Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Tejotham Bajepally

Caricato da

1985naveenDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Tejotham Bajepally

Caricato da

1985naveenCopyright:

Formati disponibili

Tejotham Bajepally

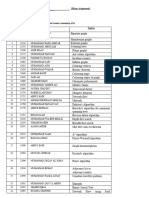

SAP MM/WM/LE Consultant at Cargill

Work Experience

SAP MM/WM/LE Consultant

Cargill August 2011 to Present

SAP MM/WM/LE Consultant

Westward Pharmaceuticals September 2010 to July 2011

SAP MM/WM Consultant

The Charles Machine Works Inc February 2009 to August 2010

SAP MM/IM Consultant

Lord Corporation January 2008 to December 2008

SAP MM/WM Consultant

Keystone Automotive Industries June 2006 to December 2007

SAP MM Consultant

Valero Energy Corporation March 2005 to April 2006

SAP MM Consultant

Valero Energy Cooperation - San Antonio, TX March 2005 to April 2006

ENVIRONMENT SAP R/3 4.7 (Implementation Support) DURATION Mar 2005 - April 2006 Valero Energy Corporation headquartered in San Antonio, Texas, is a domestic energy delivery company that includes electricity transmission and distribution, natural gas distribution and sales, interstate pipeline and gathering operations. Responsibilities: Member of Post Go-Live production support team helping users creating remedy tickets. Monitoring and resolving issues in the area of Materials Management. Configured Material Management module to meet the organizational structure for the Client's specifications and their business processes.

Proficient in customization of material records, vendor records, purchasing documents, number ranges Definition of views and fields, item categories, release procedures, creation of account groups, usage of partner functions and special stocks (Vendor Consignment, Sub-Contracting). Conducting problem analysis and communicating the solution to the user. Resolved tickets as part of the production support team. Document the solution in call logging application once getting confirmation from the user. Customizing in SAP IMG in the case of new business requirements. Providing solutions to end user problems/training. Sent files to customers for confirmation and a copy of file to process team, related to any process changes or configuration changes. Documented all required information to keep track and progress of the project. Assisted in preparing Work Instructions Templates and documented frequently occurring issues as Production Support. Responsible for preparation of the test data for super-user and end-user performance based training on the new system. Responsibilities included responding via Phone or E-Mail in a timely manner to Business Users. CLIENT Semantic Space Technologies, Hyderabad, India EXPERTISE SAP MM Consultant ENVIRONMENT SAP R/3 4.6C (Implementation Support) DURATION March 2004 - Dec. 2004 Semantic Space Technologies Limited (Semantic Space) was founded in 1997 with a mission to creatively unlock high-value for our customers by simplifying IT. Responsibilities: Configured the Enterprise Structure for Material Management module Defined plants, Storage locations, purchase organization, assigned purchasing organization to company codes, and assigned plants to company code. Set up the Material Master, Vendor Master, Source list, and Purchase Info Records. Setting of customizing parameters for all purchase documents like RFQ, Quotations, Purchase Requisitions and Purchase orders, Contracts, Scheduling Agreements. Customizing and setting up Release Procedures with and without classification for all purchasing documents namely Purchase requisition, Purchase Orders. Configured Pricing procedure. Defined condition types, access sequence, condition table, condition records and calculation schema for price determination. Configured the Inter Company Stock Transport Order process for different Plants. Used A-B-C analysis leading to better control over waste and obsoleteness. Worked on physical inventory calculation and warehouse stock monitoring. Identification of Training needs of a client for training purpose at all levels like Individual users, Transactional users and Information users. Develop Training material & support aids for end users and power users.

SAP MM Consultant

Semantic Space Technologies - Hopkins, MN March 2004 to December 2004

MN) Expertise SAP MM/WM/LE Consultant Environment ECC 6.0 (Implementation Support) Duration Aug 2011- Present Cargill is an international producer and marketer of food, agricultural, financial and industrial products and services. Founded in 1865, it is now the largest privately held corporation in the United States in terms of revenue.

Responsibilities: Worked on Logistics Execution (LE) functions like Delivery Processing (inbound and outbound processes), Picking, Packing and Transportation. Worked with various goods movements of handling units like Good Issue, Goods receipt and other movements like reversals & general goods movements posting. Worked with processing the handling units, processing work orders and monitoring of handling units. Resolved issues in inventory by using Batch management, handling of special stocks, and creation of new storage locations for business gaps. Configured smart labels for specific business unit materials. Worked with setting up condition records for different outputs. Defined the Release Group, Release code, Release Indicators, Release Strategy and Prerequisites. Configured the Automatic Output Determination process. Configured the Stock Transport Order process for different plants at intercompany level. Created customer account groups. Defined the Sales Organization, Distribution Channel and Divisions. Assigned Delivery type, Document type and defined the Checking rule. Defined and assigned the Shipping points to the plants, configured the Shipping Point Determination function. Defined the warehouse number, storage types, storage sections, storage bin types, storage bins. Configured working on the Stock Placement Control and Stock Removal Control parameters. Configured Storage Unit Management (SUM) and Handling Unit Management (HUM). Configured Material Master for packaging material. Worked with Handling Unit by creating packaging material, Goods Movements for Handling Unit. Worked on the Mobile Data entry using the wireless radio frequency (RF) terminals to record the data. Defined the RF Queue Management and designed the RF menus. Worked on Code 39 and EAN 128 types of barcodes labels, and Zebra printer. Prepared the functional specifications for the RICEF objects. Working with ABAP programmers. Mapped the source data from legacy system to the target data on SAP. Uploaded master data records using LSMW. Designed Unit testing and Integration testing scripts for testing of MM-IM-WM interface using HP Quality Center. Prepared end user training documentation and provided post implementation support to the end users using RWD uPerform. Assisted in preparing on material guides, job aids and training the end users and involved in holding additional training sessions with business key users. Responsible for preparation of the test data for Super-user and end-user Performance based training on the new system. Worked with BMC remedy tool for creating and resolving incidents. CLIENT Westward Pharmaceuticals, Eatontown, New Jersey (NJ) EXPERTISE SAP MM/WM/LE Consultant ENVIRONMENT ECC 6.0 (Implementation Support) DURATION Sep 2010 - July 2011 West-Ward Pharmaceuticals is one of the top 20 generic prescription medication providers in the US, providing pharmaceuticals to a growing number of chain stores, wholesalers, distributors, health systems and government agencies. Responsibilities: Involved in discussion with SMEs and Business process owners for understanding of current business processes. Preparation of the related documentation. Actively involved in documenting As-Is and designing of ToBe business processes, cutover strategy and planning. Designed and configured the entire warehouse organization structure. Defined the warehouse number, storage types, storage sections, storage bin types, storage bins. Defined control parameters for warehouse number. Defined shipping point & assigned warehouse to storage location, shipping point to plant. Set up interim storage areas and interim storage bins to handle goods receipt and goods issue activities.

Configured Storage type by working on the Stock Placement Control and Stock Removal Control parameters. Defined the Storage Bin structure and worked on the templates and structures of the storage binnumbering schema for automatic storage-bin creation. Configured the warehouse management data in the Material Master, creating the material master, entering data into the warehouse management screens. Configured the created materials to be batch managed. Worked on Batch number assignment, creating the batch record. Information regarding the Shelf-Life Expiration Data has been configured in the plant data storage view of the material master. Batch Management (created characteristics, classes, and assigned class types). Worked extensively on configuration of multiple WM and IM movement types. Setting up the link between them via reference movement type. Designed custom movement types. Set up immediate and automatic Transfer Orders for Transfer Requirements. Defined number ranges for TRs. Configured the Picking and Putaway Strategies. Extensive experience in Logistics Execution (LE) functions like Delivery processing ( In bound & Out bound), Picking, Packing and Goods Issue, Transportation Defined the Storage Type Indicator, configured Storage Type Search and Storage Section Search. Setup the Inventory Procedures like Annual Physical Inventory, Continuous Inventory, Cycle counting. Worked on the Mobile Data entry using the wireless radio frequency (RF) terminals to record the data. Creating new forms of barcode labels. Defined the RF Queue Management and designed the RF menus. Conducted Integration testing to ensure smooth transaction flow across modules. Prepared and documented test scenarios, test cases, training material and the end-user manual. CLIENT The Charles Machine Works, Inc., Perry, Oklahoma (OK) EXPERTISE SAP MM/WM Consultant ENVIRONMENT ECC 6.0 (Full Cycle Implementation) DURATION Feb 2009 - Aug 2010 The Charles Machine Works, Inc. is the manufacturer of Ditch Witch underground construction equipment. Located in Perry, Oklahoma, CMW is privately held by the founding family and company employees. The company boasts a record of long-term profitability. Responsibilities: Attended meeting with users on business processes. Conducted workshops to gather information on the set up and material flow. Assisted in documenting As-Is and designing the To-Be business processes. Worked on whole Procure to Pay (P2P) life cycle like Purchase Requirement, Request for Quotation (RFQ), Purchase Order (PO), Source determination, Vendor selection, Goods Receipt and Invoicing. Defined and configured the Enterprise structure, Customized Material Master, Vendor Master, Info record. Setting of customizing parameters for all purchase documents like Purchase Requisition, RFQ, Quotations, Purchase orders, Contracts, Scheduling Agreements. Managed Special Stocks such as Consignment and Subcontracting. Configured Inventory Management parameters for all goods movements like goods receipts, goods issues, GR for blocked stock, goods returns. Customizing and setting up Release Procedures with and without classification for all purchasing documents namely Purchase requisition, Purchase Orders. Customized the Pricing Procedure process by defining condition types, access sequences, calculation schema and schema determination using condition techniques. Worked on Automatic Account determination, Vendor Recon account, GR/IR clearing account, mapping valuation classes to GL account. Carried out Split Valuation for evaluating the material based on valuation category.

Define properties of the material and its batches and stored them as characteristics in the classification system. Created classes for the material and the batches and assigned the characteristics to the classes. Configured the serial number management. Configured the Bill of Materials (BOM) for use in subcontracting and sales and distribution. Prepared the Physical Inventory setting for annual and cycle counting (A-B-C indicators). Worked with RF queue management and RF screen management there by assigning and defining RF queues. Involved with bar coding and RF related activities like inbound deliveries, outbound deliveries, internal movement types, and stock management. Actively involved in testing various scenarios and master data components and fixing the issues as and when required Designed Unit testing for Procure to pay cycle. Providing solutions to end user problems/training using RWD uPerform. CLIENT Lord Corporation, Erie, Pennsylvania (PA) EXPERTISE SAP MM/IM Consultant ENVIRONMENT R/3 4.7 to ECC 6.0 (Upgrade Support) DURATION Jan 2008 - Dec 2008 Lord Corporation is a diversified technology company with a long history of developing breakthrough adhesive, coating and motion management technologies. The company provided innovative solutions to demanding aerospace, defense, automotive and industrial customer problems for more than 85 years. Responsibilities: Baseline configuration including creation and assignment of Plants to Company Code, Storage Locations to Plant and Warehouse to Storage Location. Maintaining Material Master, Vendor Master, purchasing masters - Quota Arrangements, Source List, Vendor Evaluation and Purchasing Info Record. Defined Number Ranges and Text Messages for various Purchasing Documents and Goods Movement Documents. Materials Planning: MRP (MRP Types, MRP Controllers), Lot-Size Calculation, Reorder Point Planning (Manual and Automatic), Consumption Based Planning. Configured Pricing Procedures through condition types, access sequences, condition tables, calculation schemas, schema determination, and condition records. Defined Release Groups, Release Codes, Release Indicators and Strategies with Classification. Maintained Special Stocks - Consignment, Subcontracting, Third Party materials and Stock Transfers. Configured Inventory Management for Goods Receipt, Goods Issue, Stock Transfer Orders, Transfer Posting, and Movement Types. Worked on Physical Inventory Documents and posting the difference quantity for carrying out the physical inventory using Cycle Counting for both IM and WM. Carried out Split Valuation for evaluating the material based on valuation category. Involved in Data Migration for Material Master, Vendor Master and Purchasing Info Records from legacy systems using LSMW. Performed integration testing including test plans, test scripts, test schedule, test problem resolution, etc. Created Test Problem report Log documents & procedures to provide effective flagging of issues and quick resolution. Created detailed user documentation and held training sessions for users. CLIENT Keystone Automotive Industries, Corona, California (CA) EXPERTISE SAP MM/WM Consultant ENVIRONMENT SAP R/3 4.7 (Full Life Cycle Implementation) DURATION June 2006 - Dec 2007 Keystone Automotive Industries distributes parts produced by independent manufacturers for automobiles and light trucks. Its principal product lines consist of automotive body parts, bumpers and remanufactured alloy wheels and other materials used in repairing a damaged vehicle.

Responsibilities: Conducted discussions with core business team and business process owners to get the business requirements. Worked on Business Blue print preparation, As-Is process, To-Be process, Business process mapping. Configured the Organizational structure by defining Plant, Purchase Organization, Storage locations with and without WMS Defined Master Data: Material Master, Vendor Master, Info Records, Partner Functions and Source Lists. Defined the warehouse number, storage types, storage sections, storage bin types, storage bins. Configured Storage type by working on the Stock Placement Control and Stock Removal Control parameters. Configured the physical inventory both for warehouse managed and non-warehouse managed storage locations. Set up interim storage areas and interim storage bins. Configured Storage Unit Management (SUM) and Handling Unit Management (HUM). Worked with Handling Unit by creating packaging material, Goods Movements for Handling Unit. Setting up the link between WM and IM via reference movement type. Configured the Picking and Putaway Strategies. Defined the Storage Type Indicator, configured Storage Type Search and Storage Section Search. Configured the created materials to be batch managed. Worked on Batch number assignment, creating the batch record. Batch Management (created characteristics, classes, and assigned class types). Setup the Inventory Procedures like Annual Physical Inventory, Continuous Inventory, Cycle counting. Configured Automatic Output Determination by defining the Condition Records, Procedures, Output Tpes, and Access Sequences. Worked on the Mobile Data entry using the wireless radio frequency (RF). Involved in developing Functional specs to the RF devices including RF mobile front end configuration Defined the RF Queue Management and designed the RF menus. Conducting problem analysis and communicating the solution to the user. Resolved tickets as part of the production support team. Document the solution in call logging application once getting confirmation from the user. Trained end users and provided Post live support.

Potrebbero piacerti anche

- Responsibilities Sap MM ConsultantDocumento3 pagineResponsibilities Sap MM ConsultantumarNessuna valutazione finora

- Data Warehousing and Data MiningDocumento48 pagineData Warehousing and Data MiningVijay Anand100% (1)

- Construction Management Plan TemplateDocumento15 pagineConstruction Management Plan TemplatePrasad Ghorpade100% (2)

- A Brand Building Literature ReviewDocumento17 pagineA Brand Building Literature ReviewUdaya Kumar SNessuna valutazione finora

- Aviation ManagementDocumento31 pagineAviation Managementmel_napster0% (1)

- SAP MM Functional Consultant: Work ExperienceDocumento6 pagineSAP MM Functional Consultant: Work ExperienceSANTOSH GEEKNessuna valutazione finora

- Sample SRM ResumeDocumento8 pagineSample SRM Resumemuhib12Nessuna valutazione finora

- Fluency in ReadingDocumento327 pagineFluency in Readingritunath100% (6)

- SAP SD MM Functional Consultant Resume PDFDocumento3 pagineSAP SD MM Functional Consultant Resume PDFrajkumaraei83% (6)

- Unit No: 01 Introduction To Data Warehouse: by Pratiksha MeshramDocumento38 pagineUnit No: 01 Introduction To Data Warehouse: by Pratiksha MeshramRavi SistaNessuna valutazione finora

- Sap Ewm Functional Consultant ResumeDocumento5 pagineSap Ewm Functional Consultant ResumeSAM ABRAHAM100% (3)

- SAP MM Consultant Sample ResumeDocumento6 pagineSAP MM Consultant Sample Resumemarisha100% (1)

- Fredrick - Mcdonald.SAP - EWM.Lead - Resume Think4SolDocumento5 pagineFredrick - Mcdonald.SAP - EWM.Lead - Resume Think4SolMohammedNessuna valutazione finora

- Injection Machine RobotDocumento89 pagineInjection Machine Robotphild2na250% (2)

- SAP Inventory ManagementDocumento3 pagineSAP Inventory ManagementNeeraj ChauhanNessuna valutazione finora

- Ayan Das - Gurgaon - SAP MM - Avantha Technologies LimitedDocumento4 pagineAyan Das - Gurgaon - SAP MM - Avantha Technologies LimitedPRATEEKNessuna valutazione finora

- Trouble Shooting On Conveyor BeltingsDocumento17 pagineTrouble Shooting On Conveyor BeltingsVimal Bhansali100% (1)

- SAP Resume SampleDocumento49 pagineSAP Resume SampleArthi RajendranNessuna valutazione finora

- Unit No: 02 Architecture/Infrastructure & Data Representation of DWHDocumento166 pagineUnit No: 02 Architecture/Infrastructure & Data Representation of DWHRavi SistaNessuna valutazione finora

- The Key in Business Is To Know Something That Nobody Else Knows.Documento43 pagineThe Key in Business Is To Know Something That Nobody Else Knows.Sambhaji BhosaleNessuna valutazione finora

- Abhishek Agarwal SAP WM/MM Consultant, PH: (608) 481-6241 Email: Professional SummaryDocumento6 pagineAbhishek Agarwal SAP WM/MM Consultant, PH: (608) 481-6241 Email: Professional SummaryBalu ReddyNessuna valutazione finora

- Supply Chain and Procurement Quick Reference: How to navigate and be successful in structured organizationsDa EverandSupply Chain and Procurement Quick Reference: How to navigate and be successful in structured organizationsNessuna valutazione finora

- Sap PP Resume1Documento5 pagineSap PP Resume1RajRSaravananNessuna valutazione finora

- CS2032 Data Warehousing and Data Mining PPT Unit IDocumento88 pagineCS2032 Data Warehousing and Data Mining PPT Unit IvdsrihariNessuna valutazione finora

- SAP MM Functional Consultant: Work ExperienceDocumento6 pagineSAP MM Functional Consultant: Work Experienceshaik sajid pashaNessuna valutazione finora

- SAP MM Functional Consultant: Work ExperienceDocumento6 pagineSAP MM Functional Consultant: Work Experienceshaik sajid pashaNessuna valutazione finora

- Chiranjeet - Das - SAP MMDocumento7 pagineChiranjeet - Das - SAP MMshanNessuna valutazione finora

- SAP SD MM Functional Consultant Resume PDFDocumento4 pagineSAP SD MM Functional Consultant Resume PDFSurya VijayakumarNessuna valutazione finora

- Megan Wu: Work ExperienceDocumento5 pagineMegan Wu: Work ExperienceAMAR1980Nessuna valutazione finora

- Roles and ResponsibilitiesDocumento4 pagineRoles and Responsibilitiesvaishnavi saddapalliNessuna valutazione finora

- SAP MM (Procurement) FUNCTIONAL CONSULTANT - Support ProjectDocumento2 pagineSAP MM (Procurement) FUNCTIONAL CONSULTANT - Support Projectsonu8700Nessuna valutazione finora

- Sunil Sap Fico SD MMDocumento5 pagineSunil Sap Fico SD MMKendra HickmanNessuna valutazione finora

- Reddy, Sravani - SAP-UpdatedDocumento6 pagineReddy, Sravani - SAP-UpdatedMadhu ITNessuna valutazione finora

- Professional Summary:: RACLE Manufacturing / Supply Chain Functional ConsultantDocumento6 pagineProfessional Summary:: RACLE Manufacturing / Supply Chain Functional ConsultantMuhammad Wasim QureshiNessuna valutazione finora

- AmplDocumento11 pagineAmplRahul RaviNessuna valutazione finora

- Mohammed, Moizuddin CV Updated NEWDocumento5 pagineMohammed, Moizuddin CV Updated NEWabdul momeenNessuna valutazione finora

- Om Prakash - Profile - MMDocumento6 pagineOm Prakash - Profile - MMtapas_sap648Nessuna valutazione finora

- Resume 11Documento3 pagineResume 11allan237Nessuna valutazione finora

- Understanding BA ProfessionDocumento40 pagineUnderstanding BA Professiongazalgupta30Nessuna valutazione finora

- DG A07KambleDocumento5 pagineDG A07KambleAhamedSharifNessuna valutazione finora

- Unit - 3 Data Warehouse Modelling and Online Analytical Processing IIDocumento50 pagineUnit - 3 Data Warehouse Modelling and Online Analytical Processing IIRuchiraNessuna valutazione finora

- Ratnakar Waikar: 1303-Gokul Villa, Sec 36, Kharghar Navi Mumbai, Pin: 410210Documento5 pagineRatnakar Waikar: 1303-Gokul Villa, Sec 36, Kharghar Navi Mumbai, Pin: 410210Kartheek PulluruNessuna valutazione finora

- SAP MM Having 8 Years of ExperienceDocumento5 pagineSAP MM Having 8 Years of Experiencejagadishwas09Nessuna valutazione finora

- Data Warehouse & Data MiningDocumento41 pagineData Warehouse & Data MiningSyed MotashamNessuna valutazione finora

- SAP Resume Sample 1: Don K. DennisDocumento3 pagineSAP Resume Sample 1: Don K. DennisMehedi KhanNessuna valutazione finora

- SAP FICO Analyst in Wilmington NC Resume Jonathan WaltersDocumento5 pagineSAP FICO Analyst in Wilmington NC Resume Jonathan WaltersJonathanWaltersNessuna valutazione finora

- Arshad Razak: SAP FSCM ConsultantDocumento7 pagineArshad Razak: SAP FSCM ConsultantRam PNessuna valutazione finora

- Naukri Jnagaraja (8y 5m)Documento5 pagineNaukri Jnagaraja (8y 5m)ANUSHA K SNessuna valutazione finora

- Executive SummaryDocumento4 pagineExecutive Summaryanon_590527118Nessuna valutazione finora

- Rita Weinberg ResumeDocumento3 pagineRita Weinberg ResumeRandolph EllisNessuna valutazione finora

- G.Raju Sap Bi Consultant MOB: +91-8867724560Documento4 pagineG.Raju Sap Bi Consultant MOB: +91-8867724560ajithsapbiNessuna valutazione finora

- Trends in Datawarehousing: Erp, CRM, Olap, Metadata Presented By: M.Thanigasalam D. Karan Kumar M.Saravanan G.ManojDocumento36 pagineTrends in Datawarehousing: Erp, CRM, Olap, Metadata Presented By: M.Thanigasalam D. Karan Kumar M.Saravanan G.ManojThanigasalam MurugadhasNessuna valutazione finora

- Sanjaya Shrestha PDFDocumento6 pagineSanjaya Shrestha PDFRam PNessuna valutazione finora

- ShashiMunnangi (4 3)Documento4 pagineShashiMunnangi (4 3)jagadishwas09Nessuna valutazione finora

- Shyam4 1Documento4 pagineShyam4 1Shyam ChelluriNessuna valutazione finora

- Dice Resume CV Sasikala AtmakuriDocumento7 pagineDice Resume CV Sasikala AtmakuriHarinath AkulaNessuna valutazione finora

- NPL Constructions Aug 2009 - Till DateDocumento4 pagineNPL Constructions Aug 2009 - Till DateAntony James VijayNessuna valutazione finora

- Kiran Agrawal: SAP BI/BO ConsultantDocumento3 pagineKiran Agrawal: SAP BI/BO ConsultantVeera Karthik GNessuna valutazione finora

- Mark Plano: SAP Controlling ConsultantDocumento2 pagineMark Plano: SAP Controlling ConsultantKrishnaNessuna valutazione finora

- Mohammed, Moizuddin CV Updated 24-Nov-2022 EN-GBDocumento5 pagineMohammed, Moizuddin CV Updated 24-Nov-2022 EN-GBabdul momeenNessuna valutazione finora

- Jenny GhugeDocumento4 pagineJenny GhugeNaveen MattapartyNessuna valutazione finora

- Sapmm Sample ResumeDocumento2 pagineSapmm Sample ResumeRaghu ReddyNessuna valutazione finora

- Raman MittalDocumento2 pagineRaman MittalSuresh BabuNessuna valutazione finora

- <!DOCTYPE HTML PUBLIC "-//W3C//DTD HTML 4.01 Transitional//EN" "http://www.w3.org/TR/html4/loose.dtd"> <HTML><HEAD><META HTTP-EQUIV="Content-Type" CONTENT="text/html; charset=iso-8859-1"> <TITLE>ERROR: The requested URL could not be retrieved</TITLE> <STYLE type="text/css"><!--BODY{background-color:#ffffff;font-family:verdana,sans-serif}PRE{font-family:sans-serif}--></STYLE> </HEAD><BODY> <H1>ERROR</H1> <H2>The requested URL could not be retrieved</H2> <HR noshade size="1px"> <P> While trying to process the request: <PRE> TEXT http://www.scribd.com/titlecleaner?title=Import+(bonded+warehouse)+_+SCN.pdf HTTP/1.1 Host: www.scribd.com Proxy-Connection: keep-alive Proxy-Authorization: Basic a.3 Cookie: scribd_ubtc=u%3Da8d41750-6e93-0130-3431-0025902ded18%26h%3DZditLpix23ld65WlAI7XKbEzeLjV%2BFdW8jwbHLhibr8%3D; __qca=P0-1306311192-1363237920047; _trp_hit_8989/15071_300x250=2; _scribd_session=BAh7CjoMY3NyZl9pZCIlMGZiYTFlOWE1ZWRmMzU3OGMzZDE4MjQ4NWJiOTVlMmY6HGRpc2FibGVfaW5zdGFudFDocumento3 pagine<!DOCTYPE HTML PUBLIC "-//W3C//DTD HTML 4.01 Transitional//EN" "http://www.w3.org/TR/html4/loose.dtd"> <HTML><HEAD><META HTTP-EQUIV="Content-Type" CONTENT="text/html; charset=iso-8859-1"> <TITLE>ERROR: The requested URL could not be retrieved</TITLE> <STYLE type="text/css"><!--BODY{background-color:#ffffff;font-family:verdana,sans-serif}PRE{font-family:sans-serif}--></STYLE> </HEAD><BODY> <H1>ERROR</H1> <H2>The requested URL could not be retrieved</H2> <HR noshade size="1px"> <P> While trying to process the request: <PRE> TEXT http://www.scribd.com/titlecleaner?title=Import+(bonded+warehouse)+_+SCN.pdf HTTP/1.1 Host: www.scribd.com Proxy-Connection: keep-alive Proxy-Authorization: Basic a.3 Cookie: scribd_ubtc=u%3Da8d41750-6e93-0130-3431-0025902ded18%26h%3DZditLpix23ld65WlAI7XKbEzeLjV%2BFdW8jwbHLhibr8%3D; __qca=P0-1306311192-1363237920047; _trp_hit_8989/15071_300x250=2; _scribd_session=BAh7CjoMY3NyZl9pZCIlMGZiYTFlOWE1ZWRmMzU3OGMzZDE4MjQ4NWJiOTVlMmY6HGRpc2FibGVfaW5zdGFudF1985naveenNessuna valutazione finora

- Ewm 1Documento2 pagineEwm 11985naveenNessuna valutazione finora

- Stock Transfer OrderDocumento2 pagineStock Transfer Order1985naveenNessuna valutazione finora

- Sap MM FaqsDocumento16 pagineSap MM Faqs1985naveenNessuna valutazione finora

- Project On Airlines SECTORDocumento29 pagineProject On Airlines SECTORaayushilodha100% (1)

- Kingfisher Summer ProjectDocumento70 pagineKingfisher Summer Projectkiran769Nessuna valutazione finora

- Qualifications Recruitment Promotions Scheme - University AcademicsDocumento10 pagineQualifications Recruitment Promotions Scheme - University Academicsuteachers_slNessuna valutazione finora

- Allegato 77841Documento351 pagineAllegato 77841MyScribd_ieltsNessuna valutazione finora

- Understanding Culture, Society, and Politics Quarter 2 - Module 1Documento21 pagineUnderstanding Culture, Society, and Politics Quarter 2 - Module 1Allaine's ChannelNessuna valutazione finora

- HUAWEI OCS Business Process Description PDFDocumento228 pagineHUAWEI OCS Business Process Description PDFdidier_oNessuna valutazione finora

- WSDL Versioning Best PracticesDocumento6 pagineWSDL Versioning Best Practiceshithamg6152Nessuna valutazione finora

- Drpic Syllabus TheMedievalObject 2015Documento8 pagineDrpic Syllabus TheMedievalObject 2015Léo LacerdaNessuna valutazione finora

- Medical Technology ScheduleDocumento2 pagineMedical Technology ScheduleCara Veronica MendozaNessuna valutazione finora

- Els2204 Sinsis 1718 CepDocumento7 pagineEls2204 Sinsis 1718 CepChristian MarpaungNessuna valutazione finora

- 12.22.08 Dr. King Quotes BookletDocumento16 pagine12.22.08 Dr. King Quotes BookletlamchunyienNessuna valutazione finora

- Newton's Three Law of MotionDocumento6 pagineNewton's Three Law of MotionRey Bello MalicayNessuna valutazione finora

- Mcob OcDocumento19 pagineMcob OcashisNessuna valutazione finora

- Catalogo Molas PratoDocumento176 pagineCatalogo Molas Pratocassio_tecdrawNessuna valutazione finora

- Q2 Week7g56Documento4 pagineQ2 Week7g56Judy Anne NepomucenoNessuna valutazione finora

- Notes On Guenter Lee PDEs PDFDocumento168 pagineNotes On Guenter Lee PDEs PDF123chessNessuna valutazione finora

- Neil Bryan N. Moninio: Professional GoalDocumento3 pagineNeil Bryan N. Moninio: Professional GoalNeil Bryan N. MoninioNessuna valutazione finora

- Trading Psychology - A Non-Cynical Primer - by CryptoCred - MediumDocumento1 paginaTrading Psychology - A Non-Cynical Primer - by CryptoCred - MediumSlavko GligorijevićNessuna valutazione finora

- Add-On Effect of Brahmi in The Management of SchizophreniaDocumento3 pagineAdd-On Effect of Brahmi in The Management of SchizophreniaNAITIKNessuna valutazione finora

- Presentation of Amatillah - SakinahDocumento12 paginePresentation of Amatillah - SakinahFareed Ahmed MemonNessuna valutazione finora

- Change Sequence's Current Value (CURRVAL) Without Dropping It OraExplorerDocumento6 pagineChange Sequence's Current Value (CURRVAL) Without Dropping It OraExplorerIan HughesNessuna valutazione finora

- Divide and ConquerDocumento4 pagineDivide and ConquerAli AliNessuna valutazione finora

- Module 1: Introduction To VLSI Design Lecture 1: Motivation of The CourseDocumento2 pagineModule 1: Introduction To VLSI Design Lecture 1: Motivation of The CourseGunjan JhaNessuna valutazione finora

- Graph Theory (B)Documento2 pagineGraph Theory (B)Waqar RoyNessuna valutazione finora

- Guide Specification - SDP 200: GeneralDocumento10 pagineGuide Specification - SDP 200: GeneralhbookNessuna valutazione finora

- 7.IITD 2012 Theory of VibrationDocumento9 pagine7.IITD 2012 Theory of Vibrationlaith adnanNessuna valutazione finora

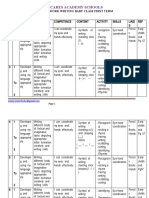

- Scheme of Work Writing Baby First TermDocumento12 pagineScheme of Work Writing Baby First TermEmmy Senior Lucky100% (1)

- Pilot Test Evaluation Form - INSTRUCTORDocumento9 paginePilot Test Evaluation Form - INSTRUCTORKaylea NotarthomasNessuna valutazione finora