Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

2RZ 3RZ SC

Caricato da

Diego PillcoDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

2RZ 3RZ SC

Caricato da

Diego PillcoCopyright:

Formati disponibili

1995 - 2001 2RZFE (2.4 L) and 3RZFE (2.

7 L)

SC-4RN-009-C, SC-TAC-006-C

Supercharger Kit Part Number: 00602-17620-700 series

Section I - Installation Preparation Kit Contents

Item # 1 2 3 4 5 6 7 Quantity Reqd. 1 1 1 1 1 1 1 Description Supercharger Assembly Idler Pulley Assembly Tensioner Kit Drive Belt Literature Kit Support Bracket Assembly Hose Kits Vehicle 2.4-L, 2RZFE 2.7-L, 3RZFE Quantity Reqd. 1 per kit 1 per kit 1 per kit Description Drive Belt Idler Pulley & Bearing Tensioner with Pulley

Color Applicability / Trim Level

Service Parts

Part # 00602-17620-730 00602-17620-019 00602-17620-725

General Applicability

1995-1999 All 2RZFE, 2000 Fed Emission Spec. 2RZFE 2000 Cal Emission Spec. 2RZFE, 2001 All 2RZFE 1995-1999 All 3RZFE, 2000 Fed Emission Spec. 3RZFE 2000 Cal Emission Spec. 3RZFE, 2001 All 3RZFE

Conflicts

None

Legend

STOP

STOP: Damage to the vehicle may occur. Do not proceed until process has been complied with. OPERATOR SAFETY: Use caution to avoid risk of injury CRITICAL PROCESS: Proceed with caution to ensure a quality installation. These points will be audited on a completed vehicle installation GENERAL PROCESS: This highlights specific processes to ensure a quality installation. These points will be audited during the accessory installation TOOLS & EQUIPMENT: This calls out the specific tools and equipment required for this process

Rev: C TRD 09/20/02

Page 1 of 21

Part Number

1995 - 2001 2RZFE (2.4 L) and 3RZFE (2.7 L)

SC-4RN-009-C, SC-TAC-006-C

Supercharger Kit

STOP

A. Preparation: 1. Before you begin, TRD recommends that you thoroughly clean the engine and engine compartment. If you dont, grease

buildup on parts could become dislodged during the procedure and fall into the engine.

2. Make sure the engine has cooled fully before you begin. 3. To help you later, you might want to draw diagrams of your engines vacuum hose routing before you disconnect

anything. However, some of the vacuum connections on your stock air intake chamber may not be the same as those on the supercharger. Study and closely follow the vacuum diagrams for your specific application included on pages 18 20.

4. The TRD supercharger kit has been designed to reuse most of the stock nuts and bolts. Therefore, as you remove them,

keep them with their components or label them for location. This will assure a faster, easier installation.

Recommended Tools:

Basic Tools: Basic Metric Socket, Allen & Open-End Wrench Sets Wide Masking Tape for Labeling Hardware and Parts Electrical Tape A Clean Work Bench A Parts Tray Rags or Shop Towels

Safety Tools: Safety Goggles Special Tools: Toyota Repair Manual (Available from Toyota, 1-800-622-2033) Accessories: Boost gauge recommended (not included in the kit)

Rev: C TRD 09/20/02

Page 2 of 21

1995 - 2001 2RZFE (2.4 L) and 3RZFE (2.7 L)

B. Removal of Stock Air Inlet System and Intake Manifold

1. Disconnect the ground cable from the battery, and then the positive cable. Remove battery from the vehicle. 2. 3. Remove air cleaner hose w/resonator. Figure 1 Remove evaporative canister vacuum switched valve (VSV) hose. Remove PCV hose.

SC-4RN-009-C, SC-TAC-006-C

Supercharger Kit

4.

Figure 1

5.

Remove EGR modulator and hoses. Note hose location and routing for re-installation. Figure 2

EGR Modulator

Figure 2

6.

Disconnect power steering idle-up connector from the sensor and also the wiring from the intake manifold bracket. See arrows in Figure 3.

Figure 3

Rev: C TRD 09/20/02

Page 3 of 21

1995 - 2001 2RZFE (2.4 L) and 3RZFE (2.7 L)

7. Remove fuel pressure regulator hose from intake air connector. Remove intake air connector. Figure 4 Disconnect Throttle Position Sensor (TPS) connector from TPS in throttle body.

SC-4RN-009-C, SC-TAC-006-C

Supercharger Kit

8. 9.

10. Disconnect Idle Air Control (IAC) connector from IAC in throttle body. 11. If vehicle is equipped with EGR, then disconnect EGR connector from EGR sensor in intake chamber.

Intake Air Connector

Figure 4

12. Remove throttle body from intake manifold and set aside. Figure 5

Figure 5

Note: If vehicle is not equipped with EGR, skip Steps 13 & 14 and proceed to Step 15. 13. Disconnect EGR feed tube at EGR valve. See A arrows in Figure 6. 14. Disconnect EGR valve from intake chamber. Leave EGR valve in place until step 22. Do not disconnect coolant lines. 15. Remove wire harness bracket from backside of intake chamber. See arrow B in Figure 6. Remove bracket from wire harness. B A

Figure 6

Rev: C TRD 09/20/02

Page 4 of 21

1995 - 2001 2RZFE (2.4 L) and 3RZFE (2.7 L)

16. Remove bolt from the upper side of the intake chamber stay. See arrow in Figure 7. Loosen lower bolt from air intake chamber stay. 17. Disconnect the DLC1 from the bracket on the air intake chamber assembly. 1995-2001 vehicles only. 18. Remove the wire harness bracket for the DLC1 wiring from the air intake chamber assembly. 1995-2001 vehicles only. 19. Disconnect the brake booster vacuum hose from the intake chamber hose barb. 20. If your vehicle is equipped with EGR, then disconnect EGR tube bracket from the backside of the cylinder head. 21. Remove the 3 bolts and 2 nuts shown in Figure 8. 22. Remo ve the air intake chamber and gasket. On vehicles with EGR, separate the EGR valve from the air intake chamber as you remove the chamber from the intake manifold runners. 23. Remove the injector wiring ground strap from the intake manifold.

SC-4RN-009-C, SC-TAC-006-C

Supercharger Kit

Figure 7

Figure 8

24. Remove the 2 bolts from the fuel return pipe and disconnect the fuel return hose from fuel pressure regulator. See Figure 9. Caution: Plug fuel return hose so that no fuel will spill. Set pipe and hose aside.

Figure 9

Rev: C TRD 09/20/02

Page 5 of 21

1995 - 2001 2RZFE (2.4 L) and 3RZFE (2.7 L)

25. Disconnect wire loom clips from the intake manifold brackets and remove the clips from the wire loom. See arrows in Figure 10. 26. On vehicles with EGR, remove the EGR vacuum switched valve bracket from the intake manifold. 27. Disconnect the camshaft position sensor connector. See Figure 10. 28. Remove wire-loom bracket and clips from the wire loom that was disconnected in Step 15.

SC-4RN-009-C, SC-TAC-006-C

Supercharger Kit

Cam Position Connector

Figure 10

A 29. Disconnect the detonation sensor connector (A), and the crankshaft position sensor connector (B). See Figure 11. Both connectors are located next to the engine block, and below the intake manifold. 30. Disconnect all four fuel injection connectors and set wiring aside. 31. On vehicles with EGR, remove the EGR coolant hose from the EGR valve. Remove only the hose that runs down through the intake manifold runners. Plug hose so that coolant will not leak. Figure 11 B

32. Disconnect the fuel inlet banjo fitting from the fuel rail. Remove both banjo washers. See Figure 12. 33. Remove the intake manifold from the cylinder head. Clean and inspect the intake manifold gasket. You may re-use the gasket if it has not been damaged. 34. Remove the original equipment (OE) intake manifold chamber stay. 35. Remove the evaporative canister steel line that is secured to the top of the radiator fan shroud and set aside. Figure 12

Rev: C TRD 09/20/02

Page 6 of 21

1995 - 2001 2RZFE (2.4 L) and 3RZFE (2.7 L)

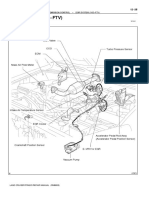

36. On 2000 and earlier model years, step 36 may not be necessary. Check the power steering pressure feed hose clearance to the supercharger by installing the supercharger main assembly onto the cylinder head. When installing the supercharger, the supercharger drive pulley and snout slides under the power steering pump return hose. If necessary, adjust the power steering line next to the banjo fitting on the power steering pump. See Figure 13. The steel line needs to be parallel with the engine centerline. Caution: Adjust carefully so the steel line will not kink. When adjusted correctly, the rubber hose that is connected to the steel line will have clearance to the supercharger housing and also to the lower radiator hose.

SC-4RN-009-C, SC-TAC-006-C

Supercharger Kit

Adjust line here

Figure 13

37. Attach the new TRD supplied 2-piece chamber stay to the engine mount with one 8mm x 25mm long flangehead hex bolt. See arrow in Figure 14. Make sure the L-portion of the chamber stay points towards the front of the vehicle. Figure 14 shows the chamber stay in the assembled position. Attach only the lower bolt in this step. Tighten bolt finger tight.

Figure 14

Rev: C TRD 09/20/02

Page 7 of 21

1995 - 2001 2RZFE (2.4 L) and 3RZFE (2.7 L)

38. Remove the radiator fan shroud for easier access to the components in the following steps. See Figure 15.

SC-4RN-009-C, SC-TAC-006-C

Supercharger Kit

Figure 15

39. Remove power steering belt including the belt tensioner. See Figure 16.

Figure 16

40. Remove the power steering pump pulley. See Figure 17. Use the Toyota Special Service Tool (SST) to stop the pulley from rotating. Remove the pulley set nut, and then the pulley. SST 09960-10010 (09962-01000, 09963-01000)

Figure 17

Rev: C TRD 09/20/02

Page 8 of 21

1995 - 2001 2RZFE (2.4 L) and 3RZFE (2.7 L)

41. Remove the two bolts that secure the power steering pump to the pump bracket. See Figure 18.

SC-4RN-009-C, SC-TAC-006-C

Supercharger Kit

Figure 18

42. Install the TRD supplied idler pulley bracket to the front of the power steering pump. See Figure 19. Use (2) 10mm x 1.25 x 100mm long bolts supplied. Both bolts replace the OE bolts removed in Step 41. Torque bolts to 39 N-m (29 ft-lbf). 43. Re-install the power steering pump pulley. Use the Toyota Special Service Tool (SST) to stop the pulley from rotating. Torque the set nut to 43 N-m (440 kgfcm, 32 ft-lbf).

Figure 19 44. Remove the bolt that secures the oil dipstick tube to the front side of the engine. Rotate dipstick tube slightly to the passenger side of the engine. See Figure 20. 45. If installing on the 2.7 L (3RZFE) engine, follow Steps 46 and 47, and then skip Step 48. If installing on the 2.4 L (2RZFE) engine, then skip Steps 46 and 47, and use Step 48. 46. Remove one bolt from the water pump housing. See arrow in Figure 20.

Figure 20

Rev: C TRD 09/20/02

Page 9 of 21

1995 - 2001 2RZFE (2.4 L) and 3RZFE (2.7 L)

47. Remove the 2.7-L tensioner from the box. Insert the 95mm long countersunk head bolt through the countersunk hole in the gold bracket. The bolt head should fit about flush with the front-side of the bracket. Next, align the slot of the tensioner bracket to the raised tang on the backside of the tensioner. Tighten the 10mm x 1.5mm crush nut to 47 N-m (35 ft-lbf). Install the TRD dynamic tensioner on the 2.7 L using two 8 x 1.25mm x 20mm long hex bolts with two 8mm washers (Arrows A), and one 8 x 1.25mm x 95mm long hex socket countersunk head bolt (Arrow B). See Figure 21. Leave the 8mm bolts finger tight and torque countersunk head bolt first. Torque all bolts to 21 N-m (16 ft-lbf). B

SC-4RN-009-C, SC-TAC-006-C

Supercharger Kit

Figure 21

48. Install the TRD dynamic tensioner on the 2.4 L using one 8 x 1.25mm x 20mm long hex bolt with 8mm washer (Arrow A), and one 8 x 1.25mm x 20mm long hex socket countersunk head bolt (Arrow B). See Figure 22. Leave the 8mm bolt finger tight and torque countersunk head bolt first. Torque both bolts to 21 N-m (16 ft-lbf). 49. Re-install dipstick tube to the front of engine using the OE bolt removed in Step 44. Torque bolt to 20 N-m (15 ft-lbf). 50. If your vehicle has eight round intake ports in the cylinder head, then proceed with steps 51 and 52. If your vehicle has four oval intake ports, then skip ahead to step 53. 51. The wires that connect to both the detonation sensor and the crankshaft position sensor need to be routed below the intake manifold. Remove the nylon split flexible tubing around the area where the wires join the main engine wire loom. See Figure 23. Separate the detonation sensor and crankshaft position sensor wires back about 6 to 8 from the original breakout point. Use electrical tape to wrap the wires that have been split out from the main wire loom. Re -install the nylon split flexible tubing around the main wire loom. Use electrical tape to secure the flexible tubing.

Figure 22 Remove cover here

Figure 23 52. Connect the detonation sensor and crankshaft position sensor connectors before installing the supercharger. Rev: C TRD 09/20/02 Page 10 of 21

Separate wires from main loom

1995 - 2001 2RZFE (2.4 L) and 3RZFE (2.7 L)

C. Installation of TRD Supercharger

53. Note: Please read all of step 53 before proceeding. Before installing supercharger main assembly onto the cylinder head, connect the 10-inch long bypass actuator hose to the hose fitting in the intake chamber and the bypass actuator. When installing the supercharger, the supercharger drive pulley and snout slides under the power steering pump return hose. See Figure 24. Before sliding the supercharger manifold over the attachment studs, insert the fuel line banjo fitting through the TRD manifold between intake ports three and four. It is easiest to do this as the manifold is being lowered into place after the supercharger snout is in position. Use another person if necessary to help with the fuel inlet banjo fitting. Snug all the nuts and bolts to secure the supercharger to the cylinder head. Start in the center of the manifold and work outward towards the ends. Torque fasteners to 29 N-m (300 kgf-cm, 22 ft-lbf) 54. Rotate the supercharger nose support bracket to align the slot in the bracket with the idler bracket bolt hole. See Figure 24. Use the supplied 10mm x 1.25 x 25mm long hex bolt and 10mm washer to secure the nose support bracket to the idler bracket. Finger tighten bolt. 55. Using the 8mm flange head nut supplied, secure the upper L-portion of the chamber stay to the 8mm stud that is in the bottom-side of the TRD intake manifold. The stud should protrude through the slot in the chamber stay. See Figure 25. Tighten chamber stay to supercharger first, and then also tighten to the engine mount. Torque: 20 N-m (200 kgf-cm, 15 ft-lbf). Finally, torque the chamber stay 8mm through bolt and nylock nut to 20 N-m (200 kgf-cm, 15 ft-lbf). 56. Tighten the 10mm bolt that secures the nose support bracket to the idler pulley bracket. Torque: 41 N-m (420 kgf-cm, 30 ft-lbf) 57. Tighten the socket head cap screw to secure the nose support bracket to the supercharger nose. Torque: 13 N-m (130 kgf-cm, 10 ft-lbf) 58. Check both the power steering pressure hose and return hose for clearance to the supercharger snout. Both lines should not touch the supercharger. Adjust lines as necessary. Figure 25

SC-4RN-009-C, SC-TAC-006-C

Supercharger Kit

Nose support bracket

Idler bracket bolt hole

Figure 24

Rev: C TRD 09/20/02

Page 11 of 21

1995 - 2001 2RZFE (2.4 L) and 3RZFE (2.7 L)

59. Reconnect the fuel inlet banjo fitting to fuel rail. Torque: 29 N-m (300 kgf-cm, 22 ft-lbf) 60. Reconnect all four fuel injection connectors. 61. Attach injector wiring ground strap removed in Step 23 to the supercharger intake manifold using the supplied 6mm hex bolt and washer. See Figure 26. Torque: 8 N-m (80 kgf-cm, 6 ft-lbf) Note: If your vehicle has eight round intake manifold ports, then skip to step 64. If your vehicle has four oval ports, then follow steps 62 and 63. 62. Route the crankshaft position sensor connector down through the opening between intake port one and intake port two of the TRD supercharger manifold and connect to the crankshaft position sensor. 63. Route detonation sensor connector through the intake manifold between ports two and three, and then connect to the detonation sensor. 64. Reconnect power steering idle up connector. Install the OE wiring bracket on to the supercharger stud. Torque nylock nut to 20 N-m (200 kgf-cm, 15 ft-lbf). See Figure 27.

SC-4RN-009-C, SC-TAC-006-C

Supercharger Kit

Figure 26

Figure 27

Install bracket here

65. On vehicles with EGR, remove the EGR temperature sensor (Arrow A) and EGR modulator bracket (Arrow B) from the OE intake chamber. See Figure 28.

Figure 28

Rev: C TRD 09/20/02

Page 12 of 21

1995 - 2001 2RZFE (2.4 L) and 3RZFE (2.7 L)

66. Check the OE intake chamber that was removed from the vehicle. Look at the quantity and location of the PCV/breather fitting/s that are next to the throttle body surface. See Figure 29. Model year 2000 (2RZFE) 2.4 L intake chamber shown.

SC-4RN-009-C, SC-TAC-006-C

Supercharger Kit

One 17mm OE PCV fitting

Figure 29

67. Check the TRD intake chamber to make sure that the quantity and location of the PCV/breather fitting/s match the OE intake chamber. See Figure 30. Note: TRD intake chamber is photographed off the engine for clarity. If the fitting/s match, then proceed with Step 68. If the fitting/s do not match, then use the supplied fittings to duplicate the PCV/breather fitting/s in the OE intake chamber. Re -use the 16mm nylon washers to seal the fittings into the intake chamb er. 68. If vehicle has EGR, install the EGR temperature sensor (Arrow A) to the TRD intake chamber. See Figure 30. Otherwise, install the TRD-supplied 10mm x 1.25 x 12mm long bolt. Teflon thread tape is recommended. 69. If vehicle has EGR, then proceed with Steps 70 through 75. If vehicle has no EGR, then skip to Step 76. 70. Use one of the supplied EGR gaskets and install the EGR valve to the backside of the TRD intake chamber. See Figure 31. Use the OE EGR valve nuts removed in Step 14. Leave the nuts loose at this time. 71. Use the second supplied EGR gasket and connect the EGR feed tube to the EGR valve. Again, use the OE nuts removed in Step 13. Leave nuts loose at this time. 72. Torque EGR valve nuts: 19 N-m (195 kgf-cm, 14 ft-lbf)

Figure 30

Figure 31 Page 13 of 21

Rev: C TRD 09/20/02

1995 - 2001 2RZFE (2.4 L) and 3RZFE (2.7 L)

73. Install the supplied EGR tube heat shield under the nuts that attach the feed tube to the EGR valve. The bend in the shield moves back towards the EGR feed tube. Torque feed tube nuts: 19 N-m (195 kgf-cm, 14 ft-lbf) 74. Reconnect EGR coolant hose removed in Step 31. 75. Re-install the EGR modulator bracket to the backside of the TRD intake chamber using the OE bolt removed in Step 65. Refer to Figure 31. 76. If the vehicle has no EGR, then use one EGR gasket, block-off plate, and two 8 x 1.25mm flange nuts to seal the EGR passage located on the backside of the TRD intake chamber. See Figure 32. Torque nuts: 19 N-m (195 kgf-cm, 14 ft-lbf). 77. Position TRD supplied throttle body gasket on to the studs on the TRD intake chamber. Position the OE throttle body also on the studs. Do not install the nuts or the bolts at this time. 78. Reconnect TPS and IAC connectors to the sensors in the throttle body. 79. Reconnect cam position sensor connector removed in Step 27. 80. Tighten the OE nuts and bolts to secure the throttle body to the intake chamber. Torque: 20 N-m (200 kgf-cm, 14 ft-lbf) 81. On vehicles with EGR, install the EGR modulator into the bracket on the TRD intake chamber. See Figure 33. 82. Reconnect the brake booster vacuum hose to the hose fitting on the side of the TRD intake chamber. See Figure 33, Arrow A 83. Remove the OE fuel return pipe and hose. Disconnect the OE hose at the hard line that is mounted on the inner fender panel. Install the new supplied fuel return hose using the OE clamps removed in Step 24. Route the new hose under the supercharger. 84. Install supercharger drive belt using the TRD supplied drive belt routing label as a guide. 85. Find a suitable area under the hood to mount the drive belt routing label. Clean area to remove any dirt or grease and affix label. 86. Re-install the radiator fan shroud removed in Step 38. Rev: C TRD 09/20/02 Page 14 of 21 A

SC-4RN-009-C, SC-TAC-006-C

Supercharger Kit

Figure 32

EGR modulator

Figure 33

1995 - 2001 2RZFE (2.4 L) and 3RZFE (2.7 L)

87. Re-install the steel line that was removed from the fan shroud in Step 35. 88. Remove the cam cover bolt and sealing washer from the rear hole on the driver side of the cam cover. See Figure 34. Remove the sealing washer from the bolt. Use the cam cover bolt to mount the supplied Z bracket onto the cam cover. The bracket should sit on top of the sealing washer. Tighten cam cover bolt. Cam cover bolt

SC-4RN-009-C, SC-TAC-006-C

Supercharger Kit

Z bracket

Figure 34

89. Mount the EGR modulator VSV to the Z bracket. See Figure 35. Use the OE 6mm bolt and washer removed in Step 26. Torque bolt: 8 N-m (80 kgf-cm, 6 ft-lbf) 90. Reconnect the VSV hoses and EGR modulator hoses per the vacuum diagram on the underside of the vehicle hood.

Figure 35

91. Reconnect the PCV hose from the PCV valve to the PCV fitting in the TRD intake chamber. See Figure 36, Arrow A 92. Reconnect the cam cover breather hose to the fitting on the throttle body. See Figure 36, Arrow B.

Figure 36 Rev: C TRD 09/20/02 Page 15 of 21

1995 - 2001 2RZFE (2.4 L) and 3RZFE (2.7 L)

93. Re-install intake air connector onto throttle body. See Figure 37. Secure intake air connector-to-connector bracket using two OE nuts removed in Step 2. Torque nuts: 18 N-m (185 kgf-cm, 13 ft-lbf) 94. Re-install air cleaner hose with resonator.

SC-4RN-009-C, SC-TAC-006-C

Supercharger Kit

Figure 37

95. On 1995-2001 vehicles, follow Steps 95 and 96. Mount OE DLC1 bracket to the unused boss on the cylinder head. See Figure 38. Use the OE bolt removed in Step 18. Torque bolt: 8 N-m (80 kgf-cm, 6 ft-lbf) 96. Slide the DLC1 onto the bracket until it locks into place. DLC1 Bracket

Figure 38

97. On 2.4 L (2RZFE) engines with production dates of 01/95 to 08/98, skip to Step 98. On 2.4 L (2RZFE) engines with production dates of 09/98 to present, remove the 1/8 NPT plug in the top of the supercharger manifold. See Figure 39. Install the supplied 1/8 brass barb fitting into the manifold. Use Teflon pipe sealant on the threads. Using the OE rubber vacuum hose, reconnect the vacuum hose from the fuel pressure regulator to the 1/8 brass barb fitting. Shorten the hose as necessary.

1/8 NPT plug

Figure 39

Rev: C TRD 09/20/02

Page 16 of 21

1995 - 2001 2RZFE (2.4 L) and 3RZFE (2.7 L)

98. On 2.4 L (2RZFE) engines with production dates of 01/95 to 08/98 and all 2.7 L (3RZFE) engines, reconnect the fuel pressure regulator hose to the air connector. 99. Recheck all vacuum lines and connections for proper placement and connections. 100. Apply the premium fuel stickers to the fuel gauge and fuel filler door. 101. Apply the TRD Executive Order (EO) label to the underside of the hood. The EO label will alert state smog inspectors that the TRD supercharger has been certified emissions legal in all 50 states. 102. On vehicles that do not need the vacuum hose fitting which is installed into the front of the TRD intake chamber, remove the rubber cap from the OE intake chamber fitting and use it to cap the TRD fitting. See Figure 40 for TRD fitting location. 103. Use the supplied cable ties to secure any wiring or hoses as necessary. 104. Re-install the battery. 105. Re-attach the positive cable, then the negative cable. 106. Start engine and check for any leaks. If any leaks are found, diagnose leaks and repair as necessary. 107. On vehicles that require the Dastek ECU, disconnect the vehicle battery and install the Dastek ECU using the installation instructions and wiring diagrams provided with the ECU. 108. On vehicles that do not use the Dastek ECU, the installation is complete.

SC-4RN-009-C, SC-TAC-006-C

Supercharger Kit

hose fitting

Figure 40

Note: In order to reach optimum performance, the vehicle must be driven several hundred miles (usually one to two tanks of fuel). These miles after the supercharger installation will allow the OE ECU to fully adjust to the additional airflow provided by the supercharger.

Rev: C TRD 09/20/02

Page 17 of 21

1995 - 2001 2RZFE (2.4 L) and 3RZFE (2.7 L)

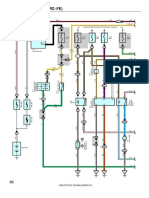

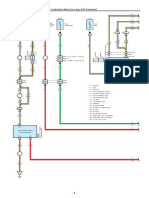

D. Vacuum Diagrams

SC-4RN-009-C, SC-TAC-006-C

Supercharger Kit

Rev: C TRD 09/20/02

Page 18 of 21

1995 - 2001 2RZFE (2.4 L) and 3RZFE (2.7 L)

SC-4RN-009-C, SC-TAC-006-C

Supercharger Kit

Rev: C TRD 09/20/02

Page 19 of 21

1995 - 2001 2RZFE (2.4 L) and 3RZFE (2.7 L)

SC-4RN-009-C, SC-TAC-006-C

Supercharger Kit

Rev: C TRD 09/20/02

Page 20 of 21

1995 - 2001 2RZFE (2.4 L) and 3RZFE (2.7 L)

SC-4RN-009-C, SC-TAC-006-C

Supercharger Kit

Symptom

Idles rough, pings (Trouble Code P0171Lean Code)

Possible Causes

Lean conditionvacuum leak

Corrective Action

Check vacuum line connections for leaks and cracked ends Review factory service manual for proper factory vacuum routing Review instructions for proper vacuum line routing Recheck torque on throttle body bolts Recheck the torque on the intake manifold bolts Use only premium fuel Drive several hundred miles in different driving modes (not all steady-state highway cruising for example) Dirty fuel filterreplace and follow the factory diagnosis and replacement procedures Low fuel pressurefollow the factory diagnosis and replacement procedures

Pings during acceleration

Low octane fuel Computer has yet to adjust to superchager Insufficient fuel delivery

Low boost

Belt slipping Air filter dirty

Injector(s) cloggedfollow the factory diagnosis and replacement procedures Check condition of belt oily, worn, high mileage Check/replace air filterTRD dyno tests have shown that the TRD air filter is among the best on the market for flow and filtering charactersitcis consider installing one now Recheck and adjust the throttle and transmission cables. Be sure that full depression on the gas pedal achieves full throttle opening at the throttle body. No remedy. Superchargers are an air pump and the pumping action is impossible without some noise. Slight rattle at idle is normal, but only if the noise sharply decreases at 400500 rpm above idle Call TRD for further diagnosis Diagnose by removing belt from supercharger and running engine for less than 30 seconds. If noise continues, source of problem is not within supercharger. Check the mounting and alignment of both the tensioner pulley and also the idler pulley Be sure that the pulleys all run trueno eccentricity No corrective action necessarybelt should be fully broken in after 2000 miles No immediate corrective action is necessaryseal should be fully mated to pulley after 2000 miles. If leaking continues, contact TRD.

Throttle not fully opened Makes a moderately loud noise under full throttleintake noise Rattling at idlegoes away at just above idle Rattling at idlegets louder with higher rpm or louder with more boost pressure Normal supercharger sound Normal supercharger sound Drive housing bearing wear or backlash Idler pulley bearing wear or excessive freeplay Supercharger belt jumps across pulley groove Misaligned tensioner pulley or idler pulley Damaged pulleys Normal break-in residue Front seal not fully broken in

Supercharger belt leaves grey/black powder on drive housing and other areas Supercharger appears to leak oil from drive housing

Rev: C TRD 09/20/02

Page 21 of 21

Potrebbero piacerti anche

- Control Engine 1kd FTV and 2kd FTDDocumento41 pagineControl Engine 1kd FTV and 2kd FTDMuxumad Cabdulahi0% (1)

- Toyota 3rzDocumento8 pagineToyota 3rzDanny Everson80% (5)

- Zd30 Ecu PinoutsDocumento10 pagineZd30 Ecu PinoutsKinaryoNessuna valutazione finora

- P1271 1272 PDFDocumento11 pagineP1271 1272 PDFHasnain Diesel100% (2)

- VEH MB ML320 ETC Control Module, TaskDocumento2 pagineVEH MB ML320 ETC Control Module, Taskd9dNessuna valutazione finora

- Navara qr25deBCSDocumento20 pagineNavara qr25deBCSAhmedNessuna valutazione finora

- Engine Mechanical PDFDocumento115 pagineEngine Mechanical PDFAndrey GladyshevNessuna valutazione finora

- TM 9-1803A Incl EngineDocumento76 pagineTM 9-1803A Incl Enginegwa4940% (1)

- Identification: Avalon (1999), Camry 3.0L, Camry Solara 3.0L & SiennaDocumento54 pagineIdentification: Avalon (1999), Camry 3.0L, Camry Solara 3.0L & SiennaJuan Carlos Martinez NuñezNessuna valutazione finora

- Sienna SparkPlug RemovalDocumento17 pagineSienna SparkPlug Removalazeemm1Nessuna valutazione finora

- Electronically Controlled TransmissionDocumento6 pagineElectronically Controlled TransmissionOliver leal100% (1)

- Manual de Taller Motor Kohler KDW 702-1003-1404 PDFDocumento116 pagineManual de Taller Motor Kohler KDW 702-1003-1404 PDFAlejandro Antonio Alvarez Balvero100% (1)

- Ecs 1azDocumento21 pagineEcs 1azjamesNessuna valutazione finora

- Toyota Diagnostic Trouble Codes Full List Obdii365Documento3 pagineToyota Diagnostic Trouble Codes Full List Obdii365Al-Bohari Kamsani100% (1)

- Ecs 1ZRDocumento17 pagineEcs 1ZRPeter SupercarsNessuna valutazione finora

- 11a Engine 4g9-GdiDocumento49 pagine11a Engine 4g9-GdiAlexandre Da Silva Pinto100% (1)

- DTC 51Documento4 pagineDTC 51victorNessuna valutazione finora

- Caldina ElectricalDocumento73 pagineCaldina ElectricalАльказар Рагнару100% (5)

- DTC Troubleshooting: Before You Troubleshoot, Review The General Troubleshooting InformationDocumento32 pagineDTC Troubleshooting: Before You Troubleshoot, Review The General Troubleshooting InformationpaniyaNessuna valutazione finora

- Genie S60Documento340 pagineGenie S60LuisTocoraNessuna valutazione finora

- 2004 Corolla Elecrtrical Diagrams - Combination MeterDocumento6 pagine2004 Corolla Elecrtrical Diagrams - Combination MeterNick Baptiste100% (1)

- Instalacion 3rz-FeDocumento5 pagineInstalacion 3rz-FeAngel Lira100% (3)

- Simtec 565Documento3 pagineSimtec 565ingestevesNessuna valutazione finora

- P1656 PDFDocumento3 pagineP1656 PDFTalleban TalNessuna valutazione finora

- Prado Manual SM - 2Documento104 paginePrado Manual SM - 2jeddo2005100% (1)

- DTC P0340/12 Engine Speed Sensor Circuit 1 (TDC or G1 Circuit)Documento2 pagineDTC P0340/12 Engine Speed Sensor Circuit 1 (TDC or G1 Circuit)Andi KaNessuna valutazione finora

- FlaDocumento553 pagineFlaObrocea Nelu100% (5)

- Terminals of Ecm: E17 E16 E15 E14Documento5 pagineTerminals of Ecm: E17 E16 E15 E14Martin ChilbetNessuna valutazione finora

- Landcruiser 200 CodesDocumento9 pagineLandcruiser 200 Codesmarran almarranyNessuna valutazione finora

- N55 - Product InformationDocumento110 pagineN55 - Product Informationsattler14100% (2)

- 3Gr-Fse Fuel: GeneralDocumento14 pagine3Gr-Fse Fuel: Generalservice_007100% (1)

- Mitsubishi Códigos Error.Documento9 pagineMitsubishi Códigos Error.Juan Manuel LaraNessuna valutazione finora

- Common Rail System (CRS) SERVICE MANUAL: Operation: J05D/J08E EngineDocumento58 pagineCommon Rail System (CRS) SERVICE MANUAL: Operation: J05D/J08E EngineAntony Colonna100% (2)

- 1NZ-FE Engine Control System PDFDocumento12 pagine1NZ-FE Engine Control System PDFjuan100% (1)

- 1kd FTV PDFDocumento2 pagine1kd FTV PDFDayro Jose Geney OrtizNessuna valutazione finora

- Atf Drain & Fill & Leveling - Camry U760eDocumento13 pagineAtf Drain & Fill & Leveling - Camry U760echuck8726842667% (3)

- 120a PDFDocumento2 pagine120a PDFNilson MaldonadoNessuna valutazione finora

- Slow SteamingDocumento3 pagineSlow SteamingArun SNessuna valutazione finora

- Part Book PDFDocumento244 paginePart Book PDFEko DianNessuna valutazione finora

- Massey Ferguson Tractor Service Manual MH S mf25 130 PDFDocumento11 pagineMassey Ferguson Tractor Service Manual MH S mf25 130 PDFNikos MakrisNessuna valutazione finora

- w58 RebuildDocumento49 paginew58 RebuildtfphoenixNessuna valutazione finora

- Parts Catalog: XE210 ExcavatorDocumento214 pagineParts Catalog: XE210 ExcavatorCAUE GABRIEL100% (4)

- Fuse Box Fiat Punto 1Documento12 pagineFuse Box Fiat Punto 1Ruben RochaNessuna valutazione finora

- The Audi 1.8L and 2.0L Third Generation Ea888 Engines: Eself-Study Program 920243Documento72 pagineThe Audi 1.8L and 2.0L Third Generation Ea888 Engines: Eself-Study Program 920243sergio ulises santi huashuaNessuna valutazione finora

- Toyota 4efe - Correa de Distribucion PDFDocumento11 pagineToyota 4efe - Correa de Distribucion PDFRonald Gareca RuedaNessuna valutazione finora

- Manual Skoda Octavia 1,9 81kWDocumento88 pagineManual Skoda Octavia 1,9 81kWCornea Horatiu Sebastian100% (4)

- Engine 1.6L (Steem G16) PDFDocumento18 pagineEngine 1.6L (Steem G16) PDFAry Duran0% (1)

- Data List For Active TestDocumento5 pagineData List For Active Testjeremih alhegnNessuna valutazione finora

- 1Nz-Fe Engine Mechanical: Service DataDocumento3 pagine1Nz-Fe Engine Mechanical: Service Dataalbert phiriNessuna valutazione finora

- C1340Documento8 pagineC1340Carlos VelásquezNessuna valutazione finora

- Mazda 5 EngineDocumento143 pagineMazda 5 EngineAngel CastNessuna valutazione finora

- Toyota Diagnostic Trouble Codes Full List Obdii365Documento2 pagineToyota Diagnostic Trouble Codes Full List Obdii365kabuye NicholasNessuna valutazione finora

- Toyota YarisDocumento5 pagineToyota YarisMohammed Yusuf100% (1)

- DTC P0130 Oxygen Sensor Circuit Malfunction (Bank 1 Sensor 1)Documento4 pagineDTC P0130 Oxygen Sensor Circuit Malfunction (Bank 1 Sensor 1)williamNessuna valutazione finora

- VGRS Actuator MalfunctionDocumento3 pagineVGRS Actuator MalfunctionHenry YogaswaraNessuna valutazione finora

- CM F PDFDocumento30 pagineCM F PDFJerroldLYIGNessuna valutazione finora

- Ewd 3C eDocumento1 paginaEwd 3C eallaucaamor100% (1)

- 2tz Fze 2Documento22 pagine2tz Fze 2che-ahmad-majdi-7191Nessuna valutazione finora

- 2004 Corolla Electrical Diagram - Cruise ControlDocumento6 pagine2004 Corolla Electrical Diagram - Cruise ControlNick BaptisteNessuna valutazione finora

- Electronic Throttle ControlDocumento67 pagineElectronic Throttle Controlmkisa70100% (1)

- BSD104DV H3axDocumento21 pagineBSD104DV H3axTiborNessuna valutazione finora

- Naza Ria Rover KV6 Engine Cam Marking ManualDocumento7 pagineNaza Ria Rover KV6 Engine Cam Marking ManualLee Ming Fee100% (1)

- Toyota Mil CodeDocumento3 pagineToyota Mil CodeinayyerNessuna valutazione finora

- 2AZ-FE FuelDocumento43 pagine2AZ-FE FuelAdedeji OluwatobilobaNessuna valutazione finora

- MY99 Legacy TwinTurbo ECU PinoutDocumento2 pagineMY99 Legacy TwinTurbo ECU PinoutJosé Fabio LouNessuna valutazione finora

- Hydraulic Brake Booster Dissasembly LC200Documento10 pagineHydraulic Brake Booster Dissasembly LC200Yannick de WalqueNessuna valutazione finora

- Evo 4 5 6 Conversion To Evo7 8 ECU Pinout DiagramsDocumento10 pagineEvo 4 5 6 Conversion To Evo7 8 ECU Pinout DiagramsRemus TuningNessuna valutazione finora

- Fiat Uno 1.4 Engine 160A1.046 Data SheetDocumento3 pagineFiat Uno 1.4 Engine 160A1.046 Data SheetMario100% (1)

- 2UZTRDDocumento33 pagine2UZTRDJd BuzzNessuna valutazione finora

- Chapt 02Documento144 pagineChapt 02Tony LoweNessuna valutazione finora

- (FORD) Diagrama de Cableado Ford FocusDocumento29 pagine(FORD) Diagrama de Cableado Ford FocusArturoNoCesaNessuna valutazione finora

- AMSOIL P.I. Performance Improver Concentrate (API)Documento2 pagineAMSOIL P.I. Performance Improver Concentrate (API)amsoildealerNessuna valutazione finora

- lt1 4 Torque SpecsDocumento10 paginelt1 4 Torque SpecsCarl YelvingtonNessuna valutazione finora

- Haltech Sport 1000 Mazda rx7Documento20 pagineHaltech Sport 1000 Mazda rx7Henry WorkshopNessuna valutazione finora

- SOQ Summary of Location - 2 OOQ CBO 6-Apr-13 As On Date: FOR FMS AnalysisDocumento983 pagineSOQ Summary of Location - 2 OOQ CBO 6-Apr-13 As On Date: FOR FMS AnalysisRam KumarNessuna valutazione finora

- Engine Fuel SystemDocumento31 pagineEngine Fuel SystemJim LiebNessuna valutazione finora

- Au 2401 LPDocumento6 pagineAu 2401 LPajd.nanthakumarNessuna valutazione finora

- Change The Way You Drive: BoschDocumento10 pagineChange The Way You Drive: BoschJithin AntonyNessuna valutazione finora

- X25 G2Documento2 pagineX25 G2nageshNessuna valutazione finora

- Baytech Service Manual For 6.0L ApplicationDocumento18 pagineBaytech Service Manual For 6.0L ApplicationmoannaNessuna valutazione finora

- Cursor 13 Entm 50.10Documento4 pagineCursor 13 Entm 50.10GLGNessuna valutazione finora

- Electrical and Electronic SystemsDocumento49 pagineElectrical and Electronic SystemsHartono Exca100% (1)

- GW4G15 Service Manual-E20170720Documento142 pagineGW4G15 Service Manual-E20170720Santiago CosNessuna valutazione finora

- Lecture - 3 Combustion Phases of SI and CI EnginesDocumento21 pagineLecture - 3 Combustion Phases of SI and CI EnginesMuhammad SaqibNessuna valutazione finora

- Electronic EngineDocumento4 pagineElectronic EngineSoumyadeep BhattacharyyaNessuna valutazione finora

- Branson 00 Series Engine Service Manual PDFDocumento77 pagineBranson 00 Series Engine Service Manual PDFLu AlexandruNessuna valutazione finora

- Izzatnagar Railway Workshop, BareillyDocumento84 pagineIzzatnagar Railway Workshop, BareillyAreeb SirajNessuna valutazione finora

- D. Base Navistar 6.0 L 2004-06 Serie FDocumento6 pagineD. Base Navistar 6.0 L 2004-06 Serie FEduardo AlvarezNessuna valutazione finora

- Ct150-Ct200-En ManualDocumento13 pagineCt150-Ct200-En ManualLuis MejiasNessuna valutazione finora