Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Phase Transformations in Iron-Ruthenium Alloys Under High Pressure

Caricato da

Jiayi YanDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Phase Transformations in Iron-Ruthenium Alloys Under High Pressure

Caricato da

Jiayi YanCopyright:

Formati disponibili

PHASE

TRANSFORMATIONS

IN IRON-RUTHENIUM HIGH PRESSURE?

LARRY KAUFMAN3

ALLOYS

UNDER

L.

D. BLACKBURNS,

and MORRIS

COHEN1

At atmospheric pressure, iron-~thenium alloys containing less than 12 atom percent ruthenium exhibit a diffusionless a(b.c.c.) s y(f.e.0,) transformation on heating and cooling, while alloys containing 12-36 atom percent ruthenium exhibit a diffusionless e(h.c.p.) s y(f.c.0.) transformation. High pressure displaces the a + y reaction to lower temperatures, but shifts the E z y reaction to higher temperatures. These effects appear to be governed by the pressure dependence of the thermodynamic properties. The application of pressure also produces a new transformation, cc* E, at room temperature in alloys which contain the a-phase at atmospheric pressure. Pressure-temperature diagrams at constant eomposition thus contain triple points involving a(b.c.c.f, y(f.c.c.) and e(h.c.p.). As the ruthenium content is increased, the t,riplo-point pressure decreases si~ificantly. Comparison of the alloy pressur~~mperature diagrams with the high-pressure behavior of iron demonstrates that the pure metal also exhibits a triple point, at which the high-pressure, low-temperafor ture phase is E. A thermodynamic analysis has yielded values of AF a+~[ 211 pure iron, thus establishing the relative stability of the e-phase in iron. TRANSFORMATION DE PHASE SOUS PRESSION ELEVEE DANS LES ALLIAGES Fe-Ru

Lors dun chauffage ou dun refroidissement B la pression atmospherique, les alliages Fe-Ru eontenant moins de 15% at. Ru, poss&lent une transformation sans diffusion a(c.c.) + y(c.f.0.); dams les memes conditions, les alliages contenant 12 a 36 % at. Ru possedent une transformation sans diffusion e(h,c.) + cc(o.f.e). Sous pression &e&e, la reaction x - y se deplace vers des tempkratures plus basses elors que la transformation E -+ y se deplace vers des temperatures plus &levees. Ces effets semblent 6tre en relation avec linfluence de la pression sur les proprietes thermodynamiques. Lapplication dune pression produit Bgalement une nouvelle transformation, a + E, qui apparait it la temperature ambiante dans les alliages contenant la phase a 8. la pression atmospherique. Les diagrammes pression-temperature, a composition con&ante, contiennent des points triples pour lesquels existent siInultan~ment les trois phases a(c.c.), y(c.f.c) et l (h.c.p.). Lorsque la teneur en Ru saccroit, on observe une diminution signifieative de la pression au point triple. La comparaison entre les diagrammes pression-temperature et le eomportement sous haute pression du fer PUP, montre que le metal pur possede aussi un point triple pour lequel la phase l existe, sous haute pression et basse temperature. Une analyse thermodynamique a fourni des valeurs de A&-e [T] pour le fer pur. Ceci prouve la stabiliti! relative de la phase E dans le Fe. PHASEN~TMWA~DL~GE~ UNTER IN EISE~-RUTHE~~U~~-LEGIERUNGE~ HOHEM DRUCK

Eisen-Ruthenium-Legierungen mit weniger als 12 At. - % Ruthenium zeigen eine diffusionslose Unwandlung a(k.r.z.) $ y(k.f.2.) beim Hochheizen und Abkiihlen unter hohem Druck. Legierungen mit 12-36 At. - 4 Ruthenium zeigen eine diffusionslose e(hexagona1 dichtest gepackt) ;=t y(k.f.z.)Umwandlung. Hoher Druck versohiebt die a + y-Reaktion zu niedrigeren Temperaturen, jedoch die E - y-Reaktion zu hoheren Temperaturen. _ Diese Effekte soheinen duroh die Druckabhiingigkeit der thermodynamisohen Eigenschaften kontrolliert zu werden. In Legierungen, welche die a-Phase bei atmosph~risch0m Druck enthalten, fiihrt die Einwirkung eines Druckes ebenfalla zu einer neuen DL e-Umwandlung bei Raumtem~rat~. + Druck-Tem~raturDiagramme enthalten folglich bei konstanter Legierungszusammensetzung einen Tripelpunkt zwischen den Phasen a(k.r.z.), y(k.f.2.) und e(hexagona1 dichtest gepackt). Mit zunchmendem Rutheniumgehalt nimmt der Druck am Tripelpunkt marklich ab. Ein Vergleich der Druck-Temperatur-Diagramme der Legierungen mit dem Verhalten von Eisen bei hohem Druck zeigt, daB beim reinen Metal1 ebenfalls ein Tripelpunkt auftritt, an dem E die Phase bei hohem Druck und niedriger Temperatur ist. Eine thermodynamische Analyst? hat Werte fiir AFa-e [T] in reinem Eisen ergeben und somit die relative Stabilit&t der e-Phase in Eisen sichergestellt.

1. INTRODUCTION

The application of high pressure may have important effects on phase relationships in metals and alloys. t Received May 6,1964. This research was sponsored by the Metallur~ Branch, Office of Naval Research, W~hing~n, D.C. under Contracts Nom 2600(00)-NR 031-627 with ManLabs Inc., and Nonr-1841-35 with the Massachusetts Institute of Technology, and is based on a doctoral thesis submitted to the Department of Metallurgy, M.I.T. in May 1963 by L. D. Blackburn. $ Formerly Department of Metallurgy, M.I.T., presently Lieutenant USAF, Air Force Materials Laboratory, WrightPatterson Air Force Base, Ohio. 5 ManLabs, Inc.. Cambridge, Mass. ff Department of Metallurgy, Massachusetts Institute of Technology, Cambridge, Mass.

ACTA METALLURGICA, VOL. 13, MAY 1965

For example, polymorphism becomes more common when both temperature and pressure are variables, rather than temperature alone. Pressure also changes the temperatures of melting and polymorphic transformations, and may thus permit a direct study of solid phases at temperatures beyond their normal range of stability at atmospheric pressure. Detailed studies of such effects may well provide new insight to the understanding of lattice stability of metals, and it is in this context that the present investigation on the iron-~thenium system was conducted. The iron-ruthenium phase diagram exhibits only

533

534

ACTA

METALLURGICA,

VOL.

13, 1965

three tion.

solid

phases

at temperatures

below

1400C: solid solutransfor-

undergoes lattice phases,

an E*

y reaction.

a(b.c.c.), mation :

y(f.c.c.)

and an extensive

r(h.c.p.)

parameters

Comparison of the of these alloys with the data of product as the

These phases interact via a eutectoid

Raub and Plate(l) shows that the metastable u and E, have the same composition

y(9.3 a/o Ru) 2 at approximately it is replaced tions. exhibit taining

x(4.8 a/o Ru) + ~(23.5 a/o Ru) 500C.(1) This reaction is very slugphase transforma-

parent phase, y; therefore, both transformations are diffusionless. Metallographic observations have indicated that the u z The molar volume from extrapolation y reaction is martensitic. relationships of the X-ray shown in Table 1 and data of Raub and

gish, however, and even with slow heating and cooling, by two diffusionless Alloys containing less than 12 at. y ruthenium an a 2 y transf or m a t ion, while alloys con12 to 36 at. /o ruthenium undergo an E2 y It is the pressure dependence of these difsystem that

are derived from the measured lattice parameters Plate(l) and Abrahamson.(9) volume, the data in Table

Based on the generaliza1 indicate that pressure for the for

tion that pressure stabilizes the phase of smaller molar should lower the transformation the E;~?ry reaction. Transformation temperatures for the diffusionless reactions were determined from electrical resistancetemperature curves. Atmospheric pressure experiand in a ments were conducted the high-pressure in an argon atmosphere, were conducted temperatures

reaction.2)

fusionless reactions which is of interest here. A high-pressure study of the iron-ruthenium offers an intriguing possibility relationships at room duced in pure iron. temperature for clarifying the phase a pressure-in-

CL y reaction but should raise the temperatures &

It is well established

iron undergoes

transformation

at a pressure of 133 kb.(3y4y5) low-temperature as either identified

The structure polymorph face-centered

of this high-pressure,

has been tentatively

experiments

cubic(3p6T7) hexagonal close-packed.(5*s) or phase diagram contains an from 23.5 to 100 at. y0 that pure lower

Now, the iron-ruthenium ruthenium. Coupled

assembly described elsewhere.(lVl) high-pressure Pressure calibration was based on the transitions in bismuth at 25.6 kb and in thallium at 36.7 kb, and on the pressure dependence in pure iron. mel-alumel thermocouples of the cce y transformation for the effect, Temperatures were measured with chrouncorrected

h.c.p. solid solution extending

with the hypothesis

iron is h.c.p. above 133 kb, this diagram suggests that additions of ruthenium to iron may progressively the transformation at atmospheric high-pressure pressure reaction, and eventually pressure. thenium may, therefore, thus facilitating ture in question. transformation pure iron.

2. EXPERIMENTAL MATERIALS PROCEDURE AND

for the b.c.c. + h.c.p. alloying with ruof the

of pressure on the e.m.f. Isobaric resistance-temperature cycles on a given specimen were recorded at ascending pressure increments, these increments effects. being varied from one specipossible thermal history men to the next to avoid

produce a stable h.c.p. phase Judicious allow the production identification

form of iron at pressures below 133 kb, the X-ray of the strucof the Compositional extrapolation

Several heating and cooling cycles were run at Metalof specimens showed no evidence materials used in the high-

each pressure, with as many as 17 cycles being obtained on a single specimen over a range of pressures. lographic observation of contamination pressure cell. An entire heating and cooling cycle (25C -+ 900C 25C) for each resistance-temperature in approximately 7-9 min. curve was However, accomplished from

pressures might then verify that the

reaction in the alloys is the same as that occurring in

The compositions,

structures

and volume

relationare

y

ships of the four alloys used in this investigation listed in Table 1. Alloys A, B and C undergo an a + transformation

varying the heating and cooling rates within the limits of the equipment. had no effect on the measured transformation temperatures.

on heating and cooling, while alloy D

TABLE

1. Compositions, structure and volume relationships of iron-ruthenium alloys Ru Structure at 25C tc G( A Va-~t(25C), cm3/mol AV rz~(25C) cma/mol AVe-~(25c) oma/mol ___-0.19 -0.35 to.16 -0.20 -0.36 +0.16 -0.22 -0.37 +0.15 -0.29 -0.44 +0.15

Alloy

Composition,

a/o

A : D

5.7 7.7 8.8 15.4

Vu..

t AVa-y E VY -

BLACKRURN

et ul.: PHASE

TRANSFORMBTIONS

UNDER

PRESSURE

535

MO-

I

5

. I

, \

I I

i

is

RUT(IENIUM

10

ATOM PERCENT

20

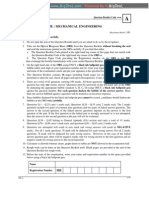

FIG. 1. Transformation temperatures and Curie temperatures of Fe-Ru alloys. 3. EXPERIMENTAL RESULTS

lowers both Ma+ and A,+, which is expected since y has the smaller molar volume (see Table 1). However, as the pressure is increased, a new reaction replaces the CL y transf ormation in these alloys. This G behavior is illustrated by the resistance-temperature curves shown in Figs. 2 and 3. Figure 2 presents the curves for all four alloys at atmospheric pressure and reveals the difference in hysteresis loops between the a ri: ^Jand E~ti:y transformations. Resistanee-temperature curves of alloy B at higher pressures are shown in Fig. 3. Comparison of these figures illustrates quite clearly that at pressures above 42 kb, the CI y s reaction vanishes and the E$sy reaction appears; that is, E replaces ct as the low-temperature phase. This conclusion was verified by high-pressure X-ray diffraction experiments performed by Professor John Jamieson of the Department of Geology, university of Chicago. He found that on applying it pressure of approximately 90 kb at room temperature, alloys A, B and C contained both b.c.c. u a,nd h.c.p. E; i.e., pressure induces an E + Etr&nsformation. Both the resistance-temperature work and the X-ray diffraction experiments demonstrated that Eis not retained when

1. Transformations at atmospheric pressure The transformation-start temperatures on heating (AZ+ and AZ+) and on cooling (M,Y- and Mr) under atmospheric pressure are shown as a, function of composition in Fig. 1. In addition to the transformation temperatures, the resistance-temperature curves revealed the Curie temperatures Ti, of the u-phase; these findings are included in Fig. 1. The present results are in good agreement with those of earlier investigat1ions.(1~12~13) A recent application of the regular solution model of Kaufman and Cohen(14)to the iron-ruthenium system has yielded values of APa+ for the diffusionless tr~nsform~tiou as a function of temperature and cornposition. From this, it is possible to calculate T&a s r), which is defined as the temperature at which AY = 0 for a given composition. Figure 1 shows a comparison of these calculated values of T,, with the experimental values of 4(M, + A,). In view of the excellent agreement shown in Fig. 1, the relation T,, = g(M, + A,) was used to evaluate T, for the a s y reaction at higher pressures. Although a lack of thermodynamic data precludes a calculation of T&E + y), it was also assumed that T, = 4(&f, + A,) for this reaction. 2. Trans~o~~t~o~ at high pressures In alloys A, B and C, the application of pressure

FIG. 2.

26I ATMOSPHERE

zoo

500 TE&K=ERATRE,-C

FJ

903

Resistance-temperature curves for Fe-Ru ELIIOJTJ

at atmospheric pressure.

536

ACTA

METALLURGICA,

VOL.

13,

1965

FIG. 4. Transformation temperatures vs. pressure for 5.7 at. A Ru alloy.

temperature accurately. Quantitative

curve

which

was difficult

to interpret behavior

results of the transformation

v: I0 Co

FIG.

MO

500

700

903

in alloys A,

and C are presented in Figs. 4-6, which

TEMPERATRE,~C

3. Resistance-temperature curves for alloy at high pressures.

7.7% Ru

show the variation of the transformation temperatures and T,, with pressure. In addition to the entree of the Es y reaction at high pressures, these plots reveal that as the ruthenium content is increased, this reacThus, in alloy C, the

the pressure is released, but rather it reverts to u via the reverse reaction, Several experiments ure the transformation tion. Unfortunately E -+ a. utilizing isothermal resistancepressures for the u z E reac-

tion occurs at lower pressures.

pressure cycles were performed in an attempt to measthese efforts were unsuccessful. factors may to detect the dc--, E transformahad insufficient pressure capa-

It is felt that one or both of the following explain this inability tion : (1) the equipment (2) the transformation gradual to be detected. bility to produce appreciable

transformation

; or

occurs gradually over a broad change is too inconsiscycling,

pressure range, and thus the resistance

The first of these factors is not necessarily tent with the results of resistance-temperature

where E definitely was produced. In these experiments it is likely that E formed from y rather than cr; that is, the first cycle reactions possibility could may be u % y 2 E, subsequent cycles then showing only E = not be conclusively 1. However, this demonstrated,

OO

10

20 PRESSURE

so

,

40

so

since the settling of the high-pressure cell on the first heating cycle always produced an irregular resistance-

KILOBAf?S

FIG. 5. Transformation temperatures vs. pressure for 7.7 at. % Ru alloy.

BLACKBURN

et al.: PHASE

TRANSFORMATIONS

UNDER

PRESSURE

537

creased. supporting

No new transformations the conclusion alloys is E.

occur in this alloy, phase

that the high-pressure

in the lower ruthenium

4.

DISCUSSION

1. Pressure dependence of a 22 y and E212y reactions The pressure transformation qualitative thus Mi+, dependence in these with of the diffusionless alloys the generalization phase is in that iron-ruthenium

agreement

pressure stabilizes

the phase of smaller molar volume; pressure, dependrequires a increase. of the pressure transformations

and At+? decrease with increasing prediction

while MTE and AfY A quantitative knowledge

ence of those diffusionless of A Vu+y, A F+ M, and A, as functions imate calculation

and the driving forces at and pressure.(16) of Ml,

of temperature

Using the only available data for AFa+Y,(15) an approxof the pressure dependence A:? and T,(a 2 y) was carried out. This calculation is identical to thst used by Kaufman et al. for the ironFIG. 6. Transformation temperetures vs. pressure for 8.8 at. % Ru alloy. cc& y reaction

nickel system.u7) experimental somewhat in Table the u e

Table 2 compares the calculated temperatures

and

transformation low, but

at several

has already disappeared T, temperatures

at 16 kb.

The were meas-

pressures for alloy A. The calculated considering required in the calculations, 2 indicates y reaction

values of AZ+7 are evidenced of in the data for of this

M,, A, and calculated The

l

for this reaction

the approximations dependence

using the same pressure dependence behavior of alloy pressure,

the agreement

ured in alloy B. transformation D at high the is inI

that the pressure is governed

by changes

pressures $ A:Y

I

900 t

is shown in Fig. 7. at atmospheric

This alloy exhibits

thermodynamic Unfortunately,

properties

under pressure. prohibits a similar calculathat E has the

y reaction

and M:+,

the lack of thermodynamic In general, the behavior with the fact suggesting properties B and that

and T&E e

I

y) are raised as the pressure

! I I

the E & y transformation tion for this reaction. reaction smaller is consistent molar volume,

the variation to this generresult

in the thermodynamic controlling alization factor. occur

with pressure is the C, where AZ-Y dewith tem-

The only exceptions

in alloys

creases as the pressure is raised. may be due to unknown perature and pressure, behavior or transformation

This anomalous

changes in Al++ or to changes mechanism

in nucleation under pressure.

2. Composition dependence qf the high-pressure transformati0n.s An important the appearance transformations treated

I

50

feature of the present of E as the high-pressure, alloys. are diffusionless, analogues for one-component

investigation low-tempera-

is

ture phase in iron-ruthenium as binary

Since the phase 4-7 may be

Figs.

of the pressure-temperasystems. Thus, the

ture diagrams 200

FIG.

I I I

10

20

30 40 PRESS"RE.KILOBARS

T,, curves in these graphs are the boundaries between the single phase fields in this type of pressure-temperature diagram. In alloys A, B and C, TO(u e to give a triple point. 7) end There T&E JFs y) intersect,

7. Transformation temperatures vs. pressure for 15.4 at. % Ru alloy.

538 TABLE 2. Comparison

ACTA

METALLURGICA,

VOL.

13,

1965 for 5.7 a/o Ru alloy at

of experimental

and calculated transformation high pressures

temperatures

P, kb

0 569

10 20 30 40

461 382 332 278

722 697 672 643 613

646 579 527 488 446

480 421 353 289

661 604 553 507

655 5s5 519 463 413

should, of course, be a third branch intersecting at the triple point corresponding to T,( tcG e). Although the latter curve could not be quantitatively demonstration measured, it is the experimental transformation of the direct u -+ E Therefore,

0 0

JOHNSON PRESENT

ET AL

124)

INVESTIGATION

shows that it exists.

in ironruthenium alloys do exhibit triple point behavior. The pressure points and temperature parameters Figs. 4-6. for iron-rutheof the triple content) are

*x5 --__ --_ ----_

0 l l

concluded the the diffusionless transformations

(which vary with the ruthenium

denoted as

P, and T, in

The establishment immediately doubt. where

of triple points

nium alloys, in which all the phase have been identified, suggests a comparison of these alloys with are still in pure iron, where the phase relationships This comparison

is made in Figs. 8 and 9, of the alloy data to pure iron is with the triple-point param1 2 ATOM I 4 PERCENT I 6 RTHENlM I B

P, and T, are

plotted as functions of composi-

tion. The extrapolation in very good agreement

eters for iron proposed by Johnson, Stein and Davis.(s) It should be emphasized positional variation that Fig. 8 shows the compressure at a of the triple-point

FIG. 9. Variation

of triple-point temperature composition.

(T,)

with

temperature formation

of approximately

450C, not the transAccordingly, the alloy

pressure at 25C.

data do not extrapolate acteristic

to a pressure of 133 kb at room However, additional

temperature in pure iron, but to a lower pressure charof the triple point. workos) by J. S. McCallum and J. C. Jamieson on ten alloys containing O-6 a/o ruthenium? itative information perature. the actual CI--+ E transformation Table 3 summarizes 90 kb and 130 kb. has yielded qualdependence of on the composition

pressure at room temthe h.c.p. reflections

which were observed in these alloys under pressures of approximately The increase in the pressure is deleading to number of h.c.p. reflections at a given pressure indicontents,

cates that the u ---f E transformation creasing with higher ruthenium

the formation of more E at the test pressure. These data demonstrate that the transformation pressure does not rise sharply with decreasing ruthenium conbent but varies smoothly to a value quite close to

Fro. 8. Variation of triple-point composition. pressure (P*) with

t These alloys were kindly supplied by Dr. E. P. Abrahemson of the Watertown Amenal during the final stages of this investigation.

BLACKBURN

et al.:

PHASE

TRANSFORMATIONS

UNDER

PRESSURE

539

TABLE 3. High-pressure X-ray diffraction results on the c( + e transformation at 25C (after J. S. McCallum and J. C. Jamiesono*) Alloy composition, at. A Ru 0.00 0.53 1.00 1.55 2.02 2.57 3.43 3.96 4.50 5.12 5.65

heat capacity of e-iron is considered in terms of lattice, electronic and magnetic contributions

P m QOkb

H.C.P reflections observed P es 130kb t;;.;\(Ref. 5)

GDQ[T] = C, where

[I

f

(1 + 10-4T) + yET + CDEw[T] (1) of e-iron coefficient to the heat

none none none none n0IIe none none none none

8 is the Debye temperature y is the electronic C,E@ is the magnetic capacity.

specific-heat contribution

(lO:l), trace of (11.0) and (10.3) I::.:\ (lo:o), (lO.l), (lO.O), (lO.O), (lO.O), (lO.O), (lO.l), (ll.O), (lO.l), (lO.l), (10.1), (lO.l), (ll.O), (10.3) (ll.O), (ll.O), (ll.O), (ll.O), (10.3) (10.3) (10.3) (10.3) (10.3)

This relation

can then be integrated

to yield an ex-

pression for the free energy of E-iron:

FyT] = Hoc +

Fe

+ FE[Tl

iyeT

(2)

where HOCis the enthalpy 133 kb. This result also provides strong support for the validity From of the extrapolation these considerations of the triple-point pressures in Fig. 8. of the iron-ruthenium low-temperThis data, it is evident that pure iron does indeed contain

a triple-point,

at OK, based on Ho G 0. the known values of can be formulated in

It is now assumed that yE = ycl = y and also that FCp = 07. Then, by employing F[T],(21) AFZ+E(=FE F)

terms of the parameters 8 and Ho. These parameters are then fixed by requiring: temperature perature of y 2 (1) that AFa+<[T] yield reasonable agreement with the calculated E at one atmosphere AFxE[T] intersects at which equilibrium (i.e. the temthe known of E-iron (i.e. intersects the

and that the high-pressure, been verified

ature form of iron is hexagonal conclusion has recently diffraction pressure X-ray

close-packed.

by very high-

function A F[ the temperature

T]) ; (2) that A Fa+E[ T] yield a reasonat which AFL[T]) AFa-<[T]

experiments.(1g~20)

able value for the melting temperature known function point and Debye to the Lindermann

3. Thermodynamics The transformation

of h.c.p. iron data on these iron-ruthenium in develproperties of the h.c.p. form studies of the pure metal y reaction in this value of

; and (3) that the melting

of h.c.p. iron conform Table 4 summarizes

temperature relation.(21)

alloys can now be used to further advantage oping the thermodynamic of iron. Previous iron. that dT&P high-pressure have yielded no information However, cZT~~)/~P = 3.3C/kb. on the Ez Using

the parameters for c-iron which result from these calculations and compares them with the corresponding parameters for u and y iron. of AF, AFY and AFL functions Figure 10 shows the variation at one atmosphere the calculated with temperature. ature is increased, larger entropy

in the alloys studied here, it is found pressure and tempressure is analye&.

These curves indicate that at T = As the temperbecause E has a AF decreases

and the known triple-point

OK, E-iron is more stable than y-iron. than CI. However,

perature, the temperature in equilibrium estimated

at which y and E would be 400K. This is an imet aZ.,@l) the

in pure iron at atmospheric

y has a still larger

to be approximately the treatment

portant piece of information Following

in t!ie following of Kaufman

t Recent measurements of the 25C and high pressures by Nicol et al.@ indicate that h.c.p. iron earlier studyz1j yielded the result

properties of a, y and E iron.

Mossbauer effect in iron at and Jurat2*J and by Pipkorn is not ferromagnetic. An ya = yy.

TABLE 4. Thermodynamic cal H, moi 0 1303

Phase

?[ T = OK] z;; 7.061

8K 432 432

cal ? mol - (K)2 12 x 10-a 12 x 10-a

cal pr mol 3wc( T] (ref. 21) PYP[ T] (ref. 21) 0

Y

E

(31)

7.216$ 6.695 $

1150 6.731 V]T] = V[T = 0](1 + 2.043 x lo-T

12 x IO-4 375 + 1.520 x lo-8T2) cma/mol

$ The two values of B[T = OK] given for f.c.c. correspond state. (a)

to a high moment-high

volume and a low moment-low

volume

540

ACTA

METALLURGICA,

VOL.

13,

1965

Frc, 11. Calculated pressure-temperature relations in Fe. FIG. 10. Free ener~-~rnper~tu~ rel&ions a(b.c.c.),y(f.c.c.),t-(h.c,p.)andliquidformsofFeat for the 1 atm.

entropy, so y becomes more stable than E at temperatures above 39OK. At higher temperatures, the magnetic contribution to the entropy of a-iron becomes important, producing a minimum in AP+. This minimum, indicating a small value of AL?~, is consistent with the very steep slope of the u e Eboundary in the pressure-temperature diagram (i.e. d T,,(a*Ftt)/d P = AVaJC/ASCLE).It should be noted that this calculation also yields values of AFC+[TJ, which is simply the difference between APE and APa++ in Fig. 10. The free energy functions AFa+E,AliY and AIW, coupled with the known volume relationships (see Table 4), can now be applied to calculations of the phase boundaries in the pressure-temperature diagram, since at the boundaries (3) On the basis of the foregoing and t,he earlier results,t2n the a/e boundary is defined by Ai\Fa+[T, P] = 0 = AFa+[T] AF-[T, P] = 0 = -1303 + 23.9PAVa-E[T] + Pup[T] y[T, P]) V[T]) (5) (4) The u/y boundary is defined by? RT In (1 AF[T, P] = 0

where y[T, P] is the fraction of high magnetic moments in f.c.c. iron at a given temperature and pressure, and Vro is the molar volume of the low magnetic moment form in f.c.c. ironcal Finally, the y/c boundary is defined by AFY-E[T, P] = AFY-[T, + APa-[T, P] PJ = 0 (6)

+ 23.9P(VC([T] -

t Equation (5) corrects a typographical error in equation (39) of Ref. 21 in which the P in the last term was omitted.

Equation (6) is solved numerically by adding equation (4) to equation (5). Figure 11 shows the calculated pressure-temperature diagram of iron. These results are in good agreement with experimental observations of the phase relationships. Thus, the thermodynamic analysis yields values of AFa+<[T] which are consistent with the observed behavior of pure iron. It is interesting to note that the computed freeenergy difference between the f.c.c. and h.c.p. forms of iron at 0K and one atmosphere is 150 cal/mol. This difference is about three times the corresponding freeenergy difference in cobalt. On this basis, the stacking fault energy of y iron would be estimated at about 30 ergs/cm2 or three times that of cobalt. The principal difference between the computed P-T diagram (Fig. 11) and the observed version (Fig. 1 of Ref. 21) is the location of the triple-point. Johnson,

BLACKBURN

et al.:

PHASE

TRANSFORMATIONS

UNDER

PRESSURE

541

Stein and Davis@) put the triple-point and 110 kb as opposed 750K and P, calculations simplifications

at about 800K values T,

phases

in pure iron which observed

are consistent

with the

to the computed

experimentally

behavior.

= 92 kb in Fig. 11. There are at least

First, the present required for unon idealizations The

two reasons for these discrepancies. are based

6. ACKNOWLEDGMENTS

authors

are indebted

to Professor

John

C.

and for the purpose of eliminating Secondly, the experimental

Jamieson and Dr. J. Stewart McCallum of the University of Chicago for performing diffraction experiments program. the high-pressure X-ray pertinent to this investigation, for assistance in the also wish alloys. at M.I.T. which to thank Arsenal for furThey

known parameters.

shock-

wave measurements of the u e y branch,(*) which were isothermally, exhibit pressure overperformed shooting of the order of 10 to 20 kb between 850 and 1150K. This overshooting can be readily seen in Fig. 1 of Ref. 21. Thus, the current differences between the computed and observed triple-points arise from uncertainties will require in both the calculations and the measurements. Resolu-

and to Mr. J. Elling of ManLabs experimental Dr. E. P. Abrahamson The General provided Electric

of Watertown Fellowship acknowledged.

nishing some of the iron-ruthenium financial support

for one of the authors

(L. D. B.) is gratefully

tion of these differences studies along both lines.

5. 1. The application

more detailed

REFERENCES 1. E. RAUB and W. PLATE, 2. MetaUk. 51, 477 (1960). 2. W. OBROWSKI, Naturwise. 46, 624 (1959). 3. D. BANCROFT, E. L. PETERSON and S. MARSHALL, J. AppZ. Phys. 27, 557 (1956). 4. H. G. DRICKAMER and A. I. BALCRAN, Rev. Sci. Instrum. 32, 308. (1961). 5. C. JAMIESON and A. W. LAWSON, J. Appl. Phys. 35, 776 (1962). 6. G. E. DIETER, Strengthening Mechanisms in Solids, p. 279. Amer. Sot. for Metals, Metals Park. Ohio (1962). 7. W. C. LESLIE, E. HORNBOGEN and G. E. DIETER, J. Iron 8. P. C. JOHNSON,B. A. STEIN and R. S. DAVIS, J. AppZ. Phys. 33, 557 (1962). 9. E. P. ABRAHAMSON, private communication. 10. E. V. CLOUURERTY and L. KAUFMAN. Hiah Preseure Measurement, p. 152. Butterworths, Washington, D.C. (1963). 11. ManLabs, Inc., Progress Report No. 6, Research and Development on High-Pressure High-Temperature Metallurgy, kF33(616)-6g-37, July 1961.12. J. MARTELLY, Ann. Phyls. 9, 318 (1938). 13. M. FALLOT, Ann. Phys. 10, 291 (1938). 14. L. KAUFMAN and M. COHEN, Trans. Amer. Inst. Min. (Metall.) Engrs. 206, 1393 (1956). 15. L. D. BLACKBURN, unpublished research. New 16. L. KAUFMAN, Solids Under Pressure. McGraw-Hill, York, 1962. 17. L. KAUFMAN, A. LEYENNAR and J. S. HARVEY, Progress in very high pressure research, p. 90. John Wiley and Sons, New York (1961). 18. J. S. MCCALLUM and J. C. JAMIESON, Dept. of Geophysics, U. of Chicago. (Private communication) to be published. 19. D. N. PIPKORN, C. K. EDGE, P. DE BRUNNER, G. DE PASQUALI, H. G. DRICKAMER and H. FRAUENFELDER,

SUMMARY

of pressure lowers the transforof the diffusionless alloys. b.c.c. 2 f.c.c. f.c.c. z pri-

mation temperatures reaction,

but raises that of the diffusionless of these transformations

h.c.p. reaction in iron-ruthenium dependence

The pressure proper-

is controlled

St. Inst., 200, 622 (1962).

marily by the variation in the thermodynamic ties with pressure. 2. In addition a pressure-induced temperature. 3. Fixed-composition grams for the binary triple-point pressure pressure-temperature iron-ruthenium to the diffusionless b.c.c. z h.c.p.

transformations reaction at room dia-

observed on heating and cooling, u-phase alloys exhibit

alloys show a

between the b.c.c., f.c.c. and h.c.p. phases. markedly, while the triple-point constant. with the highthat the with the high-

As the ruthenium content is increased, the triple-point decreases temperature remains essentially

4. A comparison pressure behavior

of these diagrams

of pure iron demonstrates

pure metal also exhibits a triple-point, pressure, low-temperature 5. A thermodynamic the free-energy differences

structure being h.c.p. between the b.c.c. and h.c.p.

Phys. Rev. 135, A1604 (1964). 20. T. TAKAHASHI and W. A. BASSETT, Science 145,483 (1964).

21. L.

analysis has yielded values for

Acta Met. 11, 323 (1963). 22. M. NICOL and G. JURA, Science 141, 1035 (1963).

KAUFMAN,

E.

V.

CLOUGHERTY and

R.

J.

WEISS,

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Chapter 15 Fluid and Chemical BalanceDocumento47 pagineChapter 15 Fluid and Chemical BalanceIntan FirmallahNessuna valutazione finora

- Carbo and Lipid Activity 2Documento2 pagineCarbo and Lipid Activity 2Perry BearNessuna valutazione finora

- AS Physics: Number of Pixels X Bits Per Pixel and 1 Byte 8 BitsDocumento2 pagineAS Physics: Number of Pixels X Bits Per Pixel and 1 Byte 8 BitsAnanYasinNessuna valutazione finora

- Activated Carbon PDFDocumento10 pagineActivated Carbon PDFDavid JoeventusNessuna valutazione finora

- احمد ابراهيمDocumento25 pagineاحمد ابراهيمAhmd amynNessuna valutazione finora

- Stain Resistant FabricDocumento4 pagineStain Resistant FabricARCUSNessuna valutazione finora

- 10000-PVC Fabric BpsDocumento4 pagine10000-PVC Fabric BpsHussain ElboshyNessuna valutazione finora

- Chemistry Notes For Class 12 Chapter 5 Surface ChemistryDocumento10 pagineChemistry Notes For Class 12 Chapter 5 Surface ChemistryNelsonMoseMNessuna valutazione finora

- Refrigeration Oil PDFDocumento17 pagineRefrigeration Oil PDFChristina PadillaNessuna valutazione finora

- Heavy Metal Removal From Water Using Moringa Oleifera Seed Coagulant and Double FiltrationDocumento4 pagineHeavy Metal Removal From Water Using Moringa Oleifera Seed Coagulant and Double FiltrationAena RabonzaNessuna valutazione finora

- Atomic PhysicsDocumento8 pagineAtomic PhysicsJahleel TroupeNessuna valutazione finora

- Two Solid Cylindrical Rods AB and 2. Select The Appropriate Pair of ElementsDocumento4 pagineTwo Solid Cylindrical Rods AB and 2. Select The Appropriate Pair of ElementsAhmed Dhempsey Hali AbdulbasikNessuna valutazione finora

- Analysis of Vinegar Via TitrationDocumento3 pagineAnalysis of Vinegar Via TitrationAfini Exo KNessuna valutazione finora

- Strange Balance: The TankDocumento10 pagineStrange Balance: The TankPredaarshan V ChandranNessuna valutazione finora

- SGL PT Brochure Systems OverviewDocumento24 pagineSGL PT Brochure Systems OverviewCésarSánchezRosasNessuna valutazione finora

- Flow AssuranceDocumento21 pagineFlow AssuranceMohamed Abd El-MoniemNessuna valutazione finora

- Chemical Resistance of Coatings Used in Light-Water Nuclear Power PlantsDocumento2 pagineChemical Resistance of Coatings Used in Light-Water Nuclear Power PlantsdorsaNessuna valutazione finora

- GenePrint Fluorescent STR Systems ProtocolDocumento50 pagineGenePrint Fluorescent STR Systems ProtocolNaveen NkNessuna valutazione finora

- Ab Initio Simulation of Helium-Ion Microscopy ImagesDocumento24 pagineAb Initio Simulation of Helium-Ion Microscopy ImagesMustafa ErolNessuna valutazione finora

- Gate 2013 Question Paper With AnswerDocumento16 pagineGate 2013 Question Paper With AnswerGurmail Singh GillNessuna valutazione finora

- GGG50 PDFDocumento2 pagineGGG50 PDFGeorge_Wabag_2014Nessuna valutazione finora

- Cad WeldDocumento24 pagineCad WeldNick JimNessuna valutazione finora

- Jahangirabad Instiute of Technology Barabanki Department of Mechanical EngineeringDocumento23 pagineJahangirabad Instiute of Technology Barabanki Department of Mechanical EngineeringMuhammad ImranNessuna valutazione finora

- Ncert Notes Class 9 Science Chapter1Documento8 pagineNcert Notes Class 9 Science Chapter1ng_nirmalNessuna valutazione finora

- Ketamina SintesisDocumento11 pagineKetamina SintesisKepa Martinez GarciaNessuna valutazione finora

- Geosphere and GeochemistryDocumento51 pagineGeosphere and Geochemistrycut nuruddiniyah50% (2)

- Conway PolyDocumento10 pagineConway PolyGaleri DesilNessuna valutazione finora

- CL 305 Vector Differential Operations, Momentum TransportDocumento10 pagineCL 305 Vector Differential Operations, Momentum TransportshubhamNessuna valutazione finora

- AOAC 990.11 Coliformes Totales y E Coli en Alimentos ISO GRIDDocumento2 pagineAOAC 990.11 Coliformes Totales y E Coli en Alimentos ISO GRIDdcardonasterNessuna valutazione finora