Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Safety Details

Caricato da

Nauman TajDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Safety Details

Caricato da

Nauman TajCopyright:

Formati disponibili

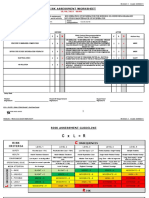

FACILITY SAFETY INSPECTION CHECKLIST

Company: Location: Inspection Completed By: Date:

Not Satisfactory Administrative:

1. 2. 3. 4. 5. Written safety rules/safe job procedures in place OSHA log updated/safety posters displayed Management Safety Policy in place All planned safety activities preformed (meetings, inspections, training) Effective new employee safety orientation

Corrective Action/Date

Life Safety Issues/Housekeeping:

1. 2. 3. 4. 5. Walkways maintained, aisles defined, uncluttered Emergency exits clearly identified, adequate number Egress routes marked and accessible Unapproved doors clearly marked NOT AN EXIT Stairs/aisleways free from material storage and debris

Emergency Medical:

1. 2. 3. 4. 5. Emergency contact information posted First aid responders available for each shift Bloodborne pathogens exposure potential adequately addressed First aid supplies adequate and available Transportation available for injured workers/plan in place

Slip/Trip/Fall Hazards:

1. Portable ladders equipped with non-slip feet. Metal ladders marked Do Not Use Around Electrical Equipment 2. Stairways in good repair with handrails, treads and risers in proper proportion and non-slip 3. Elevated areas have guardrails and toe boards 4. Work areas, aisleways, storage areas are orderly 5. Illumination adequate for normal conditions, emergency lighting in place 6. External walking, parking, break areas free of hazards, well maintained 7. Warning signs posted for wet floors or spills 8. Anti-slip mats and flooring used where appropriate

1 OF 3

FACILITY SAFETY INSPECTION CHECKLIST

Not Satisfactory Hand Tools:

1. 2. 3. 4. 5. Power tools properly grounded/have safety power switch Defective tools are removed from service Proper guards are provided, tools electrically grounded or double insulated There is a preventive maintenance/inspection program Employees are trained in the safe use of hand tools

Corrective Action/Date

Fire Safety:

1. Portable fire extinguishers of proper type are mounted properly, accessible, and inspected 2. Approved safety containers are used for flammable liquids 3. Bonding and grounding used with storage of flammable materials 4. Combustible debris disposed of regularly 5. No Smoking areas designated 6. Sprinkler system functional/inspected/documented 7. Smoke/heat detectors functional and inspected 8. Minimum 18 clearance below sprinkler heads 9. Sprinkler valves locked open

Electrical Hazards:

1. 2. 3. 4. 5. 6. 7. 8. Machinery and equipment are grounded Electrical panels have clear access Electrical panels clearly marked Outlets, switches and boxes have covers Permanent wiring in place no extension cords Exposure of overhead electrical lines controlled Emergency stops and critical electrical controls are identified Appropriate electrical systems designed for hazardous locations have been installed in spray booths and flammable liquid storage rooms

Mobile Equipment:

1. 2. 3. 4. 5. 6. 7. Observed operating at safe speeds Observed safe loading and unloading practices Equipped with back-up alarms Operators qualified/trained Equipment Inspected regularly Seat belt worn by operator Mirrors installed at blind spots

2 OF 3

FACILITY SAFETY INSPECTION CHECKLIST

Not Satisfactory Mechanical and Manual Material Handling and Storage:

1. 2. 3. 4. 5. 6. 7. Hoist chains, cables, and slings are inspected regularly and documented Storage piles are stable and secured from falling or collapse Load limits are posted for all floors above ground level Load limits are displayed on all hoists Manual handling aids available and used Weight limits set for manual lifting, carrying, pushing, pulling Workers trained in proper lifting techniques/ergonomics

Corrective Action/Date

Machinery:

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. Lockout/tagout program in place, locks available, employees trained Hazardous areas painted bright colors Guards are provided for point-of-operation of machinery Clothing and hair restrictions in place to prevent entanglement in machinery Power transmission guards are in place Noise exposures adequately addressed Warnings displayed in obvious locations Compressed air systems have pressure reduced to 30 PSI and are not used for cleaning clothing Air hoses provided with safety latch to prevent accidental disconnect Welding equipment in good condition Compressed gas cylinders are and secured to prevent falling Overhead hazards from equipment, conveyors, and process pipes, are guarded below 7 ft from floor

Chemicals:

1. 2. 3. 4. 5. Hazardous materials containers labeled MSDS available Hazard Communication Training program in place Smoking and eating prohibited in work areas where chemicals are used Eyewash/emergency shower available and functional

Personal Protective Equipment:

1. 2. 3. 4. 5. 6. 7. PPE assessment performed PPE requirements in place Employees trained in the use and maintenance of PPE training documented Hard hat areas designated and enforced Hearing protecting utilized in required areas Face/eye protection in place where needed Safety foot protection required where appropriate Protective clothing, gloves, aprons, boots, face shields, and goggles are used when handling hazardous materials 8. Approved respiratory protection equipment available and fit tested

Selective Insurance Company of America

40 Wantage Ave. Branchville, NJ 07890

www.selective.com

SM-120 (10/07)

3 OF 3

Potrebbero piacerti anche

- Safe System Of Work A Complete Guide - 2020 EditionDa EverandSafe System Of Work A Complete Guide - 2020 EditionNessuna valutazione finora

- Sample-Risk Assessment & Safe Work Method StatementDocumento4 pagineSample-Risk Assessment & Safe Work Method StatementioanchiNessuna valutazione finora

- SH-F43 - PTW Format - R02Documento2 pagineSH-F43 - PTW Format - R02vini100% (1)

- Toolbox Talks Forklift Safety EnglishDocumento1 paginaToolbox Talks Forklift Safety EnglishBayu Mandala PratamaNessuna valutazione finora

- Health & Safety Management Plan 2014-2019 Annual Key Performance IndicatorsDocumento3 pagineHealth & Safety Management Plan 2014-2019 Annual Key Performance Indicatorsmohit50% (2)

- RA Every ActvityDocumento38 pagineRA Every ActvityvijayNessuna valutazione finora

- Risk Assessment Forms - Appendix 5 (22102016)Documento2 pagineRisk Assessment Forms - Appendix 5 (22102016)Sơn Nguyễn-Lê100% (1)

- Incident Reporting Form (Ir 01) : Fatality Lti I RWC Accident NEAR MissDocumento1 paginaIncident Reporting Form (Ir 01) : Fatality Lti I RWC Accident NEAR Missmuhammadumar412296Nessuna valutazione finora

- Site Inspection Workplace Trasport ChecklistDocumento6 pagineSite Inspection Workplace Trasport ChecklisttipuNessuna valutazione finora

- HSMC Employee Induction Procedure (Offices)Documento3 pagineHSMC Employee Induction Procedure (Offices)Anonymous 4e7GNjzGWNessuna valutazione finora

- TSTI FormDocumento2 pagineTSTI FormJinu ThomasNessuna valutazione finora

- 04, Use of Hand ToolsDocumento2 pagine04, Use of Hand ToolsFrancis K BonfulNessuna valutazione finora

- JHA GasesDocumento2 pagineJHA GasesalokcNessuna valutazione finora

- Manual & Mechanical ChecklistDocumento7 pagineManual & Mechanical ChecklistMartine OtienoNessuna valutazione finora

- CTRA-23-STM-146 - TK - 11-995 - HotWorkDocumento3 pagineCTRA-23-STM-146 - TK - 11-995 - HotWorkMohamed RizwanNessuna valutazione finora

- Risk Assessment Hanging DoorsDocumento11 pagineRisk Assessment Hanging DoorsMitchRappNessuna valutazione finora

- Toolbox Talk - Permit To WorkDocumento1 paginaToolbox Talk - Permit To WorkrajNessuna valutazione finora

- Risk Assessment - House and Office CleaningDocumento6 pagineRisk Assessment - House and Office CleaningVimal Thomas100% (1)

- Unloading of EWPs From ContainersDocumento10 pagineUnloading of EWPs From ContainersPirashanth SathananthanNessuna valutazione finora

- Accident Report FormDocumento5 pagineAccident Report Formyenni mirandaNessuna valutazione finora

- HSE-06FR-02 - Environmental Incident RegisterDocumento1 paginaHSE-06FR-02 - Environmental Incident RegisterSalah S. BarihNessuna valutazione finora

- SWP 03 Heavy EquipmentDocumento7 pagineSWP 03 Heavy Equipmentমমিন মানব100% (1)

- Task Risk Assessment For (Compressed Air Line Tie-In)Documento11 pagineTask Risk Assessment For (Compressed Air Line Tie-In)Venkadesh Periathambi100% (2)

- IS0 9001 - 2008 OHSAS 18001 and ISO 14001 Requirements SummaryDocumento9 pagineIS0 9001 - 2008 OHSAS 18001 and ISO 14001 Requirements Summaryジェイ センニュリンNessuna valutazione finora

- Risk Assessment WorksheetDocumento2 pagineRisk Assessment WorksheetHergheligiu VasileNessuna valutazione finora

- Arc Welder Risk MG T FormDocumento9 pagineArc Welder Risk MG T FormMohd FikryNessuna valutazione finora

- List of Safety Forms: S. No. Title Rev. No. Rev. DateDocumento1 paginaList of Safety Forms: S. No. Title Rev. No. Rev. Dateadil khanNessuna valutazione finora

- Specific Risk Assessment For Civil Work - Kijitonyama Shule SiteDocumento5 pagineSpecific Risk Assessment For Civil Work - Kijitonyama Shule SiteemnelNessuna valutazione finora

- Manual HandlingDocumento5 pagineManual HandlingImad A KhanNessuna valutazione finora

- PPE Hazard Assessment Certification Form: (Use A Separate Sheet For Each Job/task or Work Area)Documento3 paginePPE Hazard Assessment Certification Form: (Use A Separate Sheet For Each Job/task or Work Area)eastNessuna valutazione finora

- Al Majal QMS - 2018Documento19 pagineAl Majal QMS - 2018Adam DeviatteyNessuna valutazione finora

- Larsen & Toubro Limited Buildings and Factories Independent CompanyDocumento5 pagineLarsen & Toubro Limited Buildings and Factories Independent CompanyabbasNessuna valutazione finora

- Work at Heights PermitDocumento4 pagineWork at Heights PermitFerdinand M. TurbanosNessuna valutazione finora

- Ppe Requirement List ContractorsDocumento3 paginePpe Requirement List ContractorsMartellRNessuna valutazione finora

- Near Miss 02.09.17 SCGDocumento3 pagineNear Miss 02.09.17 SCGHolly SmithNessuna valutazione finora

- Use of Hand Tools 05Documento1 paginaUse of Hand Tools 05cardyNessuna valutazione finora

- Road Safety Risk Assessment ToolkitDocumento4 pagineRoad Safety Risk Assessment ToolkitDamian R. RamesarNessuna valutazione finora

- HIRAC - Work - at - Height - Template PDFDocumento8 pagineHIRAC - Work - at - Height - Template PDFRohma Desi ThirtasariNessuna valutazione finora

- GL 28 Material Loading PlatformDocumento1 paginaGL 28 Material Loading Platformtp101267Nessuna valutazione finora

- GEN-021 Fact FindingDocumento3 pagineGEN-021 Fact Findingacanbasri1980Nessuna valutazione finora

- RA Templates ElectricalDocumento17 pagineRA Templates ElectricalAbid MujtabaNessuna valutazione finora

- HSEQ Policy Statement - English PDFDocumento1 paginaHSEQ Policy Statement - English PDFTovo RafaralahyNessuna valutazione finora

- Development and Validation of Three Step Risk Assessment Method For Ship Recycling Sector 2015 Safety ScienceDocumento15 pagineDevelopment and Validation of Three Step Risk Assessment Method For Ship Recycling Sector 2015 Safety ScienceEvi SiswantoNessuna valutazione finora

- AsdssssDocumento1 paginaAsdssssAviects Avie JaroNessuna valutazione finora

- Safety and Health ProgramsDocumento21 pagineSafety and Health ProgramsJason SunnyNessuna valutazione finora

- Qcs 2010 Section 11 Part 2.3.11 She Procedures - Permit To Work SysteDocumento20 pagineQcs 2010 Section 11 Part 2.3.11 She Procedures - Permit To Work Systebryanpastor106Nessuna valutazione finora

- Fork Lift Daily Check: (Only For FL Operated by Batery)Documento1 paginaFork Lift Daily Check: (Only For FL Operated by Batery)Martin CabelloNessuna valutazione finora

- Inherent V Residual RiskDocumento2 pagineInherent V Residual RiskAlephNessuna valutazione finora

- Safety Alert 260 - Unsafe Cradle Installation and UsageDocumento2 pagineSafety Alert 260 - Unsafe Cradle Installation and UsageAbdulKatherNessuna valutazione finora

- Tool Box Talk - Working in Hot WeatherDocumento1 paginaTool Box Talk - Working in Hot WeatherMobashir MahmoodNessuna valutazione finora

- Job Hazard Analysis ProcessDocumento25 pagineJob Hazard Analysis ProcessPavithraNessuna valutazione finora

- Incident / Injury Occurrence Report Part BDocumento2 pagineIncident / Injury Occurrence Report Part BHamzaNoumanNessuna valutazione finora

- Risk Assessment Form (RA1) : (Action by Whom and Completion Date - Use Separate Action Plan If Necessary)Documento6 pagineRisk Assessment Form (RA1) : (Action by Whom and Completion Date - Use Separate Action Plan If Necessary)michael wakuthii100% (1)

- Fit For Duty Work Policy Short FormDocumento3 pagineFit For Duty Work Policy Short FormSunish RathaurNessuna valutazione finora

- OHS 5.3.1aPreventiveandCorrectiveActionFormDocumento1 paginaOHS 5.3.1aPreventiveandCorrectiveActionFormfcleong69Nessuna valutazione finora

- MWR 135Documento20 pagineMWR 135Philip Bautista TotanesNessuna valutazione finora

- Photo: "Tulalip Bay" by Diane L. Wilson-SimonDocumento255 paginePhoto: "Tulalip Bay" by Diane L. Wilson-SimonEliana J Yazo CNessuna valutazione finora

- Ra1 - General Risk Assessment Form 2015Documento3 pagineRa1 - General Risk Assessment Form 2015api-349297013Nessuna valutazione finora

- ABC's of Fall Protection: Murray State University Susan MillerDocumento24 pagineABC's of Fall Protection: Murray State University Susan MillerSam SalesNessuna valutazione finora

- Promoters' Guide: Formation and Incorporation of Companies Under The Companies Ordinance 1984Documento14 paginePromoters' Guide: Formation and Incorporation of Companies Under The Companies Ordinance 1984Nauman TajNessuna valutazione finora

- Create A Facebook PageDocumento6 pagineCreate A Facebook PageNauman TajNessuna valutazione finora

- Measuring Tape Manufacturing FeasibilityDocumento6 pagineMeasuring Tape Manufacturing FeasibilityNauman TajNessuna valutazione finora

- Islamic Business RulesDocumento24 pagineIslamic Business RulesNauman TajNessuna valutazione finora

- Accident InvestigationDocumento36 pagineAccident InvestigationNauman Taj100% (3)

- Hazard Checklist: Marvin RausandDocumento10 pagineHazard Checklist: Marvin RausandNauman TajNessuna valutazione finora

- Equipments For Electronics Lab: SR Name of Equipments Unit Price Quantity CommentsDocumento1 paginaEquipments For Electronics Lab: SR Name of Equipments Unit Price Quantity CommentsNauman TajNessuna valutazione finora

- Tate Modern London, Pay Congestion ChargeDocumento6 pagineTate Modern London, Pay Congestion ChargeCongestionChargeNessuna valutazione finora

- A Religious LeadershipDocumento232 pagineA Religious LeadershipBonganiNessuna valutazione finora

- Gmo EssayDocumento4 pagineGmo Essayapi-270707439Nessuna valutazione finora

- 950 MW Coal Fired Power Plant DesignDocumento78 pagine950 MW Coal Fired Power Plant DesignJohn Paul Coñge Ramos0% (1)

- CBC Building Wiring Installation NC IIDocumento72 pagineCBC Building Wiring Installation NC IIFaysbuk KotoNessuna valutazione finora

- Sacmi Vol 2 Inglese - II EdizioneDocumento416 pagineSacmi Vol 2 Inglese - II Edizionecuibaprau100% (21)

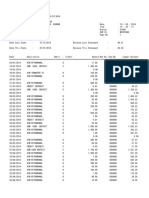

- Bank Statement SampleDocumento6 pagineBank Statement SampleRovern Keith Oro CuencaNessuna valutazione finora

- Awais Inspector-PaintingDocumento6 pagineAwais Inspector-PaintingMohammed GaniNessuna valutazione finora

- Braga - 2016 - On Standing's A Precariat Charter - Confronting The Precaritisation of Labour in Brazil and PortugalDocumento12 pagineBraga - 2016 - On Standing's A Precariat Charter - Confronting The Precaritisation of Labour in Brazil and PortugalLiam MurciaNessuna valutazione finora

- MLT Torque Ring Field Make-Up HandbookDocumento44 pagineMLT Torque Ring Field Make-Up HandbookKolawole Adisa100% (2)

- Assessment 21GES1475Documento4 pagineAssessment 21GES1475kavindupunsara02Nessuna valutazione finora

- Question Paper: Hygiene, Health and SafetyDocumento2 pagineQuestion Paper: Hygiene, Health and Safetywf4sr4rNessuna valutazione finora

- ArpitResumeISM PDFDocumento1 paginaArpitResumeISM PDFchethan rNessuna valutazione finora

- Modulation and Frequency Synthesis X Digital Wireless RadioDocumento233 pagineModulation and Frequency Synthesis X Digital Wireless Radiolcnblzr3877Nessuna valutazione finora

- Week 7 Apple Case Study FinalDocumento18 pagineWeek 7 Apple Case Study Finalgopika surendranathNessuna valutazione finora

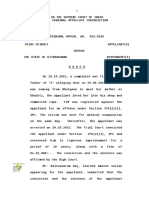

- SC-Rape-Sole Testimony of Prosecutrix If Reliable, Is Sufficient For Conviction. 12.08.2021Documento5 pagineSC-Rape-Sole Testimony of Prosecutrix If Reliable, Is Sufficient For Conviction. 12.08.2021Sanjeev kumarNessuna valutazione finora

- KrauseDocumento3 pagineKrauseVasile CuprianNessuna valutazione finora

- BACE Marketing Presentation FINALDocumento14 pagineBACE Marketing Presentation FINALcarlosfelix810% (1)

- Exoskeleton ArmDocumento5 pagineExoskeleton Armc214ocNessuna valutazione finora

- CT018 3 1itcpDocumento31 pagineCT018 3 1itcpraghav rajNessuna valutazione finora

- MEMORANDUMDocumento8 pagineMEMORANDUMAdee JocsonNessuna valutazione finora

- Residential BuildingDocumento5 pagineResidential Buildingkamaldeep singhNessuna valutazione finora

- Preventing OOS DeficienciesDocumento65 paginePreventing OOS Deficienciesnsk79in@gmail.comNessuna valutazione finora

- Vice President Enrollment Management in Oklahoma City OK Resume David CurranDocumento2 pagineVice President Enrollment Management in Oklahoma City OK Resume David CurranDavidCurranNessuna valutazione finora

- IOSA Information BrochureDocumento14 pagineIOSA Information BrochureHavva SahınNessuna valutazione finora

- UBITX V6 MainDocumento15 pagineUBITX V6 MainEngaf ProcurementNessuna valutazione finora

- Soneri Bank Compensation PolicyDocumento20 pagineSoneri Bank Compensation PolicySapii MandhanNessuna valutazione finora

- Sangeetahealingtemples Com Tarot Card Reading Course in UsaDocumento3 pagineSangeetahealingtemples Com Tarot Card Reading Course in UsaSangeetahealing templesNessuna valutazione finora

- UCAT SJT Cheat SheetDocumento3 pagineUCAT SJT Cheat Sheetmatthewgao78Nessuna valutazione finora

- Flow Chart For SiFUS Strata Title ApplicationDocumento5 pagineFlow Chart For SiFUS Strata Title ApplicationPhang Han XiangNessuna valutazione finora