Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Impact Pulveriser

Caricato da

jasenterpriseCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Impact Pulveriser

Caricato da

jasenterpriseCopyright:

Formati disponibili

JasEnterprises AnISO9001:2008CertifiedCompany 60,ShreenathjiEstate,PannaEstateRoad,Rakhial,Ahmedabad380023GujaratIndia Phone:917922743454,55Fax:917922745062 Email:info@jasenterprise.com http://www.jasenterprise.comorhttp://www.pulveriser.co.inorhttp://www.pulverizerindia.

com

Impactpulveriser

The techno wings brand impact pulveriser meets most capacityrequirements.Itlendthemselvestoawidedegreeof adjustmentwithfinesseofthefinishedproductsrangingfrom about60meshtobulkpassingthrough300meshdepending to a considerable extent on the particular materials being handled.Itcombinesgrinding,classifyingandconveyingallin one single unit. It grinds with easy, economy and safety offering a wide range of particle sizing of any nonabrasive material,hardorsoftfromgranulartofinestdustupto300 meshes.

Keyfeaturesofimpactpulveriser

Unique and reliable design o The impact series pulverisers are highly effective as well as nonstop continuous pulverizing process. Compact size. Dust free operation. Ideal for dry crushing. Increased production leading to faster return on the investments. Hardened & fully machined salving type beaters thus less wears & tears. All rotating parts are dynamically balanced for reducing friction losses and noise.

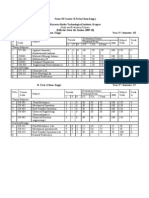

Availablemodelsofimpactpulveriser

Model no Tw-12 Required H.P. 5 H.P. (3.7 Kw.) Pulveriser R.P.M. 3500

Tw-12 broad 7.5 H.P. (5.5 Kw.) 3500 or 2800 Tw-16 10 H.P. (7.5 Kw.) 3200 Tw-16 broad 15 H.P. (11 Kw.) 3200 or 2800 Tw-20 Tw-25 Tw-32 15 H.P. (11 Kw.) 2200 2800 or 2200 2000 2000 Tw-20 broad 20 H.P. (15 Kw.) Tw-25 broad 30 H.P. (22 Kw.) 40 H.P. (30 Kw.)

25 H.P. (18.5 Kw.) 2000

JasEnterprises,AllRightsReserved.(TermsofUse) DevelopedandManagedbyJasEnterprises

JasEnterprises AnISO9001:2008CertifiedCompany 60,ShreenathjiEstate,PannaEstateRoad,Rakhial,Ahmedabad380023GujaratIndia Phone:917922743454,55Fax:917922745062 Email:info@jasenterprise.com http://www.jasenterprise.comorhttp://www.pulveriser.co.inorhttp://www.pulverizerindia.com

Tw-32 broad 50 H.P. (37.5 Kw.) 1800 Tw-42 60 H.P. (45 Kw.) 1800 1200 1500 Tw-42 broad 80 H.P. (60 Kw.)

Operatingprincipleofimpactpulveriser

The techno wings impact pulveriser consists of and encased rotor-carrying swing hammers, whizzed classifier for finesse regulation and blower fan mounted on a solid shaft. Raw material from the feed hopper enters manually or automatically roll feeder and as the feeder and as the feeder pockets rotate spills into the grinding chamber. The impact to the hammers on the feed material against the liner plates reduces it into fine powder. The ground material carried towards the whizzed classifier for clarification and the finesse regulators (whizzed classifier) and returns to the grinding chamber for further grinding reject the oversize particles. Classified material then conveyed into the cyclone for collection and bagging. A dust collector provided in the system for ensuring dustless operation and no loss of ground powder.

Constructionofimpactpulveriser

Type Body Feeder Crushing Rotor Bearings Hammer Classifier Vertical model air swept totally enclosed, high-speed swing hammer type grinding mill with whizzer air classifier. The main body is made of heavy duty cast iron, machined with top covers bolted together for easy opening and cleaning or for inspection. Every portion in the machine, which meets the material, lined with high-grade steel plates. An automatic rotary feeder gear driven from the main shaft with feed control mechanism is optional. The striking face of the crushing chamber lined with hard chilled iron replaceable. Chamber plates keeping in view of the proper protection to given to the chamber from the wear and tear, which ensures ever - losing. Thick mild steel-machined plates mounted on main shaft. Best double row self-aligning ball bearings in cast iron housing with suitable grease cups for lubrication is supply with all impact pulveriser. Forged alloy steel, and dynamical balanced hammer is supply with the machine (stainless steel 304 is optional). Heavy duty paddle type with changeable blades and arms (impellers) cyclone mild steel sheet fabricated, welded throughout cones.

JasEnterprises,AllRightsReserved.(TermsofUse) DevelopedandManagedbyJasEnterprises

JasEnterprises AnISO9001:2008CertifiedCompany 60,ShreenathjiEstate,PannaEstateRoad,Rakhial,Ahmedabad380023GujaratIndia Phone:917922743454,55Fax:917922745062 Email:info@jasenterprise.com http://www.jasenterprise.comorhttp://www.pulveriser.co.inorhttp://www.pulverizerindia.com

Dust collector Piping

Top and bottom halves of mild steel sheet to interconnect by cotton cloth dust bags.

All interconnection mild steel pipes supplied with loose flanges to facilitate easy erection opening and cleaning. Lubrication A bearing are provided with oil cup, grease cup for heavy lubrication.

Standardaccessoriesofimpactpulveriser

Impact pulveriser's & motor pulley Suitable numbers of cotton balloons. Anti vibrating foundation stand with adjustable rail for motor

Extraaccessoriesofimpactpulveriser

Suitable totally enclosed fan cooled single or three phase sq. Cage motor as per is: 325 { (special power can be accommodated): 110/220/380/415 volts, 50/60 Hz ,3 phase } Suitable starters, main switch, ampere meter, capacitor for three phase V belts Contacting parts stainless steel 304 / 316 can be accommodated.

Applicationofimpactpulveriser

The techno wings impact pulveriser are used for a wide range of application e.g. Agricultural, chemicals, carbon & graphite, coal, coke, coconut shell & wood saw dust, clay, dye stuff & pigments, detergents, ferro alloys fertilizers, fillers, food products, herbs & spices, insecticides and pesticides, katha, marine feeds, minerals, plastics, pharmaceuticals, resins, wheat, turmeric, bangle grams, etc.

JasEnterprises,AllRightsReserved.(TermsofUse) DevelopedandManagedbyJasEnterprises

JasEnterprises AnISO9001:2008CertifiedCompany 60,ShreenathjiEstate,PannaEstateRoad,Rakhial,Ahmedabad380023GujaratIndia Phone:917922743454,55Fax:917922745062 Email:info@jasenterprise.com http://www.jasenterprise.comorhttp://www.pulveriser.co.inorhttp://www.pulverizerindia.com

Sectionviewofimpactpulveriser

JasEnterprises,AllRightsReserved.(TermsofUse) DevelopedandManagedbyJasEnterprises

Potrebbero piacerti anche

- Spice Grinding PulverisersDocumento2 pagineSpice Grinding PulverisersjasenterpriseNessuna valutazione finora

- Ribbon BlenderDocumento3 pagineRibbon BlenderjasenterpriseNessuna valutazione finora

- Pounding MachineDocumento2 paginePounding MachinejasenterpriseNessuna valutazione finora

- Mini Dal MillDocumento6 pagineMini Dal MilljasenterpriseNessuna valutazione finora

- Macaroni Making MachinesDocumento2 pagineMacaroni Making MachinesjasenterpriseNessuna valutazione finora

- Khichiya Papad Making MachineDocumento3 pagineKhichiya Papad Making MachinejasenterpriseNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- AME-Chap15-Rice Milling EquipmentDocumento8 pagineAME-Chap15-Rice Milling EquipmentJordan Yap100% (1)

- ChE SyllabusDocumento30 pagineChE SyllabusSubodh DwivediNessuna valutazione finora

- Materials 10 00882 v2 PDFDocumento17 pagineMaterials 10 00882 v2 PDFVisnu SankarNessuna valutazione finora

- Optimization and Development of Pulverization MachineDocumento7 pagineOptimization and Development of Pulverization MachineIJRASETPublicationsNessuna valutazione finora

- ResumeDocumento3 pagineResumeHari Prathap ReddyNessuna valutazione finora

- Ball Mill Testingjune99Documento29 pagineBall Mill Testingjune99Shakil Ahmad83% (6)

- TPT 550 Assignment 1Documento6 pagineTPT 550 Assignment 1Irdeena Nabila ZamriNessuna valutazione finora

- Basics of Mining and Mineral Processing by W Scott Dunbar PDFDocumento179 pagineBasics of Mining and Mineral Processing by W Scott Dunbar PDFFerudun Akyol100% (1)

- Cement Production Overview - MAPLE LEAF CEMENTSDocumento38 pagineCement Production Overview - MAPLE LEAF CEMENTSSyedMeherAli100% (1)

- A Solution To The Batch Grinding Equation Reid 1965Documento11 pagineA Solution To The Batch Grinding Equation Reid 1965abrahanNessuna valutazione finora

- BwiDocumento8 pagineBwiHiresomannavar MahanteshNessuna valutazione finora

- Magic LAB: 02/08-Engl Subject To Technical ChangesDocumento16 pagineMagic LAB: 02/08-Engl Subject To Technical ChangesSoniSSontaniNessuna valutazione finora

- Wind EnergyDocumento5 pagineWind Energyvigyanashram100% (2)

- Design of Comminution Circuits Rowland 1982Documento46 pagineDesign of Comminution Circuits Rowland 1982Eigen Galvez100% (1)

- BookDocumento170 pagineBookPriscyla RoqueNessuna valutazione finora

- MCS - Armco, IncDocumento13 pagineMCS - Armco, IncMiko Victoria VargasNessuna valutazione finora

- Ball Milling Induced Borophene Flakes FabricationDocumento8 pagineBall Milling Induced Borophene Flakes Fabricationshokhul lutfiNessuna valutazione finora

- Ceramic Raw Material ProcessingDocumento33 pagineCeramic Raw Material ProcessingAziz AdamNessuna valutazione finora

- 2006 Slag Grinding With MPS Vertical Roller MillsDocumento4 pagine2006 Slag Grinding With MPS Vertical Roller Millslijosh_rexy1983Nessuna valutazione finora

- Recovery of Ultra FinesDocumento28 pagineRecovery of Ultra FinesBelen TapiaNessuna valutazione finora

- Pelletization Studies On A Beneficiated Magnetite ConcentrateDocumento7 paginePelletization Studies On A Beneficiated Magnetite ConcentrateravibelavadiNessuna valutazione finora

- Grinding Machine DefinitionDocumento8 pagineGrinding Machine DefinitionOmkar BhoyarNessuna valutazione finora

- CaseStudy IIM Trichy MTDocumento4 pagineCaseStudy IIM Trichy MTPrivate Account0% (1)

- Ball Milling in Material Science-Polymers and Nano CompositeDocumento2 pagineBall Milling in Material Science-Polymers and Nano CompositedanaeiaNessuna valutazione finora

- Edco Operator Manual - E-Sec, 2ec, 2GC-P, 4ec, GC, Gcp-I-0808Documento16 pagineEdco Operator Manual - E-Sec, 2ec, 2GC-P, 4ec, GC, Gcp-I-0808Esirpus RekufNessuna valutazione finora

- MUIR - 2005 - A Practical Guide To Re-Treatment of Gold Processing ResiduesDocumento14 pagineMUIR - 2005 - A Practical Guide To Re-Treatment of Gold Processing ResiduesLeonardo RezendeNessuna valutazione finora

- Hydraulic Conveying InternetDocumento16 pagineHydraulic Conveying InternetSaurabh Raj100% (1)

- How To Remove Scrap Materials From A Ball Mill CircuitDocumento5 pagineHow To Remove Scrap Materials From A Ball Mill Circuitsafwat hassanNessuna valutazione finora

- Moanassar,+4878 14648 1 LEDocumento10 pagineMoanassar,+4878 14648 1 LEMichel M.Nessuna valutazione finora

- Lecture 24 PDFDocumento10 pagineLecture 24 PDFBhavesh Dilip ChanchlaniNessuna valutazione finora