Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Filament Yarns: Industrial Textiles

Caricato da

Mebratu AdugnawDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Filament Yarns: Industrial Textiles

Caricato da

Mebratu AdugnawCopyright:

Formati disponibili

Industrial Textiles Introduction Yarns Filament yarns Spun yarns Ropes Twisted/Stranded Cabled Braided Packing Braided Sleeve

Tapes Webbing Tape Ladder Tape Fabrics Coated Fabric Finished Fabric Laminated Fabric Loomstate Fabric

Introduction Saveguard are specialist manufacturers of high temperature, cut and abrasion resistant textile products from fibre to finished article. We produce industrial yarns, fabrics, (wovens and non-wovens), tapes, ropes, braids and fabricated products from high performance engineering fibres Today's industrial processes use increasingly higher temperatures and with the demise of the traditional solution to high temperature and abrasive applications i.e. asbestos, new fibres are being constantly developed. These fibres all possess one or more outstanding individual characteristics e.g. temperature, abrasion resistance, high tensile strength, thermal and acoustic insulation, but when blended, used in combinations or composites, these properties can be considerably enhanced. Our expertise is in the selection and blending of these fibres and with the Saveguard range of specially formulated finishes and elastomeric coatings, we are able to design products to meet the most arduous conditions found in todays demanding applications.

Material Properties Abrasion, cut and temperature resistance, high tensile strength Up to 200C continuous Very high temperature resistance, Up to 1300C continuous. Low thermal Typical Applications Protective clothing such as cut and heat resistant gloves, Body amour, Machinery protection, Tyre cord, Sewing thread, Safety harnesses, Gasketting High temperature seals, Furnace zone divider and exit curtains, Kiln car seals,

Para Aramid Fibre

Ceramic Fibre

conductivity. High strength and temperature resistance. Up to 550C continuous for E'glass higher for S'glass. Excellent insulation properties and compatibility with resins and elastomers Inherently flame retardant, good temperature resistance. Up to 200C continuous Very high temperature resistance, 950C continuous. Low thermal conductivity. Low abrasion resistance Fire Protection, Welding blankets and curtains, Fire blankets, Plastic reinforcements, Composites, Thermal, acoustic and electrical insulation applications Protective clothing for firefighters, racing drivers and offshore workers, High temperature seals for silicon wafer furnaces, Good thermal, acoustic and electrical insulation properties. Fire Protection of cables, Good resistance to weld spatter and molten metal splash Often blended with pre-ox acrylics and paraaramids in fire block felts, Normally laminated with highly reflective films and used in fire proximity clothing

Glass Fibre

Meta Aramid Fibre

Silica Fibre

PFR Rayon

Permanent flame retardant rayon. Good strength

Industrial Applications Industrial applications is the field concerned with the support of industrial processes and engineers. Our products cover a huge range of applications including gas drying, metallurgy and surface cleaning among many more. Chemical Industry The chemical industry plays a fundamental role in our modern economy. Even though most of its products are not directly visible to consumers, they are used in the manufacture of most of the goods we consume every day.

Drilling Muds Ammoniumbifluoride can be used as a drilling aid for softening silica rocks in the exploration of oil and gas fields.

Fire Fighting Extinguishing Agents The new generation hydrofluorocarbons HFC 125 (pentafluoroethane) and HFC 227ea (heptafluoropropane) are now used for providing universal handling possibilities. Similarly Solkaflam 125 and Solkaflam 227 are important halon substitutes, primarily in sectors where space and weight are constrained or speed of suppression is vital.

Industrial Refrigeration Solkane refrigerants replace the conventionally used chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) and are therefore an environmentally safe alternative. Solkane refrigerants are applied to commercial and industrial refrigeration systems, household refrigerators, heat pumps, all kinds of unitary and centralized A/C systems as well as transport cooling and mobile air conditioning. Industrial Textile Persalts can be used in textile applications as a solid alternative to hydrogen peroxide. They can be used as the bleaching agent to improve fabric whiteness or in the dyeing process for the fixation of VAT and sulphur dyes.

Metallurgy Todays metallurgy industry draws on a variety of sophisticated techniques, depending on the nature of the metal and its intended use.

Mining Calcium Peroxide is used in the gold mining industry. Solvay can supply Calcium Peroxide as a finished (dry) product or provide assistance to customers wishing to generate Calcium Peroxide on site in slurry form. Sodium bicarbonate can be used in the alkaline leaching of some ore for extracting the relevant mineral. Solvay offers BICAR TEC grade for such applications. Oil & Gas Drilling

Inorganic peroxides have unique advantages in this field. They are slightly soluble in water and have relatively high stability to decomposition at elevated temperatures. At the desired time, these products can be activated by the addition of an acid or by other means. Plastic Processing Plastic processing covers a broad range of technologies such as extrusion of plastic through a circular die, followed by "bubble-like" expansion to explain it in general terms.

Rubber Industry In the vulcanisation process the reaction between sulphur and rubber compounds take place in order to create hardness and elasticity. A homogeneous mixture is essential for this process, so the very fine ground Solvay Sulphur is used in the blending process. Rubber is also used in many other applications. Surface Cleaning Inorganic Fluorides are used for a wide range of etching and cleaning applications not only for glass and stainless steel but also for non-ferrous metal pieces. They also work as components in cleaning and disinfecting solutions, e.g. in breweries, sugar factories, power plants and for building protection.

Products by Industry

TEXTILES / MANUFACTURING:

BEARINGS and POWER TRANSMISSION PRODUCTS:

Bearings, chain, couplings, v-belts, etc.

FLUID POWER - PNEUMATIC / HYDRAULIC: o Hose and fittings, lubricating equipment, lubricants

ELECTRICAL DRIVES AND COMPONENTS: o Custom panels, motors, variable frequency drives / soft starts, motor st buttons, photo electrics, batching systems, bar coding

STOCK OF SPECIALTY COMPONENTS: o Specialty high speed bearings, motors and starters, surface coatings, cl brakes, linear systems, head / tail pulleys, idlers, rubber belting, casters

CONVEYORS: o Stainless steel conveyors, roller bed conveyor systems (sales and servi stackers, screw conveyors, bucket elevators, belt conveyors, turn-key p

SPEED REDUCERS: o Gear box repair, refurbishing, investment recovery / surplus speed redu FIELD SERVICE CREWS: o Maintenance contracts, belt vulcanizing (in the field)

INDUSTRIAL SCALES AND LABORATORY BALANCES: o ISO 9001 and 17025 calibration services, ScalTrack VST vehicle tra software, Formweigh formulation and Freeweigh SQC software with v Scaltrack PRO production tracking software EXPORTING TRAINING: o Maintenance and safety

industrial textiles limitation

Q: What is Industrial Textiles Enhanced Twill & Poplin?

A: Industrial Textiles Enhanced Twill is made from finer Ring-Spun yarns. Ring spinning creates a superior yarn than results in a softer, more durable fabric than open-end yarn. The timehonored process of ring spinning requires two more processing steps than open-end yarn production and ring-spun takes five times longer to produce. The additional steps involve continuously twisting and narrowing the rope of cotton and polyester fibers. This continuous fiber "helix" or twist gives ring-spun yarn extra softness and strength. The resulting garments feel softer wash after wash. Industrial Textiles makes 65/35 Poly/Cotton Chef Coats and related products using Enhanced Twill, 7 ounce/square yard and 65/35 Cook Shirts using Enhanced Poplin which is 4.5 oz/square yard.

Q: What is MJS Spun Polyester and MJS Poly/Cotton Blends?

A: MJS stands for Murata Air Jet Spinning. Murata is a brand of Japanese spinning equipment developed in the 1980's. Air Jet technology creates a yarn from short staple polyester or for blends, a combination of polyester and cotton (rather than extruded, continuous filament polyester) that is naturally hairy and soft. This technology yields a fabric that has comparatively low pilling and higher absorption rate due to the low twist yarn structure. The loose yarn structure allows the fabric to dry fast as well as accept starch, this also adds to its breath ability when sewn into uniforms. For colors, MJS yarns and fabrics accept dye at lower temperatures yet its color retention is higher than most other fabrics.

Q: Is all "SPUN" made from similar yarn construction?

A: The answer is No! When Murata Air Jet spun or MJS was introduced to our industry, the term quickly was shortened to "SPUN"mills and manufacturers have since blurred the lines and stretched the meaning of "spun" to cover everything from Open End Spun, Ring Spun, Blends, Filament hybrids and more. Technically yes, most are produced with some form of "spun" yarn, but not what the industry originally migrated to in the 1990's. The term spun merely means the yarn is formed from smaller yarns (staple) and has a wrapper yarn that holds the small bundles togetherthe varying technologies to accomplish this are

generally referred to as Open End (OE) which is the fastest and cheapest way to spin, Ring (RS) which is softer and has twice the tensile strength as OE but takes up to 5x longer. Each type has its advantages and disadvantages depending on the application.

Industrial Textiles offers these choices for Polyester products: 6.4 oz MJS/Filament Hybrid-Domestic Fabric 6.4 oz MJS/Filament Hybrid-Imported Fabric 7.2 oz all Ring Spun Polyester-Imported Fabric 7.2 oz MJS Aprons and Uniforms

Q: How about the finishing? White is White, right?

A: The finishing of fabrics can vary greatly from one type of spun to another and from one vendor to another. These are important factors when finishing polyester fabric for use in linen and uniforms.

Q: Is your linen fabric spun from dull white or optical bright fibers?

A: Optical bright yarns allow the fabric to maintain its whiteness from new to used. Industrial Textiles uses only fabrics spun from optical white polyester fiber.

Q: Is your fabric dyed white in slow feed jets, or simply scoured and bleached in a series of "baths"?

A: Adding white dye in the slow feed jets is a bit more costly, but the advantages are white fabrics or linen that tends to stay white for its entire life rather than graying down. This is the normal process for colors, but it is optional with white since the fibers are already white. Industrial Textiles offers dyed white products and products that are merely bleached.

Q: Is the soil release treatment embedded in the fibers with heat and pressure, or simply "padded" on top of the fabric without heat or pressure (HP)?

A: Without question, adding soil release with high heat and pressure, normally achieved in a slow feed jet process, is the best way to lock in the long term soil release. Those that are added topically, tend to wash out over time. Industrial Textiles does not add soil release to its cotton or poly/cotton blends. Industrial Textiles all polyester products have a soil release treatment which is applied in the slow feed jet process.

Q: Is the fabric treated for anti-static control?

A: All Polyester fabrics naturally create ample amounts of static. In the absence of anti-static treatments, they tend to pick up lint on flat work ironers and elsewhere. Industrial Textiles

polyester products are treated with anti-stat.

Q: Is the fabric naturally soft or does it need to be peached/brushed/sueded?

A: MJS fabrics do not need to be suededthe yarns are created to be naturally "hairy" which also adds to the breath ability factor in uniforms. Fabrics with filament filling yarns require some softening, especially if used for napkins. There are various ways of achieving the desired hand; however, most processes do take life from the product and increase the likelihood of some pilling and/or linting especially when new. Industrial Textiles believes the sueding of spun/filament fabrics is important on napkins given that they are the items that contact the skin. Further it is Industrial Textiles belief that sueding the table tops is an unnecessary expense that only decreases the life expectancy and increases the likeliness of pilling. Industrial Textiles' Apex napkins are sueded two passes, the table tops are not sueded.

Potrebbero piacerti anche

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesDa EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesValutazione: 3.5 su 5 stelle3.5/5 (3)

- Recotec Rotafil enDocumento16 pagineRecotec Rotafil enJordan RileyNessuna valutazione finora

- Shahab (07 Ntu 050)Documento12 pagineShahab (07 Ntu 050)Shahab ShahidNessuna valutazione finora

- Smart Composites: Angel College of Engineering and TechnologyDocumento12 pagineSmart Composites: Angel College of Engineering and Technologydolly707Nessuna valutazione finora

- MarineDocumento4 pagineMarineVlad DzemgyNessuna valutazione finora

- Rane Elastomer Processors CatalogueDocumento12 pagineRane Elastomer Processors CatalogueRane Elastomer100% (1)

- Fibre GlassDocumento7 pagineFibre GlassFirly Rajabi SoeratinoyoNessuna valutazione finora

- K450 Plus Updated PDFDocumento138 pagineK450 Plus Updated PDFCongson JeffNessuna valutazione finora

- Expansion JointsDocumento8 pagineExpansion Jointsterencejustine100% (1)

- Newcomponit EngDocumento20 pagineNewcomponit EngDhelleNessuna valutazione finora

- ROCKWOOL Technical Insulation ENG 06.2015 PDFDocumento32 pagineROCKWOOL Technical Insulation ENG 06.2015 PDFSelvakumar PalaniandavarNessuna valutazione finora

- Isoking Yellow Package Fiberglass Wool Insulation BlanketDocumento6 pagineIsoking Yellow Package Fiberglass Wool Insulation Blanketviethung_01Nessuna valutazione finora

- Choose The Right RollerDocumento7 pagineChoose The Right Rollerkartik spectomsNessuna valutazione finora

- PUR Uebersicht Engl 0211Documento10 paginePUR Uebersicht Engl 0211Boris KuseljNessuna valutazione finora

- 5600 107313-Fer 09Documento4 pagine5600 107313-Fer 09carlosdayanaNessuna valutazione finora

- TPO Coated PP Fabrics and Their ApplicationsDocumento14 pagineTPO Coated PP Fabrics and Their ApplicationsrejoramaNessuna valutazione finora

- Wire Cloth Buyer's GuideDocumento15 pagineWire Cloth Buyer's Guideflorina123Nessuna valutazione finora

- Hi Performance FibersDocumento13 pagineHi Performance Fibersahmer adnanNessuna valutazione finora

- Advanced Composite Materials in Typical Aerospace Applications-LibreDocumento10 pagineAdvanced Composite Materials in Typical Aerospace Applications-LibrezaujahaminNessuna valutazione finora

- Rockwool 159Documento37 pagineRockwool 159ashish2783Nessuna valutazione finora

- ARIFLEXDocumento8 pagineARIFLEXRiyas Udheen50% (2)

- Jining QiangkeDocumento35 pagineJining QiangkeCobu LamNessuna valutazione finora

- Gasket Application and Material Selection GuideDocumento10 pagineGasket Application and Material Selection GuideTieu KakaNessuna valutazione finora

- Plastics: Submitted by - Abhijit Borkataki 01 B.arch 7 SemDocumento18 paginePlastics: Submitted by - Abhijit Borkataki 01 B.arch 7 Semkela vinesNessuna valutazione finora

- Rockwool Rti Product Catalogue ExportDocumento45 pagineRockwool Rti Product Catalogue ExportBeomHee Lee100% (1)

- Baxchem Systems Brochure 20061 PDFDocumento6 pagineBaxchem Systems Brochure 20061 PDFA MahmoodNessuna valutazione finora

- A Guide To Elastomer PropertiesDocumento5 pagineA Guide To Elastomer PropertiesGunaseelan VNessuna valutazione finora

- Bep Brochure PDFDocumento12 pagineBep Brochure PDFandrewvermaakNessuna valutazione finora

- Frenzelit Company BrochureDocumento16 pagineFrenzelit Company Brochureeduard.turonNessuna valutazione finora

- 12 PAPYEX Flexible Graphite Mersen - 09 PDFDocumento14 pagine12 PAPYEX Flexible Graphite Mersen - 09 PDFarizagameroNessuna valutazione finora

- Rubber and Sealants Market SurveyDocumento16 pagineRubber and Sealants Market SurveyAnirudh MalpaniNessuna valutazione finora

- Aufsatz Franssen RFP 03-2012Documento6 pagineAufsatz Franssen RFP 03-2012Román M Martín del CNessuna valutazione finora

- Damival en 20120516Documento8 pagineDamival en 20120516ssingaram1965Nessuna valutazione finora

- Fsa Jury Assignment Kirti PatelDocumento18 pagineFsa Jury Assignment Kirti PatelKIRTI PATELNessuna valutazione finora

- LIL-Products-PUF-PIR Pipesection For Insulation Res17 PDFDocumento2 pagineLIL-Products-PUF-PIR Pipesection For Insulation Res17 PDFJoshua FernandezNessuna valutazione finora

- Ifs Brochure 2009 PDFDocumento12 pagineIfs Brochure 2009 PDFA MahmoodNessuna valutazione finora

- Optical Fiber Manufacturing ProcessDocumento3 pagineOptical Fiber Manufacturing ProcessMavic TumbagaNessuna valutazione finora

- Methods and Tools For Minimizing Heat Loss - 2020-11-10 - Process HeatingDocumento7 pagineMethods and Tools For Minimizing Heat Loss - 2020-11-10 - Process HeatingTS WongNessuna valutazione finora

- 1.1C Fiber Used in Technical TextilesDocumento10 pagine1.1C Fiber Used in Technical TextilesDhrubo AdhikaryNessuna valutazione finora

- Atmatec - Fibreglass Products For Drainage Systems PDFDocumento44 pagineAtmatec - Fibreglass Products For Drainage Systems PDFHafiz KamalNessuna valutazione finora

- Plastic MaterialsDocumento8 paginePlastic MaterialsHailu BeyechaNessuna valutazione finora

- Transformer GasketDocumento7 pagineTransformer GasketSeindahNyaNessuna valutazione finora

- Presentation 2Documento63 paginePresentation 2Karma TsheringNessuna valutazione finora

- Company-Profile 2Documento27 pagineCompany-Profile 2Solar OngridNessuna valutazione finora

- Give Brief About Polymers Used in Automobiles IndustryDocumento14 pagineGive Brief About Polymers Used in Automobiles IndustryjasonNessuna valutazione finora

- Morgan Thermal Ceramics Product Data - Book - 2016Documento179 pagineMorgan Thermal Ceramics Product Data - Book - 2016Alex MontielNessuna valutazione finora

- Full Final VisakaDocumento77 pagineFull Final VisakaJaspreet SinghNessuna valutazione finora

- Ricwil Catalog 10 Final PDFDocumento32 pagineRicwil Catalog 10 Final PDFHermanuadi100% (2)

- Digital Assignment-3: Rohan Avachat 15bem0102 C2 Dr. Pundlik BhagatDocumento14 pagineDigital Assignment-3: Rohan Avachat 15bem0102 C2 Dr. Pundlik BhagatjasonNessuna valutazione finora

- Silicone Technical TextilesDocumento39 pagineSilicone Technical TextilesRahul Oza100% (4)

- Benson Beltings: Product InformationDocumento2 pagineBenson Beltings: Product InformationbbulutmmNessuna valutazione finora

- Alamdar ProfileDocumento63 pagineAlamdar ProfileAswin KurupNessuna valutazione finora

- Rubber MoldingDocumento33 pagineRubber MoldingFurqan AlamNessuna valutazione finora

- FloatingDocumento12 pagineFloatingrobson2015Nessuna valutazione finora

- DC Wort Brochure FullDocumento36 pagineDC Wort Brochure FullrafeeqNessuna valutazione finora

- PMT Module 1Documento73 paginePMT Module 1Palliyil UjwalNessuna valutazione finora

- Rubber GuideDocumento5 pagineRubber Guidekanthar972Nessuna valutazione finora

- OKULENDocumento8 pagineOKULENDe SaripudinNessuna valutazione finora

- GEV 2022 Company Presentation & Application - ENGDocumento33 pagineGEV 2022 Company Presentation & Application - ENGSunil R HasabnisNessuna valutazione finora

- Microeconomía - Capítulo 5Documento31 pagineMicroeconomía - Capítulo 5Carlos García SandovalNessuna valutazione finora

- Request Letter WeebDocumento1 paginaRequest Letter Weebapi-303076697Nessuna valutazione finora

- A Study of Footwear Industry and Its Major Players (Bata, Liberty, Adidas and Nike)Documento114 pagineA Study of Footwear Industry and Its Major Players (Bata, Liberty, Adidas and Nike)Gaurav Chauhan100% (3)

- Boarding PassDocumento4 pagineBoarding PassLulzimNessuna valutazione finora

- Pocket ClothierDocumento30 paginePocket ClothierBhisma SuryamanggalaNessuna valutazione finora

- Amb359 Marketing Report FinalDocumento27 pagineAmb359 Marketing Report Finalapi-378790701Nessuna valutazione finora

- Worksheet 2 - The Business Dress CodeDocumento3 pagineWorksheet 2 - The Business Dress CodeAlexandra ManescuNessuna valutazione finora

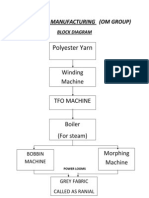

- Grey Cloth Manufacturing ProcessDocumento8 pagineGrey Cloth Manufacturing ProcessPriya JainNessuna valutazione finora

- Gul Ahmed Essential Summer Collection 2017Documento131 pagineGul Ahmed Essential Summer Collection 2017Armaghan AhmadNessuna valutazione finora

- MKT501 (50 Solved MCQS)Documento24 pagineMKT501 (50 Solved MCQS)Nadir AliNessuna valutazione finora

- Wide Strap Maxi Dress Instructions 1Documento19 pagineWide Strap Maxi Dress Instructions 1poiuy100% (1)

- System Implementation Traffic LightDocumento36 pagineSystem Implementation Traffic LightDurbar DasguptaNessuna valutazione finora

- Inventaris Barang Lab ProsmanDocumento24 pagineInventaris Barang Lab Prosmananon_291469778Nessuna valutazione finora

- B Schuhe Lederwaren ENDocumento12 pagineB Schuhe Lederwaren ENhermioneNessuna valutazione finora

- The Cornflower SweaterDocumento13 pagineThe Cornflower SweaterJavi Urbina100% (1)

- 2.history of Costume and Fashion The Medieval World 2005 PDFDocumento65 pagine2.history of Costume and Fashion The Medieval World 2005 PDFNguyễn Thiện100% (1)

- DecathlonDocumento1 paginaDecathlonNeenaNessuna valutazione finora

- TLG 12 WK 8 Las - BarongDocumento6 pagineTLG 12 WK 8 Las - BarongSkyler Reign MôntefâlcôNessuna valutazione finora

- Independent Nations Tex BD Factory Profile December 2018Documento41 pagineIndependent Nations Tex BD Factory Profile December 2018Md Faridujjaman100% (1)

- Typi - Floor Plan Memon Colony-R2-1Documento1 paginaTypi - Floor Plan Memon Colony-R2-1Khan MujahidKNessuna valutazione finora

- CN 1 BAKING TOOLS For Lesson Plan PictureDocumento15 pagineCN 1 BAKING TOOLS For Lesson Plan PictureMatt SollezaNessuna valutazione finora

- Pelican Tote-Bagstock Designs-2018Documento20 paginePelican Tote-Bagstock Designs-2018ulnaNessuna valutazione finora

- Owner's Manual Safety Instructions Operating InstructionsDocumento16 pagineOwner's Manual Safety Instructions Operating InstructionsKevin CharlesNessuna valutazione finora

- Industrial Report On Opex and Sinha Textile Group: Nasif ChowdhoaryDocumento95 pagineIndustrial Report On Opex and Sinha Textile Group: Nasif Chowdhoaryদীপ্তি হুমাইরাNessuna valutazione finora

- X KiltDocumento60 pagineX KiltHennot Do NorteNessuna valutazione finora

- Project Report On KFC PDFDocumento60 pagineProject Report On KFC PDFNiraj Vishwakarma100% (1)

- Scrolling ChartDocumento648 pagineScrolling ChartCsapCticNessuna valutazione finora

- Ficha Ingles 9 AnoDocumento18 pagineFicha Ingles 9 AnoMila SáNessuna valutazione finora

- Clothes Make The ManDocumento28 pagineClothes Make The ManAmma BiragoNessuna valutazione finora

- Bosch Tassimo Spec SheetDocumento2 pagineBosch Tassimo Spec SheetStacy ChartierNessuna valutazione finora

- To Pixar and Beyond: My Unlikely Journey with Steve Jobs to Make Entertainment HistoryDa EverandTo Pixar and Beyond: My Unlikely Journey with Steve Jobs to Make Entertainment HistoryValutazione: 4 su 5 stelle4/5 (26)

- $100M Leads: How to Get Strangers to Want to Buy Your StuffDa Everand$100M Leads: How to Get Strangers to Want to Buy Your StuffValutazione: 5 su 5 stelle5/5 (19)

- Twelve Caesars: Images of Power from the Ancient World to the ModernDa EverandTwelve Caesars: Images of Power from the Ancient World to the ModernValutazione: 3.5 su 5 stelle3.5/5 (9)

- Bare Bones: I'm Not Lonely If You're Reading This BookDa EverandBare Bones: I'm Not Lonely If You're Reading This BookValutazione: 4 su 5 stelle4/5 (11)

- House Rules: How to Decorate for Every Home, Style, and BudgetDa EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetNessuna valutazione finora

- Ikigai: The Japanese Life Philosophy to Finding Happiness and PeacefulnessDa EverandIkigai: The Japanese Life Philosophy to Finding Happiness and PeacefulnessValutazione: 5 su 5 stelle5/5 (91)

- Creative Abstract Watercolor: The beginner's guide to expressive and imaginative paintingDa EverandCreative Abstract Watercolor: The beginner's guide to expressive and imaginative paintingValutazione: 3 su 5 stelle3/5 (1)

- I Didn't Come Here to Make Friends: Confessions of a Reality Show VillainDa EverandI Didn't Come Here to Make Friends: Confessions of a Reality Show VillainValutazione: 3 su 5 stelle3/5 (47)

- The Gardner Heist: The True Story of the World's Largest Unsolved Art TheftDa EverandThe Gardner Heist: The True Story of the World's Largest Unsolved Art TheftNessuna valutazione finora

- Designing Brand Identity: A Comprehensive Guide to the World of Brands and BrandingDa EverandDesigning Brand Identity: A Comprehensive Guide to the World of Brands and BrandingNessuna valutazione finora

- The Storyteller: Expanded: ...Because There's More to the StoryDa EverandThe Storyteller: Expanded: ...Because There's More to the StoryValutazione: 5 su 5 stelle5/5 (13)

- They Can't Kill Us Until They Kill UsDa EverandThey Can't Kill Us Until They Kill UsValutazione: 4.5 su 5 stelle4.5/5 (38)

- The Hotel on Place Vendôme: Life, Death, and Betrayal at the Hotel Ritz in ParisDa EverandThe Hotel on Place Vendôme: Life, Death, and Betrayal at the Hotel Ritz in ParisValutazione: 3.5 su 5 stelle3.5/5 (49)