Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Tom Unit 3

Caricato da

jaihogoluDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Tom Unit 3

Caricato da

jaihogoluCopyright:

Formati disponibili

Theory of Machines & Mechanisms

By Rajesh K.R. Khodre Sir

Theory of Machines and Mechanisms Unit III

(Email:infinitorajkrk@hotmail.com Mob: 9752716726)

Gears Gears are machine elements, which are used to transmit motion from one shaft to another or between a shaft and a slide. A gear or a "gear wheel" is a rotating machine part having cut teeth, which mesh with another toothed part in order to transmit torque. Advantages and Disadvantages of Gear Drives The following are the advantages and disadvantages of the gear drive as compared to other drives, i.e. belt, rope and chain drives. Advantages1. The teeth of a gear prevent slipping. 2. It transmits exact velocity ratio. 3. It may be used to transmit large power. 4. It may be used for small center distances of shafts. 5. It has high efficiency. 6. It has reliable service. 7. It has compact layout. Disadvantages1. Since the manufacture of gears requires special tools and equipment, therefore it is costlier than other drives. 2. The error in cutting teeth may cause vibrations and noise during operation. 3. It requires suitable lubricant and reliable method of applying it, for the proper operation of gear drives. Classification of Gears The gears or toothed wheels may be classified as follows: 1. According to the position of axes of the shafts. The axes of the two shafts between which the motion is to be transmitted, may be a) Parallel b) Intersecting c) Non-intersecting and non-parallel. 2. According to the peripheral velocity of the gears. The gears, according to the peripheral velocity of the gears, may be classified as: a) Low velocity b) Medium velocity c) High velocity. 3. According to the type of gearing. The gears, according to the type of gearing, may be classified as: a) External gearing b) Internal gearing c) Rack and pinion. 4. According to the position of teeth on the gear surface. The teeth on the gear surface may be a) Straight b) Inclined c) Curved.

SIGNATURE INSTITUTE OF PROFESSIONAL STUDIES

Plot No.92, Top Floor MP Nagar Zone -II (-9630724520)

Theory of Machines & Mechanisms

By Rajesh K.R. Khodre Sir

(Email:infinitorajkrk@hotmail.com Mob: 9752716726)

Characteristics of Each Type of Gears

1 Spur Gear Teeth are straight & parallel to shaft axis. It transmits power & motion between rotating two parallel shafts. Features: Easy to manufacture There will be no axial force Relatively easy to produce high quality gears. The common most type. Application: Transmission components. 2 Helical Gear Teeth are twisted oblique to the gear axis. The hand of the helix is designated as either left or right. Right hand and left hand helical gears mate as a set. But they have the same helix angle. Features: Have higher strength compared with spur gear. Effective in reducing noise & vibration compared with spur gear. Gears in mesh produce thrust forces in the axial directions. Applications: Transmission components, automobile, speed reducers etc.

SIGNATURE INSTITUTE OF PROFESSIONAL STUDIES

Plot No.92, Top Floor MP Nagar Zone -II (-9630724520)

Theory of Machines & Mechanisms

By Rajesh K.R. Khodre Sir

(Email:infinitorajkrk@hotmail.com Mob: 9752716726)

3 Rack The rack is a bar containing teeth on one face for meshing with a gear. The basic rack form is the profile of the gear of infinite diameter. Racks with machined ends can be joined together to make any desired length. Features: Change a rotary motion into a rectilinear motion. Applications: A transfer system for machine tools, printing press, robots etc. 4 Internal Gear An annular gear having teeth on the inner surface of its rim. The internal gear always meshes with the external gear. Features: In the meshing of two external gears, rotation goes in the opposite direction. In the meshing of an internal gear with an external gear the rotation goes in the same direction. Care should be taken to the number of teeth when meshing a large (internal) gear with a small (external) gear, since interference can occur. Usually internal gear is driven by external (small) gear. Allows compact design of the machine. Applications: Planetary gear drive of high reduction ratios, clutches etc. 5 Bevel Gear One of a pair of gears used to connect two shafts whose axes intersect, and the pitch surfaces are cones. Teeth are cut along the pitch cone. Depending on tooth trace bevel gear is classified: i. Straight bevel gear ii. Spiral bevel gear I. Straight Bevel Gear A simple form of bevel gear having straight teeth which, if extended inward would come together at the intersection of the shaft axes. Features: Relatively easy to manufacture. Provides reduction ratio up to approximately 1:5 Applications: Machine tools, printing press etc. especially suitable for a differential gear unit. II. Spiral Bevel Gear Bevel gear with curved, oblique teeth to provide gradual engagement & bring more teeth together at a given time than an equivalent straight bevel gear. Features: Have higher contact ratio, higher strength & durability than an equivalent straight bevel gear. Allows a higher reduction ratio. Have better efficiency of transmission with reduced gear noise. Involves some technical difficulties in manufacturing. Applications: Automobile, tractor, vehicles, final reduction gearing for ships

SIGNATURE INSTITUTE OF PROFESSIONAL STUDIES

Plot No.92, Top Floor MP Nagar Zone -II (-9630724520)

Theory of Machines & Mechanisms

By Rajesh K.R. Khodre Sir

(Email:infinitorajkrk@hotmail.com Mob: 9752716726)

6 Miter Gear A special class of bevel gear where the shafts intersect at 90 & the gear ratio is 1:1. 7 Screw Gear A helical gear that transmit power from one shaft to another, non-parallel, non-intersecting shafts. Features: Used in a speed reducer and/or a multiplying gear. Tends to wear as the gear come in sliding contact. Not suitable for transmission of high horse power. Applications: Driving gear for automobile. Automatic machines that require intricate movement. 8 Worm Gear Pair: Worm is a shank having at least on complete tooth (thread) around the pitch surface; the driver of a worm wheel worm wheel is a gear with teeth cut on an angle to be driven by a worm. Features: Provides large reduction ratios for a given center distance. Quite & smooth action. A worm wheel is not feasible to drive a worm except for special occasions. Applications: Speed reducers, anti-reversing gear device making the most of its self-locking features, machine tools, indexing device, chain block, portable generator etc.

SIGNATURE INSTITUTE OF PROFESSIONAL STUDIES

Plot No.92, Top Floor MP Nagar Zone -II (-9630724520)

Theory of Machines & Mechanisms

By Rajesh K.R. Khodre Sir

(Email:infinitorajkrk@hotmail.com Mob: 9752716726)

SIGNATURE INSTITUTE OF PROFESSIONAL STUDIES

Plot No.92, Top Floor MP Nagar Zone -II (-9630724520)

Theory of Machines & Mechanisms

By Rajesh K.R. Khodre Sir

Terminology

(Email:infinitorajkrk@hotmail.com Mob: 9752716726)

SIGNATURE INSTITUTE OF PROFESSIONAL STUDIES

Plot No.92, Top Floor MP Nagar Zone -II (-9630724520)

Theory of Machines & Mechanisms

By Rajesh K.R. Khodre Sir

Terms Used In Gears

(Email:infinitorajkrk@hotmail.com Mob: 9752716726)

1. Pitch circle It is an imaginary circle which by pure rolling action, would give the same motion as the actual gear. 2. Pitch circle diameter It is the diameter of the pitch circle. The size of the gear is usually specified by the pitch circle diameter. It is also called as pitch diameter. 3. Pitch point It is a common point of contact between two pitch circles. 4. Pitch surface It is the surface of the rolling discs which the meshing gears have replaced at the pitch circle. 5. Pressure angle or angle of obliquity It is the angle between the common normal to two gear teeth at the point of contact and the common tangent at the pitch point. 6. Addendum It is the radial distance of a tooth from the pitch circle to the top of the tooth. 7. Dedendum It is the radial distance of a tooth from the pitch circle to the bottom of the tooth. 8. Addendum circle It is the circle drawn through the top of the teeth and is concentric with the pitch circle. 9. Dedendum circle It is the circle drawn through the bottom of the teeth. It is also called root circle. 10. Circular pitch It is the distance measured on the circumference of the pitch circle from a point of one tooth to the corresponding point on the next tooth. 11. Clearance It is the radial distance from the top of the tooth to the bottom of the tooth, in a meshing gear. A circle passing through the top of the meshing gear is known as clearance circle. 12. Total depth It is the radial distance between the addendum and the dedendum circle of a gear. It is equal to the sum of the addendum and dedendum. 13. Working depth It is radial distance from the addendum circle to the clearance circle. It is equal to the sum of the addendum of the two meshing gears. 14. Tooth thickness It is the width of the tooth measured along the pitch circle. 15. Tooth space It is the width of space between the two adjacent teeth measured along the pitch circle. 16. Backlash It is the difference between the tooth space and the tooth thickness, as measured on the pitch circle. 17. Diametral pitch It is the ratio of number of teeth to the pitch circle diameter in millimeters. 18. Module. It is the ratio of the pitch circle diameter in millimeters to the number of teeth. Face of the tooth. It is surface of the tooth above the pitch surface. 19. Top land It is the surface of the top of the tooth. 20. Flank of the tooth

SIGNATURE INSTITUTE OF PROFESSIONAL STUDIES

Plot No.92, Top Floor MP Nagar Zone -II (-9630724520)

Theory of Machines & Mechanisms

By Rajesh K.R. Khodre Sir

(Email:infinitorajkrk@hotmail.com Mob: 9752716726)

It is the surface of the tooth below the pitch surface. 21. Face width It is the width of the gear tooth measured parallel to its axis. 22. Profile It is the curve formed by the face and flank of the tooth. 23. Fillet radius It is the radius that connects the root circle to the profile of the tooth. 24. Path of contact It is the path traced by the point of contact of two teeth from the beginning to the end of engagement. 25. Length of the path of contact. It is the length of the common normal cut-off by the addendum circles of the wheel and pinion. 26. Arc of contact It is the path traced by a point on the pitch circle from the beginning to the end of engagement of a given pair of teeth. The arc of contact consists of two parts, i.e. (a) Arc of approach It is the portion of the path of contact from the beginning of the engagement to the pitch point. (b) Arc of recess It is the portion of the path of contact from the pitch point to the end of the engagement of a pair of teeth.

SIGNATURE INSTITUTE OF PROFESSIONAL STUDIES

Plot No.92, Top Floor MP Nagar Zone -II (-9630724520)

Potrebbero piacerti anche

- Un SymmetricalDocumento2 pagineUn SymmetricaljaihogoluNessuna valutazione finora

- Compounding of Steam TurbineDocumento2 pagineCompounding of Steam TurbinejaihogoluNessuna valutazione finora

- By Rajesh K.R. Khodre Sir: Hydraulic AccumulatorDocumento2 pagineBy Rajesh K.R. Khodre Sir: Hydraulic AccumulatorjaihogoluNessuna valutazione finora

- Skmaiti@me - Iitb.ac - In: Prof. S. K. MaitiDocumento1 paginaSkmaiti@me - Iitb.ac - In: Prof. S. K. MaitijaihogoluNessuna valutazione finora

- By Rajesh K.R. Khodre Sir: Power Transmiting TurbomachinesDocumento2 pagineBy Rajesh K.R. Khodre Sir: Power Transmiting Turbomachinesjaihogolu100% (1)

- Turbo Machinery SyllabusDocumento1 paginaTurbo Machinery SyllabusjaihogoluNessuna valutazione finora

- Heat Capacity of The Matters. It Is The Distinguishing Property ofDocumento3 pagineHeat Capacity of The Matters. It Is The Distinguishing Property ofjaihogoluNessuna valutazione finora

- Chetan CV UpdateDocumento3 pagineChetan CV UpdatejaihogoluNessuna valutazione finora

- Thermal Science: Related Links: Research FacilitiesDocumento3 pagineThermal Science: Related Links: Research FacilitiesjaihogoluNessuna valutazione finora

- Power Transmiting Turbomachines: Save Water, Save Earth Turbo Machinery by Rajesh KhodreDocumento6 paginePower Transmiting Turbomachines: Save Water, Save Earth Turbo Machinery by Rajesh KhodrejaihogoluNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- General Information: Systems OperationDocumento5 pagineGeneral Information: Systems OperationRajan Mullappilly100% (1)

- Basic Concept of Control Valves - KSBDocumento39 pagineBasic Concept of Control Valves - KSBPuspaanjaliNessuna valutazione finora

- Alan Babu (Report Seminar Rough) FinalDocumento19 pagineAlan Babu (Report Seminar Rough) FinalBharath ChandranNessuna valutazione finora

- LHB Handbook On Maintof Air Brake System in LHB Coaches (FTIL Type)Documento120 pagineLHB Handbook On Maintof Air Brake System in LHB Coaches (FTIL Type)Rakesh Jainwal100% (4)

- Vue EclateeDocumento12 pagineVue EclateeBlacheNessuna valutazione finora

- Tinywow - PROEDI 1000 HWS + PW LOOP REVERSE OSMOSIS SYSTEM + DISTRIBUTION 2.2 - 5949721Documento18 pagineTinywow - PROEDI 1000 HWS + PW LOOP REVERSE OSMOSIS SYSTEM + DISTRIBUTION 2.2 - 5949721Yacine MokhtariNessuna valutazione finora

- HiluxDocumento11 pagineHiluxVita LyNessuna valutazione finora

- Waratha Catalogo de Partes PDFDocumento181 pagineWaratha Catalogo de Partes PDFJohn SanzanaNessuna valutazione finora

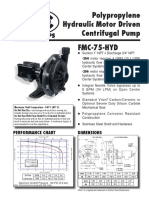

- Polypropylene Hydraulic Motor Driven Centrifugal Pump: Performance Chart DimensionsDocumento2 paginePolypropylene Hydraulic Motor Driven Centrifugal Pump: Performance Chart DimensionsIlson FariasNessuna valutazione finora

- QBMS - Question Bank Unit 1 To 4Documento29 pagineQBMS - Question Bank Unit 1 To 4Manoj ShuklaNessuna valutazione finora

- Doosan 225LL Hydraulic PDFDocumento1 paginaDoosan 225LL Hydraulic PDFHector bustosNessuna valutazione finora

- Parking Brakes For High Torque Motors Sales Catalogue UK Version PDF-1Documento16 pagineParking Brakes For High Torque Motors Sales Catalogue UK Version PDF-1Edwin Mamani DiazNessuna valutazione finora

- Case Study/ Survey:-Department: - Guided By: - Made By:-: Scotch Yoke MechanisumDocumento10 pagineCase Study/ Survey:-Department: - Guided By: - Made By:-: Scotch Yoke Mechanisum28048 Pranav KarodpatiNessuna valutazione finora

- 1 Winch Control - Jul2015 - JFEDocumento40 pagine1 Winch Control - Jul2015 - JFEmortizNessuna valutazione finora

- Report SampleDocumento184 pagineReport SamplekumarnpccNessuna valutazione finora

- Categorized AIO Command List v7.5 - DARKDocumento565 pagineCategorized AIO Command List v7.5 - DARKrandomNessuna valutazione finora

- Shimano Sienna 10SN4000FDDocumento2 pagineShimano Sienna 10SN4000FDDanielNessuna valutazione finora

- Valves: The American University in Cairo, MENG 215, Dr. Hesham Hegazi 1Documento14 pagineValves: The American University in Cairo, MENG 215, Dr. Hesham Hegazi 1almalki1100% (1)

- MASTER LIST OF CATALOGeDocumento3 pagineMASTER LIST OF CATALOGePrathamesh Pradeep MashilkarNessuna valutazione finora

- Theory of TMDocumento2 pagineTheory of TMBinal TivarNessuna valutazione finora

- CAT 349E Electrical UENR04270001Documento12 pagineCAT 349E Electrical UENR04270001Bassie100% (1)

- Verona DiagramDocumento9 pagineVerona DiagramPhillipe LysNessuna valutazione finora

- Trailer PriceDocumento45 pagineTrailer PriceAc SeihoonNessuna valutazione finora

- Ball Valve: Zhejiangbeiercontrol Valveco.,LtdDocumento16 pagineBall Valve: Zhejiangbeiercontrol Valveco.,LtdSandipan GhoshNessuna valutazione finora

- Oil Line and Connecting Parts Hyd PumpDocumento1 paginaOil Line and Connecting Parts Hyd Pumpkaswade BrianNessuna valutazione finora

- Mercedes BenzDocumento14 pagineMercedes BenzM̶i̶c̶h̶e̶l̶ Mejia100% (1)

- Cat Dcs Sis Controller4Documento15 pagineCat Dcs Sis Controller4DenNessuna valutazione finora

- "Transmission Drive Pump Pressure Override Calibration": Illustration 1 g02500239 Cat ET Calibrations MenuDocumento6 pagine"Transmission Drive Pump Pressure Override Calibration": Illustration 1 g02500239 Cat ET Calibrations MenuNurdin0% (1)

- 02 Infiniti I35Documento386 pagine02 Infiniti I35David ChalkerNessuna valutazione finora

- ACT001-Mounting Kit Chart Rev AGDocumento18 pagineACT001-Mounting Kit Chart Rev AGJezie ReyesNessuna valutazione finora