Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Mud Gas Separator Sizing

Caricato da

ermaniezDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Mud Gas Separator Sizing

Caricato da

ermaniezCopyright:

Formati disponibili

THE SPE IMAGE LIBRARY

SPE 20430

Mud/Gas Separator Sizing and Evaluation 20430 MacDougall, G.R., SPE, Chevron Canada Resources Ltd. December 1991 Summary. Recent wellsite disasters have led to an increased emphasis on properly sized mud/gas separators. This paper reviews and analyzes existing mud/gas separator technology and recommends separator configuration, components, design considerations, and a sizing procedure. A simple method of evaluating mud/gas separation within the separator vessel has been developed as a basis for the sizing procedure. A mud/gas separator sizing worksheet will assist drilling personnel with the sizing calculations. The worksheet provides a quick and easy evaluation of most mud/gas separators for a specific well application. A brief discussion of other mud/gas separator considerations is provided, including separator components, testing, materials, and oil-based-mud considerations. Introduction The mud/gas separator is designed to provide effective separation of the mud and gas circulated from the well by venting the gas and returning the mud to the mud pits. Small amounts of entrained gas can then be handled by a vacuum-type degasser located in the mud pits. The mud/gas separator controls gas cutting during kick situations, during drilling with significant drilled gas in the mud returns, or when trip gas is circulated up. This paper discusses design considerations for mud/gas separators. The purpose of this paper is to allow drilling rig supervisors to evaluate mud/gas separators properly and to upgrade (if required) the separator economically to meet the design criteria outlined in this paper, and to provide office drilling personnel with guidelines for designing mud/gas separators before delivery at the drillsite. Principle of Operation The operating principle of a mud/gas separator is relatively simple. The device is essentially a vertical steel cylindrical body with openings on the top, bottom, and side, as shown in Fig. 1. The mud and gas mixture is fed into the separator inlet and directed

THE SPE IMAGE LIBRARY

SPE 20430

at a flat steel plate perpendicular to the flow. This impingement plate minimizes the erosional wear on the separator's internal walls and assists with mud/gas separation. Separation is further assisted as the mud/gas mixture falls over a series of baffles designed to increase the turbulence within the upper section of the vessel. The free gas is then vented through the gas vent line, and mud is returned to the mud tanks. Operating pressure within the separator is equal to the friction pressure of the free gas venting through the vent line. Fluid is maintained at a specific level (mud leg) within the separator at all times. If the friction pressure of the gas venting through the vent line exceeds the mud-leg hydrostatic pressure within the separator, a blow-through condition will result sending a mud/gas mixture to the mud tanks. As one can readily see, the critical point for separator blow-through exists when peak gas flow rates are experienced in the separator. Peak gas flow rates should theoretically be experienced when gas initially reaches the separator. Types of Mud/Gas Separators Three types of mud/gas separators commonly are used today: closed bottom, open bottom, and float type. The principle of mud/gas separation within each type of vessel is identical. Differences can be found in the method of maintaining the mud leg, as discussed below. The closed-bottom separator, the vessel bottom with the mud tanks, as shown in Fig. 1. Mud by installation of an inverted Fluid level can be adjusted by the U-shaped bend. as the name implies, is closed at return line directed back to the mud leg is maintained in the separator U-shaped bend in the mud return line. increasing/decreasing the length of

Commonly called the poor boy, the open-bottom mud/gas separator is typically mounted on a mud tank or trip tank with the bottom of the separator body submerged in the mud, as shown in Fig. 2. The fluid level (mud leg) in the separator is controlled by adjusting the fluid level in the mud tank or by moving the separator up or down within the tank. Mud-tank height can restrict the maximum mud leg obtainable for open-bottom mud/gas separators. Fluid level (mud leg) is maintained in a float-type mud/gas separator by a float/valve configuration, as shown in Fig. 3. The float opens and closes a valve on the mud return line to maintain the mud-leg level. Valves can be operated by a manual linkage system connected from the float to the valve, or the valve can be air-operated with rig air. Mud-leg height can be controlled by adjusting the float assembly.

THE SPE IMAGE LIBRARY

SPE 20430

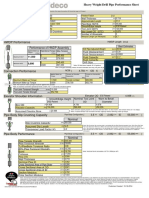

There are some inherent problems in the use of float-type mud/gas separators. The manual linkage separator has experienced problems with linkage failure resulting in improper opening or closing of the mud-return-line valve. Air-operated valves fail to function if rig air is lost, resulting in no control of fluid level within the separator. Mud-return-line valves are prone to plug with solids, preventing mud flowback to the mud pits. Because of these problems, float-type mud/gas separators are not recommended and a closed-bottom separator is preferred. Open-bottom separators are acceptable; however, one should be aware that they are restricted to a maximum mud leg, somewhat lower than the mud-tank height. Although float-type mud/gas separators are strongly discouraged, these separators can be modified easily for disconnection of the float, removal of the valve, and installation of a mud leg in the mud return line. For the purpose of this paper, a closed-bottom mud/gas separator will be considered for all separator designs. Sizing the Mud/Gas Separator Table 1 shows a mud/gas separator worksheet to assist with the sizing calculation. The mud/gas separator illustrated in Fig. 4 will be evaluated for sufficient sizing in this paper. Peak Gas Flow Rate. As discussed previously, the critical time for separator blow-through exists when peak gas flow rates are experienced. Mud/gas separator blow-through is defined as inefficient separator operation resulting in a mud/gas mixture returning to the mud tanks through the mud return line. Two situations can cause separator blow-through. 1. Friction pressure of the gas venting through the vent line exceeds the mud-leg hydrostatic pressure, resulting in evacuation of fluid from the separator. Friction pressure of the mud through the mud return line is considered negligible because of its short length. 2. Vessel ID is too small, causing insufficient retention time for the gas to separate efficiently from the mud. This situation is commonly called insufficient separator cut. To estimate a peak gas flow rate properly, we must consider a "typical" kick. The typical kick will depend on the well location, depth, type size, and component ratios of influx. Kick data should be based on previous offset well data and should be a realistic worst-case gas kick. The well and kick data in Fig. 5 will be used in this paper.

THE SPE IMAGE LIBRARY

SPE 20430

The volume and pressure of the gas upstream of the choke must first be calculated. SPEDE P. 279

Potrebbero piacerti anche

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsDa EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNessuna valutazione finora

- Mud Gas Separator Sizing and EvaluationDocumento3 pagineMud Gas Separator Sizing and EvaluationIvan Cerda0% (1)

- Mud Gas Separator Sizing and Evaluation PaperDocumento6 pagineMud Gas Separator Sizing and Evaluation PaperzapspazNessuna valutazione finora

- Mud Gas SeparatorDocumento3 pagineMud Gas SeparatorDuong DuongNessuna valutazione finora

- Mud Gas Separator (Poor Boy Degasser) Plays A Vital Role in Well Control SituationDocumento5 pagineMud Gas Separator (Poor Boy Degasser) Plays A Vital Role in Well Control Situationshoaib KhalilNessuna valutazione finora

- Poor Boy DegasserDocumento4 paginePoor Boy DegasserhibaNessuna valutazione finora

- Manual Operativo - Tijeras Wenzel Ø 6 1-2 - InglesDocumento11 pagineManual Operativo - Tijeras Wenzel Ø 6 1-2 - InglesChristian Matteo100% (1)

- Hampco H125 MGS ManualDocumento8 pagineHampco H125 MGS ManualLes OakesNessuna valutazione finora

- Mud Gas Separator CalculationDocumento16 pagineMud Gas Separator CalculationErwin Gomop-asNessuna valutazione finora

- Mud Gas Separator SizingDocumento2 pagineMud Gas Separator Sizingmadonnite3781100% (2)

- Ram BOP Manual BookDocumento28 pagineRam BOP Manual BookIgor Ungur100% (2)

- Tc1350 Drilling ChokeDocumento26 pagineTc1350 Drilling ChokeazeazeazeNessuna valutazione finora

- Diverter SystemDocumento46 pagineDiverter Systemjairaso2950100% (1)

- HeavyWeight 3.5 25.58lbs NC-38Documento3 pagineHeavyWeight 3.5 25.58lbs NC-38Инженер Луис А. ГарсиаNessuna valutazione finora

- Mud Gas Separator CalculationDocumento16 pagineMud Gas Separator CalculationErwin Gomop-as100% (2)

- 9 Mud Gas Separator PDFDocumento1 pagina9 Mud Gas Separator PDFRahmat Reza maulanaNessuna valutazione finora

- Cameron - DL-Annular BopDocumento1 paginaCameron - DL-Annular BopAnonymous 48jYxR1C100% (1)

- Trip TankDocumento23 pagineTrip TankNaser KhanNessuna valutazione finora

- BOP Dimensions 13stackDocumento3 pagineBOP Dimensions 13stackSasan AbbasiNessuna valutazione finora

- Mud PumpsDocumento16 pagineMud PumpsNigin Parambath100% (1)

- Strata RCDDocumento2 pagineStrata RCDDavid VilchesNessuna valutazione finora

- MSP Drillex BOP AnularDocumento21 pagineMSP Drillex BOP AnularDavid GonzalezNessuna valutazione finora

- Double Acting Hydraulic Drilling JarDocumento10 pagineDouble Acting Hydraulic Drilling JarDanciulescu Mircea GabrielNessuna valutazione finora

- Data Input Sheet: A Worksheet From Well Control TOOLKIT - .Documento4 pagineData Input Sheet: A Worksheet From Well Control TOOLKIT - .Abdul Hameed OmarNessuna valutazione finora

- 39 Drilling JarsDocumento26 pagine39 Drilling JarsnjileoNessuna valutazione finora

- DDZ Series Elevator Wear Data RutongDocumento2 pagineDDZ Series Elevator Wear Data RutongIsrael AyllonNessuna valutazione finora

- COMPACT DEGASSER Pages 1 Thru 72 (9090200 - )Documento72 pagineCOMPACT DEGASSER Pages 1 Thru 72 (9090200 - )waleed100% (1)

- Brandt - Desander and Desilter ManualDocumento50 pagineBrandt - Desander and Desilter ManualSisca Amalia100% (2)

- Drilling Source Book - Jim ShortDocumento588 pagineDrilling Source Book - Jim Shortprem_1975Nessuna valutazione finora

- (Equip (Accumulator)Documento34 pagine(Equip (Accumulator)Nagendra Singh Ranawat100% (4)

- (Highly Deviated and Horizontal Wells) : Pre-Recorded Sheet Keep This Data Sheet Current at All TimesDocumento7 pagine(Highly Deviated and Horizontal Wells) : Pre-Recorded Sheet Keep This Data Sheet Current at All TimesSasan AbbasiNessuna valutazione finora

- DrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFDocumento3 pagineDrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFGarcia C L Alberto100% (1)

- Accumulator Draw Down TestDocumento8 pagineAccumulator Draw Down Testadeelsn100% (4)

- Tom Mile Calculation PDFDocumento6 pagineTom Mile Calculation PDFBeni N SoloNessuna valutazione finora

- Drilling Formulas Calculation Sheet Verson 1.5Documento199 pagineDrilling Formulas Calculation Sheet Verson 1.5Vidit GuptaNessuna valutazione finora

- Under Balanced OperationsDocumento104 pagineUnder Balanced OperationsJavier Ignacio Meriles100% (1)

- Kick Tolerance2Documento4 pagineKick Tolerance2fisco4rilNessuna valutazione finora

- Preventive Maintenance Program For Spherical Blowout PreventerDocumento19 paginePreventive Maintenance Program For Spherical Blowout Preventernjava1978100% (1)

- A t3 Super Choke Operational Manual PDFDocumento64 pagineA t3 Super Choke Operational Manual PDFMonica Caicedo100% (1)

- H&P ARG Rig 335 Equipment List From Final WoDocumento12 pagineH&P ARG Rig 335 Equipment List From Final WoJuan Miguel Robledo100% (1)

- Hydrill 13'' - 5000 PsiDocumento42 pagineHydrill 13'' - 5000 PsiAli Ali75% (4)

- Maintenance Steps of Mud Gas SeparatorDocumento1 paginaMaintenance Steps of Mud Gas SeparatorNumbWong100% (1)

- M5329-R0 Dead Line AnchorDocumento26 pagineM5329-R0 Dead Line Anchorandrei20041100% (2)

- Lubricate and Bleed ProcedureDocumento1 paginaLubricate and Bleed ProcedurestevebeardsleyNessuna valutazione finora

- Crti® & Crte® Casing Running ToolsDocumento62 pagineCrti® & Crte® Casing Running ToolsLuis Arreaza BelisarioNessuna valutazione finora

- Mud-Gas Separator Sizing Worksheet: Prerecorded InformationDocumento3 pagineMud-Gas Separator Sizing Worksheet: Prerecorded InformationAbdul Hameed OmarNessuna valutazione finora

- Barco BJ PDFDocumento9 pagineBarco BJ PDFJose CamachoNessuna valutazione finora

- Rig 602 - Trinidad Drilling LTDDocumento4 pagineRig 602 - Trinidad Drilling LTDTim ClarkeNessuna valutazione finora

- API Flange Slide RuleDocumento3 pagineAPI Flange Slide RuleMohamed_saad_123100% (1)

- Tool Joint Data Assembly Data: Drill Pipe Data TablesDocumento5 pagineTool Joint Data Assembly Data: Drill Pipe Data TablesSefa AslanhanNessuna valutazione finora

- RP 10.0 Drawworks Brake Load Path Components VFinal (March 2016)Documento15 pagineRP 10.0 Drawworks Brake Load Path Components VFinal (March 2016)NataliyaLukovskaNessuna valutazione finora

- Griffith JarDocumento21 pagineGriffith Jarsaeed65Nessuna valutazione finora

- DL Annular Blowout Preventer 21-1/4" 3000 Psi WPDocumento27 pagineDL Annular Blowout Preventer 21-1/4" 3000 Psi WPJeneesh Shanmughan100% (1)

- Hydril 533Documento4 pagineHydril 533Fernando OlaveoNessuna valutazione finora

- Drilling Supervisor: Passbooks Study GuideDa EverandDrilling Supervisor: Passbooks Study GuideNessuna valutazione finora

- Air and Gas Drilling Manual: Applications for Oil, Gas, Geothermal Fluid Recovery Wells, Specialized Construction Boreholes, and the History and Advent of the Directional DTHDa EverandAir and Gas Drilling Manual: Applications for Oil, Gas, Geothermal Fluid Recovery Wells, Specialized Construction Boreholes, and the History and Advent of the Directional DTHNessuna valutazione finora

- Formulas and Calculations for Drilling OperationsDa EverandFormulas and Calculations for Drilling OperationsNessuna valutazione finora

- 1B - Drilling Cost and Drilling RateDocumento37 pagine1B - Drilling Cost and Drilling RateTu Dang TrongNessuna valutazione finora

- Presented By: Dr. Peter Hany Sobhy Riad Prof. Dr. Ahmed Ali HassanDocumento48 paginePresented By: Dr. Peter Hany Sobhy Riad Prof. Dr. Ahmed Ali Hassanph4318Nessuna valutazione finora

- WBM Important Testing ProceduresDocumento84 pagineWBM Important Testing ProceduresLazharNessuna valutazione finora

- Rig Acceptance Check ListDocumento2 pagineRig Acceptance Check ListAhmedNessuna valutazione finora

- Summary WritingDocumento10 pagineSummary WritingAyanNessuna valutazione finora

- AADE-05-NTCE-29 Hole Cleaning: The Achilles' Heel of Drilling Performance?Documento9 pagineAADE-05-NTCE-29 Hole Cleaning: The Achilles' Heel of Drilling Performance?Waleed Barakat MariaNessuna valutazione finora

- Drill in Fluids 1.0Documento29 pagineDrill in Fluids 1.0Long Nhật PhanNessuna valutazione finora

- Squeeze ProcedureDocumento4 pagineSqueeze Proceduresaa6383Nessuna valutazione finora

- Tds Premium GelDocumento1 paginaTds Premium Gelمحمد سعيدNessuna valutazione finora

- Cougar DLLG Solutions FaqDocumento5 pagineCougar DLLG Solutions FaqLenis CeronNessuna valutazione finora

- Sand ContentDocumento5 pagineSand ContentMohammed Ali AlnooriNessuna valutazione finora

- 2-A-GNLW363CD Standard Decanter CentrifugeDocumento6 pagine2-A-GNLW363CD Standard Decanter CentrifugeGeorgeNessuna valutazione finora

- Rotary DrillingDocumento74 pagineRotary DrillingadrianalexeiNessuna valutazione finora

- EP - 2000-9073 - Shell - Casing - and - Tubing - Design - Guide - Vol - 1 Rev Jan 2008 PDFDocumento165 pagineEP - 2000-9073 - Shell - Casing - and - Tubing - Design - Guide - Vol - 1 Rev Jan 2008 PDFmahdiscribd100% (2)

- Basic Mud LoggingDocumento196 pagineBasic Mud LoggingAnonymous 0OU1iqXHNessuna valutazione finora

- Balac Srdan MSC 2019Documento80 pagineBalac Srdan MSC 2019Naufal SatiNessuna valutazione finora

- 3 RPM and 6 RPMDocumento4 pagine3 RPM and 6 RPMAnonymous T32l1RNessuna valutazione finora

- 1pile Construction Issues and Quality Control of PIT TestDocumento129 pagine1pile Construction Issues and Quality Control of PIT TestShiva Raj AdhikariNessuna valutazione finora

- 2 Rotary Drilling Rig ComponentsDocumento18 pagine2 Rotary Drilling Rig ComponentsĐại Trần100% (1)

- 01 Bentonite PDFDocumento35 pagine01 Bentonite PDFIván Serrano100% (1)

- IPIMS Background Learning - Drillstring, Drill Bits and Drilling FluidDocumento14 pagineIPIMS Background Learning - Drillstring, Drill Bits and Drilling Fluidfebry_rfNessuna valutazione finora

- Well DesignDocumento55 pagineWell DesignTheezz100% (2)

- @@@@API Technical Data Book Tanques Bombas y Tuberías PDFDocumento78 pagine@@@@API Technical Data Book Tanques Bombas y Tuberías PDFjorge pajonNessuna valutazione finora

- Petrophysicist (Geologist)Documento42 paginePetrophysicist (Geologist)56962645Nessuna valutazione finora

- DW BrochureDocumento52 pagineDW BrochureMaxim Efimov100% (1)

- Virtual HydraulicsDocumento8 pagineVirtual HydraulicsLok Bahadur RanaNessuna valutazione finora

- Dynamic Linear Swellmeter 150-80Documento28 pagineDynamic Linear Swellmeter 150-80Ragha RagNessuna valutazione finora

- Drilling Rig Inspection ManualDocumento35 pagineDrilling Rig Inspection ManualSrikanth Bammidi100% (2)

- Frigaard2017 Article BinghamSModelInTheOilAndGasIndDocumento24 pagineFrigaard2017 Article BinghamSModelInTheOilAndGasIndCoolProphetNessuna valutazione finora

- Drilling Calculation SheetDocumento5 pagineDrilling Calculation SheetDewy CoxNessuna valutazione finora