Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Exercise 3 (Rice Static Head)

Caricato da

real75Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Exercise 3 (Rice Static Head)

Caricato da

real75Copyright:

Formati disponibili

AENG 233 Agricultural Process Engineering

Name: Renel M . Alucilja Professor: Dr. Ernesto P. Lozada

Date Performed: November 26, 2010 Date Submitted: December 2, 2010 Exercise No. 3 Resistance Data for Rice

I. Introduction Friction losses through agricultural products has been established for several crops especially. These friction losses are a vital data on which engineers rely on designing bins, silos and dryers. Most of the crops that have available data are corn and soybeans. For rice, there are existing data that can be found but are yet to be established or verified. In evaluation the friction loss, this paper limits the evaluation by comparing the static head at the base of the bin or the perforated floor. Considering that the air on top of the grain is zero, the reading on the static head is actually the pressure drop along the depth of the grain at a given air flow rate. This will established a required power input need for the certain air mass flow rate passing through.

II. Objectives: At the end of the exercise the student must be able to: 1. Established a model for Friction losses on air passing through a depth of grain. 2. To familiarize the student on the process on determining the head loss through a depth of grain. III. Materials 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Portable ventilator Measuring Tape Hose pipet water Pitot-tube Dwyer Manometer Improvised air duct (4.5) Improvised Grain bin Inverter

IV. Methodology 1. 2. 3. 4.

Setup the pipe duct, air ventilator and the grain bin as shown in figure 1. Fill the bin to a desired depth. Take reading of velocity in the pipe following the recommended static head. A split plot design for reading then be recorded at its desired depth at different static head. This can be achieved by regulating the air flow rate . 5. Take 3 readings of velocity at each depth in varying static head following the split splot design. 6. Analyze the data.

V. Figures/ Data Sheet a. Exercise setup

2 "2

i t o

5 .25 "

V -1

7 .45 "

4 .5 "

t e

1 '0

b. bin measurement

2 "2 1 "6

5 .25 "

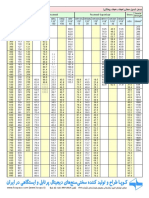

Table 1. Data for Velocity and Pressure for Rice taken from Four Different Depth( 0.75 ft, 1.5 ft, 2.25 ft and 3 ft) and Four Different Air Pressure(0.5 in, 1.0 in , 1.5 in and 2 in of water) in Split Plot Design with Three(3) replications

Air Pressure(Static)

Pressure(in of water) and Velocity, ft/min Rep I Rep II A1(0.75 ft) Rep III

b1(0.5 in) b2(1.0 in) b3(1.5 in) b4(2.0 in) b1(0.5 in) b2(1.0 in) b3(1.5 in) b4(2.0 in) b1(0.5 in) b2(1.0 in) b3(1.5 in) b4(2.0 in) b1(0.5 in) b2(1.0 in) b3(1.5 in) b4(2.0 in)

0.09, 1200 0.21, 1800 0.33, 2400 0.49, 2800

0.10, 1300 0.21, 1900 0.34, 2350 0.50, 2810

0.09, 1250 0.22, 1900 0.36, 2400 0.48, 2800

A2(1.5 ft)

0.06, 1000 0.11, 1300 0.17, 1650 0.24, 1980 0.05, 1000 0.10, 1300 0.16, 1650 0.24, 1990 0.05, 950 0.10, 1320 0.16, 1600 0.25, 2000

A3(2.25ft)

0.04, 800 0.08, 1100 0.11, 1380 0.17, 1650 0.04, 850 0.08, 1150 0.11, 1400 0.17, 1650 0.035, 800 0.08, 1200 0.11, 1400 0.17, 1650

A4(3 ft)

0.03, 700 0.06, 1000 0.09, 1250 0.13, 1500 0.03, 700 0.06, 1050 0.09, 1200 0.14, 1500 0.03, 700 0.06, 1000 0.09, 1250 0.13, 1500

VI. Results and Discussion Results shows that the mean static head loss is directly proportional to the volume flow rate of air and depth of the grain. It show that as the depth is increase, their would be a corresponding head loss. Also an increase in the volume flow rate will also result to an increase of the Static head loss. Looking at the graph, one can easily estimate the expected head loss given the depth of the rice grain and the volume flow rate of air. The graph is then tested for different models of trend line. The results shows that the curve mostly fit to a logarithmic trend. (Graph 2.). The graph also shows that the coefficient of determination (r2) of both 4 graphs has a value ranging from 97 to 100. Which means that using this model will give a high predictability.

RATE OF AIR FLOW (Cu. Ft/min sq ft)

140 120

for Various Static Head Loss

Static Head Loss

0.5 1 1.5 2

Volume Flow Rate

100 80 60 40 20 0 0.5 1 1.5 2 2.5 3 3.5

Depth of Rice Grain

Graph 1:

RATE OF AIR FLOW (Cu. Ft/min sq ft)

for Various Static Head Loss

140 120

Volume Flow Rate

100 80 60 40 20 0 0.5 1 1.5 2 2.5 3 3.5

Static Head Loss

0.5 1 1.5 2

Depth of Rice Grain

Graph 2:

V.

Appendices:

Computation: The volume flow rate of air per square feet is computed as follows.

Q=

Total Volume Flow QTOTAL Area of Bin A

QTOTAL=Velocity @ Pipe x Area of Pipe

Summary of Computation

Depth 0.75 1.5 2.25 3

0.5 1250 983.33 816.67 700

Velocity 1 1.5 2 1866.67 2383.33 2803.33 1306.67 1633.33 1990 1150 1393.33 1650 1016.67 1233.33 1500

Volume Flow Rate (ft3/sec)/Head (in water) 0.5 1 1.5 2 56.48 84.34 107.69 126.66 44.43 59.04 73.8 89.91 36.9 51.96 62.95 74.55 31.63 45.94 55.73 67.77

Potrebbero piacerti anche

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Awwa C604Documento64 pagineAwwa C604Mahdi MoarrefNessuna valutazione finora

- Ships Spares CatalogueDocumento35 pagineShips Spares CatalogueChittagong Port AgentNessuna valutazione finora

- Leakage Calculation Through ClearancesDocumento7 pagineLeakage Calculation Through Clearanceschandrasingh4564Nessuna valutazione finora

- 4we6 Series 6xDocumento12 pagine4we6 Series 6xJas SumNessuna valutazione finora

- PDIL-Stress Analysis Design Basis PDFDocumento13 paginePDIL-Stress Analysis Design Basis PDFDarshan Panchal100% (1)

- Mountain Trike Owners ManualDocumento36 pagineMountain Trike Owners ManualsiguinolfiNessuna valutazione finora

- SD110 Operator Manual Eng - GB - 20026436Documento213 pagineSD110 Operator Manual Eng - GB - 20026436mliugong94% (16)

- TDI Injection and Glow Plug System 6-Cyl 3 0 LTR 4-Valve Common Rail Generation IIDocumento87 pagineTDI Injection and Glow Plug System 6-Cyl 3 0 LTR 4-Valve Common Rail Generation IIergdegNessuna valutazione finora

- VTA28-G5: Specification SheetDocumento10 pagineVTA28-G5: Specification SheetRafatHatmNessuna valutazione finora

- C9 - Modern Robotics Mechanics, Planning, and Control by Frank C. Park Kevin M. Lynch - 2Documento1 paginaC9 - Modern Robotics Mechanics, Planning, and Control by Frank C. Park Kevin M. Lynch - 2Thế AnhNessuna valutazione finora

- 1 s2.0 S1270963820308646 MainDocumento12 pagine1 s2.0 S1270963820308646 MainSrushtiNessuna valutazione finora

- Specification Pendant TRUPORT 5000 (Trumpf-Germany)Documento2 pagineSpecification Pendant TRUPORT 5000 (Trumpf-Germany)Rizkiana SamarindNessuna valutazione finora

- Powerworld R290 Air To Water Heat Pump CatalogueDocumento6 paginePowerworld R290 Air To Water Heat Pump CatalogueFelix CaileanNessuna valutazione finora

- Valve Linkage Dual RockerDocumento1 paginaValve Linkage Dual RockerQTG channelNessuna valutazione finora

- CASE IH Farmall 115U EP Tractor Service Repair ManualDocumento30 pagineCASE IH Farmall 115U EP Tractor Service Repair Manualejky93201573Nessuna valutazione finora

- 06 Transmission and AxlesDocumento33 pagine06 Transmission and AxlesOsvaldo Donoso TorresNessuna valutazione finora

- Interior Components Diagram and Parts ListDocumento6 pagineInterior Components Diagram and Parts ListSoluciones Tecnicas GastronomicasNessuna valutazione finora

- Design of Strip FootingDocumento8 pagineDesign of Strip FootingJaime Manalili Landingin0% (1)

- Demag Drives PDFDocumento24 pagineDemag Drives PDFRafael Linarez100% (1)

- Atomic PhysicsDocumento24 pagineAtomic PhysicsReddyvari VenugopalNessuna valutazione finora

- Comapany Profile Gogreen OverseasDocumento23 pagineComapany Profile Gogreen OverseasKunal SuhagiyaNessuna valutazione finora

- Lab Report 2: BTM 2243 Fluid Power TechnologyDocumento5 pagineLab Report 2: BTM 2243 Fluid Power TechnologyIbrahim AdhamNessuna valutazione finora

- FMM Pump Lecture 2022 23Documento25 pagineFMM Pump Lecture 2022 23LolmaoNessuna valutazione finora

- Hardness Conversion Table: Tensile StrengthDocumento1 paginaHardness Conversion Table: Tensile StrengthMehdy HosseiniNessuna valutazione finora

- Geotech Final ReportDocumento38 pagineGeotech Final Reportapi-320590292Nessuna valutazione finora

- Hazop Action Sheet: Project Title Yanbu Phase 3 Power & Desalination Plant Interfaces P&ID Drawing NoDocumento4 pagineHazop Action Sheet: Project Title Yanbu Phase 3 Power & Desalination Plant Interfaces P&ID Drawing NoVijaya Seharan NairNessuna valutazione finora

- Data - TristarDocumento4 pagineData - TristarQuỳnh NhưNessuna valutazione finora

- (PPT 2 AerodyamicsDocumento43 pagine(PPT 2 AerodyamicsInnocent12345Nessuna valutazione finora

- Viscoelastic Damping 101: Paul Macioce, Roush Industries, IncDocumento3 pagineViscoelastic Damping 101: Paul Macioce, Roush Industries, IncvdertiNessuna valutazione finora