Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Stirling Engin1

Caricato da

andriamdDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Stirling Engin1

Caricato da

andriamdCopyright:

Formati disponibili

Stirling Engine

Tweet Note: This Article is not written by me.

The Stirling engine is basically a heat engine that is vastly different from the internal-combustion engine. It was Invented by Robert Stirling in 1816, the Stirling engine has the potential to be much more efficient than a gasoline or diesel engine. A Stirling engine uses the Stirling cycle, which is unlike the cycles used in internalcombustion engines. Working: The engine is designed so that the working gas is generally compressed in the colder portion of the engine and expanded in the hotter portion resulting in a net conversion of heat into work. An internal Regenerative heat exchanger increases the Stirling engine's thermal efficiency compared to simpler hot air engines lacking this feature. Here is a look at the three main types of Stirling Engine and their working. Alpha Type Stirling Engine: An alpha Stirling contains two power pistons in separate cylinders, one hot and one cold. The hot cylinder is situated inside the high temperature heat exchanger and the cold cylinder is situated inside the low temperature heat exchanger. This type of engine has a high power-to-volume ratio but has technical problems due to the usually high temperature of the hot piston and the durability of its seals. In practice, this piston usually carries a large insulating head to move the seals away from the hot zone at the expense of some additional dead space.

Beta Type Stirling Engine: A beta Stirling has a single power piston arranged within the same cylinder on the same shaft as a displacer piston. The displacer piston is a loose fit and does not extract any power from the expanding gas but only serves to shuttle the working gas from the hot heat exchanger to the cold heat exchanger. When the working gas is pushed to the hot end of the cylinder it expands and pushes the power piston. When it is pushed to the cold end of the cylinder it contracts and the momentum of the machine, usually enhanced by a flywheel,

pushes the power piston the other way to compress the gas. Unlike the alpha type, the beta type avoids the technical problems of hot moving seals.

Gamma Type Stirling Engine: The third type of Stirling engine is a gamma type sterling engine. Gamma type sterling engine can be called simply as a beta type sterling engine in which the power piston is placed in a separate cylinder alongside the displacer piston cylinder instead of the same, but is still connected to the same flywheel. The gas in the two cylinders can flow freely between both of them and remain as a single body. This configuration produces a lower compression ratio but it is mechanically simpler to the others and often used as a multi-cylinder Sterling engine.

Potrebbero piacerti anche

- Alternative Stirling Engines For Free Energy Applications And How To Go About Building Them And Using Them To Generate ElectricityDa EverandAlternative Stirling Engines For Free Energy Applications And How To Go About Building Them And Using Them To Generate ElectricityValutazione: 3.5 su 5 stelle3.5/5 (3)

- The Stirling EngineDocumento14 pagineThe Stirling Enginesrinureddy2014Nessuna valutazione finora

- Seminar PPT On Pollution Less EngineDocumento24 pagineSeminar PPT On Pollution Less Engineashwin41732Nessuna valutazione finora

- Seminar PPT On Pollution Less EngineDocumento24 pagineSeminar PPT On Pollution Less EngineOm Prakash77% (22)

- Synopsis Project Team No.: - B-10 Project Title:-Solar Stirling EngineDocumento3 pagineSynopsis Project Team No.: - B-10 Project Title:-Solar Stirling EnginePraduman AggarwalNessuna valutazione finora

- Stirling EngineDocumento70 pagineStirling Engineamitsinghbvp100% (1)

- Polution Less EngineDocumento9 paginePolution Less EnginesandypayalNessuna valutazione finora

- Sterling Engine: Submitted byDocumento9 pagineSterling Engine: Submitted byRaghav MaheshwariNessuna valutazione finora

- Pollution Less EngineDocumento23 paginePollution Less EngineYogesh Kumar GaurNessuna valutazione finora

- Q: How Do Stirling Engines Work?: A: Stirling Engines Can Be Hard To Understand. Here Are The Key Points. EveryDocumento35 pagineQ: How Do Stirling Engines Work?: A: Stirling Engines Can Be Hard To Understand. Here Are The Key Points. EveryNavneet SharmaNessuna valutazione finora

- Pollution Less EngineDocumento19 paginePollution Less Engineshailu347Nessuna valutazione finora

- Design and Fabrication Stirling EngineDocumento54 pagineDesign and Fabrication Stirling Engineermias100% (1)

- FC01 UpdatedDocumento13 pagineFC01 UpdatedSOLAIMANNessuna valutazione finora

- 3 Stirling Engine ReportDocumento29 pagine3 Stirling Engine ReportChristopher Chan Sing Kong0% (1)

- A Seminar On Stirling Engine: Vikash Kumar 07ESIAE050 4 Year, Automobile EnggDocumento17 pagineA Seminar On Stirling Engine: Vikash Kumar 07ESIAE050 4 Year, Automobile EnggPrateek NangiaNessuna valutazione finora

- Stirling Engine: It Takes A Great Coder To Serve 400 Million Users. Sign Up For The October 2011 Coding Challenge NowDocumento30 pagineStirling Engine: It Takes A Great Coder To Serve 400 Million Users. Sign Up For The October 2011 Coding Challenge NowShashi RaiNessuna valutazione finora

- Heat Engine DesignDocumento25 pagineHeat Engine DesignEamonn McStravickNessuna valutazione finora

- Hod LabDocumento32 pagineHod LabPrashant MehraNessuna valutazione finora

- Stirling EngineDocumento33 pagineStirling EnginepracheeNessuna valutazione finora

- Stirling EngineDocumento6 pagineStirling EngineGaurav Kumar50% (2)

- Stirling Cycle & Its Applications: Sustainable Future TechnologyDocumento47 pagineStirling Cycle & Its Applications: Sustainable Future TechnologyJuan S ParraNessuna valutazione finora

- Stirling EngineDocumento21 pagineStirling EngineNitish ManikeriNessuna valutazione finora

- Pollution Less EngineDocumento10 paginePollution Less Enginemicmech67% (6)

- Types of Heat Engines: What Is The Heat Engine?Documento46 pagineTypes of Heat Engines: What Is The Heat Engine?Mozammel HossainNessuna valutazione finora

- Stirling Engine ReportDocumento20 pagineStirling Engine ReportRajeshwar Singh Urff Raj100% (1)

- Stirling MotorDocumento14 pagineStirling MotorlinerNessuna valutazione finora

- Battery Charger With Stirling Engine: A Project Report ONDocumento33 pagineBattery Charger With Stirling Engine: A Project Report ONShashank100% (2)

- More About The Stirling Steele PDFDocumento18 pagineMore About The Stirling Steele PDFpichaidvNessuna valutazione finora

- Stirling Engine: Name and ClassificationDocumento22 pagineStirling Engine: Name and ClassificationAbhishek NaikNessuna valutazione finora

- Design and Fabrication of Solar Powered Stirling EngineDocumento35 pagineDesign and Fabrication of Solar Powered Stirling EngineShubham shendeNessuna valutazione finora

- Part OneDocumento9 paginePart OneJesson Jade PahitNessuna valutazione finora

- Evolution of Stirling Cycle Final DraftDocumento13 pagineEvolution of Stirling Cycle Final DraftMiguel MancillaNessuna valutazione finora

- Experiment 3 ThermoDocumento11 pagineExperiment 3 ThermoMuneeb NaveedNessuna valutazione finora

- Stirling Engine - WikipediaDocumento33 pagineStirling Engine - WikipediaH.J.PrabhuNessuna valutazione finora

- Institute of Engineering and Applied Technology: Main/Principal Parts of An Internal Combustion EngineDocumento6 pagineInstitute of Engineering and Applied Technology: Main/Principal Parts of An Internal Combustion EngineAngeloLorenzoSalvadorTamayoNessuna valutazione finora

- ConceptsDocumento8 pagineConceptsLouis Feliph RuelaNessuna valutazione finora

- 4 Stroke Petrol EngineDocumento9 pagine4 Stroke Petrol EngineZahid MughalNessuna valutazione finora

- "Pollution Less Engine": ContentsDocumento10 pagine"Pollution Less Engine": ContentsShivani RamavathNessuna valutazione finora

- Review Six Stroke EngineDocumento7 pagineReview Six Stroke EngineSuhas G FADNISNessuna valutazione finora

- Diesel and Petrol Engines ReportDocumento8 pagineDiesel and Petrol Engines ReportJonathan MalamulaNessuna valutazione finora

- Theory of Engine OperationDocumento19 pagineTheory of Engine OperationGabriel Dela Cruz LagmanNessuna valutazione finora

- Me6412 Thermal LabDocumento41 pagineMe6412 Thermal LabMECHANICAL SMCETNessuna valutazione finora

- Title Page: Project: Stirling EngineDocumento5 pagineTitle Page: Project: Stirling EngineLia FerreraNessuna valutazione finora

- Stirling Engine: From Wikipedia, The Free EncyclopediaDocumento25 pagineStirling Engine: From Wikipedia, The Free EncyclopediaysoydinçNessuna valutazione finora

- Literature Review On Development of Stirling Engine: Siddhant Jadhao, Prof .Y.V.MahantareDocumento15 pagineLiterature Review On Development of Stirling Engine: Siddhant Jadhao, Prof .Y.V.MahantareJhun Rey N SagunNessuna valutazione finora

- A Simple Lamina Flow Engine PDFDocumento2 pagineA Simple Lamina Flow Engine PDFSelva KumarNessuna valutazione finora

- Lab Report 12Documento8 pagineLab Report 12mamoona noreenNessuna valutazione finora

- How Car Engines Work PDFDocumento3 pagineHow Car Engines Work PDFMiguel Campusano RodriguezNessuna valutazione finora

- Chapter - 1: Six Stroke EngineDocumento14 pagineChapter - 1: Six Stroke EngineVivek ViruNessuna valutazione finora

- Unit 1 Construction and Operation: External Combustion EngineDocumento14 pagineUnit 1 Construction and Operation: External Combustion Enginekrishna samNessuna valutazione finora

- Types of Internal Combustion EnginesDocumento18 pagineTypes of Internal Combustion EnginesMoayadNessuna valutazione finora

- Pollution Less Engine: Name - Saif AnwarDocumento15 paginePollution Less Engine: Name - Saif AnwarSaif anwarNessuna valutazione finora

- Piston EngineDocumento29 paginePiston Enginejamilahroslien35Nessuna valutazione finora

- What Is The Difference Between A Two Stroke and Four Stroke EngineDocumento7 pagineWhat Is The Difference Between A Two Stroke and Four Stroke EngineAllen NopreNessuna valutazione finora

- A Presentation On Six-Stroke EnginesDocumento17 pagineA Presentation On Six-Stroke EnginesHarshit AgarwalNessuna valutazione finora

- How Car Engines WorkDocumento11 pagineHow Car Engines WorkAlfred E. NewmanNessuna valutazione finora

- Solar Power Stirling EngineDocumento23 pagineSolar Power Stirling EngineHariniReddy100% (1)

- Southern Marine Engineering Desk Reference: Second Edition Volume IiDa EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNessuna valutazione finora

- Review Article Thermal Conductivity MeasurementsDocumento21 pagineReview Article Thermal Conductivity MeasurementsEswaraiah VarrlaNessuna valutazione finora

- BucklingDocumento7 pagineBucklingMohammad BurhanNessuna valutazione finora

- Beam Static Study-Static 1-1Documento10 pagineBeam Static Study-Static 1-1phitahnNessuna valutazione finora

- COACHING NOTES MATH 2.pptx Version 1Documento221 pagineCOACHING NOTES MATH 2.pptx Version 1AjayBravoNessuna valutazione finora

- Heatless Desiccant Compressed Air Dryers IDW: FeaturesDocumento1 paginaHeatless Desiccant Compressed Air Dryers IDW: FeaturesyohanesNessuna valutazione finora

- Concept Strengthening Sheet (CSS-08) Based On AIATS-08 (TYM) - PhysicsDocumento6 pagineConcept Strengthening Sheet (CSS-08) Based On AIATS-08 (TYM) - PhysicsDev SoniNessuna valutazione finora

- Transport Phenomena Fluid Mechanics Problem Solution BSL - Newtonian Fluid Flow in A Circular Tube PDFDocumento5 pagineTransport Phenomena Fluid Mechanics Problem Solution BSL - Newtonian Fluid Flow in A Circular Tube PDFyudhaputraNessuna valutazione finora

- CHEN 629 Syllabus - Fall 2014Documento2 pagineCHEN 629 Syllabus - Fall 2014frankNessuna valutazione finora

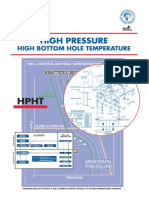

- Aberdeen Drilling School - HPHTDocumento288 pagineAberdeen Drilling School - HPHTlaaliauto100% (4)

- Analysis and Proportioning of Retaining WallsDocumento25 pagineAnalysis and Proportioning of Retaining Wallsአንተነህ ኃይሌ ክንፈገብርኤልNessuna valutazione finora

- Experiment No. 9: Chemical EquilibriumDocumento25 pagineExperiment No. 9: Chemical Equilibriumtwinkledreampoppies100% (22)

- Physics 2 Lab - Absolute ZeroDocumento3 paginePhysics 2 Lab - Absolute ZeroDigno IglesiasNessuna valutazione finora

- BFC 21103Documento9 pagineBFC 21103Kavi MaranNessuna valutazione finora

- Steel Frame Design Manual: Italian NTC 2008Documento99 pagineSteel Frame Design Manual: Italian NTC 2008Angel VargasNessuna valutazione finora

- VCCTDocumento35 pagineVCCTAshutosh SinglaNessuna valutazione finora

- CE 370-Lecture-12 (Design of Doubly Reinforced Beam Sections) (Read-Only) PDFDocumento29 pagineCE 370-Lecture-12 (Design of Doubly Reinforced Beam Sections) (Read-Only) PDFJamal RkhNessuna valutazione finora

- Genchem 2 PolarisDocumento37 pagineGenchem 2 PolarisLawrence AguilosNessuna valutazione finora

- FM-Experiment 2 - Mouthpiece (Variable Head)Documento3 pagineFM-Experiment 2 - Mouthpiece (Variable Head)reddy vardhanNessuna valutazione finora

- Avogadro HypothesisDocumento3 pagineAvogadro HypothesisNema JashNessuna valutazione finora

- Chap 2Documento47 pagineChap 2Amanu WorkuNessuna valutazione finora

- Probabilistic Assessment of Welded Joints VersusDocumento8 pagineProbabilistic Assessment of Welded Joints Versusferi muhammadNessuna valutazione finora

- Diagrama Moliere T - S - AguaDocumento1 paginaDiagrama Moliere T - S - AguaElingenioso FlorentinoNessuna valutazione finora

- ME 205-Mechanics of Materials TestDocumento2 pagineME 205-Mechanics of Materials TestDaniel Deng KuolNessuna valutazione finora

- Evaluation of Vertical Kaplan Turbine Using CFD: Conference PaperDocumento11 pagineEvaluation of Vertical Kaplan Turbine Using CFD: Conference PaperSayan KumarNessuna valutazione finora

- Fluid Mechanics ReviewDocumento17 pagineFluid Mechanics ReviewquanNessuna valutazione finora

- Problemas MdsolidDocumento11 pagineProblemas MdsolidCristian ReyesNessuna valutazione finora

- Aos 330 Lab 11Documento3 pagineAos 330 Lab 11Ariyan Abrar SaifNessuna valutazione finora

- Hydro-Structure Analysis of Composite Marine Propeller Under Pressure Hydrodynamic LoadingDocumento6 pagineHydro-Structure Analysis of Composite Marine Propeller Under Pressure Hydrodynamic LoadingAstekMaddenNessuna valutazione finora

- CFD Lecture (Introduction To CFD)Documento53 pagineCFD Lecture (Introduction To CFD)mkatweNessuna valutazione finora

- General Tank Data ExampleDocumento6 pagineGeneral Tank Data ExampleDAVE100% (1)