Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

PIN Diode Detector Useful Details

Caricato da

Yuvraj NitinDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

PIN Diode Detector Useful Details

Caricato da

Yuvraj NitinCopyright:

Formati disponibili

Carroll & Ramsey Associates

Ph. (510) 559-8153

950 Gilman St., Berkeley, CA 94710 Fax (510) 559-8158

E-mail: <cra@carroll-ramsey.com>

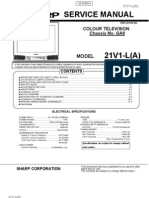

MODEL 101-H-DC-3 MULTI-CHANNEL RADIATION DETECTOR Rev. J Copyright Mar, 2000 The model 101-H-DC-3 from Carroll / Ramsey Associates is a radiation detector system intended for radiochemical synthesis and process monitoring applications in laboratory hot cells. TECHNICAL DESCRIPTION The system comprises a set of up to three miniature detector probes, plus a threechannel transresistance (current-to-voltage converter) amplifier. The maximum gain of the transresistance amplifier in each detector channel is nominally 5 x109 ohms, that is, a detector current of one nano-ampere can produce a voltage at the output of the amplifier of five volts. A multi-turn trim potentiometer on the output of each amplifier chain allows the user to adjust the overall transresistance gain of the system over a range of approximately 10:1. Probe The active element in the detector probe is a silicon PIN diode which is enclosed in Cu foil and coated with an opaque plastic resin to shield it against light and stray electromagnetic fields. The sensitive area is designated by a dot near the tip of the probe. Each probe is connected to its amplifier unit through a length of small-diameter coaxial cable. The detector probes operate in "DC" mode and are intended to be used in close proximity to concentrated sources of gamma-emitting radionuclides. Four sizes of probe are available;1 mm2, 7.6 mm2 (standard), 25 mm2, and 100 mm2. The diode substrate thickness is 300 microns, and produces ~1 pico-ampere per mm2 per rad / hr (Si).

Mechanical The probes are mechanically robust and are not damaged by normal handling. However, the probe and its connecting cable will generate spurious signals ("microphonics") if moved or flexed during use. When making a measurement, the probe and its cable should be held in place and padded if necessary to minimize coupling to sources of vibration such as fans, pumps, motors, etc. DC-Amplifiers A small positive or negative DC offset -- equivalent to ~ 5 pico-amperes or less (0.25% referred to full-scale), in the absence of radiation -- is normally present. Measurements at very low gamma radiation exposure dose levels are confounded to some degree due to this offset, and by slow changes in offset -- referred to as "drift" -which are indistinguishable from changes in radiation intensity. Other sources of error are detector diode leakage and "dark" currents--all of which, in turn, are strongly influenced by ambient temperature. Offset drift is minimized by utilizing high-quality operational amplifiers with very low initial offset. Leakage current is minimized by operating the diode at zero bias into a low-impedance ("virtual ground") transresistance amplifier input. However, the diode's dark current is still of the order of a few pico-amperes at 25o C, and increases by a factor of 2 for every 5o C rise in temperature. Thus, since the basic probe sensitivity is of the order of ~1 pA per sq. mm per rad / hr (Si), this detector system is best suited for applications involving gamma radiation fields of several roentgens per hour or greater exposure dose-rate, for example, in close proximity to concentrated sources of gamma activity of 1 mCi or more. Display The 3 1/2 digit auto-ranging numerical display on the Model 110A Remote Console reads from 0 - 1.500 volts, on the low-range setting, and 0 - 10 volts on the high-range setting.

Source-Detector distance See the attached graph to determine exposure doserate as a function of distance from a concentrated ("point") source of $+ (i.e., 511 KeV gamma in this example) activity. For very close coupling to a point source of activity, the inverse-square law has a potent effect on detector response. This can be of some advantage in reducing the amount of shielding required against ambient activity away from the source relative to activity at the source. However, if one is monitoring the amount of activity trapped in a column, for example, the exact place within the column where the activity is trapped can affect the observed doserate. Moving the detector a short distance away will mitigate this effect. The user should experiment with source-detector placement to find the best compromise between repeatability and minimum shielding.

Scale factor Since observed doserate (and, consequently, detector current) is a function of sourcedetector distance, one may place the detector at a particular distance from the source so as to provide a convenient scale reading. For example, (refer to graph) a 1 curie $+ source produces a field of 1000 roentgens / hr at a distance ~2.4 cm from the source. A "low-sensitivity" probe produces ~ 1 nanoampere at this exposure doserate, yielding a reading on the voltmeter display of "5.0" at full sensitivity; once the source-detector mounting position is fixed, the amplifier gain control potentiometer may be adjusted so as to set the scale reading to 1.0".

INSTALLATION AND OPERATING ENVIRONMENT The 3-channel amplifier box may be placed where radiation is present, but preferably away--or shielded-- from intense sources of radiation. The operating voltage for the 3-channel amplifier box is +12 to +15 VDC, wellfiltered. Mating connectors are supplied with the system. The sensitive element in each detector probe is near the tip, designated by a dot. The detector probes are connected to BNC coaxial receptacles in the 3-channel amplifier box marked Ch. 1, Ch. 2, Ch. 3, respectively. The cable connecting the 3-channel amplifier box to the remote display unit should be a 4-conductor, shielded type, with wires distinctly color-coded. One wire is used for +12VDC; 3 wires are used for the respective signal connections. The shield is used as the signal common and power return. The 9-pin D connectors are wired as follows: Channel 1 out Channel 2 out Channel 3 out 1 2 3 +12VDC Shield / ground 6 9

The connecting cables may be any length up to ~100 ft. The gain for each channel may be adjusted by means of multi-turn, screwdriver-adjust, potentiometers which are accessible from the rear of the display unit. The signal levels, which are proportional to dose-rate, may also be monitored by a digital voltmeter, high-impedance chart recorder or computer data acquisition system (1 megohm or more input impedance) which can be connected in parallel to the display console by means of the 9-pin D-Subminiature connectors on the rear of the chassis just below the connectors from the preamplifiers. Environment The system is intended for indoor use. Components have not been characterized for operation outside the range 0oC - 55oC. The system components and system wiring must not be in close proximity to any flame, heating element, or exposed electrical terminals. The system components have not been characterized for operation in extreme neutron / gamma radiation fields such as encountered in close proximity to accelerator targets during irradiation. The system and its components should be protected from contact with solvents or volatile or corrosive reagents.

TEST AND MAINTENANCE Sensitivity Sensitivity scale factor (numerical display reading) should be verified periodically against a known standard. Analog Gain Amplifier system gain may be verified by connecting a current source comprising a 1.5 VDC battery in series with a high-ohm resistor (100 megohms or more) to the amplifier BNC input ( negative polarity). For convenience and ease of maintenance, an adjustable current source (0-1500 picoamperes) is available as an accessory from Carroll / Ramsey Associates. Probe The detector probe may be tested in a gross manner as an ordinary diode using a goodquality ohmmeter with a "diode-test" setting; if it appears that a probe is not working properly check for a short- or open-circuit condition. A substantial increase in reverse leakage current due to radiation damage manifests as an equivalent drop in reverse resistance, which may, in turn, cause a noticeable increase in observed offset. However, the reverse resistance of a properly-working detector probe is of the order of a few hundreds to thousands of megohms, and cannot, in general, be read on a standard ohmmeter. When in doubt, compare a suspected probe against another unit which is known to be sound.

WARRANTY Systems are warranted against defects in materials and workmanship for a period of 90 days from date of shipment. Carroll / Ramsey Associates' (CRA) sole obligation for products that prove to be defective will be repair or replacement. In no event shall CRA's obligation exceed the buyer's purchase price. CRA specifically disclaims any implied warranties or merchantibility or fitness for a specific purpose, nor will CRA be liable for any indirect, incidental, or consequential damages. This warranty does not apply to products which have been subject to mis-use such as accident, severe mechanical shock and distress, over-voltage, immersion, exposure to volatile or corrosive agents, etc. The warranty does not apply to defects due to unauthorized modification, or which have been altered in such a way as to not be capable of undergoing functional test. Performance specifications, physical dimensions, etc. are subject to change without notice. Products sold by Carroll / Ramsey Associates are not intended for use as critical components in medical devices or life-support devices or systems. (Copyright Carroll / Ramsey Associates; Nov, 1999. All Rights Reserved)

Potrebbero piacerti anche

- 5988 5511enDocumento8 pagine5988 5511enthangaraj_icNessuna valutazione finora

- Verifying and Troubleshooting CablesDocumento6 pagineVerifying and Troubleshooting CablesTariq EhsanNessuna valutazione finora

- Isolated Open Loop Current Sensing Using Hall Effect Technology in An Optimized Magnetic CircuitDocumento12 pagineIsolated Open Loop Current Sensing Using Hall Effect Technology in An Optimized Magnetic Circuitapi-3805241Nessuna valutazione finora

- The Hazard of Tghe Transient Limiter Issue 69Documento6 pagineThe Hazard of Tghe Transient Limiter Issue 69ctmingNessuna valutazione finora

- Emissions Measurements On Switch-Mode Power Supplies: WWW - Elmac.co - UkDocumento10 pagineEmissions Measurements On Switch-Mode Power Supplies: WWW - Elmac.co - Ukאלירן שיNessuna valutazione finora

- Analysis of Oscillograms (v6.0)Documento21 pagineAnalysis of Oscillograms (v6.0)luhusapaNessuna valutazione finora

- Reg No#23 (Talha Saleem)Documento11 pagineReg No#23 (Talha Saleem)Talha ChaudryNessuna valutazione finora

- 07bDocumento30 pagine07bJorge A. Perez YebraNessuna valutazione finora

- Nuevo Transmisor MetrixDocumento18 pagineNuevo Transmisor Metrixoptech_sacNessuna valutazione finora

- Is Electrical Interference Crippling Your Control System? Understand It and You Can Defeat ItDocumento5 pagineIs Electrical Interference Crippling Your Control System? Understand It and You Can Defeat ItHayden LovettNessuna valutazione finora

- 7SG117 Argus 7 Catalogue SheetDocumento8 pagine7SG117 Argus 7 Catalogue SheetHimdad TahirNessuna valutazione finora

- SLA SeriesDocumento2 pagineSLA SeriesShashank JainNessuna valutazione finora

- Protection CTsDocumento5 pagineProtection CTscsontosbaluNessuna valutazione finora

- Locating Faults AG en US1Documento3 pagineLocating Faults AG en US1Neelakandan MasilamaniNessuna valutazione finora

- Antenna Analyzer vk5jst Version 1 Instructions PDFDocumento10 pagineAntenna Analyzer vk5jst Version 1 Instructions PDFPisu Miau Pisu MiauNessuna valutazione finora

- Resistance Earthed Systems: Fault CurrentsDocumento25 pagineResistance Earthed Systems: Fault CurrentsRameez Ahmed100% (1)

- Power Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageDa EverandPower Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageNessuna valutazione finora

- Cts 12 KsaDocumento4 pagineCts 12 Ksasurya8920% (1)

- Brochur Leviton Power PackDocumento2 pagineBrochur Leviton Power PackCarlNessuna valutazione finora

- Installation of Vibration SensorsDocumento8 pagineInstallation of Vibration SensorsnmguravNessuna valutazione finora

- RMC 131d Data Sheet 4921240104 UkDocumento8 pagineRMC 131d Data Sheet 4921240104 Ukdavid loughlinNessuna valutazione finora

- NI Tutorial 5448Documento4 pagineNI Tutorial 5448Fane PelinNessuna valutazione finora

- Service Manual: ModelDocumento60 pagineService Manual: ModeldonobeeNessuna valutazione finora

- PQ1 PowerQualitySensorDocumento10 paginePQ1 PowerQualitySensorBalamurugan BalahaisninNessuna valutazione finora

- 13VTL100Documento104 pagine13VTL100Pedro GabrielNessuna valutazione finora

- Low Voltage Capacitance & Tan Delta Testing, Measurement Method &Documento6 pagineLow Voltage Capacitance & Tan Delta Testing, Measurement Method &intrudentalert100% (1)

- Three Simple Antenna TestsDocumento5 pagineThree Simple Antenna TestsJesse R AlfonsoNessuna valutazione finora

- The Fundamentals of Protection Relay Co-Ordination and Timecurrent Grading PrinciplesDocumento9 pagineThe Fundamentals of Protection Relay Co-Ordination and Timecurrent Grading Principlesfredhalder99Nessuna valutazione finora

- 7SG117 Argus 7: Answers For EnergyDocumento10 pagine7SG117 Argus 7: Answers For EnergygovindarulNessuna valutazione finora

- Lecture On System ProtectionDocumento33 pagineLecture On System ProtectionTushar KadamNessuna valutazione finora

- Determining Zs For A Lighting Circuit - Professional ElectricianDocumento5 pagineDetermining Zs For A Lighting Circuit - Professional ElectricianPRADEEP T KNessuna valutazione finora

- 14T1LDocumento53 pagine14T1Lsuranovi6858100% (2)

- Why Use Isolated Signal Conditioners?: AN116 Dataforth Corporation Page 1 of 5Documento5 pagineWhy Use Isolated Signal Conditioners?: AN116 Dataforth Corporation Page 1 of 5gegiturNessuna valutazione finora

- The Importance of Earth Loop ImpedanceDocumento4 pagineThe Importance of Earth Loop ImpedanceKarim Amer100% (1)

- Gamma Spectroscopy PrinciplesDocumento35 pagineGamma Spectroscopy PrinciplesSara AlSaadiNessuna valutazione finora

- JVC AV-20FD24 Service ManualDocumento37 pagineJVC AV-20FD24 Service ManualAlbertoMoralesNessuna valutazione finora

- Paper Presentation On Detection by RADAR byDocumento4 paginePaper Presentation On Detection by RADAR byJanmayjay SwetankNessuna valutazione finora

- Sharp 21MFG1L Chasis GA6Documento60 pagineSharp 21MFG1L Chasis GA6Xavier Lg100% (1)

- Sharp 21VFR95S GA4M M61250 IXA983 STV9302 STR W5453 Manual PDFDocumento47 pagineSharp 21VFR95S GA4M M61250 IXA983 STV9302 STR W5453 Manual PDFAngel Goicochea100% (1)

- Technical Specification For Telemetry ProjectDocumento10 pagineTechnical Specification For Telemetry Projectnaren_knkNessuna valutazione finora

- C3 Signal Processing PDFDocumento10 pagineC3 Signal Processing PDFShweta SridharNessuna valutazione finora

- Emc Testing TechniquesDocumento15 pagineEmc Testing TechniquesBalanandha kumarNessuna valutazione finora

- LG RD - jt91 DLP ProjectorDocumento34 pagineLG RD - jt91 DLP ProjectorMalay K GhoshNessuna valutazione finora

- Switch Gear and Protection Unit 1 by Ramu. SrikakulapuDocumento75 pagineSwitch Gear and Protection Unit 1 by Ramu. SrikakulapuAnkit RohatgiNessuna valutazione finora

- Types of Neutral Earthing in Power Distribution Part 2Documento7 pagineTypes of Neutral Earthing in Power Distribution Part 2shoham985Nessuna valutazione finora

- 21v fp90sDocumento49 pagine21v fp90sMhon Adenip LloquironNessuna valutazione finora

- 29fx5ree PDFDocumento33 pagine29fx5ree PDFaldilladipoNessuna valutazione finora

- Relayoperationprinciples 141126065914 Conversion Gate01Documento43 pagineRelayoperationprinciples 141126065914 Conversion Gate01kenlavie2Nessuna valutazione finora

- Vibration Monitoring SystemDocumento15 pagineVibration Monitoring SystemusmannasrullahNessuna valutazione finora

- Service Manual: Color Television Chassis No. GA-4MDocumento42 pagineService Manual: Color Television Chassis No. GA-4MKennex Trazo50% (2)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Nessuna valutazione finora

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Valutazione: 2.5 su 5 stelle2.5/5 (3)

- Introduction to Power System ProtectionDa EverandIntroduction to Power System ProtectionValutazione: 5 su 5 stelle5/5 (1)

- Introduction to Power System ProtectionDa EverandIntroduction to Power System ProtectionNessuna valutazione finora

- Learn Amateur Radio Electronics on Your SmartphoneDa EverandLearn Amateur Radio Electronics on Your SmartphoneNessuna valutazione finora

- 3 Wire Motor Start StopDocumento5 pagine3 Wire Motor Start StopAndy DukesNessuna valutazione finora

- EC-GATE-2011 (1) .PDF SolutionDocumento28 pagineEC-GATE-2011 (1) .PDF SolutionMudit MittalNessuna valutazione finora

- Ad 7401Documento20 pagineAd 7401Yuvraj NitinNessuna valutazione finora

- Vmebus APIDocumento83 pagineVmebus APIYuvraj NitinNessuna valutazione finora

- BDocumento23 pagineBYuvraj NitinNessuna valutazione finora

- Electrical IDocumento28 pagineElectrical IdouglosNessuna valutazione finora

- Rem Control PM500 PDFDocumento18 pagineRem Control PM500 PDFraripaunescuNessuna valutazione finora

- Generation TrainerDocumento1 paginaGeneration TrainerAhsan Ali AhmedNessuna valutazione finora

- JBL 2600Documento7 pagineJBL 2600oscaralvear67Nessuna valutazione finora

- Isoelectric Homework 4-SubrataDocumento76 pagineIsoelectric Homework 4-SubrataFahim Bin Abdur RahmanNessuna valutazione finora

- HV-EHV Cables Synthetic IsolationDocumento16 pagineHV-EHV Cables Synthetic IsolationA. HassanNessuna valutazione finora

- Camera Notes Part 2 For PhotogrammetryDocumento90 pagineCamera Notes Part 2 For PhotogrammetryAnuran GayaliNessuna valutazione finora

- Deye Inverter 60kWDocumento2 pagineDeye Inverter 60kWMajstorskiFilipNessuna valutazione finora

- M6 Manual V1.0Documento38 pagineM6 Manual V1.0joehowNessuna valutazione finora

- SDC15 Single Loop Controller User's Manual: For Basic OperationDocumento144 pagineSDC15 Single Loop Controller User's Manual: For Basic OperationQuang Pham NhatNessuna valutazione finora

- Digital Micro-Ohmmeter: User S GuideDocumento26 pagineDigital Micro-Ohmmeter: User S GuideGabrielNessuna valutazione finora

- 742213V01Documento2 pagine742213V01Khawar WaheedNessuna valutazione finora

- Paper 1 SPM 2005Documento27 paginePaper 1 SPM 2005Rosmini Abdul RahmanNessuna valutazione finora

- National Grid: Check List of Energy Meter CommissioningDocumento2 pagineNational Grid: Check List of Energy Meter CommissioningsalmanNessuna valutazione finora

- RAYCHEM - EPP - 0608 Tubo Aislante Termocontraible MT PDFDocumento2 pagineRAYCHEM - EPP - 0608 Tubo Aislante Termocontraible MT PDFHaldirLeaoNessuna valutazione finora

- GCM02 MT Ing4newDocumento57 pagineGCM02 MT Ing4newGeorge BarsoumNessuna valutazione finora

- Hgsemi-Lm324n C725320Documento4 pagineHgsemi-Lm324n C725320alllim88Nessuna valutazione finora

- Cathodic ProtectionDocumento14 pagineCathodic ProtectionnazirulhakimNessuna valutazione finora

- Annexure-I (Detail of Design & Engineering Project List.)Documento1 paginaAnnexure-I (Detail of Design & Engineering Project List.)sandip maityNessuna valutazione finora

- Full CatalogDocumento128 pagineFull CatalogPaul NanceNessuna valutazione finora

- Ampeg Bass SpecsDocumento1 paginaAmpeg Bass SpecsThomas MoralesNessuna valutazione finora

- Linde E15 324-1989Documento3 pagineLinde E15 324-1989Ionut GrozaNessuna valutazione finora

- Delay Calculations: Introduction To Cmos Vlsi DesignDocumento27 pagineDelay Calculations: Introduction To Cmos Vlsi DesignbiboNessuna valutazione finora

- RF 5382h Cu001 150w CouplerDocumento2 pagineRF 5382h Cu001 150w CouplerChrisLevoNessuna valutazione finora

- Uc 2906Documento8 pagineUc 2906skipina74Nessuna valutazione finora

- Clap Switch Electonic 2Documento6 pagineClap Switch Electonic 2M WAQASNessuna valutazione finora

- Fire Detection Alarm SystemDocumento5 pagineFire Detection Alarm Systemsmartxdigital marketNessuna valutazione finora

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Documento17 pagineInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Mk MakyNessuna valutazione finora

- ABB SafelinkBA2002pres PDFDocumento35 pagineABB SafelinkBA2002pres PDFJeteendra SharmaNessuna valutazione finora

- Cat Generator PDFDocumento64 pagineCat Generator PDFmarkigldmm918100% (2)

- Written Test EimDocumento5 pagineWritten Test EimMay Esban100% (1)