Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

C7232A, B Sensor and Controller: Features

Caricato da

Nanû CbralDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

C7232A, B Sensor and Controller: Features

Caricato da

Nanû CbralCopyright:

Formati disponibili

C7232A,B Sensor and Controller

PRODUCT DATA

CARBON DIOXIDE SENSOR

FEATURES

Models available with LCD that provides sensor readings and status information. Non-Dispersion-Infrared (NDIR) technology used to measure carbon dioxide gas. Gold-plated sensor provides long-term calibration stability. Device provides voltage output based on CO2 levels. Models available with SPST relay output. Used for CO2 based ventilation control. C7232A C7232B Automatic Background Calibration (ABC) algorithm based on long-term evaluation reduces required typical zero-drift check maintenance.

APPLICATION

The C7232 Sensor and Controller is a stand-alone carbon dioxide (CO2) sensor for use in determining ventilation necessity with HVAC controllers. The C7232 measures the CO2 concentration in the ventilated space or duct. The C7232 is used in ventilation and air conditioning systems to control the amount of fresh outdoor air supplied to maintain acceptable levels of CO2 in the space.

Contents

Application ........................................................................ Features ........................................................................... Specifications ................................................................... Ordering Information ........................................................ Installation ........................................................................ Wiring ............................................................................... Calibration ........................................................................ Checkout .......................................................................... Appendix .......................................................................... 1 1 2 2 3 4 6 6 7

U.S. Registered Trademark Copyright 2003 Honeywell International Inc. All Rights Reserved

63-2571-5

C7232A,B SENSOR AND CONTROLLER

SPECIFICATIONS

Models: C7232 Sensor and Controller. A stand-alone carbon dioxide (CO2) sensor with two jumper-adjustable outputs (one analog and one spst relay). C7232A: Wall mount model. C7232B: Duct mount model. NOTE: Models are available with or without a 4-digit LCD that indicates the current CO2 concentration. Dimensions: C7232A: See Fig. 1. C7232B: See Fig. 2. Sensor Performance Ratings: Response Time: 2 min. Carbon Dioxide Sensor: Operation: Non-dispersive infrared (NDIR). Sampling: Diffusion. Range: 0 to 2000 ppm 5% and 50 ppm. Annual Drift: 20 ppm (nominal). Electrical Ratings: Power Supply: 24 Vac 20%, 50/60 Hz (Class 2). Maximum Power Consumption: 3W. Peak Current (at 20 ms): 600 mA. Relay: Configuration: Shipped N.O. (reconfigure with software.) Contact Rating: 1A at 50 Vac/24 Vdc. Minimum Permissible Load: 1 mA at 5 Vdc. Linear Analog Output: Voltage: 0/2-10 Vdc (resistive load greater than 5000 ohms). Current: 0/4-20 mA (resistive load less than 500 ohms). Outputs (Jumper Adjustable, see Table 2): Analog: 0-10 Vdc (Default: 2-10 Vdc, 500 to 1500 ppm). Relay: Normally Open Spst (Default: Close at 800 ppm). Ambient Ratings: Temperature: Operating: +32F to +122F (0C to +50C). Storage: -4F to +158F (-20C to +70C). Relative Humidity (non-condensing): 0 to 95 percent. CO2 Pressure Dependence: 1.4% change in reading per 1 kPa deviation from 100 kPa. Connections: Wiring: C7232A: 20-gauge cable with six 8 in. leadwires. C7232B: 20-gauge cable with six 6 in. leadwires. Mounting: C7232A: Vertical surface with standard single-gang junction box. C7232B: Sheet metal duct with a sampling tube. Automatic Background Calibration (ABC) default: On. Approvals: CE. Underwriters Laboratories Inc. Listed, File No. E4436. cUL. C7232B: Flammability Rating, UL94-5V. C7232A: NEMA1. C7232B: NEMA3.

1 (25) KNOCKOUTS FOR EUROPEAN APPLICATIONS 5-1/16 (128) 2-3/8 (60)

STANDARD UTILITY CONDUIT 2-3/8 BOX (60) (2X4) MOUNTING HOLES

3-5/32 (80)

M17540

Fig. 1. C7232A dimensions in in. (mm).

3-5/16 (84)

1-13/16 (46)

5-5/8 (142)

M17592

1-5/8 (41)

8 (203)

Fig. 2. C7232B dimensions in in. (mm).

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE wholesaler or distributor, refer to the TRADELINE Catalog or price sheets for complete ordering number. If you have additional questions, need further information, or would like to comment on our products or services, please write or phone: 1. Your local Honeywell Automation and Control Products Sales Office (check white pages of your phone directory). 2. Honeywell Customer Care 1885 Douglas Drive North Minneapolis, Minnesota 55422-4386 In CanadaHoneywell Limited/Honeywell Limite, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9. International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France, Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

63-25715 2

C7232A,B SENSOR AND CONTROLLER

INSTALLATION

When Installing this Product...

1. 2. 3. 4. Read these instructions carefully. Failure to follow them could damage the product or cause a hazardous condition. Check the ratings given in the instructions and on the product to make sure the product is suitable for your application. Installer must be a trained, experienced service technician. After installation is complete, check out product operation as provided in these instructions.

C7232A Cover Removal/Replacement

C7232A Cover Removal (see Fig. 3)

1. 2. 3. 4. 5. Remove button head socket cap screw and set it aside. Insert the head of a small screwdriver into the slot at the center and near the top of the cover. Gently pull the handle down toward the bottom of the device until a small gap between the subbase and the cover appears. Remove the screwdriver and pull the cover straight down until it meets a stop. Pull the cover straight off the subbase.

IMPORTANT All wiring must agree with applicable codes, ordinances and regulations.

C7232A Cover Replacement

1. 2. 3. Feed the wires through the opening in the subbase. Place the cover, with a small gap at the top, flat on top of the subbase. When the cover rests flat on the subbase, slide it straight up until it latches in place.

CAUTION

Health Hazard. Improper use can create dangerous situations. Use in application for sensing carbon dioxide only. For life-safety applications, this device can function only as a secondary or lesser device.

CAUTION

Electrical Shock or Equipment Damage Hazard. Can shock individuals or short equipment circuitry. Disconnect power supply before installation.

BUTTON HEAD SOCKET CAP SCREW

CAUTION

Equipment Damage Hazard. Electrostatic discharge can short equipment circuitry. Ensure that you are properly grounded before handling the unit.

A

M17541

C

ALLEN TOOL

Fig. 3. C7232A cover removal.

63-25715

C7232A,B SENSOR AND CONTROLLER

Location and Mounting

C7232 Sensors mount directly on the wall, sheet metal duct, or a panel. When planning the installation, allow enough clearance for maintenance and service. Mount the sensor in a well-ventilated area. NOTES: Do not install the sensor where it can be affected by: drafts or dead spots behind doors and in corners. air from ducts.

FL OW

Wall Mounting

The C7232 Wall Mount models can be mounted using two or four screws: 1. Remove C7232 cover. 2. Mount the subbase to the wall using washers and two or four screws (not supplied) appropriate for the wall material. NOTE: When mounting on a junction box, see Fig. 4. 3. Replace the cover. Fig. 5. Duct mounting (C7232B).

M17591

Duct Mounting (see Fig. 5)

1. Place gasket on aspiration tube. IMPORTANT Ensure largest tab at tube control end is at the top. 2. Insert tube into duct; attach using screws and washers.

WIRING

The factory ships the device with the output default settings shown in Tables 2 and 3. Set the jumpers and wire the device (see Table 1 and Fig. 6).

IMPORTANT Leakage into the duct or the C7232 box cover from the room will skew the sensor readings. Ensure the box cover and duct seal completely. 3. Place o-ring on tube end; mount the control to the tube.

STANDARD UTILITY CONDUIT BOX NO. 6 SCREW

CAUTION

Electrical Shock or Equipment Damage Hazard. Can shock individuals or short equipment circuitry. Disconnect power supply before installation.

CAUTION

FRONT COVER

Equipment Damage Hazard. Electrostatic Discharge Can Short Equipment Circuitry. Ensure that you are properly grounded before handling the unit.

BUTTON HEAD SOCKET CAP SCREW

SUBBASE NO. 6 SCREW

M17542

IMPORTANT 1. All low voltage connections to this device must be 24 Vac Class 2. 2. All wiring must comply with applicable local codes, ordinances and regulations. Table 1. C7232 Wiring Connections (see Fig. 6). Wire Color Red Black Yellow Brown Orange Green Designation G+ G0 OUT1 M NO COM Function 24 Vac Hot 24 Vac Common Analog Output Signal Analog Output Common Relay Output Normally Open Relay Output Common

Fig. 4. Junction box mounting (C7232A).

63-25715

C7232A,B SENSOR AND CONTROLLER

Table 3. Output Signal Jumper Settings

C7232 24V + ANALOG OUT ORANGE GREEN RED BLACK YELLOW BROWN 1 POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

M17543

L1 (HOT) L2 1

OUT AN Voltage Current NOTES: 0-100% 0-10Vdc 0-20 mA 20-100% 2-10Vdc 4-20 mA

Fig. 6. Wiring the C7232.

Input Signal

The C7232 Sensors have an adjustable range. These ranges are determined by the SW1 and SW2 jumper settings (see Table 2). Table 2. CO2 Range Jumper Settings SW1 On On Offb Off

a When

On duct models, remove the screw holding the board in place to view jumper settings on reverse. (See Fig. 7.) The CO2 settings and the output signal settings are independent of each other. 0-100% and 20-100% are simply markings for the OUT jumper settings on the sensor (to differentiate between the two voltage and the two current ranges) and do not refer to or alter the ppm range chosen.

SW2 On Off Onb Off

AN (ppm) 0 to 1000 0 to 2000 500 to 1500 500 to 2000

Relaya (ppm) 1000 1200 800 1200

SW2SW1 OUT OFF ON OFF ON 0 100% 20 100% AN Voltage Current

the level reaches this value, the contacts close; when the level drops 100 ppm below this value, the contacts open. b Setting when shipped from the factory.

Output Signal

The output signal can be adjusted for 0/2-10Vdc or 0/4-20mA (see Table 3).

M19424

Fig. 7. C7232 default jumper settings.

Example

For a CO2 setting of 0-2000 ppm and a voltage output of 0-10 Vdc, the output would be as shown in Table 4 (arbitrary points along the analog curve). Table 4. 0-10 Vdc Output Example. CO2 Level (ppm) Voltage Output (Vdc) 0 0 200 1 400 2 600 3 800 4 1000 5 1200 6 1400 7 1600 8 1800 9 2000 10

For a CO2 setting of 0-2000 ppm and a voltage output of 2-10 Vdc, the output would be as shown in Table 5 (arbitrary points along the analog curve). Table 5. 2-10 Vdc Output Example. CO2 Level (ppm) Voltage Output (Vdc) 0 2 250 3 500 4 750 5 1000 6 1250 7 1500 8 1750 9 2000 10

63-25715

C7232A,B SENSOR AND CONTROLLER

CALIBRATION

Typically, calibration is unnecessary. No calibration kits are available. However, if CO2 gas can be purged from the sensor chamber using a general gas purge device, the sensor can be rezeroed: IMPORTANT Any CO2 present during calibration skews the sensor zero level resulting in incorrect CO2 level reports. 1. 2. 3. 4. Once the sensor stabilizes, use a screwdriver to connect the two MENU soldering pads. The display should indicate CAL. Execute the zero calibration by connecting the two ENTER soldering pads. The display should return to providing the measured CO2 level.

CHECKOUT

Perform a quick test of the unit with the unit powered: 1. Stand close to the unit and breathe air into the sensor. 2. Check the CO2 level registered by the controller to ensure a strong rise. 3. When connected to a damper in a ventilation system, the controller typically signals an increase in air flow.

63-25715

C7232A,B SENSOR AND CONTROLLER

APPENDIX

IMPORTANT

This page is only for models with date code prior to 0309.

Pre 0309 Date Code Jumper Settings

Input Signal

The C7232 Sensors have an adjustable range. These ranges are determined by the SW2 and OUT1 jumper settings (see Table 6). NOTE: When choosing analog output, be sure to set the SW1 jumper to the On position. Table 6. CO2 Range Jumper Settings for models with date code prior to 0309. Jumper SW1 Jumper OUT1b Setting AN1 AN2

a

Table 7. Output Signal Jumper Settings for models with date code prior to 0309. AN1 and AN2 (set both the same) Voltage Current NOTES:

On duct models with date code prior to 0309, remove the screw holding the board in place to view jumper settings on reverse. (See Fig. 8.) The CO2 settings and the output signal settings are independent of each other. 0-100% and 20-100% are simply markings for the OUT jumper settings on the sensor (to differentiate between the two voltage and the two current ranges) and do not refer to or alter the ppm range chosen.

OUT 0-100% 0-10Vdc 0-20 mA 20-100% 2-10Vdc 4-20 mA

Jumper SW2 Ona 0 to 1000 500 to 1500 800

d

Ona X X X X

Off c

c

Off 0 to 2000 500 to 2000 1200d

Relay Switchingb

a b c d

1000d

SW2SW1 OUT OFF ON OFF ON 0 100% 20 100% AN2 Voltage Current AN1 Voltage Current OUT1 Select AN1 AN2

Setting when shipped from the factory. OUT1 jumper setting does not affect the Relay Switching. The analog output will not work properly when SW1 is Off. When the level reaches this value, the contacts close; when the level drops 100 ppm below this value, the contacts open.

Output Signal

The output signal can be adjusted for 0/2-10Vdc or 0/4-20mA (see Table 7).

M20494

Fig. 8. C7232 default jumper settings for models with date code prior to 0309.

63-25715

Automation and Control Solutions

Honeywell International Inc. 1985 Douglas Drive North Golden Valley, MN 55422 Honeywell Limited-Honeywell Limite 35 Dynamic Drive Scarborough, Ontario M1V 4Z9

Honeywell International

Control Products Honeywell Building 17 Changi Business Park Central 1 Singapore 486073

Honeywell Europe S.A.

3 Avenue du Bourget 1140 Brussels Belgium

Honeywell Latin American Region

480 Sawgrass Corporate Parkway Suite 200 Sunrise FL 33325

63-25715

B.B. Rev. 6-03

Printed in U.S.A. on recycled paper containing at least 10% post-consumer paper fibers.

www.honeywell.com

Potrebbero piacerti anche

- Beginning Digital Electronics through ProjectsDa EverandBeginning Digital Electronics through ProjectsValutazione: 5 su 5 stelle5/5 (1)

- Honeywell C7632a B Sensor Co2 PDFDocumento4 pagineHoneywell C7632a B Sensor Co2 PDFMarcello PorrinoNessuna valutazione finora

- Instruction Manual: Model 7SL High/Low LimitrolDocumento48 pagineInstruction Manual: Model 7SL High/Low LimitrolkmpoulosNessuna valutazione finora

- 117 - 4417902 - Rev.0 - Instruction Manual AlarmScout 961-962 (Loop Powered) PDFDocumento8 pagine117 - 4417902 - Rev.0 - Instruction Manual AlarmScout 961-962 (Loop Powered) PDFFrancisco Rodriguez MartinezNessuna valutazione finora

- Instruction Manual: Model 7SCDocumento52 pagineInstruction Manual: Model 7SCkmpoulos100% (2)

- DC To Pulse Width Modulator: Allows Very Eff Icient Control o FDC Motors, Heate Rs or LightsDocumento0 pagineDC To Pulse Width Modulator: Allows Very Eff Icient Control o FDC Motors, Heate Rs or Lightsapostol_menNessuna valutazione finora

- Cam Bien Vat Can Sharp GP2D12 F77Documento10 pagineCam Bien Vat Can Sharp GP2D12 F77NguyễnThanhSangNessuna valutazione finora

- Accelerometer Sensor 3145Documento2 pagineAccelerometer Sensor 3145greens99Nessuna valutazione finora

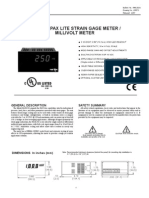

- Model Paxlsg - Pax Lite Strain Gage Meter / Millivolt Meter: C Us Listed Us ListedDocumento8 pagineModel Paxlsg - Pax Lite Strain Gage Meter / Millivolt Meter: C Us Listed Us ListedJosé Tomas CisnerosNessuna valutazione finora

- KDL42BX 320 420 AZ2 Uk ChassisDocumento34 pagineKDL42BX 320 420 AZ2 Uk ChassisDamon Brunger100% (1)

- Power Meter E51C2Documento29 paginePower Meter E51C2atereñoneNessuna valutazione finora

- Spectrum Analyzer: User ManualDocumento40 pagineSpectrum Analyzer: User ManualBenjaminBaezNessuna valutazione finora

- LG TV 29fu6rsd (RS) Chassis Cw62d, Service ManualDocumento22 pagineLG TV 29fu6rsd (RS) Chassis Cw62d, Service Manualjazjcl3269Nessuna valutazione finora

- V26 Service ManualDocumento81 pagineV26 Service ManualscotnelsonNessuna valutazione finora

- Cd5e241 l1Documento20 pagineCd5e241 l1Steven NgNessuna valutazione finora

- Strato 35 Series and 70 Series :: ROAL Living EnergyDocumento5 pagineStrato 35 Series and 70 Series :: ROAL Living EnergyroalscribdNessuna valutazione finora

- KDL40Z4500 Service ManualDocumento29 pagineKDL40Z4500 Service ManualNissanka Munasingha100% (2)

- Sony kdl-40w4000 kdl-46w4000 kdl-52w4000 Chassis Eg1lDocumento56 pagineSony kdl-40w4000 kdl-46w4000 kdl-52w4000 Chassis Eg1lmendermanNessuna valutazione finora

- BC1602K Series VER01Documento28 pagineBC1602K Series VER01Jeremiah DayNessuna valutazione finora

- Color Monitor: Service ManualDocumento35 pagineColor Monitor: Service ManualReparatii Calculatoare TimisoaraNessuna valutazione finora

- GD 4000Documento32 pagineGD 4000Naqib FuadNessuna valutazione finora

- Venticator - VC1008F: Carbon Dioxide Sensor / TransmitterDocumento2 pagineVenticator - VC1008F: Carbon Dioxide Sensor / TransmitterMarvin MarcaidaNessuna valutazione finora

- Fenwall Ionization Smoke DetectorDocumento4 pagineFenwall Ionization Smoke Detectormetal_dung2Nessuna valutazione finora

- Honeywell 5800C2W Installation ManualDocumento2 pagineHoneywell 5800C2W Installation ManualAlarm Grid Home Security and Alarm MonitoringNessuna valutazione finora

- Cd5e241 s1Documento22 pagineCd5e241 s1Steven NgNessuna valutazione finora

- Sony Eg1l Chassis Kdl-46v4800 LCD TV SMDocumento47 pagineSony Eg1l Chassis Kdl-46v4800 LCD TV SMsuysuy00Nessuna valutazione finora

- Ad9288bst 100Documento17 pagineAd9288bst 100negrea_c8079Nessuna valutazione finora

- 3797 CT-32D20BDocumento12 pagine3797 CT-32D20BЮрий ЮрченкоNessuna valutazione finora

- LG (Cl-11) Lg881y Fpd1800 LCDDocumento34 pagineLG (Cl-11) Lg881y Fpd1800 LCDGregory Adolfo AlvarezNessuna valutazione finora

- LG 42PC55 Service ManualDocumento54 pagineLG 42PC55 Service ManualThomas Oldbury100% (1)

- RTP Rata Flujo ManualDocumento18 pagineRTP Rata Flujo ManualFabian PerezNessuna valutazione finora

- Color Monitor: Service ManualDocumento24 pagineColor Monitor: Service ManualStefano PartexanoNessuna valutazione finora

- Service Manual: History Information For The Following ManualDocumento56 pagineService Manual: History Information For The Following ManualMalanie Sriya De SilvaNessuna valutazione finora

- ACPL C87B ACPL C87A ACPL C870 Precision Optically Isolated Voltage SensorDocumento14 pagineACPL C87B ACPL C87A ACPL C870 Precision Optically Isolated Voltage SensorlavaNessuna valutazione finora

- GP2Y0D02YKDocumento9 pagineGP2Y0D02YKarma_bestNessuna valutazione finora

- Abb Rdcu 12cDocumento14 pagineAbb Rdcu 12cMarco MedinaNessuna valutazione finora

- SV - 03678 - en - Na 2Documento16 pagineSV - 03678 - en - Na 2eduardodluffy268Nessuna valutazione finora

- SN74CBTS16211 24-Bit Fet Bus Switch With Schottky Diode ClampingDocumento11 pagineSN74CBTS16211 24-Bit Fet Bus Switch With Schottky Diode ClampingBa DuyNessuna valutazione finora

- Delta Dvp-Se I Mul 20130208Documento20 pagineDelta Dvp-Se I Mul 20130208daocongdablNessuna valutazione finora

- 12V 15W 1 Phase / Drp012V015W1Az: Cliq Din Rail Power SupplyDocumento11 pagine12V 15W 1 Phase / Drp012V015W1Az: Cliq Din Rail Power SupplyFacundo OmpréNessuna valutazione finora

- Model 810-N1-24VDC: Panel Mount Control EnclosureDocumento10 pagineModel 810-N1-24VDC: Panel Mount Control EnclosureWERMERMNessuna valutazione finora

- DWYER - RHP-3D-11.instruções PDFDocumento4 pagineDWYER - RHP-3D-11.instruções PDFMarcio Issao WatanabeNessuna valutazione finora

- PHILIPS LCD Ch-10.1L LLA-32PFL3605D-40PFL3605D PDFDocumento71 paginePHILIPS LCD Ch-10.1L LLA-32PFL3605D-40PFL3605D PDFAlecsandro BatistaNessuna valutazione finora

- LG 32PC5R Service ManualDocumento16 pagineLG 32PC5R Service ManualThomas OldburyNessuna valutazione finora

- Service Manual: ICF-CD2000/CD2000SDocumento44 pagineService Manual: ICF-CD2000/CD2000Slondon335Nessuna valutazione finora

- Technical Manual: NoshokDocumento4 pagineTechnical Manual: NoshokMasagus Sapta RyandaNessuna valutazione finora

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsDa EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsValutazione: 3 su 5 stelle3/5 (2)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Valutazione: 2.5 su 5 stelle2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Nessuna valutazione finora

- Digital LED Thermometer with Microcontroller AVR ATtiny13Da EverandDigital LED Thermometer with Microcontroller AVR ATtiny13Valutazione: 5 su 5 stelle5/5 (1)

- Distributed Vs Parallel ComputingDocumento31 pagineDistributed Vs Parallel Computingnazim aliNessuna valutazione finora

- Sit ParametersDocumento12 pagineSit ParametersAliNawazAhmed4Nessuna valutazione finora

- Code For Ultimate Game Play On Halo 4Documento56 pagineCode For Ultimate Game Play On Halo 4johnNessuna valutazione finora

- The Benefits of Virtual PC Desktop With TelephonyDocumento6 pagineThe Benefits of Virtual PC Desktop With Telephonyspsc059891Nessuna valutazione finora

- BASF Elastospray Booklet EngDocumento28 pagineBASF Elastospray Booklet EngPesona Karya Persada100% (1)

- Fast Cables LTD.: Manufacturing ProcessDocumento7 pagineFast Cables LTD.: Manufacturing ProcessYaredNessuna valutazione finora

- Electrical Fires, PEC & GroundingDocumento136 pagineElectrical Fires, PEC & GroundingJohn EugenioNessuna valutazione finora

- Adaptadores - BSP - NPTDocumento1 paginaAdaptadores - BSP - NPTJean DiasNessuna valutazione finora

- Configuring Hadoop Security With Cloudera ManagerDocumento52 pagineConfiguring Hadoop Security With Cloudera ManagerBoo CoriNessuna valutazione finora

- Redland Bonding Gutter Installation Instructions 3Documento9 pagineRedland Bonding Gutter Installation Instructions 3JNessuna valutazione finora

- SFU WUSC Meeting MinutesDocumento3 pagineSFU WUSC Meeting MinutesWUSC SFUNessuna valutazione finora

- Cumigrid LCTDocumento2 pagineCumigrid LCTshankarklNessuna valutazione finora

- Microprocessors Lecture SlidesDocumento30 pagineMicroprocessors Lecture Slidestourist101Nessuna valutazione finora

- 17 OEP100320 LTE Radio Network Capacity Dimensioning ISSUE 1.11Documento34 pagine17 OEP100320 LTE Radio Network Capacity Dimensioning ISSUE 1.11MashaalNessuna valutazione finora

- Esquema Elétrico GOLF 1995 PDFDocumento11 pagineEsquema Elétrico GOLF 1995 PDFLeandro RibeiroNessuna valutazione finora

- Ansys Platform Support Strategy Plans February 2019Documento3 pagineAnsys Platform Support Strategy Plans February 2019Nicola PieriNessuna valutazione finora

- Router HackingDocumento10 pagineRouter HackingferjuveloNessuna valutazione finora

- 640 Nondestructive Testing and EvaluationDocumento1 pagina640 Nondestructive Testing and EvaluationYasser Samohuallpa SerranoNessuna valutazione finora

- 3G BasicsDocumento86 pagine3G BasicsAshit SinghNessuna valutazione finora

- ZXMP s380 and s390Documento49 pagineZXMP s380 and s390محيي الدين الكميشى100% (1)

- EchoLife HG8247 GPON Terminal Product Description - (V100R002C00& C01 - 03)Documento20 pagineEchoLife HG8247 GPON Terminal Product Description - (V100R002C00& C01 - 03)Tiến Hồ VănNessuna valutazione finora

- CII Sohrabji Godrej Green Business CentreDocumento3 pagineCII Sohrabji Godrej Green Business CentrePooja Parekh0% (1)

- BPMN 2.0 - Business Process Model and Notation Innovator For Business AnalystsDocumento1 paginaBPMN 2.0 - Business Process Model and Notation Innovator For Business Analystssauloarvelos58167% (3)

- Engineering DrwaingDocumento45 pagineEngineering DrwaingKamal Krishna Kashyap100% (1)

- Article-Pastoral Nomadism in The Archaeology of India and Pakistan1Documento20 pagineArticle-Pastoral Nomadism in The Archaeology of India and Pakistan1Manas DixitNessuna valutazione finora

- Informatica IDQ Dashboard Reports 961Documento14 pagineInformatica IDQ Dashboard Reports 961Josh TownsendNessuna valutazione finora

- Int 1Documento48 pagineInt 1rachmat99Nessuna valutazione finora

- DL-T 5358-2006 Technical Code For Anticorrosion of Metal Structures in Hydroelectric and Hydraulic EngineeringDocumento43 pagineDL-T 5358-2006 Technical Code For Anticorrosion of Metal Structures in Hydroelectric and Hydraulic Engineeringsaliyarumesh2292Nessuna valutazione finora

- Staad Input FileDocumento5 pagineStaad Input FileMohammedNessuna valutazione finora

- Ag Ss Kx6 Fdc400kxe6Documento3 pagineAg Ss Kx6 Fdc400kxe6Shafik AtwiNessuna valutazione finora