Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Process Failure Mode Effects Analysis

Caricato da

sriramachandiraTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Process Failure Mode Effects Analysis

Caricato da

sriramachandiraCopyright:

Formati disponibili

Page 1 of 20

Process Failure Mode Effects Analysis

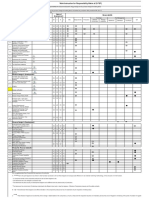

Item/Part#: Rev: Customer: Supplier: Christopher Tool & Mfg. Co. * SEV, OCC, & DET scoring per the tables provided in WPQR-9102, unless otherwise approved by Woodward. Resulting Action(s) Item / Function / Process Description SAWING-Cut blanks 5.937 1/64 long. HEAT TREATHarden, Temper and Stress Relieve Hardness: 30-36 Rc ----------------------Certs Required CNC TURNING CENTER WORKTurn the blank from the right side per CTM T-4836 sheet 1: Face to cleanup only. Center drill #3 MAX as shown. Hold all lengths near mean size for mfg. Inspect runouts: All diameters concentric within .002 T.I.R. 30 CNC TURNING CENTER WORKTurn the blank from the right side per CTM T-4836 sheet 2: Center drill as shown--#4 max. See SS-81. Inspect runout between centers: All diameters concentric within .002 T.I.R. Parts do not meet CTM in-process drawing requirements. Parts will not meet customer requirements. Programming is incorrect. Tools are not setup correctly. Tool breakage. Operators are expected to gage and adjust tooling as needed, plus a 1st. Piece is required to pass our inspection department. Correct program, adjust or replace tooling. S E V C l Potential Cause(s) a / Mechanism(s) of Failure s s Saw is not set-up correctly. Saw malfunction. Oven malfunction. O C C D E T R P N Responsibility & Target Action(s) Taken Completion Date S E V O C C D E T R P N 3595-1038 6 Process Owner: Process: FMEA Team: FMEA #: FMEA Rev: FMEA Date: Prepared by: 3595-1038

Op / Ref #

ID #

Potential Failure Mode

Potential Effect(s) of Failure

Current Controls Prevention

Current Controls Detection

Recommended Action(s)

Blanks are cut undersized. Parts do not meet customer drawing requirements per CTM P.O.

Parts will not be usable for this part. Parts will be reworked or approved by customer.

Measure parts after saw cutting. Certification required.

Adjust saw. Change blade. Anneal and reharden.

10

20

Parts do not meet CTM in-process drawing requirements.

Parts will not meet customer requirements.

Programming is incorrect. Tools are not setup correctly. Tool breakage.

Operators are expected to gage and adjust tooling as needed, plus a 1st. Piece is required to pass our inspection department. 0

Correct program, adjust or replace tooling.

4-06-3451 Rev 1 / 30-Jan-2009

40

O.D. GRINDINGLap grinding centers 100% for mfg. Rough grind the O.D. of the (2) Splines to cleanup only. Leave .005 g/s per side for mfg.

Parts do not meet traveler requirement.

The splines will be undersized.

Machine malfuntion, operator did not check parts.

Visual, and spline gage.

Adjust grinder.

Page 2 of 20

50

DEBURRINGRemove burrs and break sharp edges. See drawing notes.

Part still has burrs or the edges have exceeded the drawing requirements.

Rework parts.

Operator did not see or feel burrs, plus was not able to hold customer tolerances. Inspector was distracted or does not comprehend the dimension.

Visual, and inspection. 0

60

INSPECTION, IN PROCESS-InProcess Inspect prior to outside processes. Verify part count. Verify that all preceding operations have been completed and are signed off.

Inspector did not Rework parts. check dimension Possibly scrap correctly or did not parts. understand the requirement.

Better lighting and magnifying lens for operator. Plus being able to understand and hold customer requirements. Additional blueprint or use of precision gages training.

70

SPLINING & GEAR Spline is CUTTING-Finish undersized. shape and inspect the (2) Involute Splines per Woodward Governor drawing #3595-1038 and drawing notes 8 & 9. Hold concentricity between centers within .001 T.I.R. Gaging requirements per Woodward SS-201 rev. V. ----------------------Certs Required RECEIVING INSPECTIONInspect incoming parts to verify the part count and the vendor compliance to the requirements of the previous operation purchase order. Visually inspect all parts for handling damage (nicks and dings).

Scrap parts.

Incorrect set-up of hob.

Certifications required.

Inspection of parts.

Replace hob.

80

Part count is Short parts, or incorrect. Parts do scrap parts. not meet compliances to the P.O.

Lost or scrapped parts from vendor. Subcontractor did not check parts.

Count and inspect parts to traveler.

4-06-3451 Rev 1 / 30-Jan-2009

90

DEBURRINGRemove burrs and break sharp edges. See drawing notes.

Part still has burrs or the edges have exceeded the drawing requirements.

Rework parts.

Operator did not see or feel burrs, plus was not able to hold customer tolerances.

Visual, and inspection. 0

Better lighting and magnifying lens for operator. Plus being able to understand and hold customer requirements. Anneal and reharden.

Page 3 of 20

100

110

HEAT TREATCore Harden per Woodward Governor drawing 3595-1038, note #12, IAW SP-908 rev. B-B. Core Hardness: 4450 Rc Do not nitride. -----------------Certs Required RECEIVING INSPECTIONInspect incoming parts to verify the part count and the vendor compliance to the requirements of the previous operation purchase order. Visually inspect all parts for handling damage (nicks and dings).

Parts do not meet customer drawing requirements.

Parts will be reworked or approved by customer.

Oven malfunction.

Certification required.

Part count is Short parts, or incorrect. Parts do scrap parts. not meet compliances to the P.O.

Lost or scrapped parts from vendor. Subcontractor did not check parts.

Count and inspect parts to traveler.

120

STRAIGHTENING- Parts do not meet Lap centers 100%. runout Note: Inspect the requirements. parts between centers, and check the true position of the pitch diameters of both splines using gage pins. Use the spline gages. Determine if parts require straightening and record results. Check runout of the finished splines between centers. Maximum runout to be within .001 T.I.R. Also inspect the runout of the datum -A- flange. Straighten and Stress relieve any straightened parts as follows: NOTE: STRESS RELIEF IS REQUIRED.

Rework parts.

Center lap is misaligned, or broken stone. Needs to be straightened.

Measure and record results 100%.

4-06-3451 Rev 1 / 30-Jan-2009

130

O.D. GRINDING***Allow for .005 g/s on the right side face of the large flange.*** Green grind from the left side: Finish grind the LEFT end face. Green grind the datum -A- face, leaving .002 g/s per side. Green grind the spline O.D. leaving .002 g/s per side. Do not grind the O.D. groove or the .320 diameters.

Parts are undersized to the traveler requirements.

Scrap parts.

Machine Malfunction.

Visual and inspect.

Re-dress wheel and change set-up.

Page 4 of 20

140

O.D. GRINDING- Parts are ***Allow for .002 undersized to the g/s on the datum -A- traveler face.*** requirements. Green grind right side diameters: Finish grind the RIGHT end face. Do not grind the existing .350 diameter. Green grind the .3163, Spline O.D and .47525 diameters leaving .002 g/s per side. Leave .002 g/s on the shoulders and chamfers. Green grind the right side of the large flange leaving .002 g/s. (Allow for .002 g/s on datum -A-).

Scrap parts.

Machine Malfunction.

Visual and inspect.

Re-dress wheel and change set-up.

150

O.D. GRINDING***Allow for .002 g/s on the datum -Aface.*** Finish grind the .373/.371 diameter groove, concentric to -Band -C- within .002. Hold 32 Ra finish.

4-06-3451 Rev 1 / 30-Jan-2009

160

EDM MACHINING- Holes are out of EDM angular holes position and as required per oversized. drawing note #11. ***Allow for .002 g/s on datum -Aface.*** Qualification required per SP1084.

Re-work or scrap.

Machine malfunction.

Inspect dimensions.

Change settings or electrodes.

Page 5 of 20

170

DEBURRINGPart still has burrs Remove burrs and or the edges have break sharp edges. exceeded the drawing requirements. NITRIDE-Nitride per Woodward Governor drawing 3595-1038, including drawing notes #7 & #12, IAW SP-908 rev. BB. Core Hardness: 4450 Rc Case Hardness: 90 HR15N Final Case Depth: .006-.015 Recommended Applied Case Depth: .012-.020 Max stock removal after nitriding: .005 Max permissible White Layer: .0004 Inspect Case Depth per drawing note #21. -----------------Certs Required Parts do not meet custom drawing requirements including correct areas to be masked.

Rework parts.

Operator did not see or feel burrs, plus was not able to hold customer tolerances. Atmosphere of application is contaminated.

Visual, and inspection. 0

Better lighting and magnifying lens for operator. Plus being able to understand and hold customer requirements. Monitor settings and inspect.

180

Parts may or maynot be useable pending customer approval.

Hardness check for correct depth and visual of correct areas.

190

O.D. GRINDING- Dimensions are O.D. grind to undersized. remove the excess stock and finish grind the .320 diameters x 2 places to the left of the flange. Finish grind datum A- shoulder. Leave .0005 max lapping stock. Hold best surface finish possible.

Scrap.

Machine malfunction, or incorrect wheel.

Visual and inspect.

Change settings or wheel and re-dress.

4-06-3451 Rev 1 / 30-Jan-2009

200

O.D. GRINDINGGrind from the LEFT side: Finish grind the Spline major diameter. Finish grind the .470/.472 diameter.

Dimensions are undersized.

Scrap.

Machine malfunction, or incorrect wheel.

Visual and inspect.

Change settings or wheel and re-dress.

Page 6 of 20

210

O.D. GRINDING- Dimensions are From the right side: undersized. Remove the excess stock and finish grind the major diameter of the .3125-24 UNFJ-3A thread. Finish grind the .030 X 45 chamfer.

Scrap.

Machine malfunction, or incorrect wheel.

Visual and inspect.

Change settings or wheel and re-dress.

220

O.D. GRINDINGFinish grind all diameters on the right side. Leave .0002 max. lapping stock on the .3163/.3158 and .47525/.47475 diameters. Hold best microfinish possible (8 Ra max, 2 Ra required).

Dimensions are undersized.

Scrap.

Machine malfunction, or incorrect wheel.

Visual and inspect.

Change settings or wheel and re-dress.

230

O.D. GRINDINGFrom the left end: Finish grind the .228/.226 Shear Section diameter.

Dimensions are undersized.

Scrap.

Machine malfunction, or incorrect wheel.

Visual and inspect.

Change settings or wheel and re-dress.

240

DEBURRINGPart still has burrs Remove burrs and or the edges have break sharp edges. exceeded the drawing requirements. THREAD GRINDING-Finish grind the .312524 UNFJ-3A Thread per Woodward Governor specification SS130 rev. CG. Parts do not meet CTM P.O. requirements per drawing.

Rework parts.

Operator did not see or feel burrs, plus was not able to hold customer tolerances. Incorrect set-up. Machine malfunction.

Visual, and inspection. 0

Better lighting and magnifying lens for operator. Plus being able to understand and hold customer requirements.

250

Rework or scrap

Thread gages.

4-06-3451 Rev 1 / 30-Jan-2009

260

SURFACE LAPLap Splines if required to accept Ring Gages.

N/A if already accepted. 0

Page 7 of 20 0

270

WASH PARTSParts are dirty, Wash all parts in clean Zep Dyna 143 solvent, drain and blow dry with clean shop air. Visually inspect parts inside and out for cleanliness. Dip in MIL-C-15074 fingerprint neutralizer and Oil parts to prevent rusting.

Rework.

Used a different cleaning solvent.

Visual

Improve training and directions on traveler.

280

INSPECTION, IN PROCESS-InProcess Inspect prior to outside processes. Verify part count. Verify that all preceding operations have been completed and are signed off.In-Process Inspect prior to outside processes.

Inspector did not Rework parts. check dimension Possibly scrap correctly or did not parts. understand the requirement.

Inspector was distracted or does not comprehend the dimension.

Additional blueprint or use of precision gages training.

290

SURFACE LAPParts are out of Finish lap the tolerance. datum -A- shoulder to attain .000025 flatness and 2 Ra microfinish per the requirements of Woodward Governor drawing 3595-1038 and drawing notes #13 and #15. Also lap the opposite shoulder to satisfy drawing requirements. Ring Lap the .47525/.47475 [-B] diameter and the .3163/.3158 diameter to meet the 2 Ra drawing requirement.

Rework

Incorrect lapping compound or procedure.

Measure flatness and microfinish.

Monitor and inspect .

4-06-3451 Rev 1 / 30-Jan-2009

300

RECEIVING INSPECTIONInspect incoming parts to verify the part count and the vendor compliance to the requirements of the previous operation purchase order. Visually inspect all parts for handling damage (nicks and dings).

Page 8 of 20

310

LASER MARKING- Incorrect marking Laser mark on the or location. noted area as required per drawing note #10 Mark as follows: 66503-3595-1038 4

Rework

Operator misinterpreted the location or entered wrong numbers/letters into the machine.

Visual and approval by different person.

Improve training and notes in files.

320

INSPECTION, IN PROCESS-InProcess Inspect prior to outside processes. Verify part count. Verify that all preceding operations have been completed and are signed off.

Inspector did not Rework parts. check dimension Possibly scrap correctly or did not parts. understand the requirement.

Inspector was distracted or does not comprehend the dimension.

Additional blueprint or use of precision gages training.

330

MISC. COATINGS- Coating is Brush Coat noted inadequate or area only, with the wrong location. required material, per drawing notes #18 and #19. Material: Corrosion Preventative film per WoodwardGovernor SP-949 rev. Y (Sandstrom 9AV-35 or alternates). ---------------------Certs Required

Rework

Rust or discoloration on part.

Visual.

Replace outdated coating.

4-06-3451 Rev 1 / 30-Jan-2009

340

RECEIVING INSPECTIONInspect incoming parts to verify the part count and the vendor compliance to the requirements of the previous operation purchase order. Visually inspect all parts for handling damage (nicks and dings).

Part count is Short parts, or incorrect. Parts do scrap parts. not meet compliances to CTM P.O.

Lost or scrapped parts from vendor.

Count and inspect parts to traveler.

Page 9 of 20

350

INSPECTION, FINAL-Final Inspect complete per drawing and the requirements of the Customer Purchase Order. PRE-SHIPPINGINSPECTION-Prior to packing, when all parts are complete, inspect this traveler to verify all operations have been signed off and all part counts are correct. Visually inspect the entire lot for foreign objects (chips/dirt inside and out), the correct marking, handling nicks and general appearance.

Inspector did not Out of tolerance check dimension part gets to correctly or did not customer. understand the requirement.

Inspector was distracted or does not comprehend the dimension.

Documentation of all dimensions per customer requirements and CTM AQL .

Implement SPC monitoring throughout the manufacturing process.

360

Incorrect quantity, dirty or nicked parts, operations are not signed off.

Rework

An operation was not completed. Parts were not cleaned properly.

Visual.

Standart checklist of criteria before packing.

4-06-3451 Rev 1 / 30-Jan-2009

370

PACKAGE PARTS- Not properly Dip in Preserative packaged for Oil and drain. handling. Place in **VCI** plastic bags and heat seal. Package in protective containers as required. Pack containers in an appropriate box with all necessary certifications and inspection reports. Label package and attach shipping carrier label. Place package on the proper cart to be picked-up by the shipping carrier.

Parts may become nicked or broken and possible scrap.

Incorrect packaging.

Traveler sign-off.

Improve traveler instructions for proper packaging.

Page 10 of 20

4-06-3451 Rev 1 / 30-Jan-2009

Page 11 of 20

e Mode Effects Analysis

3595-1038

Resulting Action(s)

Status

4-06-3451 Rev 1 / 30-Jan-2009

Page 12 of 20

4-06-3451 Rev 1 / 30-Jan-2009

Page 13 of 20

4-06-3451 Rev 1 / 30-Jan-2009

Page 14 of 20

4-06-3451 Rev 1 / 30-Jan-2009

Page 15 of 20

4-06-3451 Rev 1 / 30-Jan-2009

Page 16 of 20

4-06-3451 Rev 1 / 30-Jan-2009

Page 17 of 20

4-06-3451 Rev 1 / 30-Jan-2009

Page 18 of 20

4-06-3451 Rev 1 / 30-Jan-2009

Page 19 of 20

4-06-3451 Rev 1 / 30-Jan-2009

Page 20 of 20

4-06-3451 Rev 1 / 30-Jan-2009

Potrebbero piacerti anche

- Sample FMEADocumento20 pagineSample FMEATaufikRasyadiNessuna valutazione finora

- GS-0002D, Design FMEADocumento26 pagineGS-0002D, Design FMEAmesa142100% (1)

- NCR Supplier PPAP Training PresentationDocumento166 pagineNCR Supplier PPAP Training PresentationAmitava Datta67% (3)

- IATF16949+Chapter+21 +Automotive+Core+ToolsDocumento18 pagineIATF16949+Chapter+21 +Automotive+Core+ToolsNhựt Nguyễn HữuNessuna valutazione finora

- Design Verification Process Project III Samudra Indonesia 20/11/2019 Samudra Indonesia 21/12/2019 See Project III R1 ReportDocumento6 pagineDesign Verification Process Project III Samudra Indonesia 20/11/2019 Samudra Indonesia 21/12/2019 See Project III R1 ReportAufa Jaya Perkasa LegalityNessuna valutazione finora

- SAMPLE - Process FlowDocumento2 pagineSAMPLE - Process Flowakav123Nessuna valutazione finora

- APQP ENG SiemensDocumento12 pagineAPQP ENG SiemensVikash KumarNessuna valutazione finora

- FMEA PDocumento6 pagineFMEA Pparu1982Nessuna valutazione finora

- IMM Process SetupsDocumento25 pagineIMM Process Setupslam nguyen100% (1)

- VDA-RGA Questionaire V2.0Documento70 pagineVDA-RGA Questionaire V2.0docsenNessuna valutazione finora

- Apqp Ppap TrainingDocumento2 pagineApqp Ppap TrainingAnkur DhirNessuna valutazione finora

- AIAG - Production Part Approval Process (PPAP) 4th EditionDocumento74 pagineAIAG - Production Part Approval Process (PPAP) 4th EditionIvan Bolivar BarrazaNessuna valutazione finora

- MACE - Formats - 015 - APQP Matrix Sign OffDocumento3 pagineMACE - Formats - 015 - APQP Matrix Sign OffMohit KaushikNessuna valutazione finora

- Reaction PlanDocumento14 pagineReaction PlanMariaNilaZaragozaPalacioNessuna valutazione finora

- PpapDocumento3 paginePpapVlad NitaNessuna valutazione finora

- PPAP ChecklistDocumento4 paginePPAP ChecklistHirbod HirmandNessuna valutazione finora

- Special Processes: Molding System AssessmentDocumento54 pagineSpecial Processes: Molding System AssessmentisolongNessuna valutazione finora

- PFMEA For Injection Molding ProcessDocumento2 paginePFMEA For Injection Molding ProcessDhananjay Patil100% (2)

- FMEADocumento6 pagineFMEANavnath TamhaneNessuna valutazione finora

- Training in MSA PQ Systems Training Material PDFDocumento109 pagineTraining in MSA PQ Systems Training Material PDFsaby aroraNessuna valutazione finora

- DRBFM WorksheetDocumento1 paginaDRBFM WorksheetHareth MRAIDINessuna valutazione finora

- Moudling Operation GSIC Process: MouldingDocumento13 pagineMoudling Operation GSIC Process: MouldingBalakumaran MurugesanNessuna valutazione finora

- Setting Process Conditions - Injection MoldingDocumento44 pagineSetting Process Conditions - Injection MoldingRaja PandiNessuna valutazione finora

- Setco Automotive LTD.: NP ChartDocumento4 pagineSetco Automotive LTD.: NP ChartDisha ShahNessuna valutazione finora

- TS-16949 GM Customer-Specific RequirementsDocumento13 pagineTS-16949 GM Customer-Specific Requirementstsllwt100% (1)

- APQP Supplier ProcedureDocumento20 pagineAPQP Supplier ProcedurepharmatonNessuna valutazione finora

- APQPDocumento2 pagineAPQPjitenderbawalia0% (1)

- Mizenboushi Method (未然防止法) : Good Design, Good Discussion, Good DissectionDocumento45 pagineMizenboushi Method (未然防止法) : Good Design, Good Discussion, Good DissectionXin Li100% (1)

- PFMEA AuditingDocumento18 paginePFMEA AuditingelevendotNessuna valutazione finora

- The Basics of PPAPDocumento29 pagineThe Basics of PPAPஎன் கருத்துNessuna valutazione finora

- Dfmea TemplateDocumento5 pagineDfmea TemplateHerbert WeigeltNessuna valutazione finora

- GM 1927-01 Project Plan March 2007Documento1 paginaGM 1927-01 Project Plan March 2007hmp90Nessuna valutazione finora

- Statistical Process ControlDocumento34 pagineStatistical Process ControlSurya BakshiNessuna valutazione finora

- Control Plan FormDocumento1 paginaControl Plan Formlalodevera100% (1)

- BMW FmeaDocumento48 pagineBMW FmeaDearRed FrankNessuna valutazione finora

- What Is APQPDocumento2 pagineWhat Is APQPshanramaNessuna valutazione finora

- Fit/Function KPC:: Special Characteristics 11.1 Key Product Characteristic (KPC) DefinitionsDocumento3 pagineFit/Function KPC:: Special Characteristics 11.1 Key Product Characteristic (KPC) Definitions57641Nessuna valutazione finora

- Measurement System Analysis LabDocumento32 pagineMeasurement System Analysis LabAnonymous 3tOWlL6L0U100% (1)

- Apqp Advanced Product Quality PlanningDocumento27 pagineApqp Advanced Product Quality PlanningRajesh KumarNessuna valutazione finora

- Analisis POT VDA 6.3 2010-1Documento11 pagineAnalisis POT VDA 6.3 2010-1Luis Sosa100% (1)

- Apqp PlanDocumento3 pagineApqp Plananon-448387100% (1)

- Nozzle E1 215-225 215-225 E2 220-230 220-230 E3 200-210 200-210 Hopper E4 175-185 175-185Documento1 paginaNozzle E1 215-225 215-225 E2 220-230 220-230 E3 200-210 200-210 Hopper E4 175-185 175-185KodhansNessuna valutazione finora

- APQPDocumento3 pagineAPQPapi-3742290100% (10)

- S ApqpDocumento15 pagineS ApqpIram ChaviraNessuna valutazione finora

- Global 8d WorkbookDocumento20 pagineGlobal 8d Workbookapi-556601577Nessuna valutazione finora

- PT Vs SOP 17 Tooling RepairDocumento7 paginePT Vs SOP 17 Tooling RepairRidwanNessuna valutazione finora

- Injection Molding DOEDocumento8 pagineInjection Molding DOEMatt McLouthNessuna valutazione finora

- ChryslerDocumento117 pagineChryslerdokser29100% (1)

- Responsibility Rank of Development: D:/APQP Document/ Special Product and Process CharactesticsDocumento4 pagineResponsibility Rank of Development: D:/APQP Document/ Special Product and Process CharactesticsAL BARAKAH GRAINS100% (1)

- Control PlanDocumento1 paginaControl PlanAmit PatelNessuna valutazione finora

- Risk Management Using Failure Mode and Effect Analysis (FMEA)Da EverandRisk Management Using Failure Mode and Effect Analysis (FMEA)Nessuna valutazione finora

- Design For Manufacture And Assembly A Complete Guide - 2020 EditionDa EverandDesign For Manufacture And Assembly A Complete Guide - 2020 EditionNessuna valutazione finora

- Manufacturing Facilities A Complete Guide - 2019 EditionDa EverandManufacturing Facilities A Complete Guide - 2019 EditionNessuna valutazione finora

- Process Improvement Simplified: A How-to-Book for Success in any OrganizationDa EverandProcess Improvement Simplified: A How-to-Book for Success in any OrganizationNessuna valutazione finora

- Assembly Process A Complete Guide - 2020 EditionDa EverandAssembly Process A Complete Guide - 2020 EditionNessuna valutazione finora

- 1 s2.0 S2590123021000220 MainDocumento12 pagine1 s2.0 S2590123021000220 MainAulia Sukma HutamaNessuna valutazione finora

- Staal 40: Gate ValvesDocumento8 pagineStaal 40: Gate ValvesEric LarrondoNessuna valutazione finora

- UNIBEN Physical Science and Engineering Page 1-69Documento70 pagineUNIBEN Physical Science and Engineering Page 1-69kelvin ikerionwuNessuna valutazione finora

- Concentration CalculationsDocumento5 pagineConcentration CalculationsSiyah HashTagNessuna valutazione finora

- Injection MouldingDocumento241 pagineInjection MouldingRAJESH TIWARINessuna valutazione finora

- P2 Standard Reduction Potentials by ValueDocumento6 pagineP2 Standard Reduction Potentials by ValueASTRID ELIZABET CUEVA GUTIERREZNessuna valutazione finora

- E-Program Files-AN-ConnectManager-SSIS-MSDS-PDF-HFA062 - NZ - EN - 20160512 - 1Documento10 pagineE-Program Files-AN-ConnectManager-SSIS-MSDS-PDF-HFA062 - NZ - EN - 20160512 - 1Alex MaduNessuna valutazione finora

- Chemistry Revision Test - No. 5 (Haloalkanes & Haloalkanes & Alcohols, Phenols & Ethers)Documento9 pagineChemistry Revision Test - No. 5 (Haloalkanes & Haloalkanes & Alcohols, Phenols & Ethers)Charles Murgasan Charles MurgasanNessuna valutazione finora

- Vector 4114NS Sis TDSDocumento2 pagineVector 4114NS Sis TDSCaio OliveiraNessuna valutazione finora

- Evonik Products CatalogDocumento43 pagineEvonik Products Catalog李雷Nessuna valutazione finora

- EOA 2023 VISIOMER Portfolio Brochure en Digital RZ InteraktivDocumento13 pagineEOA 2023 VISIOMER Portfolio Brochure en Digital RZ Interaktivichsan hakimNessuna valutazione finora

- Concept of Acid and Base: By, Lipsa Samal Asst. Prof (Pa & Qa), SPLS, CutmDocumento7 pagineConcept of Acid and Base: By, Lipsa Samal Asst. Prof (Pa & Qa), SPLS, Cutmkenjistorage1Nessuna valutazione finora

- Msds EthanolDocumento7 pagineMsds EthanolHeru HarnadiNessuna valutazione finora

- Exam Q'sDocumento15 pagineExam Q'smedindedic1Nessuna valutazione finora

- IBDP Biology Syllabus (2025)Documento75 pagineIBDP Biology Syllabus (2025)Alexander Stip MartínezNessuna valutazione finora

- RRRRRR Chido ReactHetExamenOrdinarioJunio2020aDocumento4 pagineRRRRRR Chido ReactHetExamenOrdinarioJunio2020aDaniel Moreno CabreraNessuna valutazione finora

- Mosselman Cosmetic IngredientsDocumento12 pagineMosselman Cosmetic Ingredientszaryab khan100% (1)

- Sawoszczuk 2015Documento16 pagineSawoszczuk 2015VincentNessuna valutazione finora

- Silica Sand LOIDocumento3 pagineSilica Sand LOIJody SubiyantoroNessuna valutazione finora

- Chem Experiment #2Documento5 pagineChem Experiment #2FAITH ALBAÑEZNessuna valutazione finora

- BiochemistryDocumento504 pagineBiochemistryeleonora josimovicNessuna valutazione finora

- Enrique Cavazos - Week1Grade7ScienceDocumento25 pagineEnrique Cavazos - Week1Grade7ScienceEnrique CavazosNessuna valutazione finora

- Universiti Teknologi Mara Test: Instructions To CandidatesDocumento13 pagineUniversiti Teknologi Mara Test: Instructions To CandidatesNur Anish Amira SalimNessuna valutazione finora

- Laboratory: (Contribution FromDocumento4 pagineLaboratory: (Contribution FromHarmanNessuna valutazione finora

- Voltage Reference Modifications - Replacing The LM336Z 5.0V ReferenceDocumento1 paginaVoltage Reference Modifications - Replacing The LM336Z 5.0V ReferenceMoseley MirandaNessuna valutazione finora

- Naming Compounds HandoutsDocumento10 pagineNaming Compounds HandoutsNICOLE ANGELIQUE M. DINOYNessuna valutazione finora

- ChemEng Lab Midterm ExamDocumento1 paginaChemEng Lab Midterm ExamLawrence Abram AlcantaraNessuna valutazione finora

- FMS PD02a Mixture and SolubilityDocumento24 pagineFMS PD02a Mixture and SolubilityValop masterNessuna valutazione finora

- Preparing Microemulsions With Silicone SurfactantsDocumento2 paginePreparing Microemulsions With Silicone SurfactantsAlain Briones-VázquezNessuna valutazione finora

- Combustion and Flame Volume 123 Issue 1-2 2000 [Doi 10.1016_s0010-2180(00)00144-9] J.J Saastamoinen; R Taipale; M Horttanainen; P Sarkomaa -- Propagation of the Ignition Front in Beds of Wood ParticlesDocumento13 pagineCombustion and Flame Volume 123 Issue 1-2 2000 [Doi 10.1016_s0010-2180(00)00144-9] J.J Saastamoinen; R Taipale; M Horttanainen; P Sarkomaa -- Propagation of the Ignition Front in Beds of Wood Particleshamed12077Nessuna valutazione finora

![Combustion and Flame Volume 123 Issue 1-2 2000 [Doi 10.1016_s0010-2180(00)00144-9] J.J Saastamoinen; R Taipale; M Horttanainen; P Sarkomaa -- Propagation of the Ignition Front in Beds of Wood Particles](https://imgv2-2-f.scribdassets.com/img/document/218948874/149x198/3faec8205c/1397800744?v=1)