Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

FS-Series PV Module Cleaning Guidelines

Caricato da

asif_hopeDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

FS-Series PV Module Cleaning Guidelines

Caricato da

asif_hopeCopyright:

Formati disponibili

FS-Series PV Module Cleaning Guidelines

First Solar modules are frameless and do not require cleaning as installed. Installed modules may collect a light layer of dust and/or dirt over time. However, for most installations, rainfall should be sufficient to remove any soiling. Cleaning activities create risk of damage to the modules and array components, as well as the potential for electric shock.

Cracked or broken modules represent a shock hazard due to leakage currents, and the risk of shock is increased when modules are wet. Before cleaning, thoroughly inspect modules for cracks, damage, and loose connections. The voltage and current present in an array during daylight hours are sufficient to cause a lethal electrical shock.

The encapsulating glass of a First Solar module provides insulating protection from electrical shock hazard when it is intact. However, in the unlikely event that the glass is cracked or if the glass is damaged during the cleaning operation, a conductive path may be created. Only properly trained personnel who understand the risks of applying water to electrical components should clean modules. Appropriate electrically insulating Personal Protective Equipment (PPE) must be worn during any cleaning or inspection operations. Professional cleaning services trained to work on live electrical systems are available for hire. Acceptable module cleaning methods are to spray the modules with low-pressure water closely matched in temperature to the module, or to use a dry brushing technique. The following guidelines minimize impact to plant power generation, reduce safety hazards, and minimize risk of module damage. These cleaning guidelines are considered requirements to maintain proper module operating conditions and failure to comply will void module warranty.

All cleaning techniques: Modules should be cleaned only when in open circuit either disconnected from load, or during times when inverter is turned off. To ensure warranty coverage, First Solar must review and approve: o o Automated or motorized cleaning tools and methods Cleaning fixtures or tools which are supported by or rest on modules

Wet cleaning: www.firstsolar.com

PD-5-804 Rev 1.3 Page 1 of 2

Tap water (with low mineral content) or deionized water may be used. If needed, a mild, non-abrasive, non-caustic detergent may be used. Do not use abrasive cleaners or de-greasers on the module. Do not use cleaning

solutions containing hydrochloric acid, D-Limonene, ammonia, or sodium hydroxide. Water pressure must not exceed 35 bar (500 psi) Do not apply water that is more than 20C warmer or colder than module surface temperature Do not clean or spray water at the Junction Box or any area on the backside of the module.

Dry or brush cleaning: If excessive soiling is present, a non-conductive brush, sponge, or other mild agitating method may be used with caution. Ensure brushes or agitating tools are not abrasive to glass, EPDM, silicone, aluminum, or steel Ensure any brushes or agitating tools are constructed with non-conductive materials to minimize risk of electric shock

Please consult First Solar (technicalsupport@firstsolar.com) for additional questions regarding cleaning methods. Module damage that arises as a result of improper cleaning will not be warranted by First Solar.

www.firstsolar.com

PD-5-804 Rev 1.3 Page 2 of 2

Potrebbero piacerti anche

- Yamuna Nagar - Plywood FactoriesDocumento16 pagineYamuna Nagar - Plywood Factoriesasif_hope83% (6)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionDa EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionValutazione: 4.5 su 5 stelle4.5/5 (3)

- Tariff, Power Factor and Power Factor ImprovementDocumento12 pagineTariff, Power Factor and Power Factor ImprovementnurliyanaNessuna valutazione finora

- Super Capacitor BatteryDocumento2 pagineSuper Capacitor Batterybuditux100% (1)

- Module Cleaning GuidelinesDocumento6 pagineModule Cleaning GuidelinesKesavanNessuna valutazione finora

- PV Module Cleaning Work Instruction: How to Safely Clean Solar PanelsDocumento7 paginePV Module Cleaning Work Instruction: How to Safely Clean Solar PanelsNithin KrishnaNessuna valutazione finora

- Install solar PV guide for safe installation and maintenanceDocumento11 pagineInstall solar PV guide for safe installation and maintenanceChandranidas06Nessuna valutazione finora

- Solar Panel Cleaning and MaintenanceDocumento1 paginaSolar Panel Cleaning and Maintenanceoussema jendoubiNessuna valutazione finora

- Automated Solar Panel Cleaning SystemDocumento52 pagineAutomated Solar Panel Cleaning Systemakhil katariNessuna valutazione finora

- Influence of Dirt Accumulation On Performance of PV Panels: SciencedirectDocumento7 pagineInfluence of Dirt Accumulation On Performance of PV Panels: SciencedirectEsra AbdulhaleemNessuna valutazione finora

- Connections - and - Connectors - Best PracticesDocumento4 pagineConnections - and - Connectors - Best PracticesVenkataramanan SNessuna valutazione finora

- Inverter DC Oversizing GuideDocumento2 pagineInverter DC Oversizing GuideRRANessuna valutazione finora

- DEH-27MP: Connecting The UnitsDocumento6 pagineDEH-27MP: Connecting The Unitsbus076Nessuna valutazione finora

- Cleaing of Solar Panel (2nd Review 6th Sem)Documento15 pagineCleaing of Solar Panel (2nd Review 6th Sem)manish yadavNessuna valutazione finora

- PV STD Permit InstructionsDocumento22 paginePV STD Permit InstructionsjuancrangelNessuna valutazione finora

- PV On Buildings and Fire Safety: Recommendation For DRRG Solar PV SystemsDocumento17 paginePV On Buildings and Fire Safety: Recommendation For DRRG Solar PV SystemsAbhinav SinhaNessuna valutazione finora

- Module 5 Community Solar Playbook 9.9.16Documento72 pagineModule 5 Community Solar Playbook 9.9.16Reselyn PalabinoNessuna valutazione finora

- Net Metering SopDocumento14 pagineNet Metering Sopamad khanNessuna valutazione finora

- String Calculator Morningstar CorporationDocumento2 pagineString Calculator Morningstar Corporationrogelio surcoNessuna valutazione finora

- Experimental Investigation of Soiling Impact On PV Module PerformanceDocumento10 pagineExperimental Investigation of Soiling Impact On PV Module PerformanceEbenezer ButarbutarNessuna valutazione finora

- Dairy Farms MechanizationDocumento29 pagineDairy Farms MechanizationMohammed UmarNessuna valutazione finora

- AC Solar Installation and Commissioning Checklist ChecklistDocumento5 pagineAC Solar Installation and Commissioning Checklist ChecklistJames K. BitokNessuna valutazione finora

- Check List For Acdb: Document NoDocumento2 pagineCheck List For Acdb: Document NoJaswant SutharNessuna valutazione finora

- MangerDocumento6 pagineMangerSalamat ShidvankarNessuna valutazione finora

- 2013 14 Vic Dairy FMPDocumento92 pagine2013 14 Vic Dairy FMPArjun KommineniNessuna valutazione finora

- Aparna Hill Park-Avenue Booking Application Form For B - 802Documento5 pagineAparna Hill Park-Avenue Booking Application Form For B - 802Rafey HussainNessuna valutazione finora

- Dairy Farming As A BusinessDocumento16 pagineDairy Farming As A BusinessRakesh JhaNessuna valutazione finora

- Drashti Project SubmissionDocumento109 pagineDrashti Project SubmissionDrashti VaishnavNessuna valutazione finora

- Installation, Commissioning, Operation, and Maintenance Process (ICOMP) of Photovoltaic ArraysDocumento11 pagineInstallation, Commissioning, Operation, and Maintenance Process (ICOMP) of Photovoltaic Arraysmohammed karasnehNessuna valutazione finora

- Dairy Farm Project Report - Crossbred Cow (Small Scale)Documento2 pagineDairy Farm Project Report - Crossbred Cow (Small Scale)RajKumarNessuna valutazione finora

- Working Capital Management in Dairy Co-opDocumento52 pagineWorking Capital Management in Dairy Co-opragvendra04Nessuna valutazione finora

- Goa Dairy's Conservation of Indigenous CowsDocumento23 pagineGoa Dairy's Conservation of Indigenous CowsAmey ChandaikarNessuna valutazione finora

- Installation of Electrical PartsDocumento262 pagineInstallation of Electrical PartsSanjib RoyNessuna valutazione finora

- Safety Standards for PV SystemsDocumento24 pagineSafety Standards for PV SystemsSabri BouloumaNessuna valutazione finora

- Solar Electric Technician, Level-I SyllabusDocumento28 pagineSolar Electric Technician, Level-I Syllabusrosan.sapkotaNessuna valutazione finora

- PV Commissioning DocumentDocumento15 paginePV Commissioning Documentsamwel kariukiNessuna valutazione finora

- Cow EntrepreneurshipDocumento3 pagineCow EntrepreneurshipUjani PalNessuna valutazione finora

- Proposal FOR: Design and Simulation of A Solar PV System University of GollisDocumento24 pagineProposal FOR: Design and Simulation of A Solar PV System University of GollisYG DENessuna valutazione finora

- Muhammad Hadi Jassar Farms PresentationDocumento22 pagineMuhammad Hadi Jassar Farms PresentationAlHuda Centre of Islamic Banking & Economics (CIBE)100% (1)

- LPM (Care and Management of Calf, Heifer, Milch Animal, Dry and Prignant Animal, Bull and Bullock)Documento20 pagineLPM (Care and Management of Calf, Heifer, Milch Animal, Dry and Prignant Animal, Bull and Bullock)Atharv KingeNessuna valutazione finora

- Feasibility Analysis of Dairy VenturesDocumento432 pagineFeasibility Analysis of Dairy VenturesMunirul IslamNessuna valutazione finora

- Solar Energy Wiring Installation TrainerDocumento54 pagineSolar Energy Wiring Installation TrainerJhepoy Lumanglas AstillaNessuna valutazione finora

- Intelligent Environmental Monitoring of PV SystemsDocumento11 pagineIntelligent Environmental Monitoring of PV SystemsVasluianuNessuna valutazione finora

- Commissioning ProcedureDocumento2 pagineCommissioning Proceduremohsin abbas Abba'sNessuna valutazione finora

- Presentation ON: Solar Panel Cleaning MachineDocumento6 paginePresentation ON: Solar Panel Cleaning MachinerassNessuna valutazione finora

- Point of Common CouplingDocumento1 paginaPoint of Common CouplingCarNessuna valutazione finora

- Mechanism Design For Walking Typed Solar Panel-Cleaning Robot Using Triple Driving LinesDocumento19 pagineMechanism Design For Walking Typed Solar Panel-Cleaning Robot Using Triple Driving LinesIAES International Journal of Robotics and AutomationNessuna valutazione finora

- Photo Voltaic Plant Routine Operation & Maintenance Manual: Prepared By-Sunil Singh (DGM D&E)Documento7 paginePhoto Voltaic Plant Routine Operation & Maintenance Manual: Prepared By-Sunil Singh (DGM D&E)Sunil SinghNessuna valutazione finora

- Design of PV SystemDocumento12 pagineDesign of PV SystemHisham MostafaNessuna valutazione finora

- Module Technology SMADocumento7 pagineModule Technology SMARicardo SouzaNessuna valutazione finora

- Commercial Dairy Farming Consultancy Services Under 40 CharactersDocumento4 pagineCommercial Dairy Farming Consultancy Services Under 40 CharactersIndra Sarma100% (1)

- CARE OF HEIFERS AND DAIRY ANIMALSDocumento4 pagineCARE OF HEIFERS AND DAIRY ANIMALSRabin Acharya100% (1)

- Inside The Indian Dairy Industry: A Report On The Abuse of Cows and Buffaloes Exploited For MilkDocumento20 pagineInside The Indian Dairy Industry: A Report On The Abuse of Cows and Buffaloes Exploited For MilkAnmol YogleelaNessuna valutazione finora

- Guardian of Traditional Cattle BreedsDocumento4 pagineGuardian of Traditional Cattle BreedsVasu DevanNessuna valutazione finora

- SYSTEM SPECIFICATION AND DETAILS OF THE 100 KWP SPV POWER PLANT IN KAVARATTIDocumento9 pagineSYSTEM SPECIFICATION AND DETAILS OF THE 100 KWP SPV POWER PLANT IN KAVARATTIankitNessuna valutazione finora

- Safety issues in PV systemsDocumento12 pagineSafety issues in PV systemsjayapal100% (1)

- Thirumala MilkDocumento25 pagineThirumala MilkSanthosh Kumar33% (3)

- PV Doctor: For The Inspection and Fault Location of The Photovoltaic ModulesDocumento16 paginePV Doctor: For The Inspection and Fault Location of The Photovoltaic ModulesSiddhartha SenguptaNessuna valutazione finora

- Management Letter - PV Module Cleaning - Taal EruptionDocumento2 pagineManagement Letter - PV Module Cleaning - Taal EruptionTom TomNessuna valutazione finora

- Installation ManualDocumento34 pagineInstallation Manualseel asefNessuna valutazione finora

- InstallationManualJinko (IEC) Updatedversion2023.01.03 111430Documento22 pagineInstallationManualJinko (IEC) Updatedversion2023.01.03 111430Moulay Nabil EL BarakaNessuna valutazione finora

- LONGi PV Module Cleaning Work InstructionDocumento6 pagineLONGi PV Module Cleaning Work InstructionJean KelvinNessuna valutazione finora

- HYPERION-Installation-Manual-Double-glassDocumento15 pagineHYPERION-Installation-Manual-Double-glassAlan ZorkotNessuna valutazione finora

- KippZonen Manual CMP CMA Series Pyranometers Albedometers V1501Documento46 pagineKippZonen Manual CMP CMA Series Pyranometers Albedometers V1501asif_hopeNessuna valutazione finora

- Incoterms 2011Documento12 pagineIncoterms 2011Rajal ChristieNessuna valutazione finora

- CPMExam RegDocumento12 pagineCPMExam Regasif_hopeNessuna valutazione finora

- Piping Fundamentals for Beginners: A Guide to Piping Systems, Components, and DesignDocumento29 paginePiping Fundamentals for Beginners: A Guide to Piping Systems, Components, and DesignManoj Pratap SinghNessuna valutazione finora

- Ratio Analysis Project Group 8Documento21 pagineRatio Analysis Project Group 8asif_hopeNessuna valutazione finora

- Bamboo Flooring Market OpportunityDocumento6 pagineBamboo Flooring Market Opportunityasif_hopeNessuna valutazione finora

- TD Esc 02 de en 15 043 Rev001 Change in Resin SystemDocumento2 pagineTD Esc 02 de en 15 043 Rev001 Change in Resin SystemFelipe SilvaNessuna valutazione finora

- Huaneng Shandong Ruyi (Pakistan) Energy PVTDocumento13 pagineHuaneng Shandong Ruyi (Pakistan) Energy PVTHumaira AtharNessuna valutazione finora

- Solar Refrigeration: Working Cycles, Advantages and ApplicationsDocumento31 pagineSolar Refrigeration: Working Cycles, Advantages and ApplicationsPrabhat Sharma100% (1)

- Wind Power PlantDocumento64 pagineWind Power PlantKenneth GabrielNessuna valutazione finora

- Project ProposalDocumento13 pagineProject ProposalSyed Mustafa NajeebNessuna valutazione finora

- CA908006E (Web)Documento29 pagineCA908006E (Web)Marco Alonzo Rodriguez MallquiNessuna valutazione finora

- Data Potensi Energi Angin Dan Surya Di IndonesiaDocumento14 pagineData Potensi Energi Angin Dan Surya Di Indonesiaasep wandi nugrahaNessuna valutazione finora

- Available Short Circuit CurrentDocumento17 pagineAvailable Short Circuit CurrentAnonymous IN80L4rRNessuna valutazione finora

- Mechanical Analysis Belt and Chain Drives: Prof Ahmed KovacevicDocumento29 pagineMechanical Analysis Belt and Chain Drives: Prof Ahmed KovacevicTamizh SelvanNessuna valutazione finora

- Carburetors to Forced Induction: A Guide to Fuel SystemsDocumento29 pagineCarburetors to Forced Induction: A Guide to Fuel SystemsMuhammad ArslaanNessuna valutazione finora

- Hydropower Enhances Lives in IndonesiaDocumento2 pagineHydropower Enhances Lives in IndonesiaAlbin Mokhammed SofianNessuna valutazione finora

- Praveen Gupta Deputy Director Central Electricity Authority New DelhiDocumento73 paginePraveen Gupta Deputy Director Central Electricity Authority New DelhiAnkur PathakNessuna valutazione finora

- BP Biobutanol FactsheetDocumento2 pagineBP Biobutanol FactsheetAnderson MoreiraNessuna valutazione finora

- Handbook of Photovoltaic Science and Engineering: Instituto de Energ Ia Solar, Universidad Polit Ecnica de Madrid, SpainDocumento8 pagineHandbook of Photovoltaic Science and Engineering: Instituto de Energ Ia Solar, Universidad Polit Ecnica de Madrid, SpainBijuNessuna valutazione finora

- CV TLazar en WebDocumento2 pagineCV TLazar en WebsayedmhNessuna valutazione finora

- Ge Icemaker Fill Tube Freeze RepairDocumento4 pagineGe Icemaker Fill Tube Freeze Repairarjr51Nessuna valutazione finora

- CS Parque Eolico Palmatir Uruguay SPDocumento68 pagineCS Parque Eolico Palmatir Uruguay SPjuliocanalesNessuna valutazione finora

- Fowler Instrumts N Msrmts 23sDocumento23 pagineFowler Instrumts N Msrmts 23syashittitaNessuna valutazione finora

- Runner of Francis Turbine:) Cot Cot (Documento5 pagineRunner of Francis Turbine:) Cot Cot (Arun Kumar SinghNessuna valutazione finora

- Indoor Unit Outdoor Unit CS-S10JKP CS-S13JKP CS-S15JKP CU-S10JKP CU-S13JKP CU-S15JKPDocumento93 pagineIndoor Unit Outdoor Unit CS-S10JKP CS-S13JKP CS-S15JKP CU-S10JKP CU-S13JKP CU-S15JKPVinh LeNessuna valutazione finora

- Front Page Format For Seminar PPT, Content and GuidelinesDocumento8 pagineFront Page Format For Seminar PPT, Content and Guidelinesrahukl patilNessuna valutazione finora

- SST 111 Steam Turbine eDocumento4 pagineSST 111 Steam Turbine eVlad Alexeiciuc100% (1)

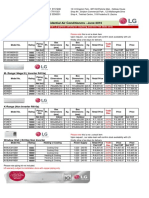

- LG Trade Price List June 2016Documento2 pagineLG Trade Price List June 2016musturNessuna valutazione finora

- JESR 2010 - 11 Final Report MEMDocumento190 pagineJESR 2010 - 11 Final Report MEMHussein BoffuNessuna valutazione finora

- DaBx PlaNYC2020 DraftDocumento79 pagineDaBx PlaNYC2020 DraftRogier Fentener van VlissingenNessuna valutazione finora

- Eurocontrol Aviation Sustainability Briefing-Edition-7Documento13 pagineEurocontrol Aviation Sustainability Briefing-Edition-7Ren TacconiNessuna valutazione finora

- POWERSTAR HQI-T - Metal Halide Lamps With Quartz PDFDocumento4 paginePOWERSTAR HQI-T - Metal Halide Lamps With Quartz PDFVinicius RodriguesNessuna valutazione finora