Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Book 11 (BGW)

Caricato da

dirgan_udyanaDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Book 11 (BGW)

Caricato da

dirgan_udyanaCopyright:

Formati disponibili

DESIGN-IV: MACHINERY BASIC DESIGN TECHNICAL SPECIFICATION OF BILGE SYSTEM

ATTACHMENT NO. NUMBER OF PAGES DOCUMENT NO.

01 3

02 2

DOC. NO. 11 - 42 09 050 - BG

02 01 REV.

09/5/12 Categorizing Eq. I Gusti N. Dirgantara 04/4/12 Document Format DATE DESCRIPTION PREPARED BY

Ir. Dwi Priyanta, MSE.

CHECKED BY

Ir. Hari Prastowo, MSc.

APPROVED BY

DESIGN-IV: MACHINERY BASIC DESIGN

TECHNICAL SPECIFICATION OF BILGE SYSTEM

Project Doc. No Rev.No Type

: DESIGN IV : 11 - 42 09 050 - BG : 01 : Table of Contents

TABLE OF CONTENTS

PHILOSOPHY DOCUMENTS 1. INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1. . . . 1.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 . . 1.2 Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 . 2. REFERENCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 . 3. ABBREVIATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 . 4. DESIGN PARAMETER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 5. DESIGN REQUIREMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 5.1 PIPING SYSTEM CLASS REQUIREMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 . . . . . . ........ . 5.2 PUMP ............................................... 4 5.3 VALVE AND FITTINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5. . ... 6. SUMMARY ............................................... 6 LIST OF TABLES Table 4.1 .................... ......................... 3 ATTACHMENT NO. 01 - CALCULATION 1. Inside Diameter .................... ......................... 1 2. Branch Bilge Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 3. Bilge Pump .................... ......................... 2 4. Head Pump .................... ......................... 2 5. The Power of Pump and Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .... 3 ATTACHMENT NO. 02 - PUMP SPECIFICATION

TECHNICAL SPECIFICATION OF BILGE SYSTEM

Project Doc. No Rev.No Type

: DESIGN IV : 11 - 42 09 050 - BG : 02 : Philosopy

1 INTRODUCTION 1.1 Description Bilge system is used as protection in ship, to solve problem that caused by leakage in every system that contains fluid. This system will needed an arrangement of bilge lines, pipe laid through tanks, bilge suction and sturms, bilge valves, reverse flow protection, and pipe layout. Bilge system on tanker are divided on two parts, as follows : a. Clean Bilge System To drain and sent out the water which caused of leaked in operation system or instllation. Those are usually from ships hull and condensation of air control. The water that doesnt mix with oil can be pumped to overboard using bilge pumps. b. Oily Bilge System While the process of loading and unloading in ship, the cargo pumps will not be able to sent out clearly the load in each tank. That will be need the operation of bilge system, in tanker the stripping system can be used as bilge system, because it has the same function. But for the oil that come out or leakage, we need to make a bilge system design such as in the engine room. That can be caused by the leakage of fuel pipe, lubricating pump or another system that has been installed in the engine room. All the leakage oil will be sent to bilge well and absorbed using separated pumps with bilge pump to clean the bilge system. Oil bilge pump will be used in this design. 1.2 Objective The purpose of this document is to design the appropriate bilge system from the calculation of the needed equipments. 2 REFERENCES a. Germanischer Lyoid Rules and Guidelines 2011 b. Marine Engineering, Roy L. Harrington, "Chapter XX - Piping System" :1971 3 ABBREVIATIONS dH = calculated inside diameter of main bilge pipe [mm] l1 = total length of spaces between cofferdam or pump-room bulkhead and stern tube bulkhead [m] B = moulded breadth of ship [m] H = depth of ship to the bulkhead deck [m] dZ = inside diameter of branch bilge line [mm] l = length of watertight compartment [m] b = maximum breadth of cargo tanks [m] h = maximum depth of cargo tanks [m] lT = length of tanks in the watertight compartment [m] Q

3 = minimum capacity [m /h]

4 DESIGN PARAMETER The calculation summary based on document number : DOC. NO. 08 - 42 09 050 - CS For the pump selection and spesification: Merk = Hyundai Merk = Sterling Type = HCP300 Type = TKH15302 Qapacity Head Frequency Power = = = = 1800 150 60 125 m3/h m Hz kW Qapacity Head Frequency Power = = = = 130 30 60 30 m3/h m Hz kW

Page 3 of 13

TECHNICAL SPECIFICATION OF BILGE SYSTEM

Table 4.3 Summary of Doc. No. 08 - 42 09 050 - CS CALCULATION SYMBOL RESULT LOADING AND UNLOADING SYSTEM

Project Doc. No Rev.No Type

: DESIGN IV : 11 - 42 09 050 - BG : 02 : Philosopy

NO

1 Area of pump A 0.193 2 Pump qapacity Q 1733.400 t 7.076 3 Time for loading or unloading hs 7.000 4 Head static hp 0.000 5 Head pressure hv 0.000 6 Head velocity Rn 1125681.818 7 Reynold number l 0.021 8 Frictional losses hf 1.690 9 Head friction1 Head losses1 hl 3.163 10 hf 1.690 11 Head friction2 hl 2.350 12 Head losses2 H 15.893 13 Head total STRIPPING SYSTEM 14 Stripping volume 15 Stripping pump qapacity 16 Inside diameter of pipe 17 Frictional losses 18 Head friction1 19 Head losses1 20 Head friction2 21 Head losses2 22 Head total vs Q D l hf hl hf hl H 245.308 122.655 5.182 0.022 4.145 3.16 4.145 2.350 20.813

m2 m3/h hours m m m

m m m m m m3 m3/h inches m m m m m

5 DESIGN REQUIREMENT 5.1 PIPING SYSTEM CLASS REQUIREMENT a. Diameter The diameter of the main bilge pipe in the engine rooms of tankers and bulk cargo/oil carriers is calculated using the formula: dH = 3.0*(((B+H)*l1)^0.5)+35 . . . [mm] . . . . . . . . . . . . . . . (1) . . . . . . . . . . . . . . . . . .......... .... .. where, dH = calculated inside diameter of main bilge pipe [mm] l1 = total length of spaces between cofferdam or pump-room bulkhead and stern tube bulkhead [m] B = moulded breadth of ship [m] H = depth of ship to the bulkhead deck [m] Germanisher Loyd, Chapter 2, Section 11 - Piping Systems, Valves and Pumps Page 1137, 2.1 b. Branch bilge line are calculated as follows: dZ = 2.15*(((B+H)*l)-(b+h)*lT)^0.5)+25 . . . [mm] . . . . . . . . . (2) . . . . . . . . . . . . . . . . . . . . ............. .... .. where, dZ = inside diameter of branch bilge line [mm] l = length of watertight compartment [m] b = maximum breadth of cargo tanks [m] h = maximum depth of cargo tanks [m]

Page 4 of 13

TECHNICAL SPECIFICATION OF BILGE SYSTEM

Project Doc. No Rev.No Type

: DESIGN IV : 11 - 42 09 050 - BG : 02 : Philosopy

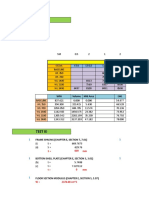

lT = length of tanks in the watertight compartment [m] The inside diameter of main and branch bilge pipes is not to be less than 50 mm. For ships under 25 m length, the diameter may be reduced to 40 mm. Germanisher Loyd, Chapter 2, Section 15 - Special Requirements for Tankers, Page 11-37, 3.1 Bilge lines and bilge suctions are to be so arranged that the bilges can be completely drained even under unfavourable trim conditions. Bilge suctions are normally to be located on both sides of the ship. For compartments located fore and aft in the ship, one bilge suction may be considered sufficient provided that it is capable of completely draining the relevant compartment. Spaces located forward of the collision bulkhead and aft of the stern tube bulkhead and not connected to the general bilge system are to be drained by other suitable means of adequate capacity. The require pipe thickness of bilge line is to be in accordance with table 4.1. Table 4.1 Minimum wall thickness group

Germanisher Loyd, Chapter 2, Section 11 - Piping Systems, Valves and Pumps Page 11-36, 1.1 Pipe Laid Through Tanks Bilge pipes may not be led through tanks lubricating oil, thermal oilm drinking water or feed water. Bilge pipe from spaces not accessible during voyage if running through fuel tanks located above double bottom are to be fitted with a non return valve directly at the point of Germanisher Loyd, Chapter 2, Section 11 - Piping Systems, Valves and Pumps Page 11-36, 1.2 Pipe Layout To prevent the ingress of ballast and seawater into the ship through the bilge system two means of reverse-flow protection are to be fitted in the bilge connections. One of such means of protection is to be fitted in each suction line. Where a direct seawater connection is arranged for attached bilge pumps to protect them against running dry, the bilge suctions are also to be Germanisher Loyd, Chapter 2, Section 11 - Piping Systems, Valves and Pumps Page 11-36, 1.6

Page 5 of 13

TECHNICAL SPECIFICATION OF BILGE SYSTEM

c. Material

Project Doc. No Rev.No Type

: DESIGN IV : 11 - 42 09 050 - BG : 02 : Philosopy

Steel Galvanized Pipe or Cast Iron accepted for temperatures up to 350 0C d. Pipe Class and Thckness Class II or III Category M (located in cargo holds) and category D (located in ballast water tank) 5.2 PUMP a. Type Centrifugal Pump A centrifugal pump is a rotodynamic pump that uses a rotating impeller to increase the pressure and flow rate of a fluid. Centrifugal pumps are the most common type of pump used to move liquids through a piping system. The fluid enters the pump impeller along a near to the rotating axis and is accelerated are typically used for large discharge through smaller heads. The example will be given by Figure 1.3 Centrifugal Pump below.

Figure 1.3 Centrifugal Pump b. Class Requirement - Capacity of bilge pump Q [m . . = 5.75*(10^-3)*dH^2 . . . . . ./h] . . . . . . . . . . . . . . . . . .(3) . . . . . . . . . . . . . . . ........ .. where,

3

3 Q = minimum capacity [m /h] dH = calculated inside diameter of main bilge pipe [mm] Germanisher Loyd, Chapter 2, Section 11 - Special Requirements for Tankers, Page 15-4, 4.1.3 - Bilge pumping equipment is to be located in the cargo area to serve the cargo pump rooms and cofferdams. A cargo pump may also be used as a bilge pump. On oil tankers used exclusively for the carriage of flammable liquids with flash points above 60 C, cargo pump rooms and cofferdams may be connected to the engine room bilge system. Where a cargo pump is used as bilge pump, measures are to be taken, e.g. by fitting screw-down non-return valves, to ensure that cargo cannot enter the bilge system. Where the bilge line can be pressurised from the cargo system, an additional non-return valve is to be fitted. Germanisher Loyd, Chapter 2, Section 15 - Special Requirements for Tankers, Page 15-4, 4.2

Page 6 of 13

TECHNICAL SPECIFICATION OF BILGE SYSTEM

Project Doc. No Rev.No Type

: DESIGN IV : 11 - 42 09 050 - BG : 02 : Philosopy

5.3 VALVE AND FITTINGS a. Butterfly Valve A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk, which allows for quick shut off. Butterfly valve are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. Used for stop valve only, for low working pressure. In this system, butterfly valve used in order before the pump, and as a connecting to another equipment to make a standby function. Below is the example of butterfly valve, shown in Figure 5.3 Butterfly Valve.

Figure 5.3 Butterfly Valve b. Non Return Valve Has same function with globe valve, working in very high pressure and just has one-way direction. Usually this valve is used in order after the pump and another lines that the fluids shall not back through the same line or just one-way direction. c. Filter Water Filter The sea water and fresh water systems on board ship are provided with line filters in order to trap the solid impurities flowing in the system. Normally the sea water sides has more number of filters incorporated in the line as compared to the fresh water system as the later is a closed system. The different applications for water filters are: - Bilge Line Filter All the bilge well suctions are provided with a strainer as the well containts the maximum solid contamination. The filter may have a bucket screen or a plate screen to trap solid impurities. d. Class Requirements - Bilge Suction and Strums Bilge suction are to be arranged as not to impede the cleaning of bilges and bilge well. They are to be fitted with easily detachable, corrosion resistant strums. Emergency bilge suction are to be arranged such that they are accesible, with free flow and at suitable distance from the tank top or the ship's bottom. For the size and design of bilge well, will refer to GL Rules for Hull Structure (I-1-1), Section 8, B.5.3. Bilge wells shall have a capacity of more than 0,2 m.Small holds may have smaller bilge wells. For the use of manhole covers or hinged covers for the access to the bilge suctions, see Chapter 2 Machinery Installations, Section 11. Germanisher Loyd, Chapter 2, Section 11 - Piping Systems, Valves and Pumps Page 11-36, 1.3

Page 7 of 13

TECHNICAL SPECIFICATION OF BILGE SYSTEM

Project Doc. No Rev.No Type

: DESIGN IV : 11 - 42 09 050 - BG : 02 : Philosopy

- Bilge Valves Valves in connecting pipes between the bilge and the seawater and ballast water system, as well as between the bilge connections of different compartments, are to be so arranged that even in the event of faulty operation or intermediate positions of the valves, penetration of seawater through the bilge system will be safely prevented. Bilge discharge pipes are to be fitted with shut-off valves at the ship's shell. Bilge valves are to be arranged so as to be always accessible irrespective of the ballast and loading condition of the ship. Germanisher Loyd, Chapter 2, Section 11 - Piping Systems, Valves and Pumps Page 11-36, 1.4 - Reverse-Flow Protection A screw-down non-return valve or a combination of a non-return valve without positive means Germanisher Loyd, Chapter 2, Section 11 - Piping Systems, Valves and Pumps Page 11-36, 1.5 6 SUMMARY NO CALCULATION SYMBOL 1 inside diameter of bilge pipe dH 2 inside diameter branch bilge line dZ 3 capacity of bilge pump 4 head total pump Bilge Pump Specification Merk = Taiko Type = EHS251C Qapacity Head RPM Power = = = = 285 25 1800 37 m3/h m rpm kW Q H

RESULT 8.747 4.97 283.83 24.46

inches inches m3/h m

Page 8 of 13

DESAIN-IV: MACHINERY BASIC DESIGN

ATTACHMENT NO. 01 CALCULATION TECHNICAL SPECIFICATION OF BILGE SYSTEM

TECHNICAL SPECIFICATION OF BILGE SYSTEM

Project Doc. No Rev.No Type

: DESIGN IV : 11 - 42 09 050 - BG : 01 : Attachment No. 01

1. The diameter of the main bilge pipe in the engine rooms of tankers and bulk cargo/oil carriers is calculated using the formula: dH = 3.0*(((B+H)*l1)^0.5)+35 . . . [mm] . . . . . . . . . (1) . . . . . . . . . . . . . . . . . . . . ............. .... .. where, dH = calculated inside diameter of main bilge pipe [mm] l1 = total length of spaces between cofferdam or pump-room bulkhead and stern tube bulkhead [m] m = 122.8 B = moulded breadth of ship [m] = 20.2 m H = depth of ship to the bulkhead deck [m] = 11.5 m Germanisher Loyd, Chapter 2, Section 11 - Piping Systems, Valves and Pumps Page 11-37, 2.1 for the result: dH = 3.0*(((B+H)*l1)^0.5)+35 [mm] = 3.0*(((20.2+11.5)*122.8)^0.5)+35 = 222.176 mm = 8.747 inches According to ANSI we can choose the pipe: Inside diameter = 8.75 inches Wall thickness = 1.1 inches Outside diameter = 10.75 inches Pipe size = 10 inches Schedule no. = 140 inches 2. Branch bilge line are calculated as follows: dZ = 2.15*(((B+H)*l)-(b+h)*lT)^0.5)+25 [mm] (2) where, dZ = inside diameter of branch bilge line [mm] l = length of watertight compartment [m] = 82.6 m b = maximum breadth of cargo tanks [m] = 18.2 m h = maximum depth of cargo tanks [m] = 10.1 m lT = length of tanks in the watertight compartment [m] = 14 m The inside diameter of main and branch bilge pipes is not to be less than 50 mm. For ships under 25 m length, the diameter may be reduced to 40 mm. Germanisher Loyd, Chapter 2, Section 11 - Piping Systems, Valves and Pumps Page 11-37, 2.1 for the result: dZ = 2.15*(((B+H)*l)-(b+h)*lT)^0.5)+25 [mm] = 2.15*(((20.2+11.5)*82.6)-(18.2+10.1)*14)^0.5)+25 = 126.35 mm = 4.97 inches According to ANSI we can choose the pipe: Inside diameter = 5.047 inches Wall thickness = 0.258 inches Outside diameter = 5.563 inches Pipe size = 5 inches

Page 10 of 14

TECHNICAL SPECIFICATION OF BILGE SYSTEM

3. Bilge Pump Capacity of bilge pump Q

Project Doc. No Rev.No Type

: DESIGN IV : 11 - 42 09 050 - BG : 01 : Attachment No. 01

= 5.75*(10^-3)*dH^2 . . . .[m. /h] . . . . . . . . . . . .(3). . . . . . . . . . . . . . . . . . . ........... . .. . where,

3 = minimum capacity [m /h] = calculated inside diameter of main bilge pipe [mm] Germanisher Loyd, Chapter 2, Section 11 - Special Requirements for Tankers, Page 15-4, 4.1.3 for the result:

Q dH

[m3/h] = 5.75*(10^-3)*dH^2 = 5.75*(10^-3)*(222.176)^2

3 = 283.833 m /h 4. Head Pump i. Head static of pump (ha) from the general arrangement drawing we can find: The distance between bilge suction well to overboard hs = T+0.75 m = 9.55 m ii. Head pressure of pump (hp) hp = 0 m pressure in the both suction and discharge is to be arranged in the same value iii. Head velocity (hv) hv = 0 m iv. Head in suction pipe viscocity (n) = 1.1

cst in 50oC

6 = n/10 2

m /s = 0.0000011 Reynold number (Rn) Rn = (vs*ds)/n = (2.5*(222.176*10^-3))/0.0000011 = 504945.5 For the frictional losses (l) will be determned if the value of reynold number <2300 will be used formula Re/64, and if not the following formula is 0.02+0.0005/D l = 0.02+0.0005/D = 0.02+0.0005/222.176*10^-3 = 0.022 Mayor losses (hf) hf

2 = l*L*v /(D*2g) where, L = the length of suction pipe = 75 m for the result:

2 = l*L*v /(D*2g) = 0.022*75*(2.5^2)/((222.176*10^-3)*2*9.8) = 2.37 m Minnor losses (hl) No Types n k nxk 1 Butterfly valve 5 0.86 4.3

hf

2 Elbow 90o 3 Flange 4 Flexible coupling

4 7 6

0.57 0.87 0.46

2.28 6.09 2.76

Page 11 of 14

TECHNICAL SPECIFICATION OF BILGE SYSTEM

Minnor losses (hl) No Types 5 SDNRV 6 SDNRV remotely 7 Strainer 8 T connection head losses

Project Doc. No Rev.No Type

: DESIGN IV : 11 - 42 09 050 - BG : 01 : Attachment No. 01

n 0 1 3 2

k 1.23 1.35 1.5 1.14 total

nxk 0 1.35 4.5 2.28 23.56

= k total*v2/(2g) = 23.56*(2.5^2)/(2*9.8) = 7.513 m v. Head in discharge pipe Minnor losses (hl) No Types n k 1 Butterfly valve 0 0.86 2 3 4 5 6 7 8 Elbow 90o Flange Flexible coupling SDNRV SDNRV remotely Strainer T connection 0 0 0 4 0 0 3 0.57 0.87 0.46 1.23 1.35 1.5 1.14 total

nxk 0 0 0 0 4.92 0 0 3.42 8.34

head losses

= k total*v2/(2g) = 8.34*(2.5^2)/(2*9.8) = 2.659 m

Therefore, the total of Heads are: H = hs+hv+hp+hf1+hf2+hl1+hl2 = 9.55+0+0+2.37+2.37+7.513+2.659 = 24.46 m 5. The Power of Pump and Motor Required: Head = 24.46 m Capacity Merk Type Qapacity Head RPM Power = 283.833 m /h = Taiko = EHS251C = = = = 285 25 1800 37 m3/h m rpm kW

3

Page 12 of 14

DESAIN-IV: MACHINERY BASIC DESIGN

ATTACHMENT NO. 02 PUMP SPECIFICATION TECHNICAL SPECIFICATION OF BILGE SYSTEM

Potrebbero piacerti anche

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsDa EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNessuna valutazione finora

- Calculation and Specification of Bilge System: Design Iv Machinery System Department of Marine EngineeringDocumento36 pagineCalculation and Specification of Bilge System: Design Iv Machinery System Department of Marine EngineeringAfanda Dwi R RNessuna valutazione finora

- Book 06 (Ak)Documento11 pagineBook 06 (Ak)dirgan_udyanaNessuna valutazione finora

- Ship DesignDocumento2 pagineShip DesignMerrel0% (1)

- Tug & Barge - Daily Activity Report - Tug AgentDocumento40 pagineTug & Barge - Daily Activity Report - Tug AgentArdiansyah BekaNessuna valutazione finora

- The ShipWeight ConceptDocumento22 pagineThe ShipWeight ConceptIwishto BeafishNessuna valutazione finora

- Draft CalcDocumento13 pagineDraft CalcДмитрий ЯрычNessuna valutazione finora

- Principal Particulars For A General Cargo Ship: Waterlines (Half Breadths)Documento13 paginePrincipal Particulars For A General Cargo Ship: Waterlines (Half Breadths)ManojNessuna valutazione finora

- Forces at An AngleDocumento2 pagineForces at An AngleVivek PatelNessuna valutazione finora

- RSW - Buoys InstallationDocumento9 pagineRSW - Buoys Installationothman salahNessuna valutazione finora

- Propeller DesignDocumento3 paginePropeller DesignYan Naing ShinNessuna valutazione finora

- Heeling Lever CalculationDocumento1 paginaHeeling Lever Calculationhlsimon100% (1)

- Preliminary DesignDocumento3 paginePreliminary DesignElmer HabloNessuna valutazione finora

- NEERAJ StabilityDocumento37 pagineNEERAJ StabilityAmal Benoy PukkunnelNessuna valutazione finora

- Loadline Calculations - Finding Various Drafts From Loadline Certificate ParticlarsDocumento1 paginaLoadline Calculations - Finding Various Drafts From Loadline Certificate ParticlarsPrinceNessuna valutazione finora

- Structural Design Support VesselDocumento95 pagineStructural Design Support VesselMarco CordonNessuna valutazione finora

- 75T Bollard Pull Asd Tug: EnduranceDocumento6 pagine75T Bollard Pull Asd Tug: EnduranceManishNessuna valutazione finora

- P S A VigDocumento95 pagineP S A VigvigneshNessuna valutazione finora

- Symbol: Principal ParticularsDocumento9 pagineSymbol: Principal ParticularsNiloy SahaNessuna valutazione finora

- RESUME Naval Architect-RkDocumento2 pagineRESUME Naval Architect-RkRama KrishnaNessuna valutazione finora

- Amal-18 Sta DDR#22 04-03-2020Documento30 pagineAmal-18 Sta DDR#22 04-03-2020eng7mohamed7hashimNessuna valutazione finora

- Longitudinal Strength CalculationDocumento15 pagineLongitudinal Strength CalculationJessica CelayaNessuna valutazione finora

- E (V) - 19 TransformersDocumento21 pagineE (V) - 19 TransformershamzehNessuna valutazione finora

- Towing Design Rev2Documento19 pagineTowing Design Rev2Ludovic LandemaineNessuna valutazione finora

- SEATECH - Forum On Marine Blue Economy - Developing The Potential of Deep Seabed Mining What Trade-Offs With BiodiversityDocumento20 pagineSEATECH - Forum On Marine Blue Economy - Developing The Potential of Deep Seabed Mining What Trade-Offs With BiodiversityDilip SarangdharNessuna valutazione finora

- BargeDocumento5 pagineBargeBudimanNessuna valutazione finora

- Resistance Powering Formulas ListDocumento5 pagineResistance Powering Formulas ListgitanodefeNessuna valutazione finora

- Taylor Series SystematicDocumento147 pagineTaylor Series SystematicAndreiVillamarBermúdezNessuna valutazione finora

- Calculation 2019 - Tugboat CW Kort NozzleDocumento2 pagineCalculation 2019 - Tugboat CW Kort NozzleAchmad RadjakibulNessuna valutazione finora

- CPV757Documento1 paginaCPV757Richard Leonel Vasquez MezaNessuna valutazione finora

- Test Ii: WPA Volume Mid Area LWLDocumento9 pagineTest Ii: WPA Volume Mid Area LWLMark Lester AndayaNessuna valutazione finora

- 31 MARCH 20 10: Offset TableDocumento27 pagine31 MARCH 20 10: Offset TableElvis JuniorNessuna valutazione finora

- 21 January 20 0 9: Tonnage CalculationDocumento3 pagine21 January 20 0 9: Tonnage CalculationElvis JuniorNessuna valutazione finora

- Bollard Pull AESDocumento7 pagineBollard Pull AESsoongbinNessuna valutazione finora

- Vibration of Deckhouse StructuresDocumento10 pagineVibration of Deckhouse StructuresrthyhtNessuna valutazione finora

- Damage CalculationDocumento2 pagineDamage CalculationmujiNessuna valutazione finora

- Perhitungan TDK Kapal BrooDocumento129 paginePerhitungan TDK Kapal Broojuiver sakaNessuna valutazione finora

- S1139 HP-13. - Arr't of Ship-Side Pipe Piece PDFDocumento15 pagineS1139 HP-13. - Arr't of Ship-Side Pipe Piece PDFCelal BozdoganNessuna valutazione finora

- Ship Design ProjectDocumento31 pagineShip Design ProjectRahul PLNessuna valutazione finora

- Ridgely-Nevitt C.resistance of A High.1967.TRANSDocumento28 pagineRidgely-Nevitt C.resistance of A High.1967.TRANSTi AnnelNessuna valutazione finora

- ABS BucklingDocumento7 pagineABS BucklingOwoseni DareNessuna valutazione finora

- Doc. No. 15 - 42 09 050 - FODocumento44 pagineDoc. No. 15 - 42 09 050 - FOdirgan_udyanaNessuna valutazione finora

- Draught Survey SpreadsheetDocumento4 pagineDraught Survey SpreadsheetNikola HercegNessuna valutazione finora

- HOLTROPDocumento7 pagineHOLTROPardi karepesinaNessuna valutazione finora

- Ship Specifications TERMPOL Surveys and StudiesDocumento37 pagineShip Specifications TERMPOL Surveys and StudiesRachmad SyafikriNessuna valutazione finora

- Perhitungan Tugas Merancang Kapal 1Documento85 paginePerhitungan Tugas Merancang Kapal 1irfan pujiantoNessuna valutazione finora

- VLCC TDC501 319 DocDocumento377 pagineVLCC TDC501 319 DocMinh Trí100% (1)

- ISODC, IIT Kharagpur Team, May 2008Documento269 pagineISODC, IIT Kharagpur Team, May 2008Prabhakar Tiwari100% (1)

- Environment/ Metdata/Geotech InputsDocumento36 pagineEnvironment/ Metdata/Geotech InputsRajith KrNessuna valutazione finora

- MV IreliaDocumento74 pagineMV IreliaDominic VillamanteNessuna valutazione finora

- Training Report On Ship DesigningDocumento18 pagineTraining Report On Ship Designingapi-26671718Nessuna valutazione finora

- QualifDocumento72 pagineQualifsabah8800Nessuna valutazione finora

- FSM CalculationDocumento20 pagineFSM CalculationRama Krishna100% (1)

- Angle Steeldata PDFDocumento2 pagineAngle Steeldata PDFRaj P. AbhaleNessuna valutazione finora

- Thesis RGdeJongDocumento108 pagineThesis RGdeJongNaval2014DNNessuna valutazione finora

- Your Propulsion Experts: Nav Schottel NavigatorDocumento8 pagineYour Propulsion Experts: Nav Schottel NavigatorMustafa TemelNessuna valutazione finora

- SV Aa Harvald Prediction of Ship ResistaDocumento70 pagineSV Aa Harvald Prediction of Ship ResistaFairuzNessuna valutazione finora

- VMOT-H53-300-03-Electrical Load ChartDocumento11 pagineVMOT-H53-300-03-Electrical Load ChartVECTOR MARINE & OFFSHORE TECHNOLOGYNessuna valutazione finora

- Book 08 (CS)Documento35 pagineBook 08 (CS)dirgan_udyanaNessuna valutazione finora

- Perhitungan Sistem Bilga Di KapalDocumento63 paginePerhitungan Sistem Bilga Di KapalNatalia Dea KartikaNessuna valutazione finora

- Book 21 (Sa)Documento13 pagineBook 21 (Sa)dirgan_udyanaNessuna valutazione finora

- Book 17 (Co)Documento25 pagineBook 17 (Co)dirgan_udyanaNessuna valutazione finora

- Book 20 (DS)Documento21 pagineBook 20 (DS)dirgan_udyanaNessuna valutazione finora

- Book 19 (Ca)Documento12 pagineBook 19 (Ca)dirgan_udyanaNessuna valutazione finora

- Book 16 (Lo)Documento13 pagineBook 16 (Lo)dirgan_udyanaNessuna valutazione finora

- Doc. No. 15 - 42 09 050 - FODocumento44 pagineDoc. No. 15 - 42 09 050 - FOdirgan_udyanaNessuna valutazione finora

- Book 18 (El)Documento18 pagineBook 18 (El)dirgan_udyanaNessuna valutazione finora

- Book 14 (Fi)Documento22 pagineBook 14 (Fi)dirgan_udyanaNessuna valutazione finora

- Book 10 (El)Documento20 pagineBook 10 (El)dirgan_udyanaNessuna valutazione finora

- Book 12 (Bgo)Documento12 pagineBook 12 (Bgo)dirgan_udyanaNessuna valutazione finora

- Book 13 (BL)Documento14 pagineBook 13 (BL)dirgan_udyanaNessuna valutazione finora

- Book 09 (El)Documento14 pagineBook 09 (El)dirgan_udyanaNessuna valutazione finora

- Book 08 (CS)Documento35 pagineBook 08 (CS)dirgan_udyanaNessuna valutazione finora

- Book 07 (DM)Documento24 pagineBook 07 (DM)dirgan_udyanaNessuna valutazione finora

- BOOKDocumento25 pagineBOOKdirgan_udyanaNessuna valutazione finora

- Book 03 (LS)Documento16 pagineBook 03 (LS)dirgan_udyanaNessuna valutazione finora

- Book 05 (Hu)Documento13 pagineBook 05 (Hu)dirgan_udyanaNessuna valutazione finora

- Book 02 (Es)Documento33 pagineBook 02 (Es)dirgan_udyanaNessuna valutazione finora

- Book 01 (PS)Documento46 pagineBook 01 (PS)dirgan_udyanaNessuna valutazione finora

- Damage To Bottom Ash Handling SysDocumento6 pagineDamage To Bottom Ash Handling SyssanjeevchhabraNessuna valutazione finora

- Turbine Flowmeters-Commonly Asked Questions and Answers: For Chemical Composition Information.)Documento8 pagineTurbine Flowmeters-Commonly Asked Questions and Answers: For Chemical Composition Information.)Alexander KlmNessuna valutazione finora

- Integrated Management System 2016Documento16 pagineIntegrated Management System 2016Mohamed HamedNessuna valutazione finora

- Nugent 2010 Chapter 3Documento13 pagineNugent 2010 Chapter 3Ingrid BobosNessuna valutazione finora

- N164.UCPE12B LANmark - OF - UC - 12x - Singlemode - 9 - 125 - OS2 - PE - BlackDocumento2 pagineN164.UCPE12B LANmark - OF - UC - 12x - Singlemode - 9 - 125 - OS2 - PE - BlackRaniaTortueNessuna valutazione finora

- English 8 q3 w1 6 FinalDocumento48 pagineEnglish 8 q3 w1 6 FinalJedidiah NavarreteNessuna valutazione finora

- Top Survival Tips - Kevin Reeve - OnPoint Tactical PDFDocumento8 pagineTop Survival Tips - Kevin Reeve - OnPoint Tactical PDFBillLudley5100% (1)

- Submitted By: S.M. Tajuddin Group:245Documento18 pagineSubmitted By: S.M. Tajuddin Group:245KhurshidbuyamayumNessuna valutazione finora

- GSP AllDocumento8 pagineGSP AllAleksandar DjordjevicNessuna valutazione finora

- Zimbabwe - Youth and Tourism Enhancement Project - National Tourism Masterplan - EOIDocumento1 paginaZimbabwe - Youth and Tourism Enhancement Project - National Tourism Masterplan - EOIcarlton.mamire.gtNessuna valutazione finora

- Xbox One S Retimer - TI SN65DP159 March 2020 RevisionDocumento67 pagineXbox One S Retimer - TI SN65DP159 March 2020 RevisionJun Reymon ReyNessuna valutazione finora

- Cultural AnthropologyDocumento12 pagineCultural AnthropologyTRISH BOCANessuna valutazione finora

- Yuzu InstallerDocumento3 pagineYuzu InstallerJohnnel PrietosNessuna valutazione finora

- Uxc01387a PDFDocumento16 pagineUxc01387a PDFmahesh123Nessuna valutazione finora

- Fractional Differential Equations: Bangti JinDocumento377 pagineFractional Differential Equations: Bangti JinOmar GuzmanNessuna valutazione finora

- Chapter 8 - Current Electricity - Selina Solutions Concise Physics Class 10 ICSE - KnowledgeBoatDocumento123 pagineChapter 8 - Current Electricity - Selina Solutions Concise Physics Class 10 ICSE - KnowledgeBoatskjNessuna valutazione finora

- The Evolution of Knowledge Management Systems Needs To Be ManagedDocumento14 pagineThe Evolution of Knowledge Management Systems Needs To Be ManagedhenaediNessuna valutazione finora

- The Abcs of Edi: A Comprehensive Guide For 3Pl Warehouses: White PaperDocumento12 pagineThe Abcs of Edi: A Comprehensive Guide For 3Pl Warehouses: White PaperIgor SangulinNessuna valutazione finora

- Matrix CPP CombineDocumento14 pagineMatrix CPP CombineAbhinav PipalNessuna valutazione finora

- Know Your TcsDocumento8 pagineKnow Your TcsRocky SinghNessuna valutazione finora

- By Vaibhav Pandya S R.information Security Consultant M.Tech Solutions (India) PVT - LTDDocumento22 pagineBy Vaibhav Pandya S R.information Security Consultant M.Tech Solutions (India) PVT - LTDtsegay.csNessuna valutazione finora

- Design and Analysis of DC-DC Boost Converter: September 2016Documento5 pagineDesign and Analysis of DC-DC Boost Converter: September 2016Anonymous Vfp0ztNessuna valutazione finora

- Infor Mashup DesignerDocumento95 pagineInfor Mashup DesignerBalayogesh Alagesan100% (1)

- Demand, Supply, and Market EquilibriumDocumento15 pagineDemand, Supply, and Market EquilibriumAnonymous HBQ86kNessuna valutazione finora

- Self-Efficacy and Academic Stressors in University StudentsDocumento9 pagineSelf-Efficacy and Academic Stressors in University StudentskskkakleirNessuna valutazione finora

- Industry GeneralDocumento24 pagineIndustry GeneralilieoniciucNessuna valutazione finora

- Week 1-2 Module 1 Chapter 1 Action RseearchDocumento18 pagineWeek 1-2 Module 1 Chapter 1 Action RseearchJustine Kyle BasilanNessuna valutazione finora

- Sun God NikaDocumento2 pagineSun God NikaElibom DnegelNessuna valutazione finora

- HAI ROBOTICS Introduction ENV2022.0829 MarketingDocumento40 pagineHAI ROBOTICS Introduction ENV2022.0829 MarketingKit WooNessuna valutazione finora

- Libel Arraignment Pre Trial TranscriptDocumento13 pagineLibel Arraignment Pre Trial TranscriptAnne Laraga LuansingNessuna valutazione finora