Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Campey - TIP - Greens Spiker Seeder - Pull Behind - Opertors Manual - 2010

Caricato da

Campey Turf Care SystemsDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Campey - TIP - Greens Spiker Seeder - Pull Behind - Opertors Manual - 2010

Caricato da

Campey Turf Care SystemsCopyright:

Formati disponibili

GS48

=T.I.P. Inc.=

GS-48 Greens Spiker/Seeder

Congratulations on your purchase of the T.I.P. GS-48 Greens Spiker/Seeder! You can rest assured that you have one of the highest quality turf care systems on the market today. With proper care and maintenance, your Spiker/Seeder will provide you with years of reliable service. If you have any questions about the GS-48 Spiker/Seeder, or any of our other turf care products, feel free to call us or drop us a line. We would be delighted to serve you in the future. Thank you for your patronage.

CONTENTS

Section Table of Contents Limited Warranty Safety Set-Up Operation Storage Maintenance *Parts: Figure 1 Figure 2 Figure 3 Miscellaneous Warranty Registration Card Page 1 2 3 5 8 8 9 10 11 12 13 14

GS48

=T.I.P. Inc.=

Limited Warranty

T.I.P. Inc. warrants that the equipment it manufactures will be free from defects in materials and workmanship for a period of one year from delivery date. This warranty is extended to the Original Purchaser only, and is non-transferrable. Should a defect in materials or workmanship be experienced within the warranty period, T.I.P. Inc. shall, at its discretion, furnish F.O.B Custer, WI, new or remanufactured parts to replace the non-conforming parts. T.I.P. Inc. shall not cover any labor costs incurred by the purchaser to replace said parts. This warranty is limited to new equipment, parts or accessories that are manufactured by T.I.P. Inc., provided that the equipment is used and maintained according to the instructions in the manual, and the Original Purchaser has completed, signed and returned the enclosed Warranty Registration form to T.I.P. Inc. within 30 days after the delivery of said equipment. This warranty does not apply to damage or deterioration to the equipment resulting from, but not limited to; natural wear and tear, abuse of goods, presence of abrasives, chemical action, improper installation, misuse, vandalism, or acts of God. This warranty does not apply to goods manufactured by others, beyond the warranties stated by the manufacturers for those goods. The limited warranty expressed hereunder, is exclusive, and T.I.P. Inc. makes no other representations, warranties, or guarantees, neither expressed nor implied, as to merchantability or the fitness of said equipment for any particular use or purpose, or that the equipment or installation of equipment when placed into operation will comply with applicable national, state, and local health and safety laws. T.I.P. Inc. shall not be liable for any consequential or indirect damages including, but not limited to, loss of anticipated profits or production, increase of cost of operation, loss due to spoilage of material, damage caused directly or indirectly to other property or goods, or penalties or fines arising from non-compliance.

GS48

SAFETY

GS-48 Greens Spiker/Seeder

UNDERSTAND AND FOLLOW SAFETY INFORMATION

ALL OPERATORS should read and understand all safety information and operating instructions for the Spiker/Seeder, and learn how to use the controls properly. Be aware of safety words such as CAUTION, WARNING and DANGER. These words alert you to important safety information. Do Not let anyone operate without proper instruction. Make sure that ALL OPERATORS can recognize and understand all safety warning labels on the machine. Keep all safety labels in good condition, and replace those that are missing or damaged. Replacement safety labels are available from your dealer.

DURING OPERATION

Operate the Spiker/Seeder only when all safety guards are in place. Before moving machine, check to make sure that no one is in the immediate vicinity. Keep hands and feet clear of the drum at all times. Never allow anyone to ride machine at any time. Be aware of pinch points on the machine. Keep away from transport wheels during operation. Wear close fitting clothing and safety gear appropriate for the operating conditions. Be aware that rocks or other debris could fly out from under the machine. The operation of the machine requires the full attention of the operator. Do not wear radio or other music headphones while operating this machine.

HYDRAULICS

Hydraulic oil is under pressure as great as 2500psi. Escaping oil under pressure can penetrate the skin and cause serious injury. Avoid this hazard by relieving pressure before disconnecting hydraulic lines. Protect hands and body from high pressure oil. Use a piece of cardboard to check for leaks. Replace all worn or cracked hoses before continued operation. If an accident occurs, seek medical attention immediately. Any injected fluid under the skin must be surgically removed in a few hours.

GS48

ELECTRICAL

GS-48 models that include a 12 volt hydraulic power unit require an electrical connection to the tow vehicle. Be aware that the hydraulic power unit is a high current draw device. Be sure connections are correct and secure. Contact with exposed electrical wires can result in severe shock and serious injury.

SAFE MAINTENANCE

Never lubricate, service or adjust machine while it is running. Keep hands, feet and clothing from power driven components. Disengage all power from machine before servicing. If machine is still connected to tow vehicle, be sure tow vehicle is turned off and secured against rolling. Securely support all parts of machine that must be raised for service work. Keep machine in good working order by replacing worn or broken parts. Be sure to remove all excess grease, oil and dirt. Properly dispose of all waste materials.

TRANSPORTATION

The Spiker/Seeder is designed for off road use only, and should not be towed on public roadways. Maximum tow speed for machine is 15mph. If it becomes necessary to tow machine on roadways, do so only on a highway approved trailer.

GS48

SET-UP

GS-48 Greens Spiker/Seeder ASSEMBLY

If your GS-48 Spiker/Seeder came delivered on a pallet, first remove machine and all parts from the pallet. Support the front of the machine and remove the jack from the frame. Align the Draw Bar assembly with the center of the frame and attach with the four U-bolts provided. Fasten the jack to the center of the draw bar assembly. The Spiker/Seeder comes with two optional hitch assemblies; one clevis-type hitch, and one 1-7/8" ball-type hitch. Select the hitch that best fits your application, and attach it to the front of the draw bar with the bolts and lock nuts provided. Select the holes that will place the hitch at the correct height to keep the machine level. (see Leveling Machine)

CONNECTION TO TOW VEHICLE

Connect the Spiker/Seeder to your tow vehicle using either the ball hitch or the clevis hitch provided. Be sure that connection is proper and secure. Be sure to rotate the parking jack to it's horizontal position. If your Spiker/Seeder will utilize the hydraulics on the tow vehicle, connect the hose ends to the hydraulic ports on the vehicle. The quick connect ends on the hoses may need to be changed to the correct size, depending on the hydraulic system on the vehicle.

CAUTION!

Make sure that hose ends are completely clean and free of all contaminants before connecting to tow vehicle. Contaminants will cause damage to the hydraulic system. If your Spiker/Seeder is equipped with the 12 volt hydraulic power unit, connect the two power leads from the power unit to the battery on the tow vehicle. The power lead marked with red tape goes to the positive side of the battery, and the black to the negative. Be sure that the leads are properly secured so they will not vibrate loose or lose contact during operation.

CAUTION!

Avoid direct contact with the battery terminals or the un-insulated portion of the leads. Electrical shock could result.

GS48

Unroll the Seeder Box Control Cable and locate the handle on the tow vehicle where it will be accessible to the operator. Clamp or fasten the handle in place. If your Spiker/Seeder has the 12 volt power unit option, locate the remote control pendant within easy access of the operator.

LEVELING MACHINE

With the Spiker/Seeder attached to tow vehicle, park in a flat, grassy area. Raise the transport wheels until they are off the ground. With the machine resting fully on the spike drum, the frame should be sitting parallel to the ground. If it is not parallel, adjust the height of the hitch assembly by locating it in a different set of holes, raising or lowering it accordingly. When the transport wheels are down and the spike drum is off the ground, the frame will NOT be parallel to the ground. This is normal operation.

ADJUSTING SEEDER BOX

The seeder box on the Spiker/Seeder must be calibrated before use to ensure proper application rates. Be sure to re-calibrate before each use. Atmospheric conditions can change flow rates of some materials. To calibrate, use the following procedure:

CAUTION!

Catching material from the outlets on the seeder box is recommended, so that no material is applied to the soil until calibration is completed. Doing otherwise is at the operator's own risk. 1. Suspend a calibration pan below the seeder box to catch falling material. 2. Set gauge to proper setting. If the proper setting is unknown, set at an approximate range. 3. Place a sufficient amount of material in the hopper for a practice area. 4. Cover a known area, such as 1000 sq ft. 5. Weigh the contents in the calibration pan. 6. Divide the weight by the known area to determine the rate. If necessary, adjust the gauge up or down and repeat. 7. When proper calibration is achieved, log gauge setting for future reference. To convert pounds per 1000 sq ft to pounds per acre, multiply your rate by 43.6. If it is impractical to mark off and cover a known area for calibration, use this alternative method to calibrate:

GS48

1. With gauge set and sufficient material in hopper, raise spike drum completely off of the ground using the transport wheels. 2. Turn the spike drum by hand the proper amount of revolutions to dispense test material. 1000 square feet of spiked area equals 52 revolutions of the drum. 1/100th of an acre equals 22 revolutions of the drum. These numbers assume no overlap in spiked area. 3. Determine the rate of material using the previous procedure. Adjust and repeat if necessary. After the rate calibration is completed, re-position spread plate at the desired angle by adjusting the chain length on the front corners of the plate.

GS48

OPERATOR'S INSTRUCTIONS

GS 48 Spiker/Seeder

Review and follow all safety information before operating the GS 48 Spiker/Seeder. Be sure all Set-Up procedures have been completed.

OPERATION

Verify that electrical or hydraulic connections are made with the tow vehicle and that the hitch pin is secured in place Fill the seeder box with the appropriate material and make sure cover is secure and metering slide is closed. After you reach the location where the spiker/seeder is to be used, lower the unit until the wheels are completely off the ground. This should be done while the vehicle is at a standstill. After the drum is completely in contact with the ground, then proceed forward in a straight line only. Turning with the spike drum in contact with the ground can cause turf damage or damage to the spiker/seeder. When you reach the end of the pass, raise spike drum completely off the ground before turning around. Be aware that the seeder box is driven from the spike drum, so the drum must be turning to operate the seeder box. When starting a pass with the spiker/seeder, be sure to start with enough extra space to allow the seeder box to deliver material to the desired area. Also, be aware that you may need to close the supply of material from the seeder box before you raise the spiker/seeder at the end of a pass.

CAUTION

Be sure to have the spiker/seeder drum completely raised when transporting machine from one location to another. NEVER have spike drum in contact with gravel or hard clay paths, concrete, asphalt, or any other hard packed surfaces. This will cause damage to the spikes.

STORAGE

Always store the GS 48 Spiker/Seeder with the transport wheels completely lowered and the drum off of the ground. Use the adjustable jack on the hitch to keep machine level and to aid in moving the machine when not connected to a tow vehicle.

GS48

MAINTENANCE

Grease wheel bearings and bearings on spike drum every 50 hours. Check tires for wear or damage Grease pivot points on lift axle before each use. Sand and other contaminants can cause damage if pivot points are not greased. Wipe off excess. Inspect hydraulic lines every 50 hours for wear or breakage. Check system for signs of leaks. Replace hoses if necessary. If system is equipped with 12v pump kit, check fluid level in the reservoir tank every 25 hours. The tank should be to 2/3 full. Fill if necessary. Use only Hydroclear hydraulic pivot oil or equivalent. Inspect entire spike drum for loose or broken/missing spikes weekly. Replace if necessary. Check tension on the seeder box drive chain. Lube chain weekly. Check operation of seeder box control cable weekly. Replace cable if operation becomes difficult.

GS48

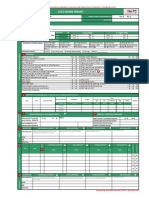

Figure 1:

2 3 4 5

12 13

11 8 15 16 14 17 9 10

Ref

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 16a* 17

Part#

BUCYR2008AR-ASA BU60UA-06x06 SP101 LL013077 GPDNO IPUC206-20G TP1002 BS142-519 TO35B32H-1-1/4 BUMRC35-100 TO35B32H-5/8 MS14X180HOSE MS14X192HOSE WSG908 FN37016 DM116SPIKE DM100SPIKE WS-03-05-00-00

Description

Wheel Lift Cylinder Swivel Adaptor, Hyd. Greens Spiker/Seeder Decal Rubber Latch Assy. "Do Not Operate" Decal Bearing Insert, Greasable Hub Assembly, 4 Bolt Tire/Wheel Assy. Chain Sprocket, Drum Roller Chain, Sold Per Inch Chain Sprocket, Seeder Hose Assy., 180" Hose Assy., 192" Chain Guard Nylock Nut for Spike Spike, Stainless 1-1/16" Standard Spike, Stainless " Optional End Cap for Spike Drum

Qty

1 2 2 2 2 2 2 2 1 43 1 1 1 1 1208 1208 1208 4

10

GS48

Figure 2: GS-48 Hydraulic Power Unit

6 5 4

1 7 2

Ref 1 2 3 4 5 6 7

Part# FADC60/KR14 FAKG13 FAKR14 FAE1-4005-12 FAKDV4 FAKMD1 FAKS1

Description 12V Hydraulic Power Unit/Pump Hydraulic Control Remote w/ Cord Tank for DC 60 12 V Power Unit Solenoid Assembly U-Valve DC Motor 12V Solenoid Starter Assembly 12V

Qty 1 1 1 2 1 1 1

11

GS48

Figure 3:

5 6

7 4 8

Ref

1 2 3 4

Part#

GP147391 TEUDL-111-2-196X TE175-601-204 TP1001

Description

Jack, 750# Swivel Side Crank Cable, Seeder Box Controller Clevis and Pin for Cable U-Bolt, 3/8x3x3

Qty

1 1 1 4

5

6 7 8

GA42-A-TIP

WS-03-05-00 IBA-4457 TP100

Seeder Box Assy.

Spike Drum Guard Assy. Brush, White Drum Cleaning Plug, Square End Plastic

1

1 1 2

12

GS48

Miscellaneous: #1 #2 #3 #4

#5 #6 #7 #8 #9

#10 #11

Ref# 1 2 3 4 5 6 7 8 9 10 11 Part# QS3245 QS145 IM449-287 IM444-218 QS66 QS3013 IM449-396 IM452-315 IM449-307 GP2081 IBA-4457 Description Decal-Danger, Moving Machinery Decal-Danger, Without Guards In Place Decal-Do Not Walk Between Decal-Do Not Stand In Front Of Decal-No Riders Decal-This Machine Has No Brain Decal-Do Not Place Hands Into Moving Decal-Read Instruction Manual Decal-Do Not Place Hand Into Chain Decal-T.I.P. Spiker/Seeder Rear Cover 48" Brush White (High Stiffness) Qty 1 1 1 1 1 1 1 1 1 1 1

13

GS48

MAIL THIS WARRANTY CARD TODAY

IF IT IS NOT REGISTERED IN THE HOME OFFICE OF T.I.P. INC. CUSTER, WI 54423 ANY CLAIM YOU HAVE UNDER THE WARRANTY WILL NOT BE HONORED.

DONT DELAY

PLEASE COMPLETE THE WARRANY REGISTRATION AND RETURN IMMEDIATELY. CUT HERE T.I.P. INC. 1619 COUNTY K CUSTER, WI 54423 PHONE 715-592-4650 FAX 715-592-5063

WARRANY REGISTRATION

NAME: ADDRESS: CITY/STATE/ZIP CODE: DEALERS NAME: DEALERS ADDRESS: CITY/STATE/ZIP CODE: DATE OF PURCHASE: S/N MODEL# I HAVE READ AND FULLY UNDERSTAND ALL SAFETY DIRECTIONS AND AGREE TO TRAIN ALL PERSONNEL OPERATING THIS MACHINE. SIGNATURE:__________________________________________ DATE:_______________________ 14

GS48

15

Potrebbero piacerti anche

- Diesel Engine Care and Repair: A Captain's Quick GuideDa EverandDiesel Engine Care and Repair: A Captain's Quick GuideValutazione: 5 su 5 stelle5/5 (1)

- Campey - TIP - Greens Spiker Seeder - 3 Point Mounted - Operators Manual - 2010Documento14 pagineCampey - TIP - Greens Spiker Seeder - 3 Point Mounted - Operators Manual - 2010Campey Turf Care SystemsNessuna valutazione finora

- Campey - TIP - Groom It - Operators Manual - 2010Documento25 pagineCampey - TIP - Groom It - Operators Manual - 2010Campey Turf Care SystemsNessuna valutazione finora

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- Campey - TIP - Brush It - Operators Manual - 2010Documento20 pagineCampey - TIP - Brush It - Operators Manual - 2010Campey Turf Care SystemsNessuna valutazione finora

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideDa EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideValutazione: 4.5 su 5 stelle4.5/5 (8)

- JWBS 18 ManualDocumento27 pagineJWBS 18 Manualmgfranz100% (1)

- Balanceador Coseng C 99 01 - ManualDocumento10 pagineBalanceador Coseng C 99 01 - ManualMáximo Méndez100% (1)

- Breakdowns and Incidents: DVSA Safe Driving for Life SeriesDa EverandBreakdowns and Incidents: DVSA Safe Driving for Life SeriesNessuna valutazione finora

- Weedeater One Service ManualDocumento20 pagineWeedeater One Service ManualBrandon HarveyNessuna valutazione finora

- Operator'S Manual: Automatic Lawn Tractor Models 607 6O8 6O9Documento48 pagineOperator'S Manual: Automatic Lawn Tractor Models 607 6O8 6O9Arlie Lawrence100% (1)

- Bolens 683 Lawn Tractor Owner's Manual 13AN683G163Documento32 pagineBolens 683 Lawn Tractor Owner's Manual 13AN683G163Steve KravitzNessuna valutazione finora

- 0 TP D Rilt°: Operator's ManualDocumento16 pagine0 TP D Rilt°: Operator's ManualRadu_ISNessuna valutazione finora

- MTD ManualDocumento48 pagineMTD ManualJoe SmithNessuna valutazione finora

- White 2150-770-10315bDocumento44 pagineWhite 2150-770-10315bBiggie D HouseNessuna valutazione finora

- Huskee Riding Mower ManualDocumento28 pagineHuskee Riding Mower ManualJared Wellman25% (4)

- Bending BrakeDocumento6 pagineBending BrakenevadablueNessuna valutazione finora

- Manual Murray 20Documento28 pagineManual Murray 20freebanker777741Nessuna valutazione finora

- 769-01442 (1) Yardmachines-Mtd Lawn Mower ManualDocumento28 pagine769-01442 (1) Yardmachines-Mtd Lawn Mower ManualJayNessuna valutazione finora

- 3 TON SUV Trolley JackDocumento31 pagine3 TON SUV Trolley JackNegrea CristianNessuna valutazione finora

- Cub Cadet 1525 Lawn Mower - Owner's ManualDocumento36 pagineCub Cadet 1525 Lawn Mower - Owner's ManualthelegendarysuitNessuna valutazione finora

- Owner'S Manual GH-1340W/1440W Lathes: Jet Equipment & Tools, IncDocumento24 pagineOwner'S Manual GH-1340W/1440W Lathes: Jet Equipment & Tools, IncNoé MuñozNessuna valutazione finora

- Manual Fresadora JetDocumento30 pagineManual Fresadora JetDavid Fernan NuñezNessuna valutazione finora

- 23302-Craftsman GT18 Garden Tractor 917.255917Documento52 pagine23302-Craftsman GT18 Garden Tractor 917.255917scottjoslyn0% (1)

- Manual VinciDocumento21 pagineManual VinciElena TurcuNessuna valutazione finora

- Jet Wood Lathe JWL-1642EVS Manual - 708359Documento32 pagineJet Wood Lathe JWL-1642EVS Manual - 708359spaytNessuna valutazione finora

- Cub Cadet Owners ManualDocumento40 pagineCub Cadet Owners ManualBill MertzNessuna valutazione finora

- LX420 & LX460 Lawn Tractors: Model No. 13AX60RG744 Model No. 13AX60RH744Documento36 pagineLX420 & LX460 Lawn Tractors: Model No. 13AX60RG744 Model No. 13AX60RH744James BryantNessuna valutazione finora

- Operator'S Manual & Parts ListDocumento9 pagineOperator'S Manual & Parts Listeveswan2008Nessuna valutazione finora

- MTD 24A 465A000 ChipperDocumento28 pagineMTD 24A 465A000 Chippernickscribd01Nessuna valutazione finora

- Perator'S Anual: Snow ThrowerDocumento28 paginePerator'S Anual: Snow ThrowerhelpmenowandlawterqNessuna valutazione finora

- Otro - Bilt - : Operator's ManualDocumento28 pagineOtro - Bilt - : Operator's ManualJason CrowleyNessuna valutazione finora

- MTD 24A46E729 Chipper-Shredder Owner's ManualDocumento20 pagineMTD 24A46E729 Chipper-Shredder Owner's ManualcpprioliNessuna valutazione finora

- P 4750319Documento16 pagineP 4750319Yaroslav KulykNessuna valutazione finora

- Snow Blower - MTD 31AE665E118 Owners ManualDocumento28 pagineSnow Blower - MTD 31AE665E118 Owners Manualanthony_monaco_667% (3)

- Bronco SuperBronce ProLineCRT 2012 769-07548Documento48 pagineBronco SuperBronce ProLineCRT 2012 769-07548Joe HowardNessuna valutazione finora

- Manual de Plancha Lisa AWDocumento16 pagineManual de Plancha Lisa AWrichardcamusNessuna valutazione finora

- Important Safety InformationDocumento3 pagineImportant Safety InformationMahmmod Al-QawasmehNessuna valutazione finora

- Instruction Sheet For Ultra-GrateGuardDocumento1 paginaInstruction Sheet For Ultra-GrateGuardjsalzmannNessuna valutazione finora

- Owner's Manual Cub Cadet 1020Documento72 pagineOwner's Manual Cub Cadet 1020dk3355Nessuna valutazione finora

- BT300KTS 674 TYM Rev04Documento53 pagineBT300KTS 674 TYM Rev04Zweli ZwelihleNessuna valutazione finora

- Mic Man R1874Documento31 pagineMic Man R1874jfsdjkljgjrgjgjkdskdgk5443Nessuna valutazione finora

- 47158Documento16 pagine47158Rosania SanchesNessuna valutazione finora

- Engine Sling: Operating Instructions & Parts ManualDocumento5 pagineEngine Sling: Operating Instructions & Parts ManualAmal BologniniNessuna valutazione finora

- Ficha Tecnica Gato Big Red 30tonDocumento16 pagineFicha Tecnica Gato Big Red 30tonCesar Augusto Arias CastroNessuna valutazione finora

- Six Inch Dual Action Air Sander 90288Documento8 pagineSix Inch Dual Action Air Sander 90288renspurNessuna valutazione finora

- Shop Press Assembly InstructionsDocumento16 pagineShop Press Assembly InstructionsOlayinka OlabanjiNessuna valutazione finora

- Operating Instructions and Parts ManualDocumento8 pagineOperating Instructions and Parts ManualHabtie WalleNessuna valutazione finora

- 210918100805371Documento31 pagine210918100805371mistyfateNessuna valutazione finora

- Elevador CarroDocumento90 pagineElevador CarroJoséNessuna valutazione finora

- Tuthill Blower Manual EqualizerManualDocumento24 pagineTuthill Blower Manual EqualizerManualmsaqibraza93Nessuna valutazione finora

- Perator'S Anual: Snow ThrowerDocumento28 paginePerator'S Anual: Snow ThroweroqutghbhfdgNessuna valutazione finora

- EQQ 7931S IM (Eng - CH) - Min 2Documento16 pagineEQQ 7931S IM (Eng - CH) - Min 2Frank LampardNessuna valutazione finora

- Craftsman Garden Tractor Manual 917.254520Documento48 pagineCraftsman Garden Tractor Manual 917.254520Dan CarsonNessuna valutazione finora

- RP360-RP360XP Manual 5041674-B OriginalDocumento120 pagineRP360-RP360XP Manual 5041674-B OriginalPolivinil Indie RockNessuna valutazione finora

- MTD Yard Machine 25 Ton Log Splitter ManualDocumento40 pagineMTD Yard Machine 25 Ton Log Splitter ManualMYMAINE1Nessuna valutazione finora

- Models: 20" PushDocumento28 pagineModels: 20" PushDavid HickeyNessuna valutazione finora

- Operator's Manual: Snow ThrowerDocumento32 pagineOperator's Manual: Snow Throwernewark0714Nessuna valutazione finora

- Campey - Koro FTM 1.5mtr - Elevator - Modular - 964b001-0 - Ondboek 2011-11Documento26 pagineCampey - Koro FTM 1.5mtr - Elevator - Modular - 964b001-0 - Ondboek 2011-11Campey Turf Care SystemsNessuna valutazione finora

- Campey - Koro FTM 1.2mtr Scarifier Collector - Modular - 963h003-0 - Ondboek 2011-11Documento22 pagineCampey - Koro FTM 1.2mtr Scarifier Collector - Modular - 963h003-0 - Ondboek 2011-11Campey Turf Care SystemsNessuna valutazione finora

- Campey - Koro FTM 1.5mtr - Scarifier Collect - Modular - 964h002-0 - Ondboek 2011-11Documento22 pagineCampey - Koro FTM 1.5mtr - Scarifier Collect - Modular - 964h002-0 - Ondboek 2011-11Campey Turf Care SystemsNessuna valutazione finora

- Campey - Raycam Infield - Operators & Parts ManualDocumento15 pagineCampey - Raycam Infield - Operators & Parts ManualCampey Turf Care SystemsNessuna valutazione finora

- Campey - Koro FTM 1.2mtr Elevator - Modular - 963b003-0 - Ondboek 2011-11Documento25 pagineCampey - Koro FTM 1.2mtr Elevator - Modular - 963b003-0 - Ondboek 2011-11Campey Turf Care SystemsNessuna valutazione finora

- Campey - Raycam Aera Seeder From H1944-H1955Documento20 pagineCampey - Raycam Aera Seeder From H1944-H1955Campey Turf Care SystemsNessuna valutazione finora

- Campey - Raycam Landscaper - Operators & Parts ManualDocumento19 pagineCampey - Raycam Landscaper - Operators & Parts ManualCampey Turf Care SystemsNessuna valutazione finora

- Campey - TIP - Sweep N Clean SW48 - Operators Manual - 2010Documento34 pagineCampey - TIP - Sweep N Clean SW48 - Operators Manual - 2010Campey Turf Care SystemsNessuna valutazione finora

- Campey - Omarv TE 120-140-160 - Operators & Parts ManualDocumento44 pagineCampey - Omarv TE 120-140-160 - Operators & Parts ManualCampey Turf Care SystemsNessuna valutazione finora

- Campey - Raycam Aera Seeder From I2032Documento19 pagineCampey - Raycam Aera Seeder From I2032Campey Turf Care SystemsNessuna valutazione finora

- Campey - Raycam - Aera Seeder - Serial No. I2042 OnwardsDocumento20 pagineCampey - Raycam - Aera Seeder - Serial No. I2042 OnwardsCampey Turf Care SystemsNessuna valutazione finora

- Campey - Imants Root Pruner - Operators ManualDocumento25 pagineCampey - Imants Root Pruner - Operators ManualCampey Turf Care SystemsNessuna valutazione finora

- Campey - Imants Shockwave 100-155-210 - Operators ManualDocumento30 pagineCampey - Imants Shockwave 100-155-210 - Operators ManualCampey Turf Care SystemsNessuna valutazione finora

- Campey - Timan RC-750 Operators ManualDocumento73 pagineCampey - Timan RC-750 Operators ManualCampey Turf Care SystemsNessuna valutazione finora

- Campey - Imants Shockwave 220 - Operator ManualDocumento30 pagineCampey - Imants Shockwave 220 - Operator ManualCampey Turf Care SystemsNessuna valutazione finora

- Campey - Imants Sandcat - Operators ManualDocumento25 pagineCampey - Imants Sandcat - Operators ManualCampey Turf Care SystemsNessuna valutazione finora

- Campey - Imants Rotosweep - Operators & Parts ManualDocumento19 pagineCampey - Imants Rotosweep - Operators & Parts ManualCampey Turf Care SystemsNessuna valutazione finora

- Campey - Greencare - Core Master Xtreme - Manual - V2011 - 1Documento40 pagineCampey - Greencare - Core Master Xtreme - Manual - V2011 - 1Campey Turf Care SystemsNessuna valutazione finora

- Campey - Dakota Turf Tender - Operators Manual 2006aDocumento44 pagineCampey - Dakota Turf Tender - Operators Manual 2006aCampey Turf Care SystemsNessuna valutazione finora

- Borcure - Packaging ConferenceDocumento5 pagineBorcure - Packaging ConferencegandhiannexNessuna valutazione finora

- At The Restaurant Esl Vocabulary Game Cards For Kids PDFDocumento7 pagineAt The Restaurant Esl Vocabulary Game Cards For Kids PDFalucardoxxNessuna valutazione finora

- Garden Bird Amigurumi PatternDocumento38 pagineGarden Bird Amigurumi PatternMyriam Zuñiga Diaz100% (10)

- Furniture Living RoomDocumento17 pagineFurniture Living RoomSil100% (1)

- BS Professional Katalog ENDocumento43 pagineBS Professional Katalog ENTatjana YurkinaNessuna valutazione finora

- Brian Bowen II Rico ComplaintDocumento85 pagineBrian Bowen II Rico ComplaintDarren Adam HeitnerNessuna valutazione finora

- Thomas Burberry - WikipediaDocumento3 pagineThomas Burberry - Wikipediahepopi3Nessuna valutazione finora

- 2002 Mazda Protege Owners ManualDocumento290 pagine2002 Mazda Protege Owners ManualBrian D Robinson100% (1)

- Magic Pos PDFDocumento3 pagineMagic Pos PDFPraveen ChoudharyNessuna valutazione finora

- A Comparison of Shipping Containers From Technical, Economic and Environmental PerspectivesDocumento8 pagineA Comparison of Shipping Containers From Technical, Economic and Environmental Perspectivesbkollarou9632Nessuna valutazione finora

- Bahrain FlyerDocumento3 pagineBahrain Flyerzahid_497Nessuna valutazione finora

- Product CatalogDocumento19 pagineProduct CatalogryanshaikhNessuna valutazione finora

- Cold Work PermitDocumento1 paginaCold Work Permitsaran985Nessuna valutazione finora

- UNIT 3 - Managing The Marketing ChannelDocumento12 pagineUNIT 3 - Managing The Marketing Channelram100% (1)

- Tata TescoDocumento9 pagineTata TescoAbhishek Karekar100% (1)

- 13 - Dry Suit Diver SpecialtyDocumento4 pagine13 - Dry Suit Diver SpecialtySerbanNessuna valutazione finora

- Math 1030 - Final ProjectDocumento6 pagineMath 1030 - Final Projectapi-251837688Nessuna valutazione finora

- My Passion For Cooking - Dhaba KarahiDocumento5 pagineMy Passion For Cooking - Dhaba KarahiAdnan R AhmedNessuna valutazione finora

- Walton Marketing PlanDocumento22 pagineWalton Marketing PlanIsmail442694% (16)

- About CAT LogicticsDocumento40 pagineAbout CAT Logicticsaskvishnu71120% (1)

- 9781473615441 (1)Documento449 pagine9781473615441 (1)iki29280% (5)

- Como Sobreviver A Um Apocalipse ZumbiDocumento30 pagineComo Sobreviver A Um Apocalipse ZumbirejaneNessuna valutazione finora

- WA101 Killrust Rust Eeter V2 - 0Documento2 pagineWA101 Killrust Rust Eeter V2 - 0bacilevuNessuna valutazione finora

- Clatronic BBA 3505 Bread MakerDocumento66 pagineClatronic BBA 3505 Bread Makerpiopio1234Nessuna valutazione finora

- The Callisia Cover-UpDocumento50 pagineThe Callisia Cover-UpKarlitaNessuna valutazione finora

- Strategic Analysis - Hindustan Unilever LTDDocumento14 pagineStrategic Analysis - Hindustan Unilever LTDdivtanejaNessuna valutazione finora

- 1 Day Meal Plan TemplateDocumento4 pagine1 Day Meal Plan TemplateMark Aaron WilsonNessuna valutazione finora

- The Menu: All Recipes Courtesy of Thebathers'pavilion Serge DansereauDocumento5 pagineThe Menu: All Recipes Courtesy of Thebathers'pavilion Serge Dansereaulexbast1419Nessuna valutazione finora

- Case Study 1Documento2 pagineCase Study 1Mauricio Martinez Pulgarin0% (1)

- Runner Ru4rxDocumento45 pagineRunner Ru4rxfcdypmsbssNessuna valutazione finora