Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Simulation of Antilock Braking Systems for Two Wheelers

Caricato da

ankush_laxmanDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Simulation of Antilock Braking Systems for Two Wheelers

Caricato da

ankush_laxmanCopyright:

Formati disponibili

Simulation Of Antilock Braking System

Imdad A. Rizvi Department of Electronics and Telecommunication Engineering, Don Bosco Institute of Technology ,Mumbai. ( e-mail:dineshc@yahoo.co.in ) Dinesh Chawde Don Bosco Institute of Technology ,Mumbai ( e-mail:imdadrizvi@gmail.com ) Department of Mechanical Engineering

the rear brake. This prevents continuous rear wheel lock-up which is one cause of rear-end skidding and second shorter stopping distances may be generally achieved by automatically providing the average rear brake pressure necessary for maximum stopping force. These advantages are generally achieved over a wide variety of road surfaces, weather conditions, and driving situations. However, the extent of the wheel lock control brake system advantages is determined by many factors such as Road surfaces, weather conditions, driver proficiency, vehicle speed, tire tread wear, tire inflation brakes and suspension components. The remainders of this paper are organized as follows. In Section 2, the need of ABS is discussed. ABS for two wheelers along with the program flowchart is discussed in Section 3. In Section 4, Fabrication is highlighted. The simulation results of the anti-lock braking system are illustrated in Section 5. Finally, some concluding remarks with future development are given in Section 6. II.NEED OF ABS Shortly hitting the brakes can be sufficient to cause wheel lock-up even on a dry road. Locked-up wheels cannot transfer lateral forces. The consequences: The vehicle doesnt react to the drivers steering input. ABS recognizes very early, if one or more wheels show a Fig.1: Basic principles of braking Fig. 1: Basic principles of braking. tendency to lock-up while braking. In this case ABS ensures that the braking pressure is kept on a constant level or reduced. The wheels do not lock up and the vehicle remains steer able. Thus the vehicle can be decelerated quickly and safely and an obstacle can be avoided. Above shows the basic principles of braking. III. ABS FOR TWO WHEELERS As two wheelers are more unstable in comparison with four wheelers so there are more chances in bikes of getting skid on slippery roads or there are chances of an accident during panic braking. This can be avoided if the similar technology of

Abstract-- This paper develops the anti-lock braking control system integrated with active suspensions applied to a two wheeler. In emergency, although the braking distance can be reduced by the control torque, the braking time and distance can be further improved if the normal force generated from active suspension systems is considered simultaneously. Finally the future developments on the ABS are dwelt on. Keywords-- Anti-lock Braking System, Backstepping Design, Lateral forces, longitudinal forces, friction, braking principles.

I. INTRODUCTION Owing to advanced development of vehicular technology, the requirement of safety for automobiles becomes more and more important. The techniques applied for various vehicles have already improved system stability and passenger safety with the use of several significant control systems, such as anti-lock braking systems (ABS) [1][2], active suspension systems [4],traction control systems [3], and so forth, popularly used in automobile industries. Recently, there are some integrated studies which combine the previous mentioned subsystems in order to control vehicle dynamic states to reach better efficiency. For example, the concept of integrating anti-lock braking systems with active suspensions has been investigated in [1]. Many theories and design methods for anti-lock braking systems and active suspension systems have been proposed individually by several literatures for decades. Various researchers have considered a slip-ratio control of anti-lock braking systems in the use of sliding mode control schemes [5]. When a driver of a vehicle hits a conventional brake hard that is during panic braking, the wheels may lock causing the vehicle to skid, especially on wet and slippery roads. Antilock brake systems provide the capability for shorter stopping distances and the ability to steer and to maintain control during hard braking, especially on wet and slippery surfaces. This system allows the driver to achieve the two main braking advantages during maximum braking stops, one better lateral stability control may be achieved by automatically pumping

antilock braking system used in cars is used in bikes. To achieve above in bikes , main aim is to reduce brake fluid pressure inside disc brake caliper in the situation when the bike is just going to skid (after applying brakes) ,as the pressure is reduced wheels will start rotating & just after a few milliseconds the pressure is increased thereby locking the wheels .This action of increasing & decreasing pressure will respectively stop & rotate the wheels referring to figure 2.This will built the necessary traction or grip between wheels & road thereby giving the rider a steering control & thus saving an accident. Therefore ABS can prove as a life saving guard.

skidding of bike then micro controller will first trigger the relay which is connected to solenoid valve. Soon after few milliseconds second relay connected to solenoid actuator gets triggered. As soon as first relay gets triggered current flows from battery to solenoid valve .Due to this solenoid valve gets energized disconnecting hydraulic connection between master cylinder & brake caliper & makes hydraulic connection between brake caliper & injection cylinder. After a delay of few seconds that is after triggering first relay, second relay gets triggered thus energizing solenoid actuator the solenoid actuator would pull master cylinder piston thus sucking in the fluid .The expansion caused in the line will decrease the brake fluid pressure. This is turn would give some motion to the locked wheel. Soon after microcontroller switch Offs the second relay thereby disconnecting the supply from battery to solenoid actuator. Solenoid actuator will no more have power to hold the shaft & thus due to spring action shaft which is connected with piston of master cylinder will move towards left thereby increasing the pressure of fluid thus locking the wheels. Thus this increase & decrease in pressure will buit enough traction between wheels & roads. This traction will help the driver to take bike to safer position. This process are repeated till micro controller finds the condition rpm1 equal to rpm2.As soon as this condition is encountered microcontroller will first switch OFF solenoid actuator & then solenoid valve thus bringing every thing into normal state. PROGRAMING FLOWCHART

Fig 2: ABS in two wheeler For working of ABS we will consider two cases, Case 1: This case is regarding normal braking operation of bike that is when there is no skid of bike. When brake lever is pressed, the fluid pressure inside the hose pipe connecting master cylinder with brake caliper through solenoid valve increases to about 8 bars .The pressure so produced is enough to bring friction pads of disc brake in contact with rotating disc thus stopping the bike. During this process sensors continuously send their output signals to micro controller. Micro controller checks for the condition of skidding that is whether rpm1 is equal to rpm2 or rpm1 is less than rpm2. As this case is of normal braking operation rpm1 will be equal to rpm2 hence it does not give any output signal. Due to this solenoid valve & solenoid actuator remains OFF. Case 2: In this case the actual working of ABS system takes place. As we know the rpm sensed by front & rear wheel sensors are continuously supplied to micro controller. Now if found that rpm1 is lesser than rpm2 which is the condition for

Fig 3: Programming Flowchart IV. FABRICATION The first step was to replace the original front wheel drum brake by disc brake kit. The next step consists of fabricating and assembling various components of the hydraulic circuit like single acting cylinder, 3/2 valve, solenoid actuator, threaded rod, spring, sensor holder, battery stand, hoses etc. A m.s. flat was cut to the required size and three holes were drilled in it. It was then fasten to the body of solenoid linear actuator by using three metal

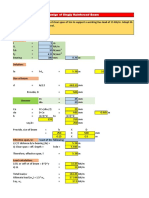

screws. One end of the threaded rod was screwed with the plunger of solenoid linear actuator. Other end of the threaded rod was screwed with the piston of the single acting cylinder. Two m.s. flats were cut to the required length and then welded with the m.s. flat which was fastened to the solenoid linear actuator. Thus the frame structure was formed. The sub assembly consisting of frame, single acting cylinder, solenoid actuator, threaded rod was then mounted on to the chassis of the bike to ensure whether it fits properly. After ensuring that the sub assembly was fitting properly we disassembled it, fitted spring, nut and locknut to it and then mounted the assembly again on to the bike. The 3/2 solenoid valve holder was made from M.S flat by bending it to the required shape & drilling two holes in it. The holder was then fitted on to the chassis through one of the holes & 3/2 solenoid valve was then mounted on it through the second hole using nut bolts. The main hose line was cut in to two halves & their ends were connected to the normally open ports of 3/2 solenoid valve through hose connectors. The third port was connected to the auxiliary hose which connects the single acting cylinder. The sensor holders were made from M.S flat by bending it to the required shape & drilling two holes in it. The holders were then fitted on to the front & rear fork. Then sensors were fitted on it. V. RESULTS: Threaded rod is modeled for the first iteration by following considerations; Length of the threaded rod is known since it is equal to the free length of the spring which has already been designed. i.e. L = 200mm, referring to figure 4.

The FE Model is then assigned with Aluminum as the material. Boundary conditions are then substituted which consists of following constraints and restraint sets: 1. An axial force of 100 N on the internal threads on actuator side. 2. A restraint at the internal threads on piston rod side The FE Model is then meshed using 4 node non-uniform tetrahedral solid elements. The refined mesh is then checked for any errors

2. Stress (Von Mises) The results are displayed using the visualizer which shows the above quantities graphically using a spectrum of colour. And the CAD model is then updated to reflect the changes as shown below:

Nominal diameter of the external threads is initially assumed as 15mm.

The ABS on the Two wheeler looks like this :

displaying these frequencies on the circuit we can used them for further operations i.e. Say timer T1 and T2 are used as counter in mode 01 and timer T0 is used as a timer for enabling the counter for counting the no of pulses in 1 sec duration. Let f1 be the no of pulses counted by timer 1 per sec. & f2 be the no of pulses counted by timer 2. If f1 - f2 is not = to zero . Then 5v d.c output should be given to appropriate terminals as to switch on the hydraulic circuit. Another development that could still improve the efficiency of ABS is to have mechanical components with very high responses. REFERENCES [1] A. Alleyne, Improved vehicle performance using combined suspension and braking forces, Vehicle System Dynamics, 1997, Vol.27. pp.235-265. [2] L. Alvarez, J. Yi, X. Claeys and R. Horowitz Emergency braking control with an observer-based dynamic tire/toad friction model and wheel angular velocity measurement, Vehicle System Dynamics, 2003, Vol.39, No.2, pp. 81-97 [3] S.V. Drakunov, B. Ashrafi, and A. Rosiglioni, Yaw control algorithm via sliding mode control, Proceedings of the American Control Conference,Chicago, Illinois, June 2000, Vol.1, pp. 580-583. [4] E.-S Kim. Nonlinear indirect adaptive control of a quarter car active suspension, Proceedings of the 1996 IEEE International Conference on Control Applications, Dearborn, MI, September, 1996, pp.61-66. [5] S.V. Drakunov, U. Ozguner, P. Dix and B. Ashrafi, ABS control using optimum search via sliding modes, IEEE Transactions on Control SystemsTechnology, Volume: 3, Issue: 1, March 1995, Pages: 79-85. [6] BOSCH AG, GERMANY (Dvd-rom ,Cd-rom, Brouchers).

VI. FUTURE DEVELOPMENT One of very prominent development required in ABS is to have a good program that will be fed in to micro controller ,the program that will check for the condition of skidding of bike & soon as the condition is satisfied to send signal to appropriate components. In case of 8031 or 8051 there are only two timer , from which we use one timer to count no of pulses & other to calculate seconds. Hence both two timer are required for detection of one wheel speed. If we used 8032, then there are three timer & the codes are very much similar as that in case of 8031. from those 3 timer, one can be used for counting seconds & other two can be used for counting no of pulses. Instead of

Imdad Rizvi is holding M.E. (Electronics) degree from University of Mumbai. He is currently working as a lecturer in Don Bosco Institute of Technology, Kurla , Mumbai. His area of interest includes Embedded systems, Image processing and Wavelets. Dinesh Chawde is holding M.E. (Mechanical) degree from University of Mumbai. He is currently working as a lecturer in Don Bosco Institute of Technology, Kurla , Mumbai. His area of interest includes Machine design, FEA and ABS.

Potrebbero piacerti anche

- Automobile EngineeringDocumento12 pagineAutomobile EngineeringsayoojNessuna valutazione finora

- Abs TCS EbdDocumento15 pagineAbs TCS EbdNB Huy100% (1)

- Antilock Brake Systems (ABS)Documento30 pagineAntilock Brake Systems (ABS)pRAMOD g pATOLENessuna valutazione finora

- Electro Magnetic BrakingDocumento19 pagineElectro Magnetic BrakingCUBE Engineering SolutionsNessuna valutazione finora

- Anti Lock Braking System ABS of CarsDocumento14 pagineAnti Lock Braking System ABS of CarsMani PrakashNessuna valutazione finora

- 4341 Aev As 3Documento19 pagine4341 Aev As 33341 Onkar KaleNessuna valutazione finora

- Service HandoutDocumento59 pagineService HandoutTapas Banerjee100% (2)

- Electro Magnetic BrakeDocumento43 pagineElectro Magnetic Brakesamy_175Nessuna valutazione finora

- P3 SRAM Cell: A Technical StudyDocumento22 pagineP3 SRAM Cell: A Technical StudyAayush AgarwalNessuna valutazione finora

- Slip Ratio Control of Anti-Lock Braking System With Bang-Bang ControllerDocumento8 pagineSlip Ratio Control of Anti-Lock Braking System With Bang-Bang Controllerniveditha trNessuna valutazione finora

- Abs 3Documento2 pagineAbs 3ภูเก็ต เป็นเกาะNessuna valutazione finora

- Toyota ABS Braking SystemsDocumento23 pagineToyota ABS Braking SystemsTriqezz AntaresNessuna valutazione finora

- Design of Electronic Semi - Automatic Clutch For Manual Actuation of Clutch in A CarDocumento6 pagineDesign of Electronic Semi - Automatic Clutch For Manual Actuation of Clutch in A CarTamilarasanRpcg100% (2)

- Abuki Anti Lock Braking SystemDocumento20 pagineAbuki Anti Lock Braking SystemAbubaker MuzayinNessuna valutazione finora

- ATT Brakes - Example TextbookDocumento15 pagineATT Brakes - Example TextbookSooraj KrishnaNessuna valutazione finora

- Brake by Wire SystemsDocumento16 pagineBrake by Wire Systemsdevhx86% (7)

- Anti Brake SystemDocumento15 pagineAnti Brake SystemRenu ShindeNessuna valutazione finora

- Modeling and Development of Antilock Braking System Project ReportDocumento25 pagineModeling and Development of Antilock Braking System Project ReportSapna KumariNessuna valutazione finora

- ABS Seminar ReportDocumento27 pagineABS Seminar ReportPrem Shankar Singh29% (7)

- Automatic Braking System For Automobiles Using IR SensorDocumento4 pagineAutomatic Braking System For Automobiles Using IR SensorSourabh SharafNessuna valutazione finora

- Electro Magnetic Braking SystemDocumento45 pagineElectro Magnetic Braking Systemchutturu mukeshNessuna valutazione finora

- Measuring the effectiveness of ABS and EBD systems in improving vehicle stability and braking performanceDocumento5 pagineMeasuring the effectiveness of ABS and EBD systems in improving vehicle stability and braking performanceShivamNessuna valutazione finora

- Interlligent Braking SystemDocumento45 pagineInterlligent Braking Systemchutturu mukeshNessuna valutazione finora

- Anti Lock Brake System (Tata Motors Information)Documento16 pagineAnti Lock Brake System (Tata Motors Information)Tapas Banerjee100% (3)

- Finite Element Analysis of AUTO SuspensionDocumento7 pagineFinite Element Analysis of AUTO SuspensionVishnu ShanmugavelNessuna valutazione finora

- Anti-Lock Brake System (Abs)Documento19 pagineAnti-Lock Brake System (Abs)Ivan Catalin100% (1)

- Braking System: Prepared By:-Jagseer Singh Sukhpal Singh Kamaljeeet Singh Lalit Kumar Atish KumarDocumento23 pagineBraking System: Prepared By:-Jagseer Singh Sukhpal Singh Kamaljeeet Singh Lalit Kumar Atish KumarAnonymous mRBbdopMKf0% (1)

- Study of Braking SystemDocumento7 pagineStudy of Braking SystemVishal ChauhanNessuna valutazione finora

- Archive of SID: Design of A New Anti-Lock Braking System For MotorcyclesDocumento9 pagineArchive of SID: Design of A New Anti-Lock Braking System For MotorcyclesIndra Chandra SetiawanNessuna valutazione finora

- ME 3011 Kinematics & Dynamics Capstone ReportDocumento20 pagineME 3011 Kinematics & Dynamics Capstone ReportMuhammad Hussain Bilal100% (1)

- Automatic Accident ControllerDocumento20 pagineAutomatic Accident ControllerSenthil KumarNessuna valutazione finora

- Electromagnetic Braking System: Misal Karade Aarti Nagre Dharmendra Choudhary Yash SahuDocumento8 pagineElectromagnetic Braking System: Misal Karade Aarti Nagre Dharmendra Choudhary Yash Sahurodrigo.cubanoNessuna valutazione finora

- SynopsisDocumento8 pagineSynopsismanoj kumarNessuna valutazione finora

- ABS Modeling and DevelopmentDocumento26 pagineABS Modeling and DevelopmentPardeepNessuna valutazione finora

- Polish Abs Translation Teves MkiiDocumento69 paginePolish Abs Translation Teves MkiiJim AllenNessuna valutazione finora

- Service Manual for SAMAND XU7JPL3 ABS Mando MGH-25Documento38 pagineService Manual for SAMAND XU7JPL3 ABS Mando MGH-25Ivan Leonardo Acevedo Galan100% (1)

- Learn About Electromagnetic BrakesDocumento21 pagineLearn About Electromagnetic BrakesHimanshu JangidNessuna valutazione finora

- DMTSDocumento17 pagineDMTSJosyula Karteek Kashyap me20b092Nessuna valutazione finora

- An Antilock-Braking Systems (ABS) Control A Technical ReviewDocumento10 pagineAn Antilock-Braking Systems (ABS) Control A Technical ReviewJoão FerroNessuna valutazione finora

- Case Study Report On AutomobileDocumento18 pagineCase Study Report On AutomobileSayaliRewaleNessuna valutazione finora

- Braking Systems: By: Navneeth C V Neeharanshu Vaidya Suraj KDocumento24 pagineBraking Systems: By: Navneeth C V Neeharanshu Vaidya Suraj KPrateekNessuna valutazione finora

- Automatic Brake Failure Indicator and Braking System Ijariie5483Documento5 pagineAutomatic Brake Failure Indicator and Braking System Ijariie5483thriveniNessuna valutazione finora

- 206-06 Hydraulic Brake ActuationDocumento19 pagine206-06 Hydraulic Brake ActuationMiguel AngelNessuna valutazione finora

- ABS Operation ExplainedDocumento5 pagineABS Operation ExplainedRaveen ShamenthaNessuna valutazione finora

- Anti Lock Brake System Tata Motors Information PDFDocumento16 pagineAnti Lock Brake System Tata Motors Information PDFValBMSNessuna valutazione finora

- Automobile Brake Failure Indicator Circuit Alerts DriversDocumento5 pagineAutomobile Brake Failure Indicator Circuit Alerts DriversBhavana GummaNessuna valutazione finora

- C4-Brake ABS TrainingDocumento8 pagineC4-Brake ABS TrainingcasvbNessuna valutazione finora

- Braking System GuideDocumento30 pagineBraking System GuideLala GuanyesNessuna valutazione finora

- Fabrication of Magnetic Suspension SystemDocumento46 pagineFabrication of Magnetic Suspension SystemNationalinstituteDsnr100% (1)

- ABSDocumento17 pagineABSAniket MehareNessuna valutazione finora

- Report On Anti Lock Braking SystemDocumento12 pagineReport On Anti Lock Braking SystemParth RathoreNessuna valutazione finora

- Shi Shenshen Thesis Automobile Brake SystemDocumento36 pagineShi Shenshen Thesis Automobile Brake SystemLina M. Abd ElSalamNessuna valutazione finora

- Friction Kinetic Energy Heat: Frictional Brakes Are Most Common and Can Be Divided Broadly Into "Shoe" or "Pad" BrakesDocumento3 pagineFriction Kinetic Energy Heat: Frictional Brakes Are Most Common and Can Be Divided Broadly Into "Shoe" or "Pad" BrakesNikhilVinayNessuna valutazione finora

- Modelling and Development of Antilock Braking System ThesisDocumento43 pagineModelling and Development of Antilock Braking System ThesisNithin ThriveniNessuna valutazione finora

- Automotive Electronic Diagnostics (Course 2)Da EverandAutomotive Electronic Diagnostics (Course 2)Valutazione: 4 su 5 stelle4/5 (2)

- Ignition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.Da EverandIgnition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.Valutazione: 3 su 5 stelle3/5 (4)

- Control of DC Motor Using Different Control StrategiesDa EverandControl of DC Motor Using Different Control StrategiesNessuna valutazione finora

- Diesel Common Rail Injection Electronic Components ExplainedDa EverandDiesel Common Rail Injection Electronic Components ExplainedValutazione: 3.5 su 5 stelle3.5/5 (7)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDa EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNessuna valutazione finora

- Semi-Active Suspension Control Design for VehiclesDa EverandSemi-Active Suspension Control Design for VehiclesValutazione: 5 su 5 stelle5/5 (1)

- VspCoreUsersGuide PDFDocumento42 pagineVspCoreUsersGuide PDFankush_laxmanNessuna valutazione finora

- PICmicro MCU C - An Introduction To Programming The Microchip PIC in CCS CDocumento135 paginePICmicro MCU C - An Introduction To Programming The Microchip PIC in CCS Cvaibhav6820100% (34)

- Sim300 An Handset Design v1.02Documento10 pagineSim300 An Handset Design v1.02ankush_laxmanNessuna valutazione finora

- Kicking Mechanism Pioner 3DXDocumento101 pagineKicking Mechanism Pioner 3DXankush_laxmanNessuna valutazione finora

- Us 5749633Documento8 pagineUs 5749633ankush_laxmanNessuna valutazione finora

- Sms and PduDocumento5 pagineSms and Pduankush_laxmanNessuna valutazione finora

- MPLAB C18 Libraries 51297fDocumento184 pagineMPLAB C18 Libraries 51297fBhausaheb BotreNessuna valutazione finora

- 07 KanekawaDocumento25 pagine07 KanekawaleidieuNessuna valutazione finora

- Ieee tvt08Documento18 pagineIeee tvt08ankush_laxmanNessuna valutazione finora

- Aiaa ValasaraptorDocumento10 pagineAiaa Valasaraptorankush_laxmanNessuna valutazione finora

- Winters FluidpowerDocumento8 pagineWinters FluidpowerJOSE DEL CARMEN TOLEDONessuna valutazione finora

- 08.precommissioning Checklist GeneralDocumento19 pagine08.precommissioning Checklist GeneralAnujGarg100% (1)

- Stress Analysis Bolted JointDocumento11 pagineStress Analysis Bolted JointGustavoYippeekayyayGusNessuna valutazione finora

- AVK Dams - Reservoirs - HydroPower BrochureDocumento15 pagineAVK Dams - Reservoirs - HydroPower Brochureindra putraNessuna valutazione finora

- Control Design and Analysis of Closed-Loop Dynamic Response For Rectilinear Vibration SystemDocumento15 pagineControl Design and Analysis of Closed-Loop Dynamic Response For Rectilinear Vibration SystemVinay Mishra100% (2)

- Design Chapter StaircaseDocumento4 pagineDesign Chapter StaircaseAsish Seeboo100% (1)

- Catalog Ecodan - ATW - 2017 PDFDocumento32 pagineCatalog Ecodan - ATW - 2017 PDFDamian OvidiuNessuna valutazione finora

- 3 - 2017 - Superia X 5 StarDocumento26 pagine3 - 2017 - Superia X 5 Starsomnath serviceNessuna valutazione finora

- Forces and Motion: Basics: Not For Sale, Exclusive For Gordon College OnlyDocumento5 pagineForces and Motion: Basics: Not For Sale, Exclusive For Gordon College OnlyAlyssa FrancoNessuna valutazione finora

- Faculty Development Programme on Fluid Mechanics PropertiesDocumento9 pagineFaculty Development Programme on Fluid Mechanics Propertiesmaran2326Nessuna valutazione finora

- Ec T30 PDFDocumento1.500 pagineEc T30 PDFNorman Valle Sáenz100% (1)

- CE 1999 GATE Question PaperDocumento14 pagineCE 1999 GATE Question Papersubhajit284Nessuna valutazione finora

- Parts Manual M0096787 06 (En Us) 01 ALLDocumento544 pagineParts Manual M0096787 06 (En Us) 01 ALLKawasakiNessuna valutazione finora

- Cadenas de Tiempo Pontiac G5Documento17 pagineCadenas de Tiempo Pontiac G5Jorge Antonio GuillenNessuna valutazione finora

- Driving Without Wheels, Flying Without WingsDocumento18 pagineDriving Without Wheels, Flying Without Wingsaditya_kumar_me100% (1)

- Controls Start-Up, Operation, Service, and TroubleshootingDocumento140 pagineControls Start-Up, Operation, Service, and TroubleshootingRick BradnamNessuna valutazione finora

- Ninja Part PDFDocumento105 pagineNinja Part PDFErlangga AlamNessuna valutazione finora

- TOX FinePress 45 201201 enDocumento16 pagineTOX FinePress 45 201201 enSirbu SorinNessuna valutazione finora

- TOTO MRP Price List - 01-04-2019Documento65 pagineTOTO MRP Price List - 01-04-2019Joshua Gnanaraj100% (1)

- CHP 4 - 4.3 Determinate Structural AnalysisDocumento57 pagineCHP 4 - 4.3 Determinate Structural Analysismhazarath murariNessuna valutazione finora

- Piston Crown Measurement PDFDocumento2 paginePiston Crown Measurement PDFmohamedNessuna valutazione finora

- RMC ParameterDocumento4 pagineRMC Parameterkishor150688Nessuna valutazione finora

- Chung2006 PDFDocumento9 pagineChung2006 PDFNguyen Tran HieuNessuna valutazione finora

- Soalan: Airplane Wings Are Shaped To Make Air Move Faster Over The Top of The Wing. When Air MovesDocumento5 pagineSoalan: Airplane Wings Are Shaped To Make Air Move Faster Over The Top of The Wing. When Air MovesHaniZs ShuhadaNessuna valutazione finora

- Strength & failure modes of concreteDocumento12 pagineStrength & failure modes of concretemaneeshaNessuna valutazione finora

- Accra Technical University: Index NumberDocumento6 pagineAccra Technical University: Index NumberMoro Adams100% (1)

- Singly Reinforced Beam ExcelDocumento3 pagineSingly Reinforced Beam ExcelVEERKUMAR100% (3)

- Specialized User Manual: Command Post WuDocumento8 pagineSpecialized User Manual: Command Post WuМарина Методиева-ЙордановаNessuna valutazione finora

- PC W130B 02 EUDocumento100 paginePC W130B 02 EUОблачноNessuna valutazione finora

- Bourdon Gauge - BellowDocumento14 pagineBourdon Gauge - BellowBikram RoyNessuna valutazione finora