Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

M M M M: Production of N-Propanol Nomenclature

Caricato da

Zaed MohdDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

M M M M: Production of N-Propanol Nomenclature

Caricato da

Zaed MohdCopyright:

Formati disponibili

Production of n-propanol Nomenclature

i

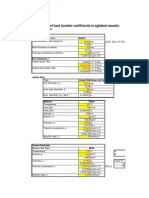

NOMENCLATURES

a

Specific interface surface, area/packing volume

3 2

/ m m

A

a

Active area of plate

2

m

w

a Effective interfacial area of packing per unit volume

3 2

/ m m

A

ap

Clearance area under apron

2

m

A

cs

Tube cross-sectional area m

2

A

c

Total column cross sectional area

2

m

A

d

Downcomer cross - sectional area

2

m

A

h

Total hole area

2

m

A

n

Net area available for vapour liqud disengagement

2

m

A

p

Perforated area

2

m

A Column area m

b

A Area of one bolt at the roof of the thread

mm

C

o

Orifice coefficient -

S

C Design factor

-

C

p

heat capacity mm

T

C Total Concentration

3

/ m kmol

D

Mols of distillate per unit time

2

/ s m

d

h

Hole diameter

c

D Diameter of the column

i

D Diameter of the cylinder

L

D Liquid diffusivity s m /

2

m

D Mean diameter

m

m

m

m

Production of n-propanol Nomenclature

ii

0

D Out diameter

m

s

D

Shell diameter

m

e

D

Shell side equivalent diameter

m

d

i

Inside tube diameter

m

d

o

Outside tube diameter

m

p

d

Diameter of packing

mm

E

mv

Plate efficiency -

E

Young Modulus

2 1

/ s m kg

e Minimum thickness mm

f

Maximum allowable stress

2

/ mm N

1

f Viscosity correction factor -

'

c

f Actual baring pressure

2

/ mm N

LV

F Flow Factor -

p

F

Packing Factor

1

m

w

F Loading due to wind pressure m N /

t

F

Temperature correction factor -

m

G Molar gas flow-rate per unit cross section area s m kmol

2

/

g

Gravitational Acceleration

2

/ s m

h

ap

Apron clearance

2

/ s m

h

b

Height of liquid back up in down comer m

h

bc

Down comer back up in term of clear liquid head m

h

d

Dry plate pressure drop, head of liquid m

h

dc

Head loss in down comer m

H

v

Height between tangent m

h

ow

Height of liquid crest over down comer weir m

h

r

Plate residual pressure drop m

h

t

Total plate pressure drop m

h

i

Tube side heat transfer coefficient

W/m

2

K

Production of n-propanol Nomenclature

iii

h

s

Shell side heat transfer coefficient

W/m

2

K

h

w

Wall heat transfer coefficient

W/m

2

K

h

w

Weir height m

I

w

Weir length m

u

I Second moment

2

/ mm N

I

p

Pitch of holes (distance between centre) m

J Joint factor -

j

h

Heat transfer factor -

j

f

Friction factor -

L Tube length

m

I

b

Baffle spacing

m

b

L Base baring width mm

m

L Molar liquid flow-rate per cross section area s m kmol

2

/

L

w

Liquid flow rate s m /

3

L

wd

Liquid mass flow rate

s kg/

mw Molecular weight kmol kg/

x

M Bending moment Nm

n Number of mole -

N

m

Minimum number of stages -

N

T

Theoretical number of stages -

b

N Number of bolts -

P Pressure bar

Apt

Total plate pressure drop

2

/ ms kg

p

t

Tube pitch m

i

P Internal pressure bar

P

o

Partial pressure

2

/ ms kg

Q Heat transfer kJ/s

q

Heat to vaporize one mol of feed divided by molar latent

heat

-

Production of n-propanol Nomenclature

iv

R Gas constant k kmol m bar /

3

R

Reflux ratio -

R

m

Minimum reflux ratio -

b

t Thickness of base ring m

t

Thickness of plate (shell) m

t

S

Skirt thickness m

Viscosity

2

/ m Ns

m c

T

,

Critical Temperature of mixture K

lm

T A

Temperature difference between fluids -

T Temperature different C

u

t

tube velocity

m/s

u

s

shell velocity

m/s

U Overall heat transfer W/m

2

K

U

a

Vapour velocity based on active area s m/

U

f

Vapour velocity through holes s m/

U

v

Superficial velocity (based on total cross sectional area) s m/

V Volume

3

m

x

i

Mole fraction of component

x

d

Mole fraction of component in distillate

w V

*

Gas mass flow-rate per unit column cross-section area s m kg

2

/

v

W Total weight of the shell

N

w

Density of water

3

/ m kg

mix

Density of mixture gases

3

/ m kg

v

Density of vapor

3

/ m kg

|

h

L

H factor

-

e Ancentric factor -

h

G

H factor

-

b

o

Bending stress

2

/ mm N

Production of n-propanol Nomenclature

v

o

w

Dead weight stress

2

/ mm N

o

cw

Compressive stress

2

/ mm N

o

ws

Stress in skirt due to weight of vessel

2

/ mm N

Potrebbero piacerti anche

- Heat Exchanger Symbols and ParametersDocumento12 pagineHeat Exchanger Symbols and ParametersAnggiRaymondPardedeNessuna valutazione finora

- Heat Exchanger-Design and ConstructionDocumento46 pagineHeat Exchanger-Design and ConstructionMohd Jamal Mohd Moktar100% (2)

- Geothermal Engineering: Fundamentals and ApplicationsDa EverandGeothermal Engineering: Fundamentals and ApplicationsNessuna valutazione finora

- Shell and Tube Heat ExchangerDocumento19 pagineShell and Tube Heat Exchangerhuangjl33% (3)

- Fundamentals of Fluidized-Bed Chemical Processes: Butterworths Monographs in Chemical EngineeringDa EverandFundamentals of Fluidized-Bed Chemical Processes: Butterworths Monographs in Chemical EngineeringNessuna valutazione finora

- Air Cooled Heat ExchangerDocumento35 pagineAir Cooled Heat ExchangerNAGARAJAN A R [CB.EN.U4CHE17035]Nessuna valutazione finora

- Handbook of Heating, Ventilating and Air ConditioningDa EverandHandbook of Heating, Ventilating and Air ConditioningValutazione: 4 su 5 stelle4/5 (6)

- m c θ c θ c c: n vi liDocumento4 paginem c θ c θ c c: n vi liVanessa SimNessuna valutazione finora

- Calculation of LDO, FO and DO Unloading Pump HeadsDocumento9 pagineCalculation of LDO, FO and DO Unloading Pump Headsmkchy12Nessuna valutazione finora

- Steam Pipe Line Deflection: Case 1 - in Between Supports Simply SupportedDocumento12 pagineSteam Pipe Line Deflection: Case 1 - in Between Supports Simply SupportedgsdaundhNessuna valutazione finora

- Thermo-hydrodynamic Lubrication in Hydrodynamic BearingsDa EverandThermo-hydrodynamic Lubrication in Hydrodynamic BearingsNessuna valutazione finora

- Appendix A: NomenclatureDocumento10 pagineAppendix A: NomenclatureFrancisco SuárezNessuna valutazione finora

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsDa EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNessuna valutazione finora

- Student Code of Ethic (SCE)Documento10 pagineStudent Code of Ethic (SCE)Rahim GenesisNessuna valutazione finora

- 01-Heat Transfer EquipmentDocumento36 pagine01-Heat Transfer EquipmentReynaldo Santiago Nunez ArcosNessuna valutazione finora

- Electronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1Da EverandElectronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1Valutazione: 4.5 su 5 stelle4.5/5 (5)

- Design HeatexchangerDocumento15 pagineDesign HeatexchangerMayurMahajan100% (1)

- Shell & TubeDocumento9 pagineShell & TubeRanjith Kumar PNessuna valutazione finora

- Understanding Process Equipment for Operators and EngineersDa EverandUnderstanding Process Equipment for Operators and EngineersValutazione: 4.5 su 5 stelle4.5/5 (3)

- Heat Transfer Analysis of Corrugated Plate Heat ExchangerDocumento6 pagineHeat Transfer Analysis of Corrugated Plate Heat Exchangerpak1t0Nessuna valutazione finora

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresDa EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresValutazione: 4 su 5 stelle4/5 (1)

- Stichlmair, J. (2010) - Distillation, 2. Equipment. Ullmann's Encyclopedia of Industrial Chemistry.Documento22 pagineStichlmair, J. (2010) - Distillation, 2. Equipment. Ullmann's Encyclopedia of Industrial Chemistry.Silvio Latini SpahnNessuna valutazione finora

- Scientific American Supplement, No. 365, December 30, 1882Da EverandScientific American Supplement, No. 365, December 30, 1882Nessuna valutazione finora

- Design of Heat ExchangerDocumento13 pagineDesign of Heat ExchangerTilak AvNessuna valutazione finora

- Losses in Pipe BendsDocumento5 pagineLosses in Pipe BendsLove KumarNessuna valutazione finora

- Pipe Heat Loss CalculationDocumento10 paginePipe Heat Loss Calculationingemarquintero67% (3)

- Pressuredrop Calculations by Kern Method SRRDocumento18 paginePressuredrop Calculations by Kern Method SRRrajeev50588Nessuna valutazione finora

- Lecture 04c - Shortcut Exchanger Design ProcedureDocumento47 pagineLecture 04c - Shortcut Exchanger Design Proceduresds0% (1)

- Rectangular Tank SizingDocumento8 pagineRectangular Tank Sizingvofaith100% (16)

- Calculation Overall Heat TransferDocumento4 pagineCalculation Overall Heat TransferDavid LambertNessuna valutazione finora

- LP Gas Amine Contactor Process DataDocumento6 pagineLP Gas Amine Contactor Process DataEddy RainNessuna valutazione finora

- Mel709 Tut7Documento34 pagineMel709 Tut7sohail1985Nessuna valutazione finora

- Design of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateDocumento7 pagineDesign of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateAnonymous xrBCp9Ej50% (4)

- Shell and Tube Heat Exchanger DesignDocumento50 pagineShell and Tube Heat Exchanger DesignAsmaa HarrazNessuna valutazione finora

- Perancangan Plate Adn Frame HEDocumento36 paginePerancangan Plate Adn Frame HEDavid LambertNessuna valutazione finora

- Heat Exchanger Calculation Sheet - 1Documento10 pagineHeat Exchanger Calculation Sheet - 1Ritesh Dev MaityNessuna valutazione finora

- Pin Fin Apparatus - UpdatedDocumento10 paginePin Fin Apparatus - UpdatedVignesh MallyaNessuna valutazione finora

- Design Sanjeev 1Documento18 pagineDesign Sanjeev 1riteshreplyNessuna valutazione finora

- Bell Method Example 7 5Documento9 pagineBell Method Example 7 5Amin FarukiNessuna valutazione finora

- Heat Exchanger DesignDocumento19 pagineHeat Exchanger DesignMohawk Chavanant Roongchao100% (2)

- Contoh Daftar NotasiDocumento11 pagineContoh Daftar NotasicxiangNessuna valutazione finora

- 26 Pressure Vessel.Documento21 pagine26 Pressure Vessel.mishtinil93% (14)

- A New Optimization Method For Evaluating Thermal Parameters in A Single Segmental Shell and Tube Heat ExchangerDocumento8 pagineA New Optimization Method For Evaluating Thermal Parameters in A Single Segmental Shell and Tube Heat Exchangertotok89Nessuna valutazione finora

- Designing of Air Cooled Heat Exchangers: by Mehaboob Basha N.BDocumento28 pagineDesigning of Air Cooled Heat Exchangers: by Mehaboob Basha N.Bgerty1818100% (2)

- Thermal Design Method of Bayonet-Tube Evaporators and CondensersDocumento11 pagineThermal Design Method of Bayonet-Tube Evaporators and CondensersSugoo LeeNessuna valutazione finora

- Aerodynamics Lab ManualDocumento42 pagineAerodynamics Lab ManualSathya Narayanan100% (2)

- The Production of Syrene From Methanol and TolueneDocumento261 pagineThe Production of Syrene From Methanol and TolueneNizar MousaNessuna valutazione finora

- Design of CondenserDocumento2 pagineDesign of CondenserEngr Renato Arriola0% (1)

- Equipos para Procesos Intercambiadores de Calor 1: Heat Exchanger Specification SheetDocumento1 paginaEquipos para Procesos Intercambiadores de Calor 1: Heat Exchanger Specification SheetAlejandro EchevarriaNessuna valutazione finora

- Air-Cooled Heat Exchanger Specification SheetDocumento4 pagineAir-Cooled Heat Exchanger Specification SheetPanca KurniawanNessuna valutazione finora

- Aeroport Cluj Technical DataDocumento5 pagineAeroport Cluj Technical DataLar Ionut AndreiNessuna valutazione finora

- Drilling Hydraulics ADocumento63 pagineDrilling Hydraulics Asryn89100% (3)

- Appendix A Notation: EnglishDocumento7 pagineAppendix A Notation: EnglishIsmael KhalilNessuna valutazione finora

- Calculation of Air Duct Pressure Loss (Rectangular)Documento15 pagineCalculation of Air Duct Pressure Loss (Rectangular)Phyu Mar Thein KyawNessuna valutazione finora

- Technical Diary OF Stage-1 (UNIT-1&2) (PTPS, Panipat) : 2 X 110 MW Unit-I & Ii Panipat Thermal Power Station PanipatDocumento138 pagineTechnical Diary OF Stage-1 (UNIT-1&2) (PTPS, Panipat) : 2 X 110 MW Unit-I & Ii Panipat Thermal Power Station PanipatapsNessuna valutazione finora

- Mitsubishi MSZ Fd25 35vahDocumento2 pagineMitsubishi MSZ Fd25 35vahZachary TaylorNessuna valutazione finora

- Lecture 6Documento41 pagineLecture 6Pragati GhumadeNessuna valutazione finora

- Worldwide Winter Diesel Fuel Quality Survey 2014: Performance You Can Rely OnDocumento18 pagineWorldwide Winter Diesel Fuel Quality Survey 2014: Performance You Can Rely OnJahmia CoralieNessuna valutazione finora

- Renault Megane RS 265 - My2012 PDFDocumento4 pagineRenault Megane RS 265 - My2012 PDFdaniel_maftei6044Nessuna valutazione finora

- Testing-and-Adjusting-Hydraulic-Systems-RENR-9585 330 PDFDocumento133 pagineTesting-and-Adjusting-Hydraulic-Systems-RENR-9585 330 PDFCarlos Ushiña100% (4)

- Husqvarna Z4220 Owner's ManualDocumento76 pagineHusqvarna Z4220 Owner's ManualDaniel SheardNessuna valutazione finora

- 1993 Probe Timing Belt 2.5 LDocumento6 pagine1993 Probe Timing Belt 2.5 Llaytonchristian1Nessuna valutazione finora

- GP 52-20 - Passive Fire Protection Fireproofing - 0900a866801074adDocumento26 pagineGP 52-20 - Passive Fire Protection Fireproofing - 0900a866801074adMichael Moore67% (3)

- T 125Documento142 pagineT 125Diego Roberto Pucuji PillajoNessuna valutazione finora

- Alfa Romeo, 2011 Alfa 159 - Alfa 159 SportwagonDocumento21 pagineAlfa Romeo, 2011 Alfa 159 - Alfa 159 SportwagonJason TaitNessuna valutazione finora

- EIL Underground StoragesDocumento12 pagineEIL Underground StoragesanandelectricalsNessuna valutazione finora

- Custody Transfer MeteringDocumento9 pagineCustody Transfer Meteringmohd_zaieriNessuna valutazione finora

- Motor RexrotDocumento6 pagineMotor RexrotSilvio RomanNessuna valutazione finora

- Fundamentals of Refining and Petrochemicals ProcessesDocumento263 pagineFundamentals of Refining and Petrochemicals ProcessesneocentricgeniusNessuna valutazione finora

- Global WarmingDocumento19 pagineGlobal WarminghamzaNessuna valutazione finora

- YME04-REN-Z-FD-0009 Yme New Development Generic Basis of Design - 01Documento119 pagineYME04-REN-Z-FD-0009 Yme New Development Generic Basis of Design - 01LionelNessuna valutazione finora

- Gs 2668 RT 2001g.Documento136 pagineGs 2668 RT 2001g.MladenNessuna valutazione finora

- Guidelines For The Avoidance of Vibration Induced Fatigue in Process PipeworkDocumento0 pagineGuidelines For The Avoidance of Vibration Induced Fatigue in Process Pipeworkviv01020% (1)

- 4g63 MIVEC EngineDocumento7 pagine4g63 MIVEC EngineHameedNessuna valutazione finora

- Manual Tecnico Bomba StanadyneDocumento3 pagineManual Tecnico Bomba StanadyneIvo Silva100% (4)

- Sugar MillDocumento6 pagineSugar MillgksaraffNessuna valutazione finora

- Gail Investor PresentationDocumento31 pagineGail Investor Presentationsurya167Nessuna valutazione finora

- Diesel Engine Exhaust Emissions Black SmokeDocumento4 pagineDiesel Engine Exhaust Emissions Black SmokesblandesNessuna valutazione finora

- HDD BroschDocumento24 pagineHDD BroschRomany AllamNessuna valutazione finora

- Colombia Oil & Gas Report Q3 2015Documento157 pagineColombia Oil & Gas Report Q3 2015edgarmerchan100% (1)

- Hydraulic Circuits Design and AnalysisDocumento19 pagineHydraulic Circuits Design and AnalysisklashincoviskyNessuna valutazione finora

- Methyl Chloride and Dichloromethane PDFDocumento7 pagineMethyl Chloride and Dichloromethane PDFM Imran SheikhNessuna valutazione finora

- Selection of Dryers I - IndiaDocumento38 pagineSelection of Dryers I - Indiasilvership2291100% (1)

- Multiquip Whisperwatttm Generator Dca 15spx3Documento132 pagineMultiquip Whisperwatttm Generator Dca 15spx3Shane De FreitasNessuna valutazione finora

- The Fabric of Civilization: How Textiles Made the WorldDa EverandThe Fabric of Civilization: How Textiles Made the WorldValutazione: 4.5 su 5 stelle4.5/5 (57)

- Sully: The Untold Story Behind the Miracle on the HudsonDa EverandSully: The Untold Story Behind the Miracle on the HudsonValutazione: 4 su 5 stelle4/5 (103)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureDa EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureValutazione: 5 su 5 stelle5/5 (124)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestDa EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestValutazione: 4 su 5 stelle4/5 (28)

- Recording Unhinged: Creative and Unconventional Music Recording TechniquesDa EverandRecording Unhinged: Creative and Unconventional Music Recording TechniquesNessuna valutazione finora

- Pale Blue Dot: A Vision of the Human Future in SpaceDa EverandPale Blue Dot: A Vision of the Human Future in SpaceValutazione: 4.5 su 5 stelle4.5/5 (586)

- Highest Duty: My Search for What Really MattersDa EverandHighest Duty: My Search for What Really MattersNessuna valutazione finora

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaDa EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaNessuna valutazione finora

- The Weather Machine: A Journey Inside the ForecastDa EverandThe Weather Machine: A Journey Inside the ForecastValutazione: 3.5 su 5 stelle3.5/5 (31)

- Transformed: Moving to the Product Operating ModelDa EverandTransformed: Moving to the Product Operating ModelValutazione: 4 su 5 stelle4/5 (1)

- A Place of My Own: The Architecture of DaydreamsDa EverandA Place of My Own: The Architecture of DaydreamsValutazione: 4 su 5 stelle4/5 (241)

- 35 Miles From Shore: The Ditching and Rescue of ALM Flight 980Da Everand35 Miles From Shore: The Ditching and Rescue of ALM Flight 980Valutazione: 4 su 5 stelle4/5 (21)

- Across the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsDa EverandAcross the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsNessuna valutazione finora

- Packing for Mars: The Curious Science of Life in the VoidDa EverandPacking for Mars: The Curious Science of Life in the VoidValutazione: 4 su 5 stelle4/5 (1395)

- The Future of Geography: How the Competition in Space Will Change Our WorldDa EverandThe Future of Geography: How the Competition in Space Will Change Our WorldValutazione: 4.5 su 5 stelle4.5/5 (4)

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationDa EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationValutazione: 4.5 su 5 stelle4.5/5 (46)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseDa EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseValutazione: 4.5 su 5 stelle4.5/5 (50)

- Data-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseDa EverandData-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseValutazione: 3.5 su 5 stelle3.5/5 (12)

- Broken Money: Why Our Financial System is Failing Us and How We Can Make it BetterDa EverandBroken Money: Why Our Financial System is Failing Us and How We Can Make it BetterValutazione: 5 su 5 stelle5/5 (3)

- A Garden of Marvels: How We Discovered that Flowers Have Sex, Leaves Eat Air, and Other Secrets of PlantsDa EverandA Garden of Marvels: How We Discovered that Flowers Have Sex, Leaves Eat Air, and Other Secrets of PlantsNessuna valutazione finora

- Mental Math for Pilots: A Study GuideDa EverandMental Math for Pilots: A Study GuideValutazione: 0.5 su 5 stelle0.5/5 (1)

- The End of Craving: Recovering the Lost Wisdom of Eating WellDa EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellValutazione: 4.5 su 5 stelle4.5/5 (80)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindDa EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNessuna valutazione finora

- Artificial Intelligence: A Guide for Thinking HumansDa EverandArtificial Intelligence: A Guide for Thinking HumansValutazione: 4.5 su 5 stelle4.5/5 (30)

- Reality+: Virtual Worlds and the Problems of PhilosophyDa EverandReality+: Virtual Worlds and the Problems of PhilosophyValutazione: 4 su 5 stelle4/5 (24)