Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Alok Singh

Caricato da

Ankit GuptaDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Alok Singh

Caricato da

Ankit GuptaCopyright:

Formati disponibili

Participant Details Name: Alok Kumar Singh Area: Operations Management and Quantitative Techniques

Contact Number: 09713224286 Email Id: f09aloks@iimidr.ac.in, alok_325@yahoo.com Expriences: 1.) Teaching Assistant, Mechanical Engineering Department, College of Technology, Pantnagar, 2001-2002. 2.) Management Trainee (Technical), Steel Authority of India Limited, 2003. 3.) Junior Manager, Mechanical Maintenance, Coke Oven, Bokaro Steel Plant, 20042005. 4.) Junior Manager, Mechanical Maintenance, Cold Rolling Mill, Bokaro Steel Plant, 2005-2007. 5.) Technical Assistant to GM, Cold Rolling Mill, Bokaro Steel Plant, 2007-2008, Department Strength of 2000 Employees. 6.) Technical Assistant to GM, Steel Melting Shop, Bokaro Steel Plant, 2009 onwards, Department Strength of 2200 Employees Academic and Professional Qualification: 1.) B.Tech Mechanical with 81% from College of Technology, Pantnagar, 2001. 2.) GATE qualified with 98.73 percentile. 2002-03 3.) CAT qualified with 90.6 percentile, 2009-10 Achievements & Awards: 1.) Best Employee of the month Certificate from Managing Director SAIL. 2.) Appreciation letter from Managing Director, BSL, SAIL, for Highest Production in my shift in Tandem Mill-II in Cold Rolling Mill in 2006. 3.) Best Participant at Technological Awareness Programme on Metallurgical Analysis and Material Characterization Techniques of Steels August 26-29, 2008, R & D centre for Iron & Steel, Ranchi, SAIL. 4.) Stood 3rd in Environment Quiz Competition held on the occasion of World Environment Day in Bokaro Steel Plant, SAIL. 5.) Member of New HCl Regeneration Plant Project team, Cold Rolling Mill, BSL, SAIL, Project Cost: 40 Crores. 6.) Member of New Cold Rolling Mill project team, BSL, SAIL, Project Cost : 800 Crores 7.) Guest Faculty for Hydraulics and Pneumatic lab located at T&D Centre, Bokaro Steel Plant, SAIL. 8.) Involved in Planning, Forecasting and procurement of spares. 9.) Coordinator of 1000T rakes shipment from CRM, BSL to Myanmar in 2008.

Area of Interest: 1.) 2.) 3.) 4.) Logistics and Supply Chain Management Human Resource development Project Management ISO and Quality Control

Publications, Projects and Conferences Attended: 1.) A.K. Singh, H. Marmat, N. Sohani, ANP with ISM based Approach for Supplier Selection Presented paper in International Conference ICC-2010, Sept. 25-28, 2010, IIM Indore. 2.) Member of Organizing team of the National Conference EREC-2010, held at IIM Indore, April 14-17, 2010 3.) Delivered Expert Lecture on Carrier options after B.Tech at Medi-Caps Institute of Tech. & Management., Indore, Sept. 21, 2010. 4.) Management Development Program at T&D centre, Bokaro Steel Plant. 5.) ISO awareness Programs at T&D Centre, Bokaro Steel Plant. 6.) Attended Workshop on Hydraulic and Pneumatic system at T&D Centre, Bokaro Steel Plant. 7.) Attended Training Programme on Mechanical Seals by A-one consultants, Pune, at T&D Centre, Bokaro Steel Plant 8.) Modification of water and Acid line piping system within HCl regeneration shop 9.) Installation of new sump pump and its piping system from HCl regeneration plant to Block of Chemicals. 10.) Execution & Supervision of annual Capital Repair Jobs in Hcl Regeneration plant as well as Pickling lines, Cold Rolling Mill, BSL, SAIL. 11.) Conversion of stand No- 3 in tandem mill-2 from water to oil hydraulics. 12.) In charge of house keeping in pickling line and Hcl Regeneration plant. 13.) Involved in Coordination of logistics system for Cold Rolled Products. 14.) Maintenance of sump pump, Polypropylene piping system, Various types of valves (Teflon lined, PP lined and rubber lined, Butterfly and globe type gas valves) 15.) Coordination with shop Operation, Electrical, Refractory, Instrumentation and Mechanical planning. 16.) Manpower handling and training. 17.) Making drawings of various parts where the drawing was not available.

Potrebbero piacerti anche

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Indefinite and Definite ArticlesDocumento19 pagineIndefinite and Definite ArticlesRantti AnwarNessuna valutazione finora

- Product Bulletin Fisher 8580 Rotary Valve en 123032Documento16 pagineProduct Bulletin Fisher 8580 Rotary Valve en 123032Rachmat MaulanaNessuna valutazione finora

- Tolkien Essay-TreesDocumento10 pagineTolkien Essay-Treesapi-657753727Nessuna valutazione finora

- Adverbial Phrases 3Documento21 pagineAdverbial Phrases 3Jobelle VergaraNessuna valutazione finora

- Rock Classification Gizmo WorksheetDocumento4 pagineRock Classification Gizmo WorksheetDiamond실비Nessuna valutazione finora

- Russia 2Documento21 pagineRussia 2api-302784045Nessuna valutazione finora

- Shanu Return Ticket To Sobani HostelDocumento1 paginaShanu Return Ticket To Sobani HostelTamseel ShahajahanNessuna valutazione finora

- Mca Lawsuit Details English From 2007 To Feb 2021Documento2 pagineMca Lawsuit Details English From 2007 To Feb 2021api-463871923Nessuna valutazione finora

- Affidavit of SeparationDocumento1 paginaAffidavit of SeparationRaysunArellano100% (9)

- A Psychological Crusade by Fernando Sorrentino - Text 7Documento2 pagineA Psychological Crusade by Fernando Sorrentino - Text 7Donnie DominguezNessuna valutazione finora

- Questions & Answers: Webinar: Leveraging Caesar Ii and Featools Featuring PRGDocumento8 pagineQuestions & Answers: Webinar: Leveraging Caesar Ii and Featools Featuring PRGMina MagdyNessuna valutazione finora

- 5 Miranda Catacutan Vs PeopleDocumento4 pagine5 Miranda Catacutan Vs PeopleMetoi AlcruzeNessuna valutazione finora

- Course Welcome and Overview ACADocumento20 pagineCourse Welcome and Overview ACAAlmerNessuna valutazione finora

- Rhetorical Analysis EssayDocumento8 pagineRhetorical Analysis Essayapi-308821140Nessuna valutazione finora

- Petitioner vs. vs. Respondents Nicanor S. Bautista Agaton D. Yaranon Bince, Sevilleja, Agsalud & AssociatesDocumento9 paginePetitioner vs. vs. Respondents Nicanor S. Bautista Agaton D. Yaranon Bince, Sevilleja, Agsalud & AssociatesBianca BNessuna valutazione finora

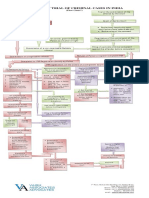

- Process of Trial of Criminal Cases in India (Flow Chart)Documento1 paginaProcess of Trial of Criminal Cases in India (Flow Chart)Arun Hiro100% (1)

- Christian Borch & Gernot Bohme & Olafur Eliasson & Juhani Pallasmaa - Architectural Atmospheres-BirkhauserDocumento112 pagineChristian Borch & Gernot Bohme & Olafur Eliasson & Juhani Pallasmaa - Architectural Atmospheres-BirkhauserAja100% (1)

- Youthful PopulationsDocumento18 pagineYouthful PopulationsJamesy66Nessuna valutazione finora

- Bibliografia Antenas y RadioDocumento3 pagineBibliografia Antenas y RadioJorge HerreraNessuna valutazione finora

- Theory of Design 2Documento98 pagineTheory of Design 2Thirumeni MadavanNessuna valutazione finora

- Whether To Use Their GPS To Find Their Way To The New Cool Teen HangoutDocumento3 pagineWhether To Use Their GPS To Find Their Way To The New Cool Teen HangoutCarpovici Victor100% (1)

- Article ReviewDocumento3 pagineArticle ReviewRAMADEVI A/P THANAGOPAL MoeNessuna valutazione finora

- Soal Dan Pembahasan Grammar Lat TOEP 1Documento6 pagineSoal Dan Pembahasan Grammar Lat TOEP 1Abdur100% (2)

- SDS Jojoba Wax Beads 2860Documento7 pagineSDS Jojoba Wax Beads 2860swerNessuna valutazione finora

- Agricultural LocationDocumento26 pagineAgricultural LocationPrince MpofuNessuna valutazione finora

- List - of - Members As On 6 3 18 PDFDocumento8 pagineList - of - Members As On 6 3 18 PDFashish jaiswal100% (1)

- Flex Li3 21 VAADocumento1 paginaFlex Li3 21 VAAAyman Al-YafeaiNessuna valutazione finora

- Kenya's Top 10 Tourist SpotsDocumento23 pagineKenya's Top 10 Tourist SpotsAaron LopezNessuna valutazione finora

- OD2e L4 Reading Comprehension AKDocumento5 pagineOD2e L4 Reading Comprehension AKNadeen NabilNessuna valutazione finora

- ORtHOGRAPHIC Plan FinalDocumento8 pagineORtHOGRAPHIC Plan FinalKrizzie Jade CailingNessuna valutazione finora