Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ME 751 - Group 3 - Project 2

Caricato da

Steve SchwadeDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ME 751 - Group 3 - Project 2

Caricato da

Steve SchwadeCopyright:

Formati disponibili

ME 751 Project: Nonlinear analysis of a car jack

A. Bayat, S. Schwade

ME 751 Project II

NONLINEAR ANALYSIS OF A CAR JACK

Alireza Bayat: 150% contribution Steve Schwade: 150 % contribution

ME 751 Project: Nonlinear analysis of a car jack

A. Bayat, S. Schwade

Introduction

The objective of this project is to determine the load bearing capability, the failure mode and failure location of a car jack under a compressive load P. Both geometric and material nonlinearities are to be considered in the analysis.

P

Figure 1: Car jack

In order to find the load carrying capacity of the jack, an analytical (static equilibrium) study was conducted to find the members carrying the highest percentage of the external load P. Buckling theory was also used to find the critical load for each member. The maximum load for each member was then determined by requiring that the stress be less than the yield stress of the material or that the load be less than the critical buckling load for that member. In all calculations and both analytical and FE analysis are done with a half model of the car jack.

ME 751 Project: Nonlinear analysis of a car jack

A. Bayat, S. Schwade

Static Analysis

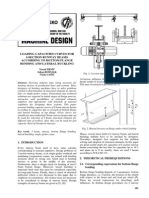

Figure 2: Geometry of the structure with the required angles and lengths

In order to find the portion of the external load in each member the geometry much first be determined. Trigonometric identities were use in the triangles that are formed by the members to find the geometric properties. The detailed calculations are listed in appendix A. Given:

ME 751 Project: Nonlinear analysis of a car jack

A. Bayat, S. Schwade

And the required angles and lengths are:

Table 1: Required angles and length for study

Calculated Dimensions

6 in

26.1

129.83

15.07

105.98

23.33

ME 751 Project: Nonlinear analysis of a car jack

A. Bayat, S. Schwade

Analytical study

Considering equilibrium equations in individual members, loads in different members were calculated (Appendix B).

Loads vs P for DEF link

8000 7000 6000 Loads in members (lb) 5000 4000 3000 2000 1000 0 0 1000 2000 3000 P (lb) 4000 5000 6000 F HD CE

Figure 3: required unknown loads for Analytical and FE analysis

ME 751 Project: Nonlinear analysis of a car jack

A. Bayat, S. Schwade

Buckling

Considering buckling in members the critical loads in individual members were calculated and the critical member DH is determined. Critical load in DH = Critical P = 2800 lbs 1880 lbs

Figure 4: Buckling model in DH member

ME 751 Project: Nonlinear analysis of a car jack

A. Bayat, S. Schwade

FE Analysis

Two different approaches were studied in order to find the critical loads in the members; 1) Individual members and 2) Whole structure study.

Individual members study

Based on the calculated loads from the theoretical study three critical members (DEF, DH, and CE) were identified to be analyzed using a nonlinear finite element analysis including linear and nonlinear1 material properties.

Figure 5: Critical members in members

See Appendix C for nonlinear material properties.

ME 751 Project: Nonlinear analysis of a car jack

A. Bayat, S. Schwade

Boundary Conditions

In order to study contacts in pin areas in members different models were tried. A model with 1 pin, 2pin and without pins (Fig6, 7). The models with pins consider contact which should yield a more accurate result; unfortunately it led to a non-convergent simulation in the models with nonlinear material properties.

Figure 6: DEF - with 1 pin and contact in joint D

Figure 7: DEF - with 2 pins and contacts in joint E and F

ME 751 Project: Nonlinear analysis of a car jack

A. Bayat, S. Schwade

Chosen Boundary conditions for DEF, DH and CE Comparing stress results for linear solution from the different models (1pin, 2 pin and without pins) the maximum stress in the models with pins were identical to models without pins. So the results from the model with bearing loads only would be reasonable enough for study.

Figure 8: DEF - Boundary conditions with no pins and bearing loads

Figure 9: DH - Boundary conditions with no pins and bearing loads

ME 751 Project: Nonlinear analysis of a car jack

A. Bayat, S. Schwade

Figure 10: CE - Boundary conditions with no pins and bearing loads Linear material-Linear FEA results for DEF

Figure 11: DEF - Von-Mises stress result

Figure 12: DEF - Deformation results 10

ME 751 Project: Nonlinear analysis of a car jack

A. Bayat, S. Schwade

Linear Material-Nonlinear solution for DEF

Figure 13: DEF - Von-Mises stress results

Figure 14: DEF - Deformation results

11

ME 751 Project: Nonlinear analysis of a car jack

A. Bayat, S. Schwade

Nonlinear Material FEA results

Figure 15: DEF - Nonlinear Material Von-Mises stress results

Figure 16: DEF - Nonlinear Material deformation results

12

ME 751 Project: Nonlinear analysis of a car jack

A. Bayat, S. Schwade

FE analyses for links DH and CE were conducted as well, the results are shown in Table 1 for 3 cases: 1) Linear Material- Linear Solution (LM-LS) 2) Linear Material- Nonlinear Solution (LM-NLS) 3) Nonlinear Material (NLM)

Table 2: FEA results for different solutions for three critical members DEF, DH and CE2

P = 2000 lbs. Max Stress (Psi) Link LM-LS DEF DH CE 37959 29427 6300 LM-NLS 38171 29434 6300 NLM 32601 24580 5779 LM-LS 145.54 3.1427 3.3165 LM-NLS 156.47 1.459 3.3116 NLM 320.0 2.940 6.341 Max Deformation (10^-4 in)

The critical member in the jack is DEF as expected because of the moment in the link. So based on trial and error FE analyses was performed with varying loads. Failure was found to occur at a load of 1,500 pounds.

Table 3: FE analyses results for P = 3000 lbs. that failure occurred

P = 3000 lbs. Max Stress (Psi) Link LM-LS DEF 56939 LM-NLS 57429 NLM 44714 LM-LS 218.27 LM-NLS 243.8 NLM 519.34 Max Deformation (10^-4 in)

LM: Linear material properties used in simulation, NLM: Nonlinear mater properties used in nonlinear simulation, LS: Linear simulation used, NLS: Nonlinear simulation used

13

ME 751 Project: Nonlinear analysis of a car jack

A. Bayat, S. Schwade

Complete Structure Analysis

In order to validate our static analysis and boundary condition assumptions a FEA of the complete structure was needed to establish the nonlinear member interactions after deformation.

Figure 17: nonlinear structure analysis Von-Mises Stress Distribution3 The simulation was conducted with nonlinear material properties, revolute joints, and frictional body connections (with =0.7). Maximum stress occurs in the member DEF which verifies the outcome of our static equilibrium analysis.

Deformation show with 0.5 times auto scale (9.3 times magnification)

14

ME 751 Project: Nonlinear analysis of a car jack

A. Bayat, S. Schwade

Figure 18: DEF Isolated Von-Mises Stress Distribution4 Member DEF experiences both displacement and rotation when the entire structure is simulated which invalidates the boundary conditions that were used in the individual member study. This rotation results in a slightly higher equivalent stress distribution and maximum stress (35.3 ksi vs 32.6 for the individual member study).

Deformation show with 0.5 times auto scale (9.3 times magnification)

15

ME 751 Project: Nonlinear analysis of a car jack

A. Bayat, S. Schwade

Empirical Results

For h = 6in the jack was setup under an Instron machine and compressive load was continuously applied on the jack till failure occurred (fig 19). The associated graphs for 3 tested jacks are shown in fig 20. The average maximum load the jack held was 4387 lbs.

Figure 19: Experimental setup for h = 6 in.

16

ME 751 Project: Nonlinear analysis of a car jack

A. Bayat, S. Schwade

5 4.5 4 3.5 Force [kip] 3 Jack 1 2.5 2 1.5 1 0.5 0 0 0.2 0.4 0.6 0.8 1 1.2 Total Displacement [in] Jack 2 Jack 3

Figure 20: Experimental results for 3 tested jacks.

Conclusion

The static and FEA results predict a similar outcome failure due to yielding with a load of 3,000 lbs. This is further confirmed by the experimental failure test data. All three of the jacks that were tested displayed a nearly linear force vs. displacement curve from 500 to 3,000 pounds, as the load exceeded 3,000 pounds the structure began to deform plastically and it was this plastic deformation that eventually resulted in the ultimate failure. Table 4: Maximum load via different approaches [lbs] Theory Maximum carrying load 2800 FEA individual FEA Complete Experiment members model structure model 3000 3000 4387

The difference between experiments with theory can be justified as: 1. Maximum loads estimated in the theory and FEA is based on the safety factor of 1, while safety factor in the real jack is definitely higher than 1. 2. Maximum stress failure in theory and FEA is based on maximum yielding stress failure, while the maximum carrying load from the experiments are the failure in plastic region.

17

ME 751 Project: Nonlinear analysis of a car jack

A. Bayat, S. Schwade

Feasibility Study

Ultimate failure was caused by out of plane buckling that the 2D simulations cannot account for. To better predict the causes of this failure, and locate areas for improvement, a complete three dimensional model would need to be simulated.

The two dimensional model identifies that a significant portion of the member DEF is under a compression stress which is further compounded by the axial force added by member CE. In order to withstand a greater load without yielding this behavior would need to be addressed.

18

ME 751 Project: Nonlinear analysis of a car jack

A. Bayat, S. Schwade

Appendix

G F

Appendix A: Geometry

E BDC ( , , ACD ( ( ADH ( )( ) ( ), )( ) ,

( )( )

)(

) D

)( ) B A

( )( )

Table 5: Coordinates of the points (Xi and Yi)5 Point A B C D E F G H X (in) 0 AB*cos AC*cos AD*cos( ) XD+ DE*cos XD + DF*cos AH Y (in) 0 AB*sin AC*sin AD*sin( ) YD + DE*sin YD + DF*sin 0

Note: the height of the jack h is the y value of point F + pins to top and bottom surfaces. 19

ME 751 Project: Nonlinear analysis of a car jack

A. Bayat, S. Schwade

20

ME 751 Project: Nonlinear analysis of a car jack

A. Bayat, S. Schwade

21

ME 751 Project: Nonlinear analysis of a car jack

A. Bayat, S. Schwade

22

ME 751 Project: Nonlinear analysis of a car jack

A. Bayat, S. Schwade

Appendix B: Forces in Members

Member HD or (

(

),

P

)

G y E F

From Free body GFAH as shown , ( )

Let HY be the Y component of force H:

( )

) (

Member GF(Free body GF) , ( ) ( )

Ay

B

x H

Ax

H

Member DEF (Free body DEF as shown) ( ( , ,

E Dy

D

( , )

) ( )

( ) (

), ( ) ( ) ) ( ( ) )

E F

Fy Fx

Dx

1

C

23

ME 751 Project: Nonlinear analysis of a car jack

A. Bayat, S. Schwade

Appendix C: Nonlinear Material Properties

Table 6: Nonlinear Stress & Strain

Figure 21: Nonlinear Stress - Strain Curve

24

Potrebbero piacerti anche

- "Grdslab" - Concrete Slab On Grade Analysis: Program DescriptionDocumento11 pagine"Grdslab" - Concrete Slab On Grade Analysis: Program Descriptioncjcute91100% (1)

- Design Vehhhih6h6h6hcle AnalysisDocumento35 pagineDesign Vehhhih6h6h6hcle AnalysisHarymurti S. Adi100% (1)

- Tkam Revision PackDocumento39 pagineTkam Revision Packtattie-bogle362100% (4)

- 50 Activities For Achieving Excellent Customer ServiceDocumento272 pagine50 Activities For Achieving Excellent Customer ServiceTrinimafia100% (1)

- Reynolds PPT Ch01 An Overview of EthicsDocumento29 pagineReynolds PPT Ch01 An Overview of EthicsLi Yu80% (5)

- Mahakala SadhanaDocumento4 pagineMahakala SadhanaSuvajra Dh100% (1)

- Scion - AyllusDocumento30 pagineScion - AyllusLivio Quintilio GlobuloNessuna valutazione finora

- Leaf Springs Design Calculation and TestDocumento10 pagineLeaf Springs Design Calculation and TestJorge Leonardo Fonseca DondaNessuna valutazione finora

- ACA Code of EthicsDocumento4 pagineACA Code of EthicsMohamad Shuhmy ShuibNessuna valutazione finora

- Teacher Classroom Observation ChecklistDocumento4 pagineTeacher Classroom Observation ChecklistAphze Bautista VlogNessuna valutazione finora

- Fatigue Life of A Mining Dump Truck...Documento9 pagineFatigue Life of A Mining Dump Truck...Esteban FaundezNessuna valutazione finora

- Post Subcultural TheoryDocumento6 paginePost Subcultural TheoryAkhmad Alfan RahadiNessuna valutazione finora

- 181-186 For Web PDFDocumento6 pagine181-186 For Web PDFdiego.peinado8856100% (1)

- Spur Gear Design Learn EngineeringDocumento4 pagineSpur Gear Design Learn EngineeringImran Sajid ShahidNessuna valutazione finora

- Load Distribution Between Threads in Threaded ConnectionsDocumento5 pagineLoad Distribution Between Threads in Threaded ConnectionsConradodaMattaNessuna valutazione finora

- Fatigue Strength Analysis On The Automobile Stabilizer BarDocumento5 pagineFatigue Strength Analysis On The Automobile Stabilizer BarSantiago UrgilesNessuna valutazione finora

- Final Speechfest Guidelines PDFDocumento38 pagineFinal Speechfest Guidelines PDFEladAquinoNessuna valutazione finora

- A Calculation of Piston Rod Strength - Bennet, M.CDocumento12 pagineA Calculation of Piston Rod Strength - Bennet, M.CLeandro FabrisNessuna valutazione finora

- Mathematics Quiz 1 Prelims Kuya MeccsDocumento13 pagineMathematics Quiz 1 Prelims Kuya MeccsBeng BebangNessuna valutazione finora

- NES Case StudyDocumento2 pagineNES Case Studysunjida80% (5)

- Stress Analysis On CrankshaftDocumento5 pagineStress Analysis On CrankshaftChanduReddyNessuna valutazione finora

- Finite Element Analysis Concepts and ApplicationsDocumento3 pagineFinite Element Analysis Concepts and Applicationsbhargav5508Nessuna valutazione finora

- Design and Analysis of Vehicle Front Axle: Ponshanmugakumar A & Rajavel RDocumento6 pagineDesign and Analysis of Vehicle Front Axle: Ponshanmugakumar A & Rajavel RTJPRC PublicationsNessuna valutazione finora

- Automotive SIMULIA Tech Brief 08 Iterative Design Evaluation FullDocumento4 pagineAutomotive SIMULIA Tech Brief 08 Iterative Design Evaluation Fullklomps_jrNessuna valutazione finora

- Designing efficient pallet rack analysis programDocumento16 pagineDesigning efficient pallet rack analysis programrenjisrsNessuna valutazione finora

- Dynamic Load Analysis and Optimization of Connecting Rod of Samand EngineDocumento9 pagineDynamic Load Analysis and Optimization of Connecting Rod of Samand EnginecamiloromezNessuna valutazione finora

- Helical Pipe Heat Exchanger Modeling FEADocumento15 pagineHelical Pipe Heat Exchanger Modeling FEAUsama ArifNessuna valutazione finora

- BAEK Et Al. Fatigue Life Prediction Based On The Rainflow Cycle Counting Method For The End Beam of A Freight Car BogieDocumento7 pagineBAEK Et Al. Fatigue Life Prediction Based On The Rainflow Cycle Counting Method For The End Beam of A Freight Car BogiePPNNessuna valutazione finora

- Finite Element Modeling of Cable Hook BoltsDocumento12 pagineFinite Element Modeling of Cable Hook BoltsNing LettuceNessuna valutazione finora

- Lecture Notes 6.1 - 6.3Documento22 pagineLecture Notes 6.1 - 6.3Hidayah KamaludinNessuna valutazione finora

- Finite Element Analysis of Elliptical Pressure VesselsDocumento7 pagineFinite Element Analysis of Elliptical Pressure VesselsAJER JOURNALNessuna valutazione finora

- Optimization of Connecting Rod Parameters Using CAE Tools: Student, Mechanical Engineering GJUS&T, HisarDocumento7 pagineOptimization of Connecting Rod Parameters Using CAE Tools: Student, Mechanical Engineering GJUS&T, HisarMahesh JadhavNessuna valutazione finora

- Stress Analysis of Front Axle for Modified Combine HarvesterDocumento3 pagineStress Analysis of Front Axle for Modified Combine HarvesterRajendra PraharajNessuna valutazione finora

- 31 PDFDocumento24 pagine31 PDFRafael Severo da SilvaNessuna valutazione finora

- 03 Radioss BITSDocumento6 pagine03 Radioss BITSSharada GunjalNessuna valutazione finora

- Expert Module Application and Practical Subjects Mechanical Branch 2015Documento13 pagineExpert Module Application and Practical Subjects Mechanical Branch 2015nima1977Nessuna valutazione finora

- FE-Based Wheel Fatigue Analysis Using MSC - FATIGUE: X y XyDocumento5 pagineFE-Based Wheel Fatigue Analysis Using MSC - FATIGUE: X y Xypkpnitian_152297088Nessuna valutazione finora

- OptimizationDocumento8 pagineOptimizationThaiHuynhNgocNessuna valutazione finora

- Chassis Mulitleaf Auc02 ChryslerDocumento14 pagineChassis Mulitleaf Auc02 ChryslerIndranil BhattacharyyaNessuna valutazione finora

- Design and Analysis of Connecting Rods Usign Ansys Softwere 16.0Documento13 pagineDesign and Analysis of Connecting Rods Usign Ansys Softwere 16.0ali danishNessuna valutazione finora

- Fem of Double Wishbone SuspensionDocumento6 pagineFem of Double Wishbone SuspensionShubham GuptaNessuna valutazione finora

- Direct Analysis Method - Part IIDocumento6 pagineDirect Analysis Method - Part IISamKtkNessuna valutazione finora

- Bicycle WheelDocumento19 pagineBicycle Wheelnikhil5811100% (1)

- Comparison of Analytical and Numerical Models On Torque and Hookload CalculationDocumento7 pagineComparison of Analytical and Numerical Models On Torque and Hookload Calculationsaeed65Nessuna valutazione finora

- Adem Candaş, Serpil Kurt, İsmail Gerdemeli and Eren KayaoğluDocumento4 pagineAdem Candaş, Serpil Kurt, İsmail Gerdemeli and Eren KayaoğluAkin ErsozNessuna valutazione finora

- Experimental and Numerical Analysis On Coil Springs Preset Plastic DeformationDocumento5 pagineExperimental and Numerical Analysis On Coil Springs Preset Plastic DeformationRobinson Ferrari BarbosaNessuna valutazione finora

- Transport Noise 02Documento10 pagineTransport Noise 02reek_bhatNessuna valutazione finora

- Chassis Analysis of Electric Vehicle Designed For Teknofest Efficiency Challenge Race (#1239731) - 2906366Documento10 pagineChassis Analysis of Electric Vehicle Designed For Teknofest Efficiency Challenge Race (#1239731) - 2906366Dekeba GetemaNessuna valutazione finora

- KaeriDocumento74 pagineKaerihamadaniNessuna valutazione finora

- Software Verification: Example 1 Plane Frame With Beam Span Loads - Static Gravity Load Analysis Problem DescriptionDocumento3 pagineSoftware Verification: Example 1 Plane Frame With Beam Span Loads - Static Gravity Load Analysis Problem DescriptionRyu Rey RogerNessuna valutazione finora

- M Jayakumar Paper (17142691331)Documento12 pagineM Jayakumar Paper (17142691331)N V DhandapaniNessuna valutazione finora

- Pedagogy of The Concept of Load at A Distance in F.E.A. Codes (Basic Case Studies)Documento20 paginePedagogy of The Concept of Load at A Distance in F.E.A. Codes (Basic Case Studies)Henrique MarquesNessuna valutazione finora

- FEA Mesh Convergence and Singularity in Connecting LugDocumento11 pagineFEA Mesh Convergence and Singularity in Connecting LugDarshanPatel100% (1)

- Neuber FEADocumento12 pagineNeuber FEAPrashantha RajuNessuna valutazione finora

- Stress Analysis of Connecting Rod Using FEADocumento5 pagineStress Analysis of Connecting Rod Using FEAer.jayeshmoreNessuna valutazione finora

- Err Or! Ref Ere Nce Sou Rce Not Fou ND.: Software VerificationDocumento2 pagineErr Or! Ref Ere Nce Sou Rce Not Fou ND.: Software VerificationAnitha Hassan KabeerNessuna valutazione finora

- 3. مهم جداvery Important Conrod Reference and Experimental WorkDocumento8 pagine3. مهم جداvery Important Conrod Reference and Experimental WorkAhmed M. El-DyastyNessuna valutazione finora

- A Study On The Stress Distri and Saddle Nition of Pressure Vessel SupportDocumento4 pagineA Study On The Stress Distri and Saddle Nition of Pressure Vessel SupportSaam SasanianNessuna valutazione finora

- Fracture Specimen Stree AnalysisDocumento15 pagineFracture Specimen Stree AnalysisGaurav PundirNessuna valutazione finora

- REF 1 55A - Finite in This Study Static Linear Finite Element Analysis Was Used To Obtain ResultsDocumento4 pagineREF 1 55A - Finite in This Study Static Linear Finite Element Analysis Was Used To Obtain ResultsImthiyas MohamedNessuna valutazione finora

- 5.accidental Car Impact Analysis and CFDDocumento6 pagine5.accidental Car Impact Analysis and CFDprojectzfourNessuna valutazione finora

- Static Analysis, Design Modification and Modal Analysis of Structural Chassis FrameDocumento5 pagineStatic Analysis, Design Modification and Modal Analysis of Structural Chassis FrameGopinath ChakrabortyNessuna valutazione finora

- Stepped Shaft Finite Element Study ReportDocumento7 pagineStepped Shaft Finite Element Study ReportMohammad AzemNessuna valutazione finora

- Task Report 3Documento8 pagineTask Report 3Muhamad RohaizadNessuna valutazione finora

- Design Optimization and Analysis of A Parabolic Leaf SpringDocumento7 pagineDesign Optimization and Analysis of A Parabolic Leaf Spring'İlker BaharNessuna valutazione finora

- FEA of PipeDocumento11 pagineFEA of Pipedimos dimouNessuna valutazione finora

- Guided Tour: Chapter IntroductionDocumento3 pagineGuided Tour: Chapter IntroductionJenny PriceNessuna valutazione finora

- Fatigue of Textile and Short Fiber Reinforced CompositesDa EverandFatigue of Textile and Short Fiber Reinforced CompositesNessuna valutazione finora

- HAT 2007 Marking SchemeDocumento6 pagineHAT 2007 Marking SchemerusteeeeNessuna valutazione finora

- Creativity PresentationDocumento26 pagineCreativity PresentationDivyansh TomarNessuna valutazione finora

- Charles Keys - Weber and AnthropologyDocumento24 pagineCharles Keys - Weber and AnthropologyMarcos Magalhães RosaNessuna valutazione finora

- Bhabha - of Mimicry Anb Man - The Ambivalence of Colonial DiscourseDocumento10 pagineBhabha - of Mimicry Anb Man - The Ambivalence of Colonial DiscourseGuerrila NowNessuna valutazione finora

- 12: Consumer BehaviourDocumento43 pagine12: Consumer Behaviournageswara_mutyalaNessuna valutazione finora

- Chapter 1. The First Law of Thermodynamics For Close System Key Learning OutcomesDocumento16 pagineChapter 1. The First Law of Thermodynamics For Close System Key Learning OutcomesLi BushNessuna valutazione finora

- Taghoot ExplainedDocumento10 pagineTaghoot ExplainedTafsir Ibn KathirNessuna valutazione finora

- Creating Character: By: Annie Besant and C.W. LeadbeaterDocumento25 pagineCreating Character: By: Annie Besant and C.W. Leadbeaterxenocid3rNessuna valutazione finora

- Retire Statistical Significance NatureDocumento3 pagineRetire Statistical Significance NaturebNessuna valutazione finora

- English DraftDocumento5 pagineEnglish Draftapi-452150993Nessuna valutazione finora

- Comic Strip Lesson PlanDocumento3 pagineComic Strip Lesson Planapi-242583948Nessuna valutazione finora

- ERP Implementation and Upgrade in KenyaDocumento288 pagineERP Implementation and Upgrade in Kenyasanyal2323Nessuna valutazione finora

- Group5 Affective Social Experiences PrintDocumento11 pagineGroup5 Affective Social Experiences PrintshrutiNessuna valutazione finora

- Water Jet Procedd PDFDocumento788 pagineWater Jet Procedd PDFVijendraAgar100% (1)

- Arsrv14 N1 P17 37Documento20 pagineArsrv14 N1 P17 37Ikin NoraNessuna valutazione finora

- Chapter 3 The Filipino WayDocumento12 pagineChapter 3 The Filipino WayJoy Estela MangayaNessuna valutazione finora

- Lilly Ryden - Gms - Lesson Plan 3Documento4 pagineLilly Ryden - Gms - Lesson Plan 3api-289385832Nessuna valutazione finora

- Guido Adler: 1.2 A Pioneer of MusicologyDocumento3 pagineGuido Adler: 1.2 A Pioneer of MusicologyAnonymous J5vpGuNessuna valutazione finora

- Conversion Between Displacement, Velocity and Acceleration - CBMAppsDocumento3 pagineConversion Between Displacement, Velocity and Acceleration - CBMAppsniraj_hwbNessuna valutazione finora