Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Document

Caricato da

Taha SaeedDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Document

Caricato da

Taha SaeedCopyright:

Formati disponibili

Developmental Product

TEXIN DP7-1198

Thermoplastic Polyurethane

Aromatic Polyether-Based Grade

Product Information

Description and Application

Texin DP7-1198 resin is an aromatic polyether-based thermoplastic polyurethane. It is processed by injection molding, extrusion, or blow molding. Texin DP7-1198 is characterized by outstanding abrasion resistance, impact strength, toughness, and flexibility. Typical applications include gaskets, hose, tubing, connectors, belting and miscellaneous molded articles. As with any product, use of Texin DP7-1198 resin in a given application must be tested (including but not limited to field testing) in advance by the user to determine suitability.

Storage, Drying and Regrind Usage

The use of regrind material should be avoided entirely in those applications where resin properties equivalent to virgin material are required, but not limited to color quality, impact strength, resin purity and/or load-bearing performance.

Injection Molding, Extrusion and Blow Molding Conditions

Texin thermoplastic polyurethane resins are hygroscopic and will absorb ambient moisture. The resins should remain in their sealed containers and be stored in a dry area. Storage temperature should not exceed 86F (30C). Unused resin from opened containers, or reground material that is not to be used immediately, should be stored in sealed containers under cool and dry conditions. Prior to processing, Texin DP7-1198 resin must be thoroughly dried for a minimum of 2 hours in a desiccant dehumidifying hopper dryer to a moisture content of less than 0.03%. Hopper inlet air temperature should be 210 230F (100110C), the inlet air dew point should be -20F (-29C) or lower. Where end-use requirements permit, up to 20% Texin regrind may be used with virgin material. Regrind material must be generated from properly molded/extruded parts, sprues, runners, trimmings, and/or films. Degraded or discolored material may not be used for regrind. All regrind material must be free of contaminations and thoroughly blended with virgin material prior to drying and processing. Finished parts containing regrind must be tested to ensure that end-use requirements are fully met.

Typical starting conditions for injection molding, extrusion, and blow molding are noted below. Actual processing conditions will depend on machine size, mold design, material residence time, shot size, part geometry, etc.

Typical Injection Molding Conditions Barrel Temperatures: Rear Middle Front Nozzle Melt Temperature Mold Temperature Injection Pressure Hold Pressure Back Pressure Screw Speed Injection Speed Cushion

390 - 420F (199 - 216C) 395 - 425F (202 - 218C) 395 - 425F (202 - 218C) 400 - 430F (204 - 221C) 400 - 430F (204 - 221C) 60 - 110F (15 - 45C) 6,000 15,000 psi 60 80 % of Injection Pressure 800 psi max 40 80 rpm Slow to Moderate 1/8 in max

Typical Temperature Profile for Extrusion and Blow Molding Rear (Feed) Middle (Transition) Front (Meter) Die Melt 370 400F (188204C) 390 420F 390 420F 390 430F 400 430F (199216C) (199216C) (199221C) (204221C)

Page 1 of 3 Document contains important information and must be read in its entirety.

Regulatory Compliance Information

Health and Safety Information

Some of the end uses of the product described in this bulletin must comply with applicable regulations, such as the FDA, NSF, USDA, and CPSC. If you have any questions on the regulatory status of this product, contact your Bayer MaterialScience representative or Bayers Regulatory Affairs Manager in Pittsburgh, Pa.

Note: Texin DP7-1198 resin is a developmental product and is not considered part of the Bayer MaterialScience line of standard commercial products. Complete commercialization and continued supply are not assured. The purchaser/user agrees that Bayer MaterialScience reserves the right to discontinue this product without prior notice.

Appropriate literature has been assembled which provides information concerning the health and safety precautions that must be observed when handling Texin DP7-1198 resin. Before working with this product, you must read and become familiar with the available information on its hazards, proper use, and handling. This cannot be overemphasized. Information is available in several forms, e.g., material safety data sheets and product labels. Consult your Bayer MaterialScience representative or contact Bayers Product Safety and Regulatory Affairs Department in Pittsburgh, Pa.

Page 2 of 3 Document contains important information and must be read in its entirety.

Typical Properties* for Natural Resin General Specific Gravity Shore Hardness Taber Abrasion: H-18, 1000-g Load, 1,000 Cycles Bayshore Resilience Mold Shrinkage at 100-mil Thickness: Flow Direction Cross-Flow Direction Mechanical Tensile Strength Tensile Stress at 50% Elongation Tensile Stress at 100% Elongation Tensile Stress at 300% Elongation Ultimate Elongation Tear Strength, Die C Flexural Modulus: 158F (70C) 73F (23C) Compression Set: As Molded [Postcured]a 22 Hours at 158F (70C) 22 Hours at 73F (23C) Compressive Load: 2% Deflection 5% Deflection 10% Deflection 15% Deflection 20% Deflection 25% Deflection 50% Deflection Thermal Low-Temperature Brittle Point Glass Transition Temperature (Tg) Vicat Softening Temperature, Rate A

ASTM Test Method (Other) D 792 (ISO 1183) D 2240 (ISO 868) D 3489 (ISO 4649) D 2632 D 955 (ISO 2577)

Units U.S. Conventional

SI Metric

Texin DP7-1198 Resin U.S. SI 1.17 65D

mg Loss % in/in (mm/mm) in/in (mm/mm)

75 50 0.008 0.008 7,500 2,900 3,300 6,000 350 kN/m MPa MPa 1,200 6,100 61,000 210 42.1 420.6 51.7 20.0 22.8 41.4

D 412 (ISO 37) D 412 (ISO 37) D 412 (ISO 37) D 412 (ISO 37) D 412 (ISO 37) D 624 (ISO 34) D 790 (ISO 178)

lb/in2 lb/in2 lb/in2 lb/in2 % lbf/in lb/in2 lb/in2

MPa MPa MPa MPa

D 395-B (ISO 815) % % D 575 lb/in2 lb/in2 lb/in2 lb/in2 lb/in2 lb/in2 lb/in2 D 746 (ISO 974) (DMA)b D 1525 (ISO 306) F F F MPa MPa MPa MPa MPa MPa MPa C C C 200 800 1,500 1,950 2,400 2,950 7,950 <-90 14 280 1.4 5.5 10.3 13.4 16.5 20.3 54.8 <-68 -10 138 88 [35] 28 [20]

* These items are provided as general information only.They are approximate values and are not part of the product specifications. a Postcured 16 hours at 230F (110C). b DMADynamic Mechanical Analysis.

Note: The information contained in this bulletin is current as of June 2010. Please contact Bayer MaterialScience to determine whether this publication has been revised.

Bayer MaterialScience LLC

100 Bayer Road Pittsburgh, PA 15205-9741 Phone: 1-800-662-2927 www.BayerMaterialScienceNAFTA.com

The manner in which you use and the purpose to which you put and utilize our products, technical assistance and information (whether verbal, written or by way of production evaluations), including any suggested formulations and recommendations are beyond our control. Therefore, it is imperative that you test our products, technical assistance and information to determine to your own satisfaction whether they are suitable for your intended uses and applications. This application-specific analysis must at least include testing to determine suitability from a technical as well as health, safety, and environmental standpoint. Such testing has not necessarily been done by us. Unless we otherwise agree in writing, all products are sold strictly pursuant to the terms of our standard conditions of sale. All information and technical assistance is given without warranty or guarantee and is subject to change without notice. It is expressly understood and agreed that you assume and hereby expressly release us from all liability, in tort, contract or otherwise, incurred in connection with the use of our products, technical assistance, and information. Any statement or recommendation not contained herein is unauthorized and shall not bind us. Nothing herein shall be construed as a recommendation to use any product in conflict with patents covering any material or its use. No license is implied or in fact granted under the claims of any patent.

20387 6/10

Page 3 of 3 Document contains important information and must be read in its entirety.

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Acer Computers Aspire 9300 Aspire 9300 Aspire 7000 Service Guide Ae6e07aDocumento143 pagineAcer Computers Aspire 9300 Aspire 9300 Aspire 7000 Service Guide Ae6e07acvotechnicalsNessuna valutazione finora

- TD Operation MaintenanceDocumento51 pagineTD Operation MaintenanceHassam Ahmad100% (1)

- 8bit Microprocessor Using VHDLDocumento16 pagine8bit Microprocessor Using VHDLTanu Newar0% (2)

- Sap BarcodesDocumento59 pagineSap BarcodesDarmin MemiševićNessuna valutazione finora

- HILTI Typical Plumbing ApplicationsDocumento140 pagineHILTI Typical Plumbing ApplicationskuraimundNessuna valutazione finora

- Pre Joining Formalities Campus Medical FormDocumento18 paginePre Joining Formalities Campus Medical Formrafii_babu1988Nessuna valutazione finora

- Power GenerationDocumento34 paginePower GenerationTaufiq AkbarNessuna valutazione finora

- Technology Architecture For NginX, postgreSQL, postgRESTDocumento5 pagineTechnology Architecture For NginX, postgreSQL, postgRESTkarelvdwalt9366Nessuna valutazione finora

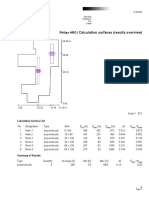

- Calculation Surfaces (Results Overview) : Philips HRODocumento4 pagineCalculation Surfaces (Results Overview) : Philips HROsanaNessuna valutazione finora

- Drilling Data Handbook 9th EditionDocumento4 pagineDrilling Data Handbook 9th Editiondedete50% (2)

- Fireplace ManualDocumento40 pagineFireplace Manualresistancebeta6Nessuna valutazione finora

- Session 2A JonkerDocumento15 pagineSession 2A JonkerD_D_ANessuna valutazione finora

- Tata MotorsDocumento9 pagineTata MotorsNaim Ahmed SisirNessuna valutazione finora

- ASH ReportDocumento3 pagineASH ReportChandra SekharNessuna valutazione finora

- CHAPTER 2 Eff Comm ModelsDocumento9 pagineCHAPTER 2 Eff Comm ModelsSubhash SoniNessuna valutazione finora

- Generic TWS600S Service ManualDocumento113 pagineGeneric TWS600S Service ManualWise So100% (2)

- Composition Code ExampleDocumento3 pagineComposition Code ExampleREBEL USMANNessuna valutazione finora

- Notes On Foam From SFPE HandbookDocumento10 pagineNotes On Foam From SFPE HandbookkdsessionsNessuna valutazione finora

- S2N Gyro Interface ManualDocumento20 pagineS2N Gyro Interface ManualAfrizal Setiawan100% (1)

- SB658Documento3 pagineSB658ricardo novoa saraviaNessuna valutazione finora

- Automatic Transmission: Models FA and FB With Allison AT542Documento22 pagineAutomatic Transmission: Models FA and FB With Allison AT542nguyenxuanvinhv3Nessuna valutazione finora

- Feedwater Heating SystemsDocumento82 pagineFeedwater Heating SystemsJitendra ChaudhariNessuna valutazione finora

- Toyota 5L Terminales de EcmDocumento9 pagineToyota 5L Terminales de EcmAlfred Nayb Cañoli Ildefonso0% (1)

- Pressure Sensors - Nautilus: For Control Circuits, Type XML-F PresentationDocumento11 paginePressure Sensors - Nautilus: For Control Circuits, Type XML-F PresentationxzxNessuna valutazione finora

- Chpt6 Taylor Made HONDocumento23 pagineChpt6 Taylor Made HONManju MudakaviNessuna valutazione finora

- Colorado Brand GuidelinesDocumento63 pagineColorado Brand GuidelineszpweeksNessuna valutazione finora

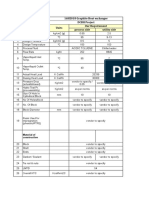

- 16HE018 Graphite Heat Exchanger DCBH Project Sr. No. Particulars Units Our Requirement Process Side Utility SideDocumento2 pagine16HE018 Graphite Heat Exchanger DCBH Project Sr. No. Particulars Units Our Requirement Process Side Utility SideBhaumik BhuvaNessuna valutazione finora

- Chapter 3 Hydro Thermal SchedulingDocumento65 pagineChapter 3 Hydro Thermal Schedulingbik_mesiloveNessuna valutazione finora

- Comparative Analysis of Wear Rate of Coated Hss Tool and Non-Coated Hss Tool by Using Cr-Zn-NiDocumento21 pagineComparative Analysis of Wear Rate of Coated Hss Tool and Non-Coated Hss Tool by Using Cr-Zn-Nithai avvaiNessuna valutazione finora

- BSBPMG531 - Assessment Task 3 v2Documento19 pagineBSBPMG531 - Assessment Task 3 v2Felipe ParadaNessuna valutazione finora