Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Sampling

Caricato da

Popa Costin AugustinDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Sampling

Caricato da

Popa Costin AugustinCopyright:

Formati disponibili

For complete instructions on sampling electrical insulating fluids for GAS ANALYSIS and determination of water content refer

to ASTM D 3613-92.

Syringe Sampling

Some considerations before sampling: w Syringe should be filled to 80% full. w The handle of the plastic stopcock always points to the closed port. w DO NOT PULL BACK ON THE BARREL. This will result in bubble formation. Allow the fluid pressure to push back the barrel and fill the syringe. Apply a slight resistance to the barrel with your thumb. w Filled syringe should contain no air bubbles. However, samples will begin releasing gases soon after sampling. Do not release any evolved gases since these gases must be included in the DGA Analysis. Adjust flow from sampling port for a gentle flow of fluid through the tubing and stopcock. 1 Bleed fluid through stopcock Handle at Position 1. 2 Fill syringe Handle at Position 2. 3 Evacuate fluid from syringe Handle at Position 3. 4 Repeat steps 2 & 3 three times 5 Fill syringe to 80% full Handle at Postion 2. Ensure no bubbles at this time. 6 Close syringe Handle at Position 4. You should now have a representative sample from the insulating fluid within the unit. Record the temperature and any other pertinent information onto the sample data sheet.

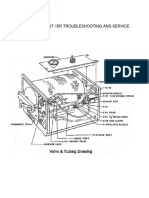

Metal Cylinder Sampling

Notes: w Hold the cylinder in a vertical position at all times. This will ensure all air bubbles rise to the top and exit the container. w Be sure to drain an adequate amount of fluid through the transformer drain valve to flush out stagnant fluid, water, and debris. 1 Drain the Sampling Valve Flush enough fluid through the drain valve to remove any stagnant fluid, moisture, and debris. Attach a plug fitting with a tubing connector to the drain valve. 2 Attach the tubing to the cylinder Connect tubing to the cylinder as illustrated. 3 Open valves in ordered sequence First open the transformer valve (A), then the container's lower valve (B) and finally its upper valve (C). Allow about 1 quart to flow through. Rap the sides and shake the cylinder to dislodge any air bubbles. 4 Shut valves in reverse order Closed the valves C, B, then, A in that order. 5 Re-assemble drain valve and plug Remove the plug with the tubing connector from the drain valve and replace the original plug.

POSITION 1 - Bleeding

POSITION 2 - Filling

POSITION 3 - Evacuating

Still have more questions? Give us a call at the lab. We can also supply you with tubing and hose fittings if necessary. Your local hardware store carries these items also.

POSITION 4 - Closed

6 Fill out sample data sheet You should now have a representative sample from the insulating fluid within the unit ready to be shipped to the lab.

Potrebbero piacerti anche

- DGA Oil Sampling ProceduresDocumento2 pagineDGA Oil Sampling ProceduresSimon CondorNessuna valutazione finora

- Series TK-1 Installation InstructionsDocumento4 pagineSeries TK-1 Installation InstructionsFEBCONessuna valutazione finora

- Series TK-9A Installation InstructionsDocumento4 pagineSeries TK-9A Installation InstructionsWattsNessuna valutazione finora

- TK-99E Backflow Preventer Test Kit Installation InstructionsDocumento4 pagineTK-99E Backflow Preventer Test Kit Installation InstructionsWattsNessuna valutazione finora

- DGA SamplingDocumento2 pagineDGA SamplingSreeram PanigrahiNessuna valutazione finora

- TJH2b - Oil Sampling ProcedureDocumento7 pagineTJH2b - Oil Sampling ProcedurePanas JeNessuna valutazione finora

- TK-99D Installation InstructionsDocumento4 pagineTK-99D Installation InstructionsWattsNessuna valutazione finora

- Transformer Oil Sampling Procedure PDFDocumento2 pagineTransformer Oil Sampling Procedure PDFwinston11Nessuna valutazione finora

- SOP Gas AbsorptionDocumento19 pagineSOP Gas AbsorptionKevin EsmunaldoNessuna valutazione finora

- 6.1.001 ES Troubleshooting Fluid Flow IssuesDocumento3 pagine6.1.001 ES Troubleshooting Fluid Flow IssuesHadi BitarNessuna valutazione finora

- Reef Octopus Nwb-150: Parts Check ListDocumento2 pagineReef Octopus Nwb-150: Parts Check ListRicardo GonzalezNessuna valutazione finora

- Maintenance ServicetruckDocumento4 pagineMaintenance ServicetruckNardin BorneoNessuna valutazione finora

- Instructions: For Chilled Water Buffer Tank Maintenance MODELS: CVU/CVL 120 - 1000Documento2 pagineInstructions: For Chilled Water Buffer Tank Maintenance MODELS: CVU/CVL 120 - 1000Vũ Đình QuangNessuna valutazione finora

- Liquid SamplingDocumento7 pagineLiquid SamplingSrewaBenshebilNessuna valutazione finora

- Topic:: 1: Commissioning 2: Shut DownDocumento6 pagineTopic:: 1: Commissioning 2: Shut DownKaleemNessuna valutazione finora

- Coc Oral Exam Preparation (Part - 17) : Boiler Safety ValveDocumento3 pagineCoc Oral Exam Preparation (Part - 17) : Boiler Safety ValveshashankrawatNessuna valutazione finora

- 400 InstructionsDocumento2 pagine400 InstructionsjimmylovelyNessuna valutazione finora

- Checklist For Wet SprayingDocumento4 pagineChecklist For Wet SprayingWiwa Hernandez DonosoNessuna valutazione finora

- Surface Sampling of Reservoir FluidsDocumento6 pagineSurface Sampling of Reservoir FluidsMuhammad MufarridNessuna valutazione finora

- Accumulator Maintenance Instructions Rev BDocumento6 pagineAccumulator Maintenance Instructions Rev BJohn Néstor Ramirez CalderónNessuna valutazione finora

- Autoclave Harvey 5000Documento16 pagineAutoclave Harvey 5000Cesar Alfonso Saldivar MontoyaNessuna valutazione finora

- All About Carbon DioxideDocumento3 pagineAll About Carbon DioxideShiva RajNessuna valutazione finora

- 9E-A User Manuals and ServiceDocumento10 pagine9E-A User Manuals and Servicerponce161276Nessuna valutazione finora

- Wato 2Documento103 pagineWato 2Soluciones Biomedicas de ColombiaNessuna valutazione finora

- S T K SQ1: Set Up and User GuideDocumento16 pagineS T K SQ1: Set Up and User GuideschumonNessuna valutazione finora

- LLE Assignment and Procedure - Fall 2021Documento4 pagineLLE Assignment and Procedure - Fall 2021Kevin YangNessuna valutazione finora

- Owner'S Manual: Artmolds' Pressure PotDocumento4 pagineOwner'S Manual: Artmolds' Pressure PotAnonymous Wyb8Y1Nessuna valutazione finora

- Toilet Installation Instructions: Instrucciones para Instalación de SanitariosDocumento2 pagineToilet Installation Instructions: Instrucciones para Instalación de SanitarioswilfredoNessuna valutazione finora

- Changing CylindersDocumento1 paginaChanging CylindersZeina FarhatNessuna valutazione finora

- Calibration of Volumetric Glassware: Chemistry 321: Quantitative Analysis Lab WebnoteDocumento6 pagineCalibration of Volumetric Glassware: Chemistry 321: Quantitative Analysis Lab WebnoteArif AshrafNessuna valutazione finora

- Advia 120 Troubleshooting GuideDocumento21 pagineAdvia 120 Troubleshooting GuideJaime Elias100% (1)

- Autotrol Performa Valve With 400 Series Control Installation InstructionsDocumento24 pagineAutotrol Performa Valve With 400 Series Control Installation InstructionsWattsNessuna valutazione finora

- MODEL NR3XL Pressure RegulatorDocumento2 pagineMODEL NR3XL Pressure Regulator63ragtopNessuna valutazione finora

- Autotrol Performa Prosoft PDFDocumento24 pagineAutotrol Performa Prosoft PDFintermountainwaterNessuna valutazione finora

- Appendix I PipettingDocumento2 pagineAppendix I PipettingAshleye GramNessuna valutazione finora

- FH3 EL FHT ManualDocumento2 pagineFH3 EL FHT ManualRubi WantoNessuna valutazione finora

- Service Truck Maintenance: Learning CenterDocumento4 pagineService Truck Maintenance: Learning CenterDemo OnlyNessuna valutazione finora

- Hydrogen Sampling InstructionsDocumento8 pagineHydrogen Sampling Instructionstruongthaihung2510Nessuna valutazione finora

- Laboratory Experiment 1. Calibration of Volumetric GlasswareDocumento3 pagineLaboratory Experiment 1. Calibration of Volumetric GlasswareArif AshrafNessuna valutazione finora

- Flowmeter DEMONSTRATIONDocumento20 pagineFlowmeter DEMONSTRATIONAfiq IkhwanNessuna valutazione finora

- Manufacturer'S Operating Instructions TEST PUMP MODEL DP-Series (3/4/6/8/56-250)Documento2 pagineManufacturer'S Operating Instructions TEST PUMP MODEL DP-Series (3/4/6/8/56-250)babjihanumanthuNessuna valutazione finora

- VOLUMETRIC Glassware LSMDocumento7 pagineVOLUMETRIC Glassware LSMNona NonicaaNessuna valutazione finora

- Operating and Maintenance Instructions For: Air Valve For Waste Water and Potable WaterDocumento3 pagineOperating and Maintenance Instructions For: Air Valve For Waste Water and Potable WaterhoseyliauNessuna valutazione finora

- Lab2 PDFDocumento3 pagineLab2 PDFFahrizal FazaNessuna valutazione finora

- Microsoft PowerPoint - BoileroperationsDocumento55 pagineMicrosoft PowerPoint - BoileroperationsGOBLIN XXXNessuna valutazione finora

- User Manual Thetford Cassette C200Documento36 pagineUser Manual Thetford Cassette C200Robert MillsNessuna valutazione finora

- W.RT. Reciprocating Air Compressor Explain The Cause of The Following FaultsDocumento51 pagineW.RT. Reciprocating Air Compressor Explain The Cause of The Following FaultsSri VasanNessuna valutazione finora

- Reactor Startup ProcedureDocumento3 pagineReactor Startup ProcedureAjgaj1Nessuna valutazione finora

- Dosing Pots: SpecificationDocumento3 pagineDosing Pots: SpecificationMohamed AdelNessuna valutazione finora

- Fila 121 Autoclave Quadrant (M)Documento14 pagineFila 121 Autoclave Quadrant (M)Cap. de Per. 4-14 Maat 1Nessuna valutazione finora

- Orifice and Free Jet Flow Experiment: Updated 8/9/06Documento3 pagineOrifice and Free Jet Flow Experiment: Updated 8/9/06shaneshaneshaneshaneNessuna valutazione finora

- Qeehs Departmental Manual Maintenance (Electrical) : DOC NO. SOP For Transformer Oil Sample CollectionDocumento2 pagineQeehs Departmental Manual Maintenance (Electrical) : DOC NO. SOP For Transformer Oil Sample CollectionSiemens OLM BorlNessuna valutazione finora

- A Beginner's Guide To The Rotary EvaporatorDocumento4 pagineA Beginner's Guide To The Rotary EvaporatordominicbelawingNessuna valutazione finora

- 0993-5260 - AS800 Quick Ref R3 AS800Documento14 pagine0993-5260 - AS800 Quick Ref R3 AS800Renata RoaNessuna valutazione finora

- Manual de Válvula de Prevención de SobrellenadoDocumento14 pagineManual de Válvula de Prevención de SobrellenadoEmiliano CamarenaNessuna valutazione finora

- Experiment 2Documento18 pagineExperiment 2Pravin NairNessuna valutazione finora

- Eo Reactor Work Instruction RevDocumento4 pagineEo Reactor Work Instruction Revvishal bailurNessuna valutazione finora

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDa EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNessuna valutazione finora

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsDa EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNessuna valutazione finora

- Prevention of Actuator Emissions in the Oil and Gas IndustryDa EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNessuna valutazione finora

- LaMotte 1756 Fluoride Tracer PockeTester InstructionsDocumento16 pagineLaMotte 1756 Fluoride Tracer PockeTester InstructionsPromagEnviro.comNessuna valutazione finora

- Dispersion Characteristics of Substrate IntegratedDocumento3 pagineDispersion Characteristics of Substrate IntegratedUsman QureshiNessuna valutazione finora

- Module 2.2A: Moles, Molar Mass and Avogadro's Number Alexandra Melise D. HulogDocumento17 pagineModule 2.2A: Moles, Molar Mass and Avogadro's Number Alexandra Melise D. HulogDarnell SimmonsNessuna valutazione finora

- Mihalos Cracker Processing Biscuit Technology 2014 TC PDFDocumento44 pagineMihalos Cracker Processing Biscuit Technology 2014 TC PDFAshish AroraNessuna valutazione finora

- The Preparation of Potassium Tris (Oxalate) Ferrate (III) TrihydrateDocumento8 pagineThe Preparation of Potassium Tris (Oxalate) Ferrate (III) Trihydrateapple33% (6)

- BFC 3042 Chapter 4bDocumento10 pagineBFC 3042 Chapter 4bInahMisumiNessuna valutazione finora

- Soil Freeze-Thaw Effects On Bank Erodibility and Stability: ElecteDocumento23 pagineSoil Freeze-Thaw Effects On Bank Erodibility and Stability: ElecteiliavaNessuna valutazione finora

- Koel Colours FINALDocumento20 pagineKoel Colours FINALShruti Lovekar100% (1)

- Ni 1882Documento81 pagineNi 1882estradeiroNessuna valutazione finora

- Aluminio Por AcidoDocumento7 pagineAluminio Por AcidojackyNessuna valutazione finora

- (1967) History of The Lenz-Ising ModelDocumento13 pagine(1967) History of The Lenz-Ising ModelJakler NicheleNessuna valutazione finora

- NGL Fractionation Using HYSYSDocumento30 pagineNGL Fractionation Using HYSYSAhmad Deyab100% (3)

- DP FlowDocumento47 pagineDP FlowGustavo PuenteNessuna valutazione finora

- Author's Accepted Manuscript: Nano EnergyDocumento52 pagineAuthor's Accepted Manuscript: Nano EnergySteven KmiecNessuna valutazione finora

- ASTM A385-Providing High-Quality Zinc Coatings (Hot-Dip)Documento8 pagineASTM A385-Providing High-Quality Zinc Coatings (Hot-Dip)trjithinraj100% (2)

- SW 041910 PlasticDocumento2 pagineSW 041910 Plasticapi-262527276Nessuna valutazione finora

- A General Review of The Causes and Acceptance of Shape ImperfectionsDocumento7 pagineA General Review of The Causes and Acceptance of Shape ImperfectionsMuhammed SulfeekNessuna valutazione finora

- Concrete Mix Proportioning Using EMMA SoftwareDocumento12 pagineConcrete Mix Proportioning Using EMMA SoftwareYuliusRiefAlkhalyNessuna valutazione finora

- Injection MouldingDocumento20 pagineInjection MouldingSumanta Das100% (1)

- Aakash Rank Booster Test Series For NEET Aakash Rank Booster Test Series For NEET-2020 2020Documento12 pagineAakash Rank Booster Test Series For NEET Aakash Rank Booster Test Series For NEET-2020 2020VedNessuna valutazione finora

- Dirac Notation PM r4Documento19 pagineDirac Notation PM r4Andrea BucciNessuna valutazione finora

- ABS Polar Ice Class Ship Structure DesignDocumento48 pagineABS Polar Ice Class Ship Structure Designronny-suNessuna valutazione finora

- 2 - Sterilization TechniquesDocumento3 pagine2 - Sterilization Techniquesmufeesahamed2215Nessuna valutazione finora

- CRM47885 Lrac9768Documento5 pagineCRM47885 Lrac9768Sergio mauricio sergioNessuna valutazione finora

- The Origin of The UniverseDocumento7 pagineThe Origin of The UniverseEve Lyn RemedioNessuna valutazione finora

- Chemistry Schemes Form 1Documento4 pagineChemistry Schemes Form 1NZURE NJOKANessuna valutazione finora

- Storage Stability of A Processed Ginger PasteDocumento2 pagineStorage Stability of A Processed Ginger PasteevelinNessuna valutazione finora

- Sodium Hexameta Phosphate e CHB 038Documento1 paginaSodium Hexameta Phosphate e CHB 038Wasif KarimNessuna valutazione finora

- Superpave Laboratory WorkshopDocumento62 pagineSuperpave Laboratory WorkshopAugusto M. ReyesNessuna valutazione finora

- Concrete TestingDocumento32 pagineConcrete TestingAveesh singh100% (1)