Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Quadrant EPP Ketron® PEEK 1000 Polyetheretherketone, Unfilled, Extruded Material Data Sheet

Caricato da

Ramez NakadDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Quadrant EPP Ketron® PEEK 1000 Polyetheretherketone, Unfilled, Extruded Material Data Sheet

Caricato da

Ramez NakadCopyright:

Formati disponibili

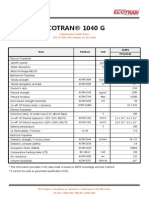

Quadrant EPP Ketron PEEK 1000 Polyetheretherketone, unfilled, extruded Material Data Sheet

Ketron PEEK grades offer chemical and hydrolysis resistance similar to PPS, but can operate at higher temperatures. Unreinforced, extruded Ketron PEEK offers good wear resistance and can be used continuously to 480F (250C). It can also be used in hot water or steam without permanent loss in physical properties. For hostile environments, PEEK is a high strength alternative to fluoropolymers. PEEK carries a V-O flammability rating and exhibits very low smoke and toxic gas emission when exposed to flame.

Physical Properties Specific Gravity Water Absorption

Metric 1.31 g/cc 0.1 %

English Comments 0.0473 lb/in ASTM D792 0.1 % Immersion, 24hr; ASTM D570(2)

Water Absorption at Saturation

0.5 %

0.5 % Immersion; ASTM D570(2)

Mechanical Properties Hardness, Rockwell M Hardness, Rockwell R Hardness, Shore D Tensile Strength, Ultimate Elongation at Break Tensile Modulus Flexural Modulus Flexural Yield Strength Compressive Strength Compressive Modulus Shear Strength Coefficient of Friction 100 126 85 110 MPa 40 % 4.34 GPa 4.14 GPa 172 MPa 138 MPa 3.45 GPa 55.2 MPa 0.4 100 ASTM D785 126 ASTM D785 85 ASTM D2240

16000 psi ASTM D638 40 % ASTM D638 630 ksi ASTM D638 600 ksi ASTM D790 25000 psi ASTM D790 20000 psi 10% Def.; ASTM D695

500 ksi ASTM D695 8000 psi ASTM D732 0.4 Dry vs. Steel; QTM55007 QTM 55010 4:1 safety factor; QTM 55007

K (wear) Factor Limiting Pressure Velocity

755 x 10-8 mm/N-M 375 x 10-10 in-min/ft-lb-hr 0.298 MPa-m/sec 8500 psi-ft/min

Izod Impact, Notched

0.534 J/cm

1 ft-lb/in ASTM D256 Type A

Electrical Properties Surface Resistivity per Square Dielectric Constant Dielectric Strength Min 1e+013 ohm 3.3 18.9 kV/mm Min 1e+013 ohm 3.3 480 V/mil EOS/ESD S11.11 1MHz; ASTM D150 Short Term; ASTM D149 1MHz; ASTM D150

Dissipation Factor

0.003

0.003

Thermal Properties CTE, linear 68F 46.8 m/m-C 26 in/in-F (-40F to 300F); ASTM E831 ASTM F433 Crystalline, Peak; ASTM D3418 Long Term 1/8 inch

Thermal Conductivity Melting Point

0.252 W/m-K 340 C

1.75 BTU-in/hr-ft-F 644 F

Maximum Service Temperature, Air Deflection Temperature at 1.8 MPa (264 psi) Flammability, UL94 (Estimated Rating) Qualitative Processing Properties Compliance - FDA Machinability Service in Alcohols Service in Aliphatic Hydrocarbons Service in Aromatic Hydrocarbons Service in Chlorinated Solvents Service in Ethers Service in Ketones Service in Strong Acids Service in Strong Alkalies Service in Sunlight Service in Weak Acids Service in Weak Alkalies

249 C 160 C V-0

480 F V-0

320 F ASTM D648

Compliant 5 Acceptable Acceptable Acceptable Acceptable Acceptable Acceptable Limited Acceptable Limited Acceptable Acceptable 1-10, 1=Easier to Machine

All statements, technical information and recommendations contained in this database are presented in good faith, based upon tests believed to be reliable and practical field experience. The reader is cautioned, however, that Quadrant EPP and Automation Creations, Inc. cannot guarantee the accuracy or completeness of this information, and it is the customer's responsibility to determine the suitability of Quadrant EPP's products in any given application.

Call Professional Plastics at (888) 995-7767 or E-Mail sales@proplas.com

Order Online at www.professionalplastics.com

Potrebbero piacerti anche

- Compd Data Sheet 1040G ASTM Ver 150106Documento1 paginaCompd Data Sheet 1040G ASTM Ver 150106nimonhNessuna valutazione finora

- Set 7Documento11 pagineSet 7Tare Er Kshitij100% (1)

- Sanalite Hdpe Hoja TecnicaDocumento1 paginaSanalite Hdpe Hoja TecnicaFreddy VeraNessuna valutazione finora

- Nylon MC901Documento2 pagineNylon MC901V ShankarNessuna valutazione finora

- peekDocumento23 paginepeekwamikshahidrizviNessuna valutazione finora

- Ensinger Tecapeek® CF30 Polyetheretherketone, 30% Carbon Reinforced (PEEK)Documento2 pagineEnsinger Tecapeek® CF30 Polyetheretherketone, 30% Carbon Reinforced (PEEK)Arthur EmidioNessuna valutazione finora

- MaterialData - Nylon 101Documento3 pagineMaterialData - Nylon 101maxthesuperiorNessuna valutazione finora

- Air/Ship Microwave Material With High Performance: Excellent Dimensional Stability & Phase StabilityDocumento4 pagineAir/Ship Microwave Material With High Performance: Excellent Dimensional Stability & Phase StabilityDale XiaoNessuna valutazione finora

- ETFE Vs ECTFE PDFDocumento2 pagineETFE Vs ECTFE PDFpinkNessuna valutazione finora

- UHMW-PE Tivar 1000Documento2 pagineUHMW-PE Tivar 1000centurion2988Nessuna valutazione finora

- PTFE DatasheetDocumento2 paginePTFE DatasheetthodatisampathNessuna valutazione finora

- (PTFE) Polytetrafluoroethylene: Physical Properties Metric English CommentsDocumento2 pagine(PTFE) Polytetrafluoroethylene: Physical Properties Metric English CommentsMakhdum Muhardiana PutraNessuna valutazione finora

- High Performance RF Antenna Material: FeaturesDocumento3 pagineHigh Performance RF Antenna Material: FeaturesDale XiaoNessuna valutazione finora

- ReportDocumento21 pagineReportFaisal AkhterNessuna valutazione finora

- Envirotemp FR3-Data SheetDocumento8 pagineEnvirotemp FR3-Data SheetJavier EcheverryNessuna valutazione finora

- Quadrant EPP PVC - Polyvinyl Chloride, Type I, Grade 1: Physical Properties Metric English CommentsDocumento1 paginaQuadrant EPP PVC - Polyvinyl Chloride, Type I, Grade 1: Physical Properties Metric English CommentsArif OthmanNessuna valutazione finora

- Halene - H : Technical Data SheetDocumento1 paginaHalene - H : Technical Data SheetDaya Shanker PalNessuna valutazione finora

- Thermal Insulation Systems: High Performance Heat Shield With Superior Thermal InsulationDocumento2 pagineThermal Insulation Systems: High Performance Heat Shield With Superior Thermal InsulationMikeNessuna valutazione finora

- Apmln 2019 07 15 - 13 23 57Documento3 pagineApmln 2019 07 15 - 13 23 57yannNessuna valutazione finora

- Delrin 150Documento1 paginaDelrin 150Sardar. Vikramjit Singh RandhawaNessuna valutazione finora

- Freecorev - Micro - 10 - English ARtecoDocumento5 pagineFreecorev - Micro - 10 - English ARtecoManh Nguyen TheNessuna valutazione finora

- PTFE Technical Data Sheet Highlights Chemical Resistance and Wide Temperature RangeDocumento1 paginaPTFE Technical Data Sheet Highlights Chemical Resistance and Wide Temperature RangeMarisa Yuni Nur AzizaNessuna valutazione finora

- Technical Data Sheet Teflon (Ptfe) : (Polytetrafluoroethylene Resin)Documento1 paginaTechnical Data Sheet Teflon (Ptfe) : (Polytetrafluoroethylene Resin)Dharmendra DubeyNessuna valutazione finora

- RC300C - High Performance RF Antenna MaterialDocumento3 pagineRC300C - High Performance RF Antenna MaterialDale XiaoNessuna valutazione finora

- Armaflex C1Brochure en 20190604Documento6 pagineArmaflex C1Brochure en 20190604Adil AminNessuna valutazione finora

- Ghid Mase PlasticeDocumento3 pagineGhid Mase PlasticeLavinia CalinNessuna valutazione finora

- POM C Acetal Copolymer Properties and ApplicationsDocumento1 paginaPOM C Acetal Copolymer Properties and ApplicationsRelu ChiruNessuna valutazione finora

- Technical Insulation Heavy Duty Wired MatDocumento2 pagineTechnical Insulation Heavy Duty Wired Matwassim nasriNessuna valutazione finora

- ABS (Acrylonitrile Butadiene Styrene) :: S.R. No. Propery ASTM Test Method Units ABS FR Physical MechanicalDocumento1 paginaABS (Acrylonitrile Butadiene Styrene) :: S.R. No. Propery ASTM Test Method Units ABS FR Physical Mechanicalshailesh284Nessuna valutazione finora

- Commercial Microwave and RF Multilayer MaterialsDocumento3 pagineCommercial Microwave and RF Multilayer MaterialsDale XiaoNessuna valutazione finora

- Thermal Interface Materials Guide by Shenzhen Pinshuo ElectronicDocumento21 pagineThermal Interface Materials Guide by Shenzhen Pinshuo ElectronicSanju Ayub KhanNessuna valutazione finora

- High Performance RF Antenna Material: FeaturesDocumento3 pagineHigh Performance RF Antenna Material: FeaturesDale XiaoNessuna valutazione finora

- PAROC WiredMat80AluCoat enDocumento1 paginaPAROC WiredMat80AluCoat enSpinu DanielNessuna valutazione finora

- ElectraGuard Specifications - 2Documento5 pagineElectraGuard Specifications - 2Yavuz SolmazNessuna valutazione finora

- Ottocool Catalog enDocumento40 pagineOttocool Catalog enBrian ReyesNessuna valutazione finora

- Wirsbo Q&E Master ProDocumento4 pagineWirsbo Q&E Master ProUPOTERMNessuna valutazione finora

- Sec Etg Series BrochureDocumento11 pagineSec Etg Series BrochurenenaddejanovicNessuna valutazione finora

- Rockwool Rti-Prorox-Sl-980 - ExpDocumento1 paginaRockwool Rti-Prorox-Sl-980 - Expdedy setiawanNessuna valutazione finora

- Armaflex Class 1: Engineered To Prevent CondensationDocumento6 pagineArmaflex Class 1: Engineered To Prevent CondensationTeoxNessuna valutazione finora

- General Properties of PetDocumento3 pagineGeneral Properties of PetpavithraNessuna valutazione finora

- FR-4 Spec'sDocumento2 pagineFR-4 Spec'splakkampelliNessuna valutazione finora

- Plastic Steel Putty A v3Documento2 paginePlastic Steel Putty A v3feri.ferdianto02Nessuna valutazione finora

- Poly Phenylene Oxide (PPO) : Corporate Training and PlanningDocumento27 paginePoly Phenylene Oxide (PPO) : Corporate Training and PlanningAkash YadavNessuna valutazione finora

- Nelco N4000-11: Nelco Advanced Circuitry MaterialsDocumento2 pagineNelco N4000-11: Nelco Advanced Circuitry MaterialsMandeep ChaudharyNessuna valutazione finora

- Published 2 Resources Documents 98 Materials Materials hfs100 PDFDocumento1 paginaPublished 2 Resources Documents 98 Materials Materials hfs100 PDFTeddy112Nessuna valutazione finora

- Guida Coprax Eng 2015 LightDocumento82 pagineGuida Coprax Eng 2015 Lightairsys7projec100% (1)

- Prorox SL 950 SaDocumento1 paginaProrox SL 950 SaHardiman ArbiNessuna valutazione finora

- Iig - ENERWRAP - MA - 960DataSheetDocumento1 paginaIig - ENERWRAP - MA - 960DataSheettmp_rootsNessuna valutazione finora

- AISL/DE Austenitic Stainless Steel Properties and ApplicationsDocumento3 pagineAISL/DE Austenitic Stainless Steel Properties and ApplicationsLebasNessuna valutazione finora

- Ens TecDocumento28 pagineEns TecBorja CanalsNessuna valutazione finora

- TC600 Laminates Data SheetDocumento4 pagineTC600 Laminates Data SheetEduardo Ruiz PalominoNessuna valutazione finora

- FMC - Novolastic Subsea Thermal Insulation - LOW RESDocumento3 pagineFMC - Novolastic Subsea Thermal Insulation - LOW RESalphading50% (2)

- Hopelen PP Homopolymer General Information: DescriptionDocumento2 pagineHopelen PP Homopolymer General Information: DescriptionKormanyos JoppeNessuna valutazione finora

- Ethylene Content and The Role of Added Polyethylene in Epr InsulationDocumento3 pagineEthylene Content and The Role of Added Polyethylene in Epr InsulationeducardxNessuna valutazione finora

- 1.8 Thong So Ky Thuat Bao On AeroflexDocumento1 pagina1.8 Thong So Ky Thuat Bao On AeroflexDatNessuna valutazione finora

- Daelim M-LLD Roto Lh3750mDocumento1 paginaDaelim M-LLD Roto Lh3750mGabs GabrielaNessuna valutazione finora

- PyraluxAPclad DataSheetDocumento9 paginePyraluxAPclad DataSheetSunny SharmaNessuna valutazione finora

- Datasheet-Prevectron 3 TS10Documento1 paginaDatasheet-Prevectron 3 TS10Sandeep VijayakumarNessuna valutazione finora

- Corona Performance of KaptonDocumento4 pagineCorona Performance of KaptonAlfChenNessuna valutazione finora

- Sample - Pipe Manufacturer Data SheetDocumento22 pagineSample - Pipe Manufacturer Data SheetAmal KaNessuna valutazione finora

- Cr-Product Manual - PDFDocumento28 pagineCr-Product Manual - PDFThơ Thẫn ThờNessuna valutazione finora

- Reinforced High-Strength Concrete Beams in FlexureDocumento11 pagineReinforced High-Strength Concrete Beams in FlexureAndrei IancuNessuna valutazione finora

- Alumínio Cold ASM Material Data SheetDocumento2 pagineAlumínio Cold ASM Material Data Sheetmarcelogf74Nessuna valutazione finora

- 1 s2.0 S2213343714002498 MainDocumento8 pagine1 s2.0 S2213343714002498 MainTHE MASTER SIDENessuna valutazione finora

- PEEK PropertiesDocumento56 paginePEEK Propertiesa100acom50% (2)

- Cochin College: Soil Reinforcement Using ParawebDocumento30 pagineCochin College: Soil Reinforcement Using ParawebRowbina Machinchery100% (1)

- CPED Activity 8 - Key concepts in pressure vessel and pipe designDocumento6 pagineCPED Activity 8 - Key concepts in pressure vessel and pipe designJeanne Roselle Dulatre CortezNessuna valutazione finora

- Borealis Ls4201sDocumento3 pagineBorealis Ls4201smanish450inNessuna valutazione finora

- Indian Standard: Specification For Indented Wire For Prestressed ConcreteDocumento17 pagineIndian Standard: Specification For Indented Wire For Prestressed ConcreteAjit P. SinghNessuna valutazione finora

- Enhanced Fatigue Performance of Tandem MIG 5083 Aluminium Alloy Weld Joints by Heat Sink and Static Thermal TensioningDocumento13 pagineEnhanced Fatigue Performance of Tandem MIG 5083 Aluminium Alloy Weld Joints by Heat Sink and Static Thermal TensioningHarry Laksono NugrohoNessuna valutazione finora

- Corrosion Science: Y. Garbatov, C. Guedes Soares, J. Parunov, J. KodvanjDocumento8 pagineCorrosion Science: Y. Garbatov, C. Guedes Soares, J. Parunov, J. KodvanjSachin SukumaranNessuna valutazione finora

- Me212: Mechanics of Deformable Bodies: Course TitleDocumento38 pagineMe212: Mechanics of Deformable Bodies: Course TitleASHISH PATILNessuna valutazione finora

- Mds-Ongc-C-Dss-Astm-A995-4a-Nace-6d-001-Rev A - (M3709)Documento5 pagineMds-Ongc-C-Dss-Astm-A995-4a-Nace-6d-001-Rev A - (M3709)SPACE ALLOYSNessuna valutazione finora

- C 297 - C 297M - 04 - Qzi5ny9dmjk3tq - PDFDocumento6 pagineC 297 - C 297M - 04 - Qzi5ny9dmjk3tq - PDFAnil100% (1)

- Mechanical Properties and Performance of Materials: Hardness TestingDocumento5 pagineMechanical Properties and Performance of Materials: Hardness TestingjballinasNessuna valutazione finora

- Simple Stress and Strain PDFDocumento29 pagineSimple Stress and Strain PDFRubem JesusNessuna valutazione finora

- SM Eng Mat 1 Ashby 4 PDFDocumento52 pagineSM Eng Mat 1 Ashby 4 PDFdsfsNessuna valutazione finora

- ASTM A36 Steel, PlateDocumento1 paginaASTM A36 Steel, PlateI-SignNessuna valutazione finora

- Atomic Force Microscope (AFM) : Block Copolymer Polymer BlendDocumento71 pagineAtomic Force Microscope (AFM) : Block Copolymer Polymer Blendsvo svoNessuna valutazione finora

- The Effect of Fiber Architecture On The Mechanical Properties of Carbon-Carbon Fiber CompositesDocumento13 pagineThe Effect of Fiber Architecture On The Mechanical Properties of Carbon-Carbon Fiber CompositesBolaji SuberuNessuna valutazione finora

- LT Steel STDocumento9 pagineLT Steel STSyed Umair RizviNessuna valutazione finora

- FIG. 1 Rectangular Tension Test SpecimensDocumento1 paginaFIG. 1 Rectangular Tension Test SpecimensAlvaro Alexis Mendoza PradaNessuna valutazione finora

- FORMOLENE LB1810E2 Homotipo Venelene 11pg4Documento1 paginaFORMOLENE LB1810E2 Homotipo Venelene 11pg4Luis Eduardo Julio MovillaNessuna valutazione finora

- BS EN 10319 GeosyntheticsDocumento24 pagineBS EN 10319 GeosyntheticsLuca RuiseccoNessuna valutazione finora

- Experimental Stress Analysis 1986 PDFDocumento624 pagineExperimental Stress Analysis 1986 PDFHassan AlaaNessuna valutazione finora

- Base PlateDocumento34 pagineBase PlaterohitnrgNessuna valutazione finora

- Hollow SectionsDocumento199 pagineHollow SectionsmandregomesNessuna valutazione finora

- Superheated Steam Condensate TankDocumento4 pagineSuperheated Steam Condensate TankGanesh BhardwajNessuna valutazione finora