Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Course Outline

Caricato da

Sheri KhanDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Course Outline

Caricato da

Sheri KhanCopyright:

Formati disponibili

Course Code IM 223

Credit Hours (Th-Pr) 3-0

Manufacturing Processes

Contact Hrs/Week (Th-Pr) 3-0

Total Periods Allocated (Th-Pr) 54-0

Course Outline: Introduction to Manufacturing Processes, Joining Processes & Equipment, Forming and Shaping, Metal Casting Processes & Equipment, Forming & Shaping of Plastics & Composite Materials, Metal Cutting, Surface Treatment & Coating. Prerequisite(s): IM 231, ME 121, IM 131, ME 212

Recommended Text Books S. No 1 2 3. 4. 5 Title Materials & processes in manufacturing Manufacturing Engineering & Technology Fundamentals of Modern Manufacturing Introduction to Manufacturing Processes Processes and Materials of Manufacturing Author(s) E. Paul Degarmo Serope Kalpakjian Mikell P. Groover John A. Schey Roy A. Lindberg Assigned Code DEG KAL GRO SHY LIN

Course Objectives: The objective of the course is to impart knowledge of the basic Manufacturing Processes involved in the fabrication of equipment and mechanical components. Topics Covered No. 1 Topics Joining Processes & Equipment Temporary and Permanent Fastening Methods, Soldering and Brazing, Plastic and Fusion Welding, Gas Welding, Processes of Resistance Welding, Electric Arc Welding Processes. Forming and Shaping Bulk Deformation Process, Types of Rolling, Forging and its Types, Extrusion, Drawing, Hot Spinning. Sheet Metal Forming, Drawing of Wires, Rod & Tubes, Stretch Forming, Squeezing, Bending, Shearing, Hobbing, Shot Peening, Metal Spinning, Cold Extrusion, Impact Extrusion and Press Work.

Text Books Allocated periods

DEG LIN

KAL DEG

10

No.

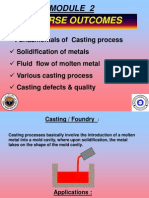

Topics Metal Casting Processes & Equipment Foundry Techniques, Types of Sand Casting, Molding Procedures, Types of Patterns and Their Allowances, Sand Testing, Cores and Core Making, Pouring and Cleaning Castings, Special Casting Processes, Die Casting, Permanent Mold Casting, Centrifugal Casting. Forming & Shaping of Plastics & Composite Materials Compounding and Performing, Compression Molding, Transfer Molding, Injection Molding, Jet Molding, Extruding, Rotational Molding, Blow Molding, Potting and Embedding Thermoforming, Reinforced Plastics, Fiber Glass. Metal Cutting Material Removing Machines. Lathe, Milling, Shapers and Planers, Drilling Machines and Their Operations. Tool and Work Holding Devices. Safety Measures, Abrasives, Grinding Wheels, Grinding Processes, Grinding Fluids, Types of Grinders, Finishing Operations, and Honing, Lapping and Coated Abrasive. Surface Treatment & Coating Mechanical Surface Treatment and Coating, Electroplating, Electro-Forming, Thermal Spraying, Anodizing, Hot Dipping, Surfaces Cleaning.

Text Books

Allocated periods

DEG SHY

10

KAL LIN SHY

10

KAL LIN

10

DEG SHY

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- 1 AAM Body-StructuresDocumento84 pagine1 AAM Body-StructuresKabilan MuthukannanNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Process Flow ChartDocumento22 pagineProcess Flow ChartKumar Ashutosh100% (1)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Casting Fundamentals and Basics ConceptsDocumento68 pagineCasting Fundamentals and Basics Conceptsquiron2010Nessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Industrial Trainning Report at BMTFDocumento10 pagineIndustrial Trainning Report at BMTFJunayed HasanNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Pewterers Guild Introduction To Basic Pewter CastingDocumento13 paginePewterers Guild Introduction To Basic Pewter CastingArthur DiependalNessuna valutazione finora

- Asme Section II A-2 Sa-476 Sa-476mDocumento6 pagineAsme Section II A-2 Sa-476 Sa-476mAnonymous GhPzn1xNessuna valutazione finora

- Module 1 - Design Considerations DMEDocumento59 pagineModule 1 - Design Considerations DMEsreeramhariharanNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- DBA Cat 2013 Version2aDocumento113 pagineDBA Cat 2013 Version2adavidninrioNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- 1 Sand CastingDocumento21 pagine1 Sand CastingMayank GroverNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- 2010 Ross CatalogDocumento32 pagine2010 Ross CatalogmedphotoNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Causes and Remedies of Blow Holes in SanDocumento33 pagineCauses and Remedies of Blow Holes in SanNikhil KumarNessuna valutazione finora

- Spinning For TroutDocumento15 pagineSpinning For TroutvioguitarNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Casting DefectsDocumento35 pagineCasting DefectsYaser Mohamed AbasNessuna valutazione finora

- Casting Brass C.W. AmmenDocumento20 pagineCasting Brass C.W. Ammenfoundryjoe100% (5)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- ME106 - Casting (2015)Documento64 pagineME106 - Casting (2015)just randomNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Die Casting Die Design - Runner, Gate, EtcDocumento45 pagineDie Casting Die Design - Runner, Gate, EtcVig PankajNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Nondestructive Examination (NDE) Technology and Codes Student Manual Classification and Interpretation of IndicationsDocumento43 pagineNondestructive Examination (NDE) Technology and Codes Student Manual Classification and Interpretation of IndicationsJayeshNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Pattern MakingDocumento407 paginePattern MakingJason BowmanNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- 4-Engine Components and SystemsDocumento103 pagine4-Engine Components and Systemswigung tri febriantoNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Sand MouldingDocumento17 pagineSand MouldingbvbprasadNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Thermophysical PropertiesDocumento14 pagineThermophysical PropertiesKalinga BalNessuna valutazione finora

- RAYS PresentationDocumento17 pagineRAYS PresentationKarol CzerwińskiNessuna valutazione finora

- Casting: Shival Dubey Assistant Professor Mechanical EngineeringDocumento31 pagineCasting: Shival Dubey Assistant Professor Mechanical EngineeringChirag TaterNessuna valutazione finora

- Is - 00210 - 2009Documento13 pagineIs - 00210 - 2009sangitaghaisasNessuna valutazione finora

- Sand Casting of Metals - Gating System For CastingDocumento31 pagineSand Casting of Metals - Gating System For CastingAmruta Rane100% (1)

- Seiatsu GBDocumento10 pagineSeiatsu GBthom_rnNessuna valutazione finora

- Die CastingDocumento6 pagineDie Castingkutik3bugerNessuna valutazione finora

- Discussion MoldingDocumento4 pagineDiscussion MoldingNur' Ayuni100% (1)

- Foundry and Forging Lab ManualDocumento15 pagineFoundry and Forging Lab ManualManjunatha Babu N.sNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Harrington BRCH Ner Er Electric Chain HoistsDocumento6 pagineHarrington BRCH Ner Er Electric Chain HoistsGerardo VzzNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)