Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Cellulose Hydrolysis by Cellulomonas Fimi and Ethanol Production by Zymomonas Mobilis

Caricato da

jamonlineTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Cellulose Hydrolysis by Cellulomonas Fimi and Ethanol Production by Zymomonas Mobilis

Caricato da

jamonlineCopyright:

Formati disponibili

Jamonline / 2(2); 2012 / 214222 Research Article

Srivastava AK and Pushpa Agrawal

Journal of Atoms and Molecules

An International Online Journal

ISSN 2277 1247

CELLULOSE HYDROLYSIS BY CELLULOMONAS FIMI AND ETHANOL PRODUCTION BY ZYMOMONAS MOBILIS Ajeet Kumar Srivastava*, Pushpa Agrawal Department of Biotechnology, R V College of Engineering, R.V. Vidyaniketan Post, Bangalore, India, Received on: 21-04-2012 Abstract: lignocellulosic material is one of the most abundant and renewable resource on earth for conversion to readily utilizable hydrolyzate conversion .Degradation of lignin is a prerequisite for rendering cellulose for action by cellulose hydrolyzing enzymes. While various pretreatments have been proposed for lignin degradation use of oxidizing agent such as inorganic oxidants ozone, per acetic acid and hydrogen peroxide has been reported as effective for lignin degradation and cellulose hydrolysis.It is proposed to employ mechanical disintegration of paddy straw followed by treatment with MnSO4 and H2O2 as they enhance the susceptibility of rice straw to enzymatic saccharification. To initiate the production of industrially important products from lignocellulosic biomass, bioconversion of the lignocellulosic components into fermentable sugars is necessary that could be used for ethanol production. Cellulomonas is known to produce both cellulases and hemicellulases and it is used for the saccharification . This present study reports on the microbial pretreatment and saccharification of the agricultural residues like rice straw (raw material) using a bacterial strain Cellulomonas fimi (MTCC-24) and ethanol production by Zymomonas mobilis. Key Words: Cellulose hydrolysis, ethanol production, lignocellulosic material, saccharification, fermentable sugars, microbial pretreatment. Introduction: * Corresponding author Ajeet Kumar Srivastava, Email: ajeeth@rvce.edu.in Tel: +91 9916830878 The natural energy resources such as fossil fuel, petroleum and coal are being utilized at a rapid rate and these resources have been estimated exhaust over a few years. Revised on: 26-04-2012 Accepted on: 29042012

Therefore, alternative energy resources such www.jamonline.in 214

All rights reserved 2011

Jamonline / 2(2); 2012 / 214222 as ethanol, methane, and hydrogen are being considered. A worldwide interest in the utilization of bioethanol as an energy source has stimulated studies on the cost and efficiency of industrial processes for ethanol production. Lignocellulose is an abundant material created from solar energy and renewable resources on earth, which makes them attractive for production of sugar through saccharification process.

Srivastava AK and Pushpa Agrawal cellulose at the ends of glucan chains by C. fimi cellobiohydrolases CbhA and CbhB is strongly suggested by hydrolysis experiments using cellooligosaccharides [6,7,8,9,10].

Previous studies have indicated that CenA attacks susceptible linkages in soluble CMC in a relatively nonprocessive manner[11] i.e., the enzyme dissociates from the substrate after each hydrolytic event. While CenB and CenD attack CMC in a similar way,C. fimi CenC seems to act in a more processive fashion [12,13]. Therefore, CenC activity was analyzed in order to determine if the enzyme behaves in a similarly processive manner on cellulose. Previous determinations of

Lignocellulose is composed of three main fractions like cellulose (~ 45% of dry weight), hemicellulose (~30% of dry weight) and lignin (~25% of dry weight). In these waste products (rice straw, wheat straw and rice husk) cellulose and hemicellulose are closely associated with lignin in the plant cell wall [1]. Cellulose, the most abundant polymer on earth is composed of thousands of molecules of anhydroglucose linked by (1, 4)glycosidic bonds. Cellulose can be effectively hydrolyzed and depolymerized into

molecular size distribution during hydrolysis have shown that the choice of substrate is an important consideration [14]. In this study used surface/volume ratios and substrate heterogeneity, which are associated with the use of substrates like rice straw [15, 16]. Objective: 2.1.To used Potential availability of some agricultural residues in India like rice straw. 2.2.To achieve high yields of fermentable sugar 2.3.From cellulosic components using

fermentable sugars by the enzyme cellulase [2, 3, 4, 5]. A number of microorganisms are capable of producing extracellular cellulase enzyme and among which Cellulomonas fimi widely used candidates for cellulase enzyme production. Cellulomonas fimi produces at least six -1, 4-glucanases, of which four (CenA, CenB, CenC, and CenD) are

microorganisms 2.4.To determine the effect of sugar yield using a Cellulomonas fimi bacteria. 2.5.To achieve high yields of ethanol at economic level using Zymomonas mobilis bacteria

endoglucanases and two (CbhA and CbhB) appear to be cellobiohydrolases that are the functional equivalents of Trichoderma reesei CBHI and CBHII. The preferential attack of

All rights reserved 2011

www.jamonline.in 215

Jamonline / 2(2); 2012 / 214222 Material and Methods: Raw materials Rice straw was procured from a rice mill in Bangalore, It was cleaned dried and powdered to 100 mesh size in a ball mill. Powder of raw material was used as carbon source. Microorganisms Cellulomonas fimi and Zymomonas mobilis were procured from MTCC, Chandigarh. Culture medium Media for Cellulomonas fimi: Beef Extract 1.0g, Yeast Extract 2.0g, Peptone 5.0g, NaCl - 5.0g, Agar 15g, Distilled water 1 litre. Media for Zymomonas mobilis: Glucose 80g, Yeast Extract 10g, KH2PO41.0g, MgSO4.7H2O0.5g, Agar-15g, Distilled Water-1 litre. Standardisation of pre-treatment process Three samples of Cellulosic material (Rice straw Powder) was suspended in three different sterilized conical flask of hydrogen peroxide solution containing MnSO4 at concentration of the molar ratio 1: 100 against H2O2 and were allowed to stand for 2 hrs at three temperatures viz. 25C, 50C, 72C and continuously stirred using glass stirrer. The pretreated material were washed several times with deionised water and then dried with hot air oven for 24 hrs at 70C then dry fibrous cake was weighed which further processed for microbial saccharification All rights reserved 2011

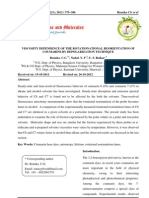

Srivastava AK and Pushpa Agrawal Microbial saccharification Saccharification was carried out using 10ml of active bacterial culture (incubated for 24 hrs, in orbital shaker), 1.8g of raw material and 90ml media so that volume of broth becomes 100ml. The experimental setup was kept in the orbital shaker for saccharification to occur. After each 24hrs levels of reducing sugar in the above setup were checked quantitatively by DNStest [17]. Determination of total carbohydrate The carbohydrate content of pretreated raw materials in the culture broth was measured by Anthrone method [18]. Fermentation Culture filtrate was further inoculated with Zymomonas mobilis strain and allowed for fermentation for seven days [19]. After fermentation it was filtered and ethanol content was determined. Ethanol estimation Determination of ethanol content was done by spectrophotometric method [20] Results and Discussions: 1) Rice straw pretreatment method was standardised for easy access of the substrate surface for microbial action. 2) The alkali pretreatment has yielded optimum reducing sugar at 72C using Cellulomonas fimi.

www.jamonline.in 216

Jamonline / 2(2); 2012 / 214222 3) Increase in the microbial concentration shows increase in reducing sugar level. 4) Delignificationand depolymerisation of Rice straw was needed in order to utilise it as a potential substrate in

Srivastava AK and Pushpa Agrawal analysis of CMC hydrolysis. CenC appeared to show a more processive action, relative In to the the other present

endoglucanases.

investigation we have compared the activities of CenA, CenC, CbhA, and CbhB by determining the molecular size

saccharification. 5) The chemical composition of Rice straw is lignin (24.8 %), Cellulose (34 %), and hemicellulose (28.2%). The total sugar estimated before pre treatment (3.74 mg/g). 6) The percentage loss of weight of Rice straw due to pretreatment can be

distribution

products

obtained

by

hydrolysis of rice straw. 10) For all enzymes, it is evident that substantial solubilization of BMCC

occurred without major changes in the overall shapes of distribution profiles. Loss of high-DP cellulose was slightly more pronounced for CenA than for CbhA and CbhB, as expected for a randomly acting endoglucanase, but the the activity of CenA is not easily

attributed to the dissolved lignin content to larger extent and hemicellulose and cellulose molecule to the some extent. 7) Lignin forms the barrier for

microorganisms to utilise cellulose as carbohydrate for it growth. The

distinguished from the activities of the two cellobiohydrolases when rice straw is used as the substrate 11) The data support our earlier suggestion that C. fimi CbhA and CbhB correspond to similar pairs of cellobiohydrolases seen in fungal cellulase systems and, more generally, that aerobic fungi and bacteria have similar types of cellulase systems. 12) It has been reported that the bacteria Zymomonas mobilis which gives a high ethanol yield, tolerates high ethanol concentrations and can ferment arabinose and xylose (18% of ethanol).

Amorphous nature of substrate after pretreatment was due the removal of lignin. 8) Powdering the substrate increases the surface area and the pore size of the particle necessary for the absorption of moisture and penetration of microbes. 9) The cellulose-degrading system of C. fimi contains at least six cellulases. Four of these enzymes (CenA, CenB, CenC, and CenD) were designated as

endoglucanases and two (CbhA and CbhB) were designated as

cellobiohydrolases, based largely on All rights reserved 2011 www.jamonline.in 217

Jamonline / 2(2); 2012 / 214222

Srivastava AK and Pushpa Agrawal

Table 1: Initial composition of the raw materials in mg/gm SI. No 1 Raw materials Rice straw Total sugar 1.89 Reducing sugar 1.81 Non reducing sugar .08

Table 2 After 24 hrs Control (O.D) 0.0 0.0 0.0 Test (O.D) .005 .002 .001 % of reducing sugars .054 .033 0.00 % of ethanol 5 3 0

Sl. No

Sample 250C 500C 720C

Conc. g/ml

1 2 3

5 3 0

Table 3 After 48hrs Control (O.D) 0.0 0.0 0.0 Test Conc. g/ml (O.D) .075 .045 .015 80 50 20 sugars .88 .56 .22 % of reducing % of ethanol 7 4 2

Sl. No

Sample

1 2 3

250C 500C 720C

All rights reserved 2011

www.jamonline.in 218

Jamonline / 2(2); 2012 / 214222

Srivastava AK and Pushpa Agrawal

Table 4 After 72hrs Control (O.D) 0.0 0.0 0.0 Test (O.D) .44 .37 .29 490 380 290 Conc. g/ml % of reducing sugars 5.4 4.2 3.2 % of ethanol 15 13 10

Sl. No

Sample

1 2 3

250C 500C 720C

Table 5 After 120hrs Control (O.D) 0.0 0.0 0.0 Test Conc. g/ml (O.D) .545 .625 .74 550 620 730 sugars 6.1 6.9 8.2 % of reducing % of ethanol 16 10 12

Sl. No

Sample

1 2 3

250C 500C 720C

Table 6 After 168hrs Control (O.D) 0.0 0.0 0.0 Test Conc. g/ml (O.D) .56 .70 .90 555 620 854 sugars 6.16 7.66 9.32 % of reducing % of ethanol 9 14 18

Sl. No

Sample

1 2 3

250C 500C 720C

All rights reserved 2011

www.jamonline.in 219

Jamonline / 2(2); 2012 / 214222

Srivastava AK and Pushpa Agrawal

Variation In Concentration of Reducing Sugar with Time and Temperature

900 800 700 600 500 400 300 200 100 0 24 48 Sample A 25 'C Sample C 70'C 72 120 Time (hrs) 168

Concentration (ug/ml)

Sample B 50 'C

Conclusion It is seen that pretreatment with H2O2 and MnSO4 effectively expels Lignin and Hemicellulose and allow the microorganisms to utilize the cellulose without any hindrance to produce reducing sugar .Sugar conversion from cellulosic materials holds great potential due to the widespread availability, abundance and relatively low cost. In this article Cellulomonas fimi used for saccharification and Zymomonas mobilis used for ethanol production. Many laboratories around the world are involved in research on the different aspects of natural biodegradation of cellulosic All rights reserved 2011

materials. Consequently, processes that use microorganisms are being developed to explore the potential for their

biotechnological application because high cost of cellulase is one of the major hindrance to make the process commercialized. This can be reduced by adopting cellulase producing microorganisms. Acknowledgement The authors thank Prof. B.S. Satyanarayana, Principal R.V. College of Engineering for his constant encouragement and support

throughout the research work.

www.jamonline.in 220

Jamonline / 2(2); 2012 / 214222 References 1. Ballerini D, Desmarquest JP, Pourquie J, Ethanol production from lignocellulosics: Large scale experimentation and

Srivastava AK and Pushpa Agrawal 7. Meinke A, Gilkes N R, Kilburn D G, Warren R A J, Miller R C., Jr . Cellobiohydrolase Cellulomonas analogous to A fimi is a major

-1,4-glucanase reesei

economics, Biores. Tech., 50, 1994, 1723. 2. Lee J W, Gwak K S, Park J Y, et al, Biological pretreatment of softwood Pinus densiflora by three white rot fungi. J Microbiol, 45, 2007, 485491. 3. Singh P, Suman A, Tiwari P,et al, Biological pretreatment of sugarcane trash for its conversion to fermentable sugars. World J Microbial Biotechnol, 24, 2008, 67673. 4. Kuhar S, Nair L M,Kuhad R C,

Trichoderma

cellobiohydrolase II. In: Shimada K, Ohmiya K, Kobayashi Y, Hoshino S, Sakka K, Karita S, editors; Shimada K, Ohmiya K, Kobayashi Y, Hoshino S, Sakka K, Karita S, editors. Genetics, biochemistry and ecology of

lignocellulose degradation. Tokyo, Japan: Uni Publishers; 1993, 286297. 8. Meinke A, Gilkes N R, Kwan E, Kilburn D G, Warren R A J, Miller R C., Jr Cellobiohydrolase A from the cellulolytic bacterium Cellulomonas fimi is a -1,4exocellobiohydrolase Trichoderma reesei analogous CBH II. to Mol

Pretreatment of lignocellulosic material with fungi capable of higher lignin degradation degradation and lower carbohydrate substrate acid

Microbiol,12, 1994, 413422. 9. Shen H, Gilkes N R, Kilburn D G, Miller R C J, Warren R A J. Cellobiohydrolase B (CbhB), a second cellobiohydrolase from the cellulolytic bacterium Cellulomonas fimi. Biochem J.,311,1995, 6774. 10. Shen H, Meinke A, Tomme P, Damude H, Kwan E, Kilburn D G, Miller R C, Jr, Warren R A J, Gilkes N R. Cellulomonas fimi cellobiohydrolases. ACS Symp.,618, 1995, 174196. 11. Gilkes N R, Langsford M L, Kilburn D G, Miller R C, Jr, Warren R A J. Mode of action and substrate specificities of

improves

hydrolysis and the eventual conversion to ethanol. Can J Microbiol, 54, 2008, 305313. 5. Shi J, Chinn M S, Sharma, Shivappa R R, Microbial pretreatment of cotton stalks by solid state cultivation of Phanerochaete chrysosporium. Bioresour Technol, 99, 2008, 65566564. 6. Gilkes N R, Kwan E, Kilburn D G, Miller R C, Warren R A J. Attack of

carboxymethylcellulose at opposite ends by two cellobiohydrolases from

Cellulomonas fimi. J Biotechnol., 57, 1997, 8390 All rights reserved 2011 www.jamonline.in 221

Jamonline / 2(2); 2012 / 214222 cellulases from cloned bacterial genes. J BiolChem.,259,1984,1045510459. 12. Moser B, Gilkes N R, Kilburn D G, Warren R A J, Miller R C., Jr Purification and characterization of endoglucanase C of Cellulomonas fimi, the cloning of its gene, and analysis of in vivo transcripts of the gene. Appl Environ Microbiol, ,55, 1989, 24802487. 13. Tomme P, Kwan E, Gilkes N R, Kilburn D G, Warren R A J. Characterization of CenC, an enzyme from Cellulomonas fimi with both endoand exoglucanase

Srivastava AK and Pushpa Agrawal 18. Sadasivam S.,Manickam A, Biochemical methods,New age international

publishers.,Delhi,2006 19. Manjunath S. Gurav, and G. S. Geeta, Effectiveness of Fungal Pretreatment of Agro Residues on Ethanol Production by Yeasts and Zymomonas mobilis, 2007,

Karnataka J. Agric. Sci, 20 (2), 301-304,

20. Caputi A Jr, Ueda M, Brown T, Spectrophotometric determination of

ethanol in wine. Am. J. Enol. Viti, 19, 1968,160-165

activities. J Bacteriol, 178, 1996, 4216 4223. 14. Kleman-Leyer K M, Gilkes N R, Miller R C, Jr, Kirk T K. Changes in the molecular size distribution of insoluble celluloses by the action of recombinant Cellulomonas fimi cellulases. Biochem J., 302, 1994, 463469. 15. Ong E, Gilkes N R, Miller R C, Jr, Warren R A J, Kilburn D G. The cellulose-binding (CBDCex) domain of an exoglucanase from Cellulomonas fimi: production in Escherichia of the coli and

characterization

polypeptide.

Biotechnol Bioeng.,42, 1993,401409. 16. Tomme P, Warren R A J, Gilkes N R. Cellulose hydrolysis by bacteria and fungi. AdvMicrobPhysiol.,37,1995,181. 17. Miller, G. L, Use of dinitrosalicylic acid reagent for determination of reducing sugar, Anal. Chem, 31, 1959, 426-428.

All rights reserved 2011

www.jamonline.in 222

Potrebbero piacerti anche

- JAM 3 5 1 ReviewDocumento3 pagineJAM 3 5 1 ReviewjamonlineNessuna valutazione finora

- Optical Textures in Liquid Crystal MixturesDocumento6 pagineOptical Textures in Liquid Crystal MixturesjamonlineNessuna valutazione finora

- A Model To Study The Effect of Boiling On Water Borne Bacterial Diarrheal AgentsDocumento6 pagineA Model To Study The Effect of Boiling On Water Borne Bacterial Diarrheal AgentsjamonlineNessuna valutazione finora

- Jam - 3 - 2 - 5 A Comparative Study of Vitex Doniana and Pterocarpus Soyauxi As Corrosion Inhibitors of Mild Steel in HCL MediumDocumento11 pagineJam - 3 - 2 - 5 A Comparative Study of Vitex Doniana and Pterocarpus Soyauxi As Corrosion Inhibitors of Mild Steel in HCL MediumjamonlineNessuna valutazione finora

- Journal of Atoms and MoleculesDocumento14 pagineJournal of Atoms and MoleculesjamonlineNessuna valutazione finora

- A Developed Process For The Synthesis of Tryptophol A Key Starting Material For IndoraminDocumento4 pagineA Developed Process For The Synthesis of Tryptophol A Key Starting Material For IndoraminjamonlineNessuna valutazione finora

- Native Potato Starch Nps Blended With Polypropylene Effect of Soil Burial On Mechanical PropertiesDocumento7 pagineNative Potato Starch Nps Blended With Polypropylene Effect of Soil Burial On Mechanical PropertiesjamonlineNessuna valutazione finora

- Jam - 3 - 3 - 1 A Developed Process For The Synthesis of 2-Ethyl Phenyl Hydrazine Hydrochloride, A Key Starting Material For 7-Ethyl Tryptophol.Documento4 pagineJam - 3 - 3 - 1 A Developed Process For The Synthesis of 2-Ethyl Phenyl Hydrazine Hydrochloride, A Key Starting Material For 7-Ethyl Tryptophol.jamonline100% (3)

- Synthesis and Antioxidant Activity of Some Derivatives of 2 2 Oxo 4 Phenyl 2h Chromen 7 Yloxy Aceto HydrazideDocumento16 pagineSynthesis and Antioxidant Activity of Some Derivatives of 2 2 Oxo 4 Phenyl 2h Chromen 7 Yloxy Aceto HydrazidejamonlineNessuna valutazione finora

- Jam - 3 - 3 - 3 Native Cassava Starch (NCS) / Polypropylene Blends: Effects of Soil Burial On The Mechanical PropertieDocumento7 pagineJam - 3 - 3 - 3 Native Cassava Starch (NCS) / Polypropylene Blends: Effects of Soil Burial On The Mechanical PropertiejamonlineNessuna valutazione finora

- Jam - 3 - 3 - 2 Synthesis and Antimicrobial Activity of Noval Metal Chelates of 2 - (8-Quinolinol-5-Yl) - Methyl Amino - 5 - (4-Methyl-Phenyl) - 1, 3, 4 - Thiadiazole DerivativesDocumento6 pagineJam - 3 - 3 - 2 Synthesis and Antimicrobial Activity of Noval Metal Chelates of 2 - (8-Quinolinol-5-Yl) - Methyl Amino - 5 - (4-Methyl-Phenyl) - 1, 3, 4 - Thiadiazole DerivativesjamonlineNessuna valutazione finora

- Jam - 3 - 2 - 4 Diellectric Relaxation Study of Pentanenitrile With Dichloroethane at 350C Using TDRDocumento5 pagineJam - 3 - 2 - 4 Diellectric Relaxation Study of Pentanenitrile With Dichloroethane at 350C Using TDRjamonlineNessuna valutazione finora

- Jam - 3 - 1 - 3 A Stability - Indicating Liquid Chromatographic Method For The Quantification of Antithyroid Drug PropylthiouracilDocumento9 pagineJam - 3 - 1 - 3 A Stability - Indicating Liquid Chromatographic Method For The Quantification of Antithyroid Drug Propylthiouraciljamonline100% (1)

- Review 1 PHYTOCHEMICAL SCREENING OF PAEDERIA FOETIDA A RARE MEDICINAL PLANT - A REVIEWDocumento6 pagineReview 1 PHYTOCHEMICAL SCREENING OF PAEDERIA FOETIDA A RARE MEDICINAL PLANT - A REVIEWjamonlineNessuna valutazione finora

- Jam - 3 - 2 - 3 Ultrasonic Studies in The Solutions of Three Hydrate Drugs in MethanolDocumento13 pagineJam - 3 - 2 - 3 Ultrasonic Studies in The Solutions of Three Hydrate Drugs in MethanoljamonlineNessuna valutazione finora

- Synthesis and Characterization of Various 3 - (3,5-BisDocumento5 pagineSynthesis and Characterization of Various 3 - (3,5-BisjamonlineNessuna valutazione finora

- Jam - 3 - 2 - 1 Antioxidant Potential of The Leaf Extract of Pilostigma Thonningii (Caesalpiniacea)Documento4 pagineJam - 3 - 2 - 1 Antioxidant Potential of The Leaf Extract of Pilostigma Thonningii (Caesalpiniacea)jamonlineNessuna valutazione finora

- Review 2 HYDROGEN PEROXIDE AS AN OXIDANT FOR ORGANIC REACTIONSDocumento22 pagineReview 2 HYDROGEN PEROXIDE AS AN OXIDANT FOR ORGANIC REACTIONSjamonlineNessuna valutazione finora

- A Sensitive Differential Pulse Adsorptive Stripping VoltammetricDocumento4 pagineA Sensitive Differential Pulse Adsorptive Stripping VoltammetricjamonlineNessuna valutazione finora

- Jam - 3 - 1 - 4 Green Chemistry Approach To Novel Chalcones and Their Antioxidant PropertiesDocumento6 pagineJam - 3 - 1 - 4 Green Chemistry Approach To Novel Chalcones and Their Antioxidant PropertiesjamonlineNessuna valutazione finora

- Journal of Atoms and Molecules: An International Online JournalDocumento6 pagineJournal of Atoms and Molecules: An International Online JournaljamonlineNessuna valutazione finora

- Jam - 3 - 1 - 5 Molecular Interactions of Butanenitrile With Chlorobenzene at 100C Using MicrowavesDocumento5 pagineJam - 3 - 1 - 5 Molecular Interactions of Butanenitrile With Chlorobenzene at 100C Using MicrowavesjamonlineNessuna valutazione finora

- Jam - 3 - 1 - 1 Determination of Fluoride Around in Surajpur District Chhattisgarh, IndiaDocumento11 pagineJam - 3 - 1 - 1 Determination of Fluoride Around in Surajpur District Chhattisgarh, IndiajamonlineNessuna valutazione finora

- Viscosity Dependence of The Rotationational Reorientation ofDocumento12 pagineViscosity Dependence of The Rotationational Reorientation ofjamonlineNessuna valutazione finora

- Reaction of Hydrazine Hydrate and Hydrazine Hydrochloride With Dibenzoylmethane and Flavone Role of Solvent and PH OnDocumento5 pagineReaction of Hydrazine Hydrate and Hydrazine Hydrochloride With Dibenzoylmethane and Flavone Role of Solvent and PH OnjamonlineNessuna valutazione finora

- Scattering Study of Liquid Crystal MixturesDocumento8 pagineScattering Study of Liquid Crystal MixturesjamonlineNessuna valutazione finora

- Microwave Assisted Synthesis, Characterization and ThermalDocumento11 pagineMicrowave Assisted Synthesis, Characterization and ThermaljamonlineNessuna valutazione finora

- Method Development and Validation of Roflumilast in TabletDocumento6 pagineMethod Development and Validation of Roflumilast in TabletjamonlineNessuna valutazione finora

- Study The Molecular Correlation of Pentenenitrile With 1,2Documento5 pagineStudy The Molecular Correlation of Pentenenitrile With 1,2jamonlineNessuna valutazione finora

- Effect of Blanching On Nutreint and Anti-Nutrient Level of LeavesDocumento7 pagineEffect of Blanching On Nutreint and Anti-Nutrient Level of LeavesjamonlineNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Physical Science - q3 - Slm3Documento15 paginePhysical Science - q3 - Slm3Boyet Alvarez AtibagosNessuna valutazione finora

- 2.9&10 Synthesis Adn Stereoisomerism Exam Qs - 4Documento4 pagine2.9&10 Synthesis Adn Stereoisomerism Exam Qs - 4sureshthevanNessuna valutazione finora

- NCL ReportDocumento20 pagineNCL ReportSwati Tripathi33% (3)

- Norris Claire White Paper Liftware PDFDocumento14 pagineNorris Claire White Paper Liftware PDFmeysam NaaNessuna valutazione finora

- Inu 2216 Idt - Question PaperDocumento5 pagineInu 2216 Idt - Question PaperVinil JainNessuna valutazione finora

- (2022) Loneliness Is Associated With Maladaptive Schema Modes in Patients With Persistent Depressive DisorderDocumento5 pagine(2022) Loneliness Is Associated With Maladaptive Schema Modes in Patients With Persistent Depressive DisorderJúlio César SouzaNessuna valutazione finora

- Screening Criteria For Application of EOR Processes in Offshore FieldsDocumento7 pagineScreening Criteria For Application of EOR Processes in Offshore FieldsSajad FalahNessuna valutazione finora

- KitchenAid 5ksm150psDocumento18 pagineKitchenAid 5ksm150psFrancisco AlvarezNessuna valutazione finora

- Blessed Are Those Who MournDocumento7 pagineBlessed Are Those Who MournPatrick MabbaguNessuna valutazione finora

- Hiv MCQDocumento89 pagineHiv MCQEliza Spark80% (5)

- Stakeholders in The Iep Process JDocumento9 pagineStakeholders in The Iep Process Japi-546526887Nessuna valutazione finora

- 6d Class 10Documento10 pagine6d Class 10Euna DawkinsNessuna valutazione finora

- Glaus Corp. inventory note amortization adjusting entryDocumento5 pagineGlaus Corp. inventory note amortization adjusting entryPatrick HarponNessuna valutazione finora

- Making your own Agar PlateDocumento8 pagineMaking your own Agar PlateCheska EngadaNessuna valutazione finora

- 1 s2.0 S0149763418301957 MainDocumento24 pagine1 s2.0 S0149763418301957 MainjackNessuna valutazione finora

- ABS and Air Conditioner Wiring DiagramDocumento207 pagineABS and Air Conditioner Wiring Diagramservice_00783% (30)

- TLE Pre-Assessment Most & Least Learned SkillsDocumento7 pagineTLE Pre-Assessment Most & Least Learned SkillsRd DavidNessuna valutazione finora

- Filipino Nurses' Deep Faith and Cultural Attitudes in HealthcareDocumento41 pagineFilipino Nurses' Deep Faith and Cultural Attitudes in HealthcareKeziah Marie Chua Santa-AnaNessuna valutazione finora

- Masagana High School: Module 4: Planning For Continuing Professional Development and Lac PlanningDocumento6 pagineMasagana High School: Module 4: Planning For Continuing Professional Development and Lac PlanningjhonaNessuna valutazione finora

- Pronunciation Pairs Unit 2-6 Answer KeyDocumento5 paginePronunciation Pairs Unit 2-6 Answer KeyChloe Liu50% (2)

- Distance Protection SchemesDocumento10 pagineDistance Protection SchemesdebasishNessuna valutazione finora

- Bed MakingDocumento14 pagineBed MakingHarold Haze Cortez100% (1)

- Pastillas DelightDocumento12 paginePastillas DelightBryan DutchaNessuna valutazione finora

- Multiple Choice RadioactivityDocumento4 pagineMultiple Choice RadioactivityGodhrawala AliasgerNessuna valutazione finora

- CoWIN Portal StepsDocumento23 pagineCoWIN Portal StepsU VenkateshNessuna valutazione finora

- Star T: Flowchart "Physical Fitness Test"Documento1 paginaStar T: Flowchart "Physical Fitness Test"Eller-Jed Manalac MendozaNessuna valutazione finora

- KGMC DirectoryDocumento6 pagineKGMC DirectoryFaisal KhanNessuna valutazione finora

- Home Study Report of Resident Indian Parent: Name of The Social WorkerDocumento4 pagineHome Study Report of Resident Indian Parent: Name of The Social WorkerVmksNessuna valutazione finora

- Save Our Forests Through Sustainable DevelopmentDocumento33 pagineSave Our Forests Through Sustainable DevelopmentGeehthanJINessuna valutazione finora

- Phychem Expt. 1Documento8 paginePhychem Expt. 1Bren Julius PabloNessuna valutazione finora