in the

bay, shock mountings are nv:. re<;uired on the

electrical equipment cabinet since tl-.e entire

equipment bay will be shock-mo:.:nted in accordance

with standard hardening procedurrs. For wall

mounting, a special bracket with shock isolators is

used.

Ameri!an T!lephont and Cornpany. )!HiS

l'rint"d in t:.s.A. Page 1

1.07 For mann(d faciliti<'s, the detector is designed

for rn;;nuai reset after triggering. A 3-minute

time delay on reset is incorporated to prevent

opening the blast valves as a shock wave is

approaching. For unmanned facilities, automatic

reset, after a 30-minute delay, is provided. For

both manned and unm:mned facilities, a key lock

S\\:itch is pnnidt'd to bypass the entire detector.

syst.m. allowing: tlw blast valves to be opened if

tlwy :;:n-e closed due to a failure in the detection

eqt:!pmC'nt and also to allow the blast valves to be

oper.td in an emergency. The key lock switch is

dC'signcd so the key cannot be removed when the

switch is in the MANUAL (bypass) position but

can be removed with the switch in the AUTO

position. Cnder normal operating conditions the

key should be removed from the switch to prevent

the detection system from inadvertently being

bypassed.

2. DESCRI?TION

2.01 The KS-19557 detector is a nuclear explosion

detection system activated by the gamma

radiation pelse released by the detonation of a

nuclear device. The detection system consists of

a detection unit, an electrical equipment cabinet,

and a connecting cable.

2.02 The detection unit (Fig. 1) is shock-mounted

within a shield assembly (Fig. 2} which is

shock-mounted above ground. The detection unit

and shield assembly are designed to withstand

repeated blast overpressures of 50 pounds per

square inch. The shield also provides adequate

insulation to prevent high temperatures from

damaging the scintillation plastic in the detection

unit. The scintillation plastic can withstand

temperatures up to 60oC for extended periods;

however, the temperature of the plastic must never

exceed 70C.

2.03 Activation of the detection unit is caused

by a gamma radiation pulse. The radiation

pulse reacts with the scintillation plastic, producing

a light pulse which is picked up by a photomultiplier

tube. After converting the light pulse to an

- ~ - - ~

----------

\ _,- '

/ .

/

/

.

/

Fig. 1-Detection Unit

Page '2

0

0

0

0

~

u

0

'\

(o

..

(0

rD.

~

(0

"-

--

- - - - - - ~ ....

. .,.,..

ISS 3, SECTION 480-325-101

l

I

l

l

I

!

A

I

l

}

/

. - .. : ... ..... ~ ... ...._.-.--... ~ - ____ . . _ _ _ - - - - - - ~

Fig. 2-Upper and lower Shield Assembly

electronic pulse, the tube and associated printed

circuit board components amplify the signal and

send it to the electrical equipment cabinet (Fig. 3)

where an output relay is deactivated.

2.04 When the output relay opens, devices (blast

shield, alarms, etc) connected to the detection

system will operate to protect the facility. A

fail-safe system is provided to ensure operation of

the devices should a de power failure occur. The

contact on the output relay is rated at a continuous

2-ampere resistive load at 250Vdc.

2.05 The general location of the components of

the KS-19557 detector is shown in Fig. 4

which depicts a typical hardened communications

facility. Detailed installation information for the

detector is given in KS-19557 i\uclear Blast Detector

Installation drawing, B-995326.

3. OPERATION

3.01 The following controls are provided on the

front panel of the electrical equipment

cabinet:

(a) OX-OFF switch-Controls all power to the

detector.

Page 3

,_ .. - - - - . . - - - ~ -

.i

..t

.....

o

- ~

~ J

INOICATING

L

FUSE

D

~

, . '

"--

(_',

I

I

. I

.I

:l

.. ~ ,

, ~

0

-

.I

,!

Fig. 3-Eiectrical Equipment Cabinet

(b) RESET switch-Following the proper time

interval, resets the circuit after it has been

tripped.

(c) TEST switch-Provides circuit test.

(d) TEST light-Flashing light when TEST switch

is operated indicates proper functioning of

detector. Continuous operation of the light

indicates detector has tripped.

(e) E :\1 ERG E :K C Y VALVE C 0 NT R 0 L,

:\IA:\UAL-AUTO-A key lock switch that is

operated to the AUTO position for normal

operation. In the MANUAL position, the detector

is bypassed and is no longer protecting the

facility.

(f) DETECTOR BYPASSED light-When lighted,

indicates detector is bypassed.

(g) Indicating fuse-When operated, indicates

overload or short circuit in equipment.

3.02 Operational T.est on Detector System After

Installation:

(1) Test is to be performed prior to the

attachment of station equipment that is to

be detector controlled.

Page 4

(2) Check to be sure B-995325 cable, connecting

the electrical cabinet to the detection unit,

is properly connected.

(3) Install the proper fuses in the electrical

equipment cabinet and in the facility power

distribution board at the designated location.

(4) E:\IERGENCY VALVE CONTROL switch

should be in the AUTO position.

(5)- Operate the detector ON-OFF switch to the

ON position. The TEST light should light

and glow continuously.

(6) After approximately 3 minutes on most

models, push the RESET switch. The TEST

light should go out. In detectors wired for

automatic reset, this step is automatically

performed by the equipment after a 30-minute

interval rather than the 3-minute interval.

(7) Push and hold TEST switch. The TEST

light should flash at approximately 112-second

intervals.

(8) Operate the E.MERGENCY VALVE COl\"TROL

key lock switch to the MANUAL position.

The DETECTOR BYPASSED light should light.

Return the switch to the AUTO position.

Ji!{S 4 4 L\ 9 tJiH ;c 41 ~ _;w.- c ;p ouc.QJA Ei

- - ~ . . _ . . . - - - - ~ .

t

L)

...

ta

\iii

ISS 3, SECTION 480-325:-101

DETECTION UNIT

ABOVE GROUND

ENTRANCE TO INSTALLATION

EQUIPMENT BAY

ELECTRICAL EQUIPMENT

CABINET

UNDERGROUND

FACILITY

Fig. 4-Typical KS-19557 Detector Installation

REINFORCED CONCRETE

MOUNTING PEDESTAL

Page 5

SECHON 480-325-101

'

,. (9) Station equipment may now be attached to

the detector output.

4. TROUBLESHOOTING

4.01 Operate detector ON-OFF switch to the ON

pos1t10n. The TEST light should glow

continuously. If it does not light, there is no

power to the detector, the fuse is open, or the

bulb is bur ned out.

4.02 Wait approximately 3 minutes, then push

RESET switch. (On the appropriate model,

a 30-minute wait will be required.) If the detector

fails to reset or if the TEST fails (see 3.02 (7)1

after resetting is accomplished, proceed to the

following steps:

(1) Keep the power on the detector.

(2) Set a VOM or VTV.M to measure t ::24Vdc

accordi.ng to the polarity of the power source.

H"H VOLTm SETTIN'

+ ---- voc

IC3

0

0

(a) Connect the hot lead to TS2 terminal 1.

See Fig. 5 for location of terminals in

the electrical equipment cabinet. Connect

the common lead to the chassis. If the voltage

is 21 to 28 volts, the proper power is reaching

the detector output.

(b) Move the positive lead to TSl terminal 1

and connect the negative lead to the

chassis. The voltage should be +23 to

+ 26Vdc .

Note: If the voltages (2) or (3) are incorrect,

disconnect the cable that goes to the detection

unit and remeasure the voltages. If the

proper readings are then present, the cable,

its connectors, or the detection unit is at

fault.

(3) Set a VOM to the 250Vdc scale. Connect

the negative lead of the meter to TPl

located on the side of the high voltage compartment.

Connect the positive lead to the chassis. For

0

0

II

uo

0

0 0

~ FLI

0

~

~ 0 0 2

0

Fig. S- Eiectrical Equipment Cabinet -Cover Open

Page 6

(;)

0

0

"

'

(G

I

()

(j

dl'tcctor:' for high ckvation, the meter

should ir.die:tt( hl'tWcl'n 11 \)and t:nVdc. Voltages

for all other detectors should be between 121

and 152\'Jc. The voltage for a given detector

system is determined by the detection unit. One

specific voltage is required for each detection

unit !see 6.28 (5)]. If the meter indication is

correct, the proper high voltage is being generated.

(4) Set a to measure -130Vdc. Connect

the nC'gative lead to the lower terminal of

resistor R3S. Resistor R38 is located on the

bracket next to switch S4 on the inside of the.

front paneL It is the resistor farthest away

from the switch. Connect the positive lead to

the chassis. Depress the TEST button. The

meter should indicate greater than 90Vdc.

4.03 If the tests in 4.01 and 4.02 are satisfactorily

completed and an oscilloscope is available,

perform the following:

(1) Set oscilloscope as follows:

Horizontal-100 f!Sec/cm

Yertical-5 volts/em

Trigger-internal positive

(2) Connect the ground lead to the chassis and

the input lead to. TB3 terminal E3.

(3) Depress and hold the TEST switch. The

observed pulse should be at least 3.5 volts. _

If this pulse is present, the detector trouble is

probably in the multivibrator circuit or the output

relay (Kl). If this pulse is not present, the

trouble is in the cable or connectors to the

detection unit or the detection unit itself.

5. MAINTENANCE OF ENVIRONMENTAL SHIELD

5.01 For the detector to function properly should

a nuclear explosion occur, the flame sprayed

aluminum surfaces of the environmental shield

must be kept clean.

5.02 The flame sprayed aluminum surfaces may

be cleaned with soap and water and a soft

bristled brush. Under no circumstances should

these surfaces be given an orgamc finish.

,;oowP'"I!I - $ ) *"i#.

ISS 3, SECTION 480-325-101

6. PROCEDURE FOR DETECTION UNIT REPLACEMENT

6.01 Should it become necessary to replace a

detection unit, the high voltage converter

located in the electrical equipment cabinet must

be adjusted to the operating voltage requirement

for the new detection unit. This adjustment must

be made prior to using the detection system. The

required operating voltage, which is stamped on

the side of the detection unit directly below the

serial number, should be recorded in place of the

old requirement in the electrical equipment cabinet.

It is imperative that this adjustment be made, as

covered in 6.28, since each detection unit has a

different operating voltage requirement.

6.02 List of Tools and Materials Required for

Detection Unit Replacement:

CODE OR

SPEC NO.

TOOLS

R-2812

R-1060

MATERit.LS

DESCRIPTION

3/16-Inch Allen Wrench

Putty Knife

1-1/8 Inch Socket Wrench

Ratchet Wrench

6-Inch Screwdriver, Captive Type

(see note)

Automobile Bumper Jack

P Long-Nose Pliers

Torque Wrench (capable of meas-

uring 106 foot pounds)

Wood Blocks 3- by 1- by 1/4-inch

thick (approximately) 2 required.

Note: If a captive type screw-

driver is not available a 6-inch

C screwdriver and a 606 screw-

starter.

Heavy gauge plastic, cardboard,

or other similar material to be

used for padding on the lifting

jaw of the bumper jack. Also,

a large enough piece of the same

material to be placed on the

Page 7

..J

ground and used as a mat to

protect the flame sprayed surface

of the upper shield from chipping

after it has been removed.

EC-1020 Sealer, l\Hnnesota ~ l i n

ing and Mfg. Co., St. Paul, Minn.

8451 "0"-Ring, 15.50-inch O.D.,

Minnesota Rubber Co., Minnea-

polis, ~ ! i n n . or Parker Seal Co.

equivalent.

Protect-Sorb 121 Silica Gel, two

8-unit Lantuck Bags, Davison

Chemical Co., Baltimore, Mary-

land.

REMOVING THE DETECTION UNIT

6.03 Remove the twelve 3/4-inch bolts.

6.04 Place a protective pad under one of the four

handhold lugs of the upper shield and emplace

the bumper jack with its lifting jaw under the lug.

6.05 Slowly jack up the upper shield until there

is enough clearance to emplace the wooden

blocks.

6.06 Remove jacks.

Caution: When ha;:zdling the upper shield,

exercise care to prevent chipping the flame

sprayed surface. The shield cannot function

properly under nuclear blast conditions

unless its surface is clean and free of

defects.

6.07 Partially lift out the upper shield and detection

unit assembly and rest it at an angle in

the lower shield to allow removal of the cable

through the 4-112 inch hole in the bottom of the

inner container. If properly placed, the operator

should be able to see the connectors through the

hole. Disconnect the two connectors and the ground

wire.

6.08 Lift out the upper shield and detection unit

assembly, invert, and place on the protective

mat.

6.09 Remove the 15.50-inch "0" -ring and discard.

Page 8

6.10 Remove silica gel packets. Th('y can be

reactivated for later use or di:-cardcd.

6.11 Clean off the majority of the EC-1020 sealant

with a putty knife.

6.12 Through the hole in the bottom of the inner

container, remove the five screws holding

the detection unit to the 5-inch diameter spring.

Save the screws.

6.13 Remove and save the 12 socket head screws

from the upper shield, then remove and

invert the inner container.

6.14 Release the six springs by applying the

long-nose pliers on the loop at thP. detection

unit end of the spring. Use care to avoid crushing

the insulation which is easily damaged.

6.1 s Remove detection unit. Do N 0 T lift using

scintillator cone.

REPLACING THE DETECTION UNIT

6.16 Place the detection unit on the large spring

properly oriented so the 8-pin connector is

located next to the spring plate cutout.

6.17 Engage the 6 springs.

6.18 Place the inner container carefully on its

side and secure the detection unit to the

5-inch -diameter spring using the screws removed

in 6.12.

6.19 Place the inner container on the inverted

upper shield and attach it with the 12 socket

head screws. Two 1/4-20 setscrews placed 180

degrees apart can be used to orient the container

for easier assembly. They need not be removed

if their height is equal to or less than the head

height of the socket screws they replace.

6.20 Place a new 15.50-inch diameter "0" -ring in

the groove on the lower shield.

6.21 Place the EC-1020 sealant on the lower shield.

6.22 Position the assembly at an angle as in 6.07

and attach the ground wire and connectors.

,.aP _,.. 4 ifhc;ucww$ .1 _ .-.;::: _;& = %0 44!4hW ji U; MiJl -

1

'

(

.1

6.23 Remove the two 8-unit silica from

their foil wrap and place in the bottom of

the lower shield in the well created by the lower

mounting ring.

6 .24 Check the EC-1020 sealant placement.

6.25 Lower the upper shield carefully

into the lower shield, orienting the bolt holes

properly. Once the two surfaces meet with the

entire weight of the upper shield, it will be impossible

to reorient them without again using the bumper

jack as a lifting aid. (EC-1020 may have to

be replaced.)

6.26 Tighten the 3/4-inch bolts to 106 foot pounds

of torque.

6.27 Check to be sure that the EC-1020 has

squeezed out uniformly around flange. Surface

areas of the flange which are not coated with the

sealant will rust since they contain no other

protective coating.

ADJUSTING THE HIGH VOLTAGE CONVERTER

6.28 After replacing a detection unit, adjustment

of the high voltage conver ter on the electrical

equipment cabinet is necessary. The method of

adjusting the high voltage converter is given in

the following steps:

(1) Operate the switch on the front

panel to the OFF position.

(2) Remove fuse from the front panel.

(3) Remove the screws and open the front

panel.

(4) Remove the screws from the high voltage

compartment CO\'er located in the upper left

hand corner of the electrical equipment cabinet,

and r e move the cover. The high voltage

compartment is illustrated in Fig. 6.

_.A.___ _______ _

ISS 3, SECTION 480-325-1

HIGH VOLTAGE

CONVERTER--;....:.

Fig. 6-High Voltage Compartment - Cover Removed

(5) Refer to the correct detection unit voltage

as stamped on the new unit. In some

instances, adjusting the electrical cabinet hiEh

voltage may require changing resistor R35. Check

the value of R35. The following list shows

values for R35 based on the required detection

unit voltage and the limits of the high voltage

converter .

R3S IN OHMS

56,000

33,000

10,000

DETECTION UNIT VOLTAGE

740 through 830

830 through 910

910 through 960

If necessary, change resistor R35.

(6) Remove the cap from the adjusting screw

of DOL

(7) Push out the adjusting hole plug in the

right side of the compartment.

(8) To determine the correct voltage at TPl.

multiply the high voltage requi red by the

detection unit by 0.161. For example, a detection

unit requiring 850Vdc will produce a test point

reading of 137Vdc. Set the meter accordingly.

Connect the negative lead of a de voltmeter to

TPl. Connect t he positive lead to the chassis.

(9) Insert an insulated tool through the hole in

the right side of the compartment and into

the alignment screw in DOl. The tool should

have a 1/8-inch wide screwdr iver-type end.

(10) Replace the high voltage compartment

cover in order to engage the interlock.

Page 9

I

'

SECTION 4 80-3 25-1 01

(11) Replace the front panel fuse.

(12) Operate the ON-OFF switch to the ON

position.

(13) Adjust DD1 by turning the insulated tool

slowly until the meter indicates the correct

test point voltage. (Turn clockwise to increase

voltage.)

(14) Operate the ON-OFF switch to the OFF

position.

(15) Remove high voltage compartment cover

and replace the cap on the adjusting screw

in DDl.

(16) Replace the plug in the side of the

compartment.

(17) Replace the high voltage compartment

cover.

(18) Replace the front panel.

7. tCABLE ASSEMBLY

7.01 The electronic equipment end of the KS-19557

cable assembly (Fig. 7) is furnished raw-ended.

The connectors are shipped loose with the cable

assembly and must be wired at the installation site.

7.02 Termination of KS-19557 Cable Assembly

(a) Termination of connector plug PT06E-12-8P

(1) Remove approximately 5 inches of outer

jacket from the B-995163 special electrical

cable. Do not damage the inner cable jackets.

(2) Prepare both tv.:isted pair sections of the

cable as shovm in Fig. SA and 8B. Remove

the minimum length of jacket to allow for

the required length of skinner and assembly

of inner ferru!e. Do not nick the strands of

shielding.

(3) Tin the i ~ n e r conductors.

(4) Slide the size 6 insulation sleeving onto

the cable jacket.

Page 10

(5) Slide the inner ferrule over the conductors

and under the shielding as close as possible

to the end of the outer jacket (Fig. 8B). Trim

the shielding 1116 inch from the edge of the

inner ferrule. Do not comb out the shielding

unless it is too tight to assemble the inner

ferrule.

(6) Slide the outer ferrule forward over the

shielding and insert the bare conductor

of the shield conductor under the outer ferrule.

The outer ferrule shall be within 1132 inch

from the inner ferrule as shown in Fig. 8B.

(7) Crimp the outer ferrule using an appropriate

tool. Verify that the inner ferrule has

not collapsed from the crimping operation.

(8) Slide size 6 insulation sleeving forward

over entire termination (Fig. 8B). Shrink

sleeving by applying an approved heat source.

(9) Cut shield conductor to same length as

insulated conductors.

(10) Perform Steps 4 through 9 for the other

twisted pair section of the cable.

{11) Disassemble the connector. Remove

the cable clamp parts from the rear body

of connector. Discard clamp, nut parts, and

rubber wire sealing grommet.

(12) Slide 1-112 inch insulation sleeving over

. the shield conductors and both twisted

pair cables onto their jackets.

(13) Slide rear body of connector and grommet

retaining ring over conductors and shield

terminations.

(14) Slide 5/8-inch length insulation sleeving

over all insulated shield conductors

(Fig. 8B).

{15) Solder inner conductors to proper terminals

as shown in Fig. 7. Slide insulation

sleeving over soldered terminations.

(16) Assemble the connector.

(17) Slide 1-112 inch length insulation sleeving

forward over shield termination and cable

clamping tabs of rear connector body (Fig. 7).

Shrink sleeving by applying an approved heat

source.

I

l

G

I

I

Q

l

I

I

l

6

J

1

CONNECTOR PLUG

(MALE)

NO. PT06E- 12- 8P

INSULATION SLEEV!NG

1-1/2 IN. LENGTH

I

!-- ------- AS

REQUIRED

NOTE:

ISS 3, SECTION 480-325-101

INSULATION SLEEVING

1-112 IN. LENGTH

CONNECTOR PLUG

(FEMALE)

NO PT06E -12-85

ELECTRONIC EQUIPMENT

CABINET END OF CABLE THIS END MUST BE WIRED AT THE INSTALLATION SITE,

PARTS ARE SHIPPED LOOSE WITH CABLE ASSEMBLY.

DETECTION UNIT

END OF CABLE

W-BL

VIEW FROM WIRING SIDE

P4

CONDUCTORS

BL G W-G w W-G

P2

BK

CABLE

CONDUCTORS

G -BL BL. w

Fig. 7-Cable Assembly

(b) Termination of Connector Plug 2085-1

(1) Prepare cable containing high voltage wire

as shown in Fig. 8A and 8C.

(2) Pull shielding toward end of conductor

and shape open end of shielding into a

cone. Outer surface of :,.;lielding will be

smooth.

(3) Slide clamp nut, plain washer, and rubber

gasket over shielding and onto jacket;

then slide shield clamp over shielding of cable

until the inside protrusion butts against outer

jacket (Fig. 8C).

(4) Fold shielding back over shield clamp,

forming a smooth outside surface with no

crossover of strands.

(5) Cut shielding to the outside diameter of

shield clamp as shown in Fig. 8C.

(6) Remove dielectric to dimension shown.

Do not nick the inner conductor. Tin

bare conductor, insert into contact pin, and

solder. Contact pin must butt against dielectric.

Page 11

_ ........ ._. ____

... SECTION 480-325- 101

..

'

Remove from oulo;;ide of contact.

Be sure cable dielectric is not heated excessively

and swollen so as to prevent it from entering

the connector body.

(7) Push assembly into connector body

far as possible. Hold cable and shell

OUTER JACKET OF

8-99!)163 CABLE

INSUL.ATION

SLEEVING

SIZE 6

INSULATION SHIELD

TWIST!> PAIR SIZE

slide clamp nut into body, and screw

into place with wrench until secure .

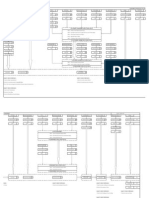

8. SCHEMA TIC AND WIRING DI AGRAM

8.01 Fig. 9 and 10 give the schematic and w1rmg

diagram, respectively, for the KS-19557

detector.

INSULATED CONDUCTORS

TWISTED PAIR SECTION OF CABL

A

SECTION OF CABL

CLAMP

HIGH VOLTAGE NUT

SECTION J WASHER

OUTER JACKET /(1 GASKET

- SHIELDING

... '

SHIELD CLAMP

CONTACT PIN

DIELECTRIC

SHIELDING

SHIELD

CLAMP

SECTION

S:.. EEVI NG

INSULATING SLEEVING

B

5/B IN. LENGTH

c

Fig. 8-Connettor Termination

Page 12

<9

I

I

'

! :r __ "2- --- n

I

I

Cl2

0.01

E4

E2

E3

E4

1

E2

Rl4

6800

Ql

16F

CRI

IN666

L

CIB

0.01

+

10 -

CI4I

Cl6

0.47

Rl7

1800

Ll

10

__ El

Cl5

10.47

E5

Jl PI - P3

A :-----.,.1

I I I ol I

8 > I II I I I

U

: I

I I

I

I

I

I

I

I

I

I

I

I

I

I

G

'I

II

II

I I

I I

II

II

,I

:I

II

"

fl

,,

I H nil

:

I ::t-------4 F

II

I

i

[

E

INPUT -

VOLTAGE

tjl OW .C, W:.&41(Lti.!!1ijP - _s:_p;: 4 &C*<?i i.f .. '!llf'7 .,. .... SC 49 .P, ,.P -CI$31( 4QS !Q44Q

---

f. hZAOU -

""

,.

P3

I

A

B

C22

47

,8+1

I

J3

'I

I

"'I

-r

----B

I

J

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

G

I

I

I

I

I

I

I

I

I

I

I

I

I

I

11''

I GRD

I A

I

I

' I

H 'f

I

I

F

I

I

("' BAT

I

GRO

I

l...

I

I

I

--- ---------

El

TB3

MULTIVIBRATOR

C27

H 1000 UUF

I

J

I

I

R22 !>

Q5

I

Rl9 R20

2N2219A

E2

I

3300.

.

82,000

.6j

.A

{{)Q6 R23

2NI719

C21

0.12 MEG

I

C20

I

l\

I

0.5

Q4

I .HE-

-A !\tv

I 16F

I

R21

I

30,000

CR5

INIOO

R24

10,000

lr

CR2

IN673

-1330

I

CR3

I

INIOO

'

CR4

I I

IN673

I

R25?

y CR7

I

_j

1000

IN673

R26

;:-

E3 2000

.JI,

--- --- ---

C24

47

R36

0.39 MEG

I v

C28 :'::::

R38

o.o1-

5600

..A 'A

- C25

l4

0.47

":::"

54

P/0

TEST 10

TS2

C29

I 0.25

___.i__

II

l

2

-

2

TSI-1,2

I

+

Fl

51

002

:r- .JI

2 2A 3

4

I 2

TSI-4

....,

OFF-ON

1 I

TSHS

1

P/0 P/0

TS3 +

-:I

3 4

C30

G)

3

+

0.25

!/1

I

5

;.._

l

FLI

t---<

'----

4

-

;:-

TSI-3 2

2

.,.- .

l

L__

L__

--

L ___ -=-

---- --.:;__ __

ELECTRONIC I

052

TEST

Kl

17 {g

oTto

: 15

6t

221r-

CR6

IN673

_ .....

Kl

I

13

2t

2

3 1

I

K3

' 53

RESET

R39

270

-v' '\r

2 I

Kl

18 _ill

t 12

*

R34 _>

), TSI-

JB

.J1o

P6

R37

I

560

I

I I I

I I

./21

TSI-3

I

,,.

1

":::"

I

-- -----

,Q#J:p::;:;!i,SC)!

. :OC. V. t $i 1 i!P jW. IUA ,4 iC:-4. 4WAIPflW W4 .+!if411Ui#l:t. $944 " c .4 T lA SNIQI(!M

I!>!> SECTION 480-325-101

EQUIPMENT

EIIER

5

G

2

ENCY DS3 - -

VALVE CONTROL DETECTOR

BYPASSED

I

Kl K3

14 7

p p

p

P/0

TS2

Y:h

J5

J5

J5

16

I

- -- -

6

----L-3-- C z3- --------

IO.SH I

....... H

I DDI

I

5 +

K2

TIME DELAY RELAY

(MINUAL RESET)

NOTES:

I. UNLESS OTHERWISE SPECIFIED, RESISTANCE

VALUES ARE IN OHMS. CAPACITANCE VALUES

ARE IN MICROFARADS. INDUCTANCE VALUES ARE

I IN MILLIHENRIES.

. 2. SEE STOCK LIST OF ASSEMBLY DRAWINGS

I B-B76946 FOR INFORMATION CONCERNING

COMPONENTS REFERRED TO BY REFERENCE.

3.

PROVIDE

FEATURE

OR

APP

OPTION

FIG. OR QUANTITY

FIG.

MANUAL RESET

I PER CKT

AUTOMATIC RESET T

I PER CKT

AVAILABLE

r---

MFR

!"PUT

9

i----

SUPPLIED, r---

VOLTAGE

t---- i----

PROPER

AT

CONN TO BE

INSTALLA-

+24V

r-y MADE AT

TION

:z--

INSTALLA-

-24V

TION

--1--lli -=-

I

-__ ----_- __ -__ _____

Fig. 9--KS-19557 Detector (Nuclear Blast) Schematic

Page 13

"'--

I

Potrebbero piacerti anche

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDa Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsValutazione: 4 su 5 stelle4/5 (1)

- SAC Guide To ICBM Operations Crew Duty - 1988Documento63 pagineSAC Guide To ICBM Operations Crew Duty - 1988c126358Nessuna valutazione finora

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Nessuna valutazione finora

- 110 Waveform Generator Projects for the Home ConstructorDa Everand110 Waveform Generator Projects for the Home ConstructorValutazione: 4 su 5 stelle4/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Valutazione: 2.5 su 5 stelle2.5/5 (3)

- Information Operations Primer (Unclassified)Documento194 pagineInformation Operations Primer (Unclassified)c126358Nessuna valutazione finora

- Equipment CapabilitesDocumento19 pagineEquipment Capabilitesapi-1975359897% (194)

- US Nuclear Targeting Policy Review (1978)Documento19 pagineUS Nuclear Targeting Policy Review (1978)c126358Nessuna valutazione finora

- TM-10-8340-221-13 Tent Shelter Half and MountainDocumento32 pagineTM-10-8340-221-13 Tent Shelter Half and Mountainc126358100% (1)

- GuidewireClaimCenter Performance TestPlanDocumento18 pagineGuidewireClaimCenter Performance TestPlanshanthan117Nessuna valutazione finora

- High Speed Embeddable Cryptographic Chipset (Unclassified)Documento45 pagineHigh Speed Embeddable Cryptographic Chipset (Unclassified)c126358Nessuna valutazione finora

- Inside A Soviet SS-18 ICBM ComplexDocumento86 pagineInside A Soviet SS-18 ICBM Complexc126358Nessuna valutazione finora

- AFGSC 91-1005 ICBM Nuclear Code Operations (Unclassified)Documento56 pagineAFGSC 91-1005 ICBM Nuclear Code Operations (Unclassified)c126358100% (1)

- Introduction to Power System ProtectionDa EverandIntroduction to Power System ProtectionNessuna valutazione finora

- Chapter 3 Generator Circuit Breaker (GCB)Documento15 pagineChapter 3 Generator Circuit Breaker (GCB)Anonymous nwByj9LNessuna valutazione finora

- TM-10-8415-236-10 ECWCS ClothingDocumento95 pagineTM-10-8415-236-10 ECWCS Clothingc126358100% (1)

- TAIL Project NewsletterDocumento9 pagineTAIL Project NewsletterAbdul R. MustaphaNessuna valutazione finora

- 21M-HGM-25A-1Titan I ICBM Technical Operations Manual 1964 (Unclassified)Documento594 pagine21M-HGM-25A-1Titan I ICBM Technical Operations Manual 1964 (Unclassified)c126358100% (1)

- Electronic Systems: Study Topics in Physics Book 8Da EverandElectronic Systems: Study Topics in Physics Book 8Valutazione: 5 su 5 stelle5/5 (1)

- The Joint Strategic Target Planning Staff and SIOP4 1973 (Unclassified)Documento70 pagineThe Joint Strategic Target Planning Staff and SIOP4 1973 (Unclassified)c126358Nessuna valutazione finora

- Explosive Magnetic Flux Generators (Los Alamos)Documento34 pagineExplosive Magnetic Flux Generators (Los Alamos)c126358Nessuna valutazione finora

- EASA Part 66 Module 7 MCQ and Essay QuestionsDocumento4 pagineEASA Part 66 Module 7 MCQ and Essay QuestionsazadairNessuna valutazione finora

- Scallops Are Cut Outs in Weld Corners Which Are Used in Many Structures As in BridgesDocumento3 pagineScallops Are Cut Outs in Weld Corners Which Are Used in Many Structures As in BridgesJanuel BorelaNessuna valutazione finora

- Power Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageDa EverandPower Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageNessuna valutazione finora

- TM 55 1680 349 10 Survival Kit Hot ClimateDocumento41 pagineTM 55 1680 349 10 Survival Kit Hot Climatec126358100% (1)

- A Practical GuideDocumento10 pagineA Practical GuidepartisNessuna valutazione finora

- NX Training Syllabus Module IDocumento5 pagineNX Training Syllabus Module IDharaiya HardikNessuna valutazione finora

- Liebert Ac3 Auto Change OverDocumento19 pagineLiebert Ac3 Auto Change OverHasib Khan50% (2)

- Advanced clutter options for radio propagation modelingDocumento40 pagineAdvanced clutter options for radio propagation modelingLaura VillarrealNessuna valutazione finora

- Introduction to Power System ProtectionDa EverandIntroduction to Power System ProtectionValutazione: 5 su 5 stelle5/5 (1)

- Infiltration Ventilation LeakageDocumento42 pagineInfiltration Ventilation LeakageBulut YildizNessuna valutazione finora

- 1963 Missile Launch Officer Training Manual For Atlas F ICBM (21M-HGM-16-F-1)Documento46 pagine1963 Missile Launch Officer Training Manual For Atlas F ICBM (21M-HGM-16-F-1)c126358100% (2)

- Installation And Maintenance Manual JOSLYN P/N 1455-85-M JOSLYN P/N 1455-85-MN Ac Power Arresters 208/120 VAC, 3φ, 4 WIRE, GROUNDED WYEDocumento8 pagineInstallation And Maintenance Manual JOSLYN P/N 1455-85-M JOSLYN P/N 1455-85-MN Ac Power Arresters 208/120 VAC, 3φ, 4 WIRE, GROUNDED WYEsrogan2323Nessuna valutazione finora

- A Isometer IR475LYDocumento3 pagineA Isometer IR475LYUrsula JohnsonNessuna valutazione finora

- S310 OpManIssue3Documento24 pagineS310 OpManIssue3service3397Nessuna valutazione finora

- CT 4534Documento51 pagineCT 4534Matthew WinksNessuna valutazione finora

- Apex Mod. At1302 Cn-12c-TextDocumento55 pagineApex Mod. At1302 Cn-12c-Textluchador1000Nessuna valutazione finora

- Advance PP3 Twin DC SupplyDocumento13 pagineAdvance PP3 Twin DC SupplyJohn DosherNessuna valutazione finora

- 50UX58BDocumento88 pagine50UX58Bnip27Nessuna valutazione finora

- 33kV Indoor Switchgear Technical DetailsDocumento19 pagine33kV Indoor Switchgear Technical DetailsBala KumaranNessuna valutazione finora

- Series: Photoelectric Smoke DetectorDocumento4 pagineSeries: Photoelectric Smoke DetectorRuben MoralesNessuna valutazione finora

- Sharp 14v-r70m Chassis Ga-4mDocumento43 pagineSharp 14v-r70m Chassis Ga-4mRiza Badua75% (4)

- Smoke DetectorDocumento2 pagineSmoke DetectoratharvawazurkarNessuna valutazione finora

- 14T1LDocumento53 pagine14T1Lsuranovi6858100% (2)

- Sharp 19c140 SMDocumento24 pagineSharp 19c140 SMRaymon SinghNessuna valutazione finora

- 26MR70Documento28 pagine26MR70jotas2525Nessuna valutazione finora

- 50UX19KDocumento77 pagine50UX19Ksprock2Nessuna valutazione finora

- LA 76931S 7N DatasheetDocumento20 pagineLA 76931S 7N DatasheetjulioescandonNessuna valutazione finora

- Service Manual: Sharp CorporationDocumento34 pagineService Manual: Sharp CorporationIrwingSanchezNessuna valutazione finora

- Service Manual: Color Television Chassis No. SN-012Documento28 pagineService Manual: Color Television Chassis No. SN-012inglarkinNessuna valutazione finora

- The Oxford Polytechnic: Log SheetDocumento9 pagineThe Oxford Polytechnic: Log SheetAnonymous EayGj0Nessuna valutazione finora

- 32 Ls 400Documento44 pagine32 Ls 400drone001Nessuna valutazione finora

- Service Manual: ModelDocumento60 pagineService Manual: ModeldonobeeNessuna valutazione finora

- Samsung Sync Master 955DF AQ19LS AQ19JSDocumento62 pagineSamsung Sync Master 955DF AQ19LS AQ19JSClaudio Hector ArrosaNessuna valutazione finora

- 21V-FR95S Service ManualDocumento47 pagine21V-FR95S Service ManualAngel Goicochea100% (1)

- Sharp 21MFG1L Chasis GA6Documento60 pagineSharp 21MFG1L Chasis GA6Xavier Lg100% (1)

- Service Manual: Color Television Chassis No. GB-3UDocumento40 pagineService Manual: Color Television Chassis No. GB-3UEder Espinoza Bajonero100% (1)

- Service Manual: Color Television Chassis No. GA-4MDocumento42 pagineService Manual: Color Television Chassis No. GA-4MKennex Trazo50% (2)

- 21v fp90sDocumento49 pagine21v fp90sMhon Adenip LloquironNessuna valutazione finora

- Service Manual: 20LK30A/60ADocumento31 pagineService Manual: 20LK30A/60Apineda910Nessuna valutazione finora

- TV Sharp 19k-m100Documento36 pagineTV Sharp 19k-m100psequera29100% (1)

- LCD-FUNAI A1504 Inverter - A2004 (L4100 - 4200EA)Documento67 pagineLCD-FUNAI A1504 Inverter - A2004 (L4100 - 4200EA)TvcrepairNessuna valutazione finora

- 27RFS1Documento42 pagine27RFS1hhr_leoNessuna valutazione finora

- Sharp 27ks100 SMDocumento62 pagineSharp 27ks100 SMperseo232Nessuna valutazione finora

- Samsung UN32C4000PDDocumento114 pagineSamsung UN32C4000PDGilberto Nunes Dualdo JuniorNessuna valutazione finora

- Service Manual: Color Television Chassis No. GA-1'Documento28 pagineService Manual: Color Television Chassis No. GA-1'tecniconivelNessuna valutazione finora

- Sharp 19r-m100 (Srec) Chassis Sn-010Documento27 pagineSharp 19r-m100 (Srec) Chassis Sn-010Wilmer Mendoza0% (1)

- Sharp 14T1 LDocumento45 pagineSharp 14T1 LCarlos R Sevilla T100% (1)

- 21FL94 TV Sharp PDFDocumento48 pagine21FL94 TV Sharp PDFJose Luis100% (3)

- Man-1078 SigmaCP 24Documento24 pagineMan-1078 SigmaCP 24Viddhesh ManjrekarNessuna valutazione finora

- 20 F 650Documento50 pagine20 F 650Edgar PimentelNessuna valutazione finora

- 708 Supertrol Electrical SystemsDocumento24 pagine708 Supertrol Electrical SystemsPepe PintoNessuna valutazione finora

- 29FL90Documento38 pagine29FL90canamaNessuna valutazione finora

- Sharp 29mu70 Chassis C-BM D-BM SM PDFDocumento28 pagineSharp 29mu70 Chassis C-BM D-BM SM PDFManuel Melara100% (1)

- 27 UC4 SharpDocumento40 pagine27 UC4 SharpJosé David López LópezNessuna valutazione finora

- Private Bradley Manning Court StatementDocumento34 paginePrivate Bradley Manning Court Statementc126358Nessuna valutazione finora

- NSA TS Cryptolog December 1975 (Unclassified)Documento31 pagineNSA TS Cryptolog December 1975 (Unclassified)c126358Nessuna valutazione finora

- Code Name FurtheranceDocumento65 pagineCode Name Furtherancec126358Nessuna valutazione finora

- 2012 DOD Sensitive Compartmented Information Security Manual (Unclas)Documento72 pagine2012 DOD Sensitive Compartmented Information Security Manual (Unclas)c126358Nessuna valutazione finora

- Global Hawk RQ-4 Operations (Unclassified)Documento8 pagineGlobal Hawk RQ-4 Operations (Unclassified)c126358Nessuna valutazione finora

- US Air Force Crypto Mod 2009 (Unclassified)Documento21 pagineUS Air Force Crypto Mod 2009 (Unclassified)c126358Nessuna valutazione finora

- Defense Atomic Support Agency (Unclassified)Documento50 pagineDefense Atomic Support Agency (Unclassified)c126358Nessuna valutazione finora

- US Reduction of Nuclear WarheadsDocumento47 pagineUS Reduction of Nuclear Warheadsc126358Nessuna valutazione finora

- First Aid: FM 4-25.11 NTRP 4-02.1 AFMAN 44-163 (I)Documento224 pagineFirst Aid: FM 4-25.11 NTRP 4-02.1 AFMAN 44-163 (I)Giuseppe TrovatoNessuna valutazione finora

- Criticality Event Analysis For Plutonium ComponentsDocumento24 pagineCriticality Event Analysis For Plutonium Componentsc126358Nessuna valutazione finora

- 21M-HGM-16F-1 Atlas ICBM Technical Operation Manual (Unclassified) 1964Documento507 pagine21M-HGM-16F-1 Atlas ICBM Technical Operation Manual (Unclassified) 1964c126358Nessuna valutazione finora

- ICBM Inertial Guidance System Theory 1959 (Unclassified)Documento14 pagineICBM Inertial Guidance System Theory 1959 (Unclassified)c126358Nessuna valutazione finora

- SAC MCCC Leadership GuideDocumento47 pagineSAC MCCC Leadership Guidec126358Nessuna valutazione finora

- V-2 A-4 Rocket Operations ManualDocumento167 pagineV-2 A-4 Rocket Operations Manualc126358100% (2)

- Aidmans Medical Guide FM 8-36Documento71 pagineAidmans Medical Guide FM 8-36Lone CommissarNessuna valutazione finora

- Baja Parts Catalog PX250S Motorcycle VIN Prefix LUAHDocumento20 pagineBaja Parts Catalog PX250S Motorcycle VIN Prefix LUAHholycostNessuna valutazione finora

- Hybrid or Standard?: Why The Urge To "Go Green"Documento20 pagineHybrid or Standard?: Why The Urge To "Go Green"Tyler McPhersonNessuna valutazione finora

- Hdfs Default XML ParametersDocumento14 pagineHdfs Default XML ParametersVinod BihalNessuna valutazione finora

- Universal CNC Turning Center Maxxturn 65 G2Documento13 pagineUniversal CNC Turning Center Maxxturn 65 G2Vũ LêNessuna valutazione finora

- What Is AmplifierDocumento18 pagineWhat Is AmplifierEbayLunaNessuna valutazione finora

- Mktech Is1-19Hd & Receptor: Receptor PVR de Satelit Si Semnal Terestru Raport de TestareDocumento7 pagineMktech Is1-19Hd & Receptor: Receptor PVR de Satelit Si Semnal Terestru Raport de TestareAlexander WieseNessuna valutazione finora

- LMS Adaptive FiltersDocumento14 pagineLMS Adaptive FiltersalialibabaNessuna valutazione finora

- Gilding Manual PDFDocumento14 pagineGilding Manual PDFIva VazNessuna valutazione finora

- Linthwaite: Conservatio N AreaDocumento26 pagineLinthwaite: Conservatio N Areabill baileyNessuna valutazione finora

- Linux CommandsDocumento2 pagineLinux CommandsVishwas BeedeNessuna valutazione finora

- CRCM Manual 2 9 16Documento33 pagineCRCM Manual 2 9 16Kamagara Roland AndrewNessuna valutazione finora

- Measurement & Calculation of Vehicle Center of Gravity Using Portable Wheel ScalesDocumento11 pagineMeasurement & Calculation of Vehicle Center of Gravity Using Portable Wheel ScalesVedant KodagiNessuna valutazione finora

- Troubleshoot Microlab 600 DiluterDocumento3 pagineTroubleshoot Microlab 600 DiluterAkmal RakhmadiNessuna valutazione finora

- Vista 128BPT Program ManualDocumento72 pagineVista 128BPT Program ManualyalmanzaNessuna valutazione finora

- Chapter 4.1 Basic Call Procedure (ED01 - 53 - EN)Documento53 pagineChapter 4.1 Basic Call Procedure (ED01 - 53 - EN)quaderbtech06Nessuna valutazione finora

- Bluskies Engineering PVT LTD: Acp Panel Inpection ReportDocumento7 pagineBluskies Engineering PVT LTD: Acp Panel Inpection ReportRavi Shankar KolluruNessuna valutazione finora

- Especificaciones LuminariasDocumento3 pagineEspecificaciones LuminariasRoni DominguezNessuna valutazione finora

- c600 17lookinsideDocumento6 paginec600 17lookinsideИван МинчевNessuna valutazione finora

- 3M Cold Shrink Cable Joints MV HV 11kV 33kV 66kV BrochureDocumento4 pagine3M Cold Shrink Cable Joints MV HV 11kV 33kV 66kV BrochureMohammed MustafaNessuna valutazione finora

- LB2 UC30 Data Sheet enUS 80218564235Documento5 pagineLB2 UC30 Data Sheet enUS 80218564235Ahmed ShawkyNessuna valutazione finora

- Appendix 400.4 - Traffic Count TemplateDocumento7 pagineAppendix 400.4 - Traffic Count TemplateOgunranti RasaqNessuna valutazione finora

- Process Level ChartDocumento2 pagineProcess Level ChartzaidinNessuna valutazione finora