Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Slack Flow

Caricato da

Engr AhmadDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Slack Flow

Caricato da

Engr AhmadCopyright:

Formati disponibili

HYDRAULIC GRADE LINE (HGL)

Discussion relating to slack flow requires an understanding of the hydraulic grade line. It is also the basis for operator training and an excellent visual tool to assess the operating limits of the pipeline. The energy line is a graphic representation of Bernoullis equation, expressed in meters of Column height of that particular liquid. The total energy, also referred to as total head (H), is made up of three components: the potential head, or height of the pipeline above sea level (Z); the static head, which is a function of the pressure and the density of the liquid in the pipeline (p/, or pressure expressed in meters of fluid); and the dynamic head, a function of velocity (v2/2g): H = p/ + v2/2g + z (energy line) When plotted as a function of pipeline distance, the total head in meters of liquid is a straight sloped line, assuming a constant pipe diameter and constant liquid density in steady state. The slope of the line represents the loss of head (friction) in the pipeline. Since, in most pipelines, the dynamic head is negligible, this term is eliminated from the equation, and the remaining terms represent the hydraulic grade line, sometimes referred to as the piezometric headline: H = p/ + z (hydraulic grade line) When superimposing the pipeline terrain profile (or potential head Z) on the same plot, the distance between the profile and the hydraulic grade line conveniently represents the pressure in the pipeline expressed in meters of that fluid. Therefore, if fluids of different densities (say slurry and water) are in the same pipeline, at the interface of the two liquids, a discontinuity will appear in the hydraulic gradient. This is because; on one side of the interface the pipeline pressure is expressed in meters of slurry, while on the other side of the interface it is expressed in meters of water. Another set of lines shown on the same graph represent allowable head for steady-state and for transient conditions. These lines are also plotted in meters of fluid, and therefore, will also show a discontinuity at the interface of two batches. For proper operations, the hydraulic gradient must always stay in the area between the allowable headlines and the profile. If the hydraulic grade line intersects the allowable headlines, the pipeline is over-pressured, and if the hydraulic grade line intersects the profile, the flow will go slack (i.e., partially filled pipe). Figure 3 shows commonly used definitions in slurry pipeline engineering.

Allowable head for transient conditions Discontinuity at the Interface of two batches Allowable head for steady state

Hydraulic grade line

Discontinuities at wall thickness change points Head loss of energy dissipation station

p/

Pipeline Profile

Figure 3: Definitions used in slurry pipeline engineering

SLACK FLOW Slack flow means that the fluid transported does not fill the cross section of the pipeline. This condition occurs when the pressure in the pipeline drops to the liquids vapor pressure, which for water is 6m to 10m, depending on altitude and water temperature. However, for practical purposes, PSI considers slack flow to occur when p/ = 0, or when the hydraulic grade line H = z. Graphically, this means that we consider slack flow to occur when the hydraulic grade line intersects the profile as shown in the Figure 1.

Slack flow section

Slurry batch

Water batch

Figure 1: Representation of slack flow

Physically, when the pressure drops below the vapor pressure, we encounter an open channel flow regime, with flow velocities many times higher than for the full-pipe flow regime. In open channel conditions, the velocity (a function of the pipe diameter, the pipe grade, as well as the flow rate in the pipeline) is usually unacceptably high for slurry flow due to wear and cavitation considerations. A concentrate pipeline is expected to have a life of at least 20 years, with little to no wear when operating in a packed condition. However, when subjected to continuous slack flow, wear could erode the pipe very rapidly.

If slack flow avoidance were only a matter of maintaining the flow rate in the pipeline high enough, it would not be an issue. However, when liquids of different densities flow in a pipeline with an undulating profile, slack flow can develop when the interface of the two dissimilar liquids moves into a low point of the profile, and the denser liquid is upstream. Figures 2 and 3 show the HGL for a slurry/water batch combination at different interface locations. In both cases the flow rate is the same and the density of the slurry is assumed to be twice that of water. In Figure 2 there is no slack flow, in Figure 3, where the interface is in the valley, slack flow occurs in the slurry batch in the upstream leg of the valley.

Figure 2: No slack flow

Figure 3: Slack flow occurs when slurry pushes water down

We have shown in Figure 4, a scenario with slurry on the upstream side of the valley, and water on the downstream side, causing slack flow. However, under the same flow conditions, but with water on the upstream side of the valley and slurry on the downstream side, over-pressure occurs, as shown in Figure 5.

Figure 4: No over-pressure

Figure 5: Over-pressure occurs when water pushes slurry down

Inserting water batches between the slurry batches to mitigate possible crosscontamination requires more complex operating procedures. The densities of the copper and zinc slurries are approximately twice that of the adjoining water, and conditions of slack flow (partially filled pipe) and over-pressure (pressure exceeds pipe allowable) can develop as the interfaces move through the pipeline in mountainous terrain. Both conditions are detrimental to the integrity of the pipeline but can be prevented with adjustable energy dissipation (choke) stations and careful operation of the pipeline .

Potrebbero piacerti anche

- Line Sizing CriteriaDocumento2 pagineLine Sizing CriteriaPaul OhiorNessuna valutazione finora

- Two Phase FlowDocumento4 pagineTwo Phase FlowsindalvaleriNessuna valutazione finora

- Choked Flow at PSV Outlet FlangeDocumento5 pagineChoked Flow at PSV Outlet FlangeHitesh PanchalNessuna valutazione finora

- Understanding Distillation Using Column Profile MapsDa EverandUnderstanding Distillation Using Column Profile MapsNessuna valutazione finora

- FISHER 95 Series Regulators PDFDocumento40 pagineFISHER 95 Series Regulators PDFArturo Villena0% (1)

- Scandpower Fire Guidelines Version 2 PDFDocumento81 pagineScandpower Fire Guidelines Version 2 PDFliNessuna valutazione finora

- Safety Valve Sizing Reliefv PDFDocumento9 pagineSafety Valve Sizing Reliefv PDFLiam MoylanNessuna valutazione finora

- Operate A Personal Computer PDFDocumento56 pagineOperate A Personal Computer PDFBirhanu Girmay100% (8)

- UET Research Proposal TemplateDocumento9 pagineUET Research Proposal TemplateEngr AhmadNessuna valutazione finora

- Cooling Water BasicsDocumento163 pagineCooling Water BasicsEduardo Castillo100% (1)

- Stepped Retaining Wall Design CalculationsDocumento1 paginaStepped Retaining Wall Design CalculationsEngr AhmadNessuna valutazione finora

- Flow Special - Sizing Orifice Plates - ISADocumento4 pagineFlow Special - Sizing Orifice Plates - ISAamarnethaNessuna valutazione finora

- Concrete Curing CompoundDocumento6 pagineConcrete Curing CompoundEngr AhmadNessuna valutazione finora

- Correctos Calculos en Blow DownDocumento4 pagineCorrectos Calculos en Blow Downroberdani12100% (2)

- Control Valve DPDocumento8 pagineControl Valve DPAmit SawantNessuna valutazione finora

- Multiphase Flow 1995Da EverandMultiphase Flow 1995A. SerizawaNessuna valutazione finora

- Relief Valves Sizing MethodsDocumento10 pagineRelief Valves Sizing MethodsRicardo BecNessuna valutazione finora

- Select Best Model Two-Phase Relief Sizing: The ForDocumento9 pagineSelect Best Model Two-Phase Relief Sizing: The ForjowarNessuna valutazione finora

- Two Phase Flow BibliographyDocumento41 pagineTwo Phase Flow BibliographyShiv Pratap SinghNessuna valutazione finora

- Reduced Bore Valve Resistance Coefficient CalculationDocumento3 pagineReduced Bore Valve Resistance Coefficient CalculationRafael ReyesNessuna valutazione finora

- Application of UG-140 For Overpressure Protection: FeaturesDocumento4 pagineApplication of UG-140 For Overpressure Protection: FeaturesB rg100% (1)

- Evaporative Rates of A SpillDocumento3 pagineEvaporative Rates of A SpillkurtbkNessuna valutazione finora

- Gail Gas Limited City Gas Distribution Project DewasDocumento9 pagineGail Gas Limited City Gas Distribution Project DewasankeshkatochNessuna valutazione finora

- Topic 7 Oil and Gas Pipeline SolutionsDocumento17 pagineTopic 7 Oil and Gas Pipeline SolutionsImranMajidli100% (1)

- Pressure Loss Steel Pipe FittingDocumento112 paginePressure Loss Steel Pipe FittingCherdsakul TorsakulNessuna valutazione finora

- Avoid Pressure-Relief System PitfallsDocumento8 pagineAvoid Pressure-Relief System PitfallschublackNessuna valutazione finora

- MMD 74 XX DR PS 0020 - C03Documento1 paginaMMD 74 XX DR PS 0020 - C03bramexNessuna valutazione finora

- Reaction Forces Pressure Relief SystemDocumento2 pagineReaction Forces Pressure Relief SystemkhaliliNessuna valutazione finora

- Pressure Relief Smith BurgessDocumento12 paginePressure Relief Smith Burgesssammar_10Nessuna valutazione finora

- EHB en 7.5 Sizing According To ISO 4126 1Documento10 pagineEHB en 7.5 Sizing According To ISO 4126 1XpizmonNessuna valutazione finora

- Gas Line VelocityDocumento3 pagineGas Line Velocityputrude100% (1)

- Flare Systems-Conclusion Safety, Noise, and Emissions Elements Round Out FlaDocumento10 pagineFlare Systems-Conclusion Safety, Noise, and Emissions Elements Round Out FlaJR RomanNessuna valutazione finora

- Drawings, Diagrams, and Line Lists IP 1-1-1: ScopeDocumento25 pagineDrawings, Diagrams, and Line Lists IP 1-1-1: ScopeNABE0% (1)

- White Paper - Calculating Safe NPSH (A)Documento3 pagineWhite Paper - Calculating Safe NPSH (A)Stephen BeasleyNessuna valutazione finora

- Hydraulic Design For Energy GenerationDocumento33 pagineHydraulic Design For Energy Generationmasmello2011Nessuna valutazione finora

- Quality Risk ManagementDocumento29 pagineQuality Risk ManagementmmmmmNessuna valutazione finora

- Theory, Applications and Sizing of Air ValvesDocumento11 pagineTheory, Applications and Sizing of Air Valvesretrospect1000Nessuna valutazione finora

- Study Improves Control of Slack Line Flow - Oil & Gas JournalDocumento10 pagineStudy Improves Control of Slack Line Flow - Oil & Gas Journalchemsac2Nessuna valutazione finora

- Acoustic Induced Vibration - Flare Systems PDFDocumento2 pagineAcoustic Induced Vibration - Flare Systems PDFsri9987Nessuna valutazione finora

- Two-Phase Flow Discharge in Nozzles and Pipes - A Unified ApproachDocumento6 pagineTwo-Phase Flow Discharge in Nozzles and Pipes - A Unified ApproachAksheyNessuna valutazione finora

- NPSHDocumento6 pagineNPSHAnsari SuhailNessuna valutazione finora

- Sandia Pool FireDocumento39 pagineSandia Pool FireMarino ValisiNessuna valutazione finora

- ClydeBergemannSootblowers PrinceGeorge06Documento36 pagineClydeBergemannSootblowers PrinceGeorge06Arun YogaNessuna valutazione finora

- Aspen Simulation Workbook Webinar FAQDocumento3 pagineAspen Simulation Workbook Webinar FAQluaweb123Nessuna valutazione finora

- Modelamiento de Sistemas MultifasicosDocumento21 pagineModelamiento de Sistemas MultifasicosEdi Agurto CarrascoNessuna valutazione finora

- FLARENET Getting Started GuideDocumento60 pagineFLARENET Getting Started Guidealastairwong90Nessuna valutazione finora

- Fathom 9 Slurry ModelDocumento12 pagineFathom 9 Slurry ModeljjirwinNessuna valutazione finora

- OrificeDocumento10 pagineOrificeRicha GhoshNessuna valutazione finora

- Anyone Can Suggest The Criteria of Velocity in Downcomer For Valve TrayDocumento4 pagineAnyone Can Suggest The Criteria of Velocity in Downcomer For Valve Trayonizuka-t2263Nessuna valutazione finora

- 521taaai 2Documento7 pagine521taaai 2Erwin FerdianNessuna valutazione finora

- Minimum Submergence Required For Vortex Breaker - Industrial Professionals - Cheresources - Com CommunityDocumento7 pagineMinimum Submergence Required For Vortex Breaker - Industrial Professionals - Cheresources - Com CommunitySHINessuna valutazione finora

- FDA Det Flame ArrestorsDocumento2 pagineFDA Det Flame Arrestorsali kararNessuna valutazione finora

- Heat-Exchanger Bypass Control: William L. LuybenDocumento9 pagineHeat-Exchanger Bypass Control: William L. LuybenYu Hui100% (1)

- Considerations in Designing Multiphase Flow Lines - Pipeline & Gas JournalDocumento9 pagineConsiderations in Designing Multiphase Flow Lines - Pipeline & Gas Journalt_rajith1179Nessuna valutazione finora

- Tube Rupture. Dynamic SimulationDocumento5 pagineTube Rupture. Dynamic SimulationAbbasNessuna valutazione finora

- ISO 12213-3 Part 1 - Introduction and GuidelinesDocumento8 pagineISO 12213-3 Part 1 - Introduction and GuidelinesserefbingolNessuna valutazione finora

- GoyalDocumento3 pagineGoyalVan LeNessuna valutazione finora

- Screening Reactor For Water HammerDocumento49 pagineScreening Reactor For Water HammerYu GanNessuna valutazione finora

- Flowmeter Installation EffectsDocumento12 pagineFlowmeter Installation EffectsgykataiNessuna valutazione finora

- Easily Find The Wetted Surface Area of Side HeadsDocumento4 pagineEasily Find The Wetted Surface Area of Side HeadsЛеонид КорельштейнNessuna valutazione finora

- Chemical Resistance GuideDocumento35 pagineChemical Resistance GuideAGPNessuna valutazione finora

- Process Engineer - Blowdown Valve (BDV) To Flare SystemDocumento4 pagineProcess Engineer - Blowdown Valve (BDV) To Flare SystemIOCPC100% (1)

- Aspen Tech Compressor Modeling in AspenDocumento16 pagineAspen Tech Compressor Modeling in AspenIgnacio ChaparroNessuna valutazione finora

- CIV 402 Chapter 2 Pipe FlowDocumento29 pagineCIV 402 Chapter 2 Pipe FlowAmit RoyNessuna valutazione finora

- Week 11 of Aqs110 Fluid MechanicsDocumento7 pagineWeek 11 of Aqs110 Fluid MechanicsKyle DavidNessuna valutazione finora

- Fluid MechanicsDocumento19 pagineFluid MechanicsengNessuna valutazione finora

- Viscous Fluid Flow: 5.1 ViscosityDocumento6 pagineViscous Fluid Flow: 5.1 Viscositypasser byNessuna valutazione finora

- Flow in Open ChannelsDocumento3 pagineFlow in Open Channelskaran5singh-12Nessuna valutazione finora

- To Amend The Khyber Pakhtunkhwa River Protection Ordinance, 2002Documento1 paginaTo Amend The Khyber Pakhtunkhwa River Protection Ordinance, 2002Engr AhmadNessuna valutazione finora

- Standard Bidding DocumentsDocumento80 pagineStandard Bidding DocumentsEngr AhmadNessuna valutazione finora

- Canal and Drainage Amendment Act2015Documento1 paginaCanal and Drainage Amendment Act2015Engr AhmadNessuna valutazione finora

- BMI Calculator: Units Standard Weight 160 Pounds Height 5 Feet 9 InchesDocumento1 paginaBMI Calculator: Units Standard Weight 160 Pounds Height 5 Feet 9 InchesEngr AhmadNessuna valutazione finora

- PC-II Proforma Gujar Garhi Canal ParkDocumento12 paginePC-II Proforma Gujar Garhi Canal ParkEngr AhmadNessuna valutazione finora

- Working Paper Takht Bhai Bypass Road MardanDocumento3 pagineWorking Paper Takht Bhai Bypass Road MardanEngr AhmadNessuna valutazione finora

- KP - Gov.pk DownlaodsDocumento151 pagineKP - Gov.pk DownlaodsSultan SikanderNessuna valutazione finora

- Ground Water Management in PakistanDocumento10 pagineGround Water Management in PakistanEngr AhmadNessuna valutazione finora

- Request For Proposal RFP Mardan 1510Documento74 pagineRequest For Proposal RFP Mardan 1510Engr AhmadNessuna valutazione finora

- Retaining Wall AhmadDocumento1 paginaRetaining Wall AhmadEngr Ahmad100% (1)

- Feasibility PC-II Proforma Gujar Garhi Canal ParkDocumento9 pagineFeasibility PC-II Proforma Gujar Garhi Canal ParkEngr AhmadNessuna valutazione finora

- Rehabilitation of 2/9 Hoti Minor RD:10700 - 11600 in ReachesDocumento1 paginaRehabilitation of 2/9 Hoti Minor RD:10700 - 11600 in ReachesEngr AhmadNessuna valutazione finora

- Design Calculations: Project Site Input Data RRMDocumento1 paginaDesign Calculations: Project Site Input Data RRMEngr AhmadNessuna valutazione finora

- Vertical Wall DesignDocumento1 paginaVertical Wall DesignEngr AhmadNessuna valutazione finora

- Vertical Wall DesignDocumento1 paginaVertical Wall DesignEngr AhmadNessuna valutazione finora

- Lacey Design SheetDocumento6 pagineLacey Design SheetEngr AhmadNessuna valutazione finora

- Drive ConfigDocumento136 pagineDrive ConfigGiangDoNessuna valutazione finora

- Universal USB Installer - Easy As 1 2 3 - USB Pen Drive LinuxDocumento4 pagineUniversal USB Installer - Easy As 1 2 3 - USB Pen Drive LinuxAishwarya GuptaNessuna valutazione finora

- FHV19 - Exhibitor Manual - 10 DECEMBER - Manual PDFDocumento50 pagineFHV19 - Exhibitor Manual - 10 DECEMBER - Manual PDFHien Hien NguyenNessuna valutazione finora

- BME (Steel)Documento8 pagineBME (Steel)Mohil JainNessuna valutazione finora

- Isuzu 4hk1x Sheet HRDocumento4 pagineIsuzu 4hk1x Sheet HRMuhammad Haqi Priyono100% (1)

- 5 6176700143207711706Documento198 pagine5 6176700143207711706abc defNessuna valutazione finora

- Centrala Termica Pe Lemn Si Carbune Rima SF Manual Tehnic LB EnglezaDocumento26 pagineCentrala Termica Pe Lemn Si Carbune Rima SF Manual Tehnic LB EnglezaDobrin PaulNessuna valutazione finora

- Book - Adams Tutorial Ex17 W PDFDocumento121 pagineBook - Adams Tutorial Ex17 W PDFKamran ShahidNessuna valutazione finora

- Transfer Action in Sap HRDocumento3 pagineTransfer Action in Sap HRKarthi MrvkNessuna valutazione finora

- Moody DiagramDocumento18 pagineMoody DiagramWilson JustinoNessuna valutazione finora

- CS 162 Memory Consistency ModelsDocumento22 pagineCS 162 Memory Consistency Modelsravikumarsid2990Nessuna valutazione finora

- (WWW - Manuallib.com) - MOELLER EASY512&Minus AB&Minus RCDocumento8 pagine(WWW - Manuallib.com) - MOELLER EASY512&Minus AB&Minus RCErik VermaakNessuna valutazione finora

- ICON Catalog LocationsDocumento16 pagineICON Catalog LocationsTools StuffsNessuna valutazione finora

- Ijet V3i6p54Documento6 pagineIjet V3i6p54International Journal of Engineering and TechniquesNessuna valutazione finora

- EMI RFI Generation From LRT SystemsDocumento27 pagineEMI RFI Generation From LRT SystemsShahidan StellarNessuna valutazione finora

- DFM54 EngDocumento2 pagineDFM54 EngAnonymous KWO434Nessuna valutazione finora

- Logcat 1693362990178Documento33 pagineLogcat 1693362990178MarsNessuna valutazione finora

- STOD-OTP-PMT-0805-HS-SPE-0001 Specification For Temporary Construction Camps and Ancillary FacilitiesDocumento25 pagineSTOD-OTP-PMT-0805-HS-SPE-0001 Specification For Temporary Construction Camps and Ancillary Facilitiesjfl2096Nessuna valutazione finora

- Data Flow Diagrams PDFDocumento9 pagineData Flow Diagrams PDFYasmine2410Nessuna valutazione finora

- Brochure sp761lfDocumento10 pagineBrochure sp761lfkathy fernandezNessuna valutazione finora

- Construction of Rajive Gandhi Urja Bhawan, Ongc Energy Center & Corporate OfficeDocumento23 pagineConstruction of Rajive Gandhi Urja Bhawan, Ongc Energy Center & Corporate OfficeDevendra SharmaNessuna valutazione finora

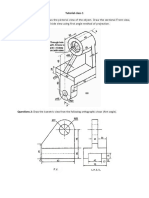

- Tutorial Class 1 Questions 1Documento2 pagineTutorial Class 1 Questions 1Bố Quỳnh ChiNessuna valutazione finora

- Bomba FlightDocumento2 pagineBomba FlightGustavo HRNessuna valutazione finora

- Cable Ties DatasheetDocumento7 pagineCable Ties DatasheetGovind ChaudhariNessuna valutazione finora

- Green Line TransformerDocumento4 pagineGreen Line TransformerwakasNessuna valutazione finora

- Astm D3350-10Documento7 pagineAstm D3350-10Jorge HuarcayaNessuna valutazione finora