Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

FPD 16 e

Caricato da

bhanuduttaDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

FPD 16 e

Caricato da

bhanuduttaCopyright:

Formati disponibili

Concentrated Solar Power

Parabolic Trough Power Tower

Experience In Motion

A Pump for Every Application Under the Sun

Flowserve is the driving force in the global industrial pump marketplace. From the introduction of the first direct acting steam pump in 1840 to todays most advanced nuclear station design, Flowserve has pioneered virtually every significant advancement in pumping technology for the power generation industry.

Today, Flowserve is extending that leadership to the many forms of alternative energy generation, including concentrated solar power (CSP). Flowserve offers the industrys most comprehensive package of pump products, technical support and services for CSP. From molten salts and heat transfer fluids to condensate extraction cooling water systems, Flowserve has proven pump solutions that are both highly reliable and highly efficient. No other pump company in the world can boast a product line that includes pumps for every CSP application.

Product Brands of Distinction

ACEC Centrifugal Pumps Aldrich Pumps Byron Jackson Pumps Calder Energy Recovery Devices Cameron Pumps Durco Process Pumps Flowserve Pumps IDP Pumps Lawrence Pumps Niigata Worthington Pumps Pacific Pumps Pleuger Pumps Scienco Pumps Sier-Bath Rotary Pumps TKL Pumps United Centrifugal Pumps Western Land Roller Irrigation Pumps Wilson-Snyder Pumps

Worthington Pumps Worthington Simpson Pumps

flowserve.com

Supplier of Choice to the Concentrated Solar Power Industry

With its extensive experience in power generation, unmatched pumping technology and best-in-class technical know-how, Flowserve is the trusted choice for renewable energy generation. No other pump company in the world has the depth and breadth of expertise in the successful application of pre-engineered, engineered and special purpose pumps and systems for all CSP services. High-pressure vertical molten salt pumps Heavy-duty, radially split, between bearings heat transfer fluid (HTF) pumps Between bearings, radially and axially split, multistage boiler feed water pumps Vertical and horizontal circulating water pumps Mixed flow and vertical turbine condensate extraction pumps Radially split, axially split and overhung auxiliary service pumps

Committed to the Complete Pump System Life Cycle

For more than two centuries, Flowserve has served industries requiring solutions that add value and reduce costs throughout the life cycle of a pumping system. Power generation Oil and gas Chemical Water General industry

Complete System Responsibility

Flowserve pump, valve and seal divisions work in concert to develop optimally designed and fully integrated process equipment. That means Flowserve provides complete system responsibility so CSP generators can focus on their mission harnessing the clean energy of the sun.

Flowserve partners with customers to respond to the dynamic business conditions that affect them. Flowserve works with customers to improve efficiency, maximize throughput and control process quality. Whether customer needs involve on-site technical assistance, equipment upgrades or broader project planning with full turnkey responsibility, Flowserve delivers professional, reliable results.

The worlds only complete line of pumps for concentrated solar power generation

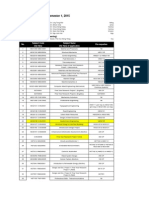

Parabolic Trough

Parabolic trough CSP stations require a broad range of pumps to handle applications including high-temperature heat transfer fluids (HTF), superheated feedwater, condensate and cooling water. Flowserve is the only pump manufacturer able to provide a solution for every application in parabolic trough solar power stations. The most demanding of these pump applications are heat transfer fluid circulation and molten salt heat exchange storage. At temperatures approaching 400C (750F), they present difficult hydraulic and sealing challenges. Flowserve has successfully and routinely surmounted these hurdles.

Simplified Parabolic Trough Flow Diagram

SOLAR FIELD

Hot Pipe Header Molten Salt Pump

THERMAL STORAGE

Solar Superheater

POWER BLOCK

Steam Turbine

Electrical Generator

Substation

Hot Tank

HTF Gas Heater

Cooling Tower Condenser

Salt HTF Heat Exchanger Molten Salt Pump Solar Steam Generator Solar Preheater Solar Reheater Expansion Vessel Cold Pipe Header HTF Pump Deaerator

Feed Water Pump

Condensate Pump

Cooling Water Pump

Cold Tank

Low-Pressure Preheater

flowserve.com

Gemasolar Plant Property of Torresol Energy Torresol Energy

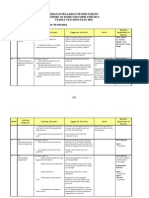

Power Tower

Whether using molten salt or superheated water, power Superheated water systems face numerous tower systems present varied and unique pumping demands. challenges associated with high pressure and With unmatched product and application expertise, Flowserve temperature pumping. Whether axially or provides the best combination of equipment, materials radially split, single or double case, Flowserve and ancillary systems for efficient operation and extended can provide custom engineered pumps for the reliability in these onerous services. harshest applications. Molten salt systems produce harsh operating conditions as temperatures near 600C (1100F). Flowserve is the leading supplier of high-pressure vertical pumps for this service. Flowserve also offers a complete package of power station pumps, including those for conventional turbine-generator main cooling and condensate service, solar pre-warmer feed and auxiliaries.

Simplified Power Tower Flow Diagram

COLLECTOR FIELD

Solar Receiver

MOLTEN SALT SYSTEM

POWER BLOCK

HP Turbine

IP/LP Turbine

Generator

Substation Receiver Tower

Reheater Superheater

Condenser

Molten Salt Pump

Molten Salt Storage

Steam Generator/ Evaporator

Cooling Water Pump Feedwater Pump Feedwater Preheaters Condensate Tank

Cooling Tower

565C (1050F)

290C (550F)

Heliostat Field

Molten Salt Pump

Molten Salt Storage

Condensate Pump

The Flowserve Molten Salt VTP is the industrys leading vertical pump for molten salt circulation.

Thermal mapping mitigates distortion

Molten Salt Pumps

A mixture of sodium nitrate (NaNO3) and potassium nitrate (KNO3), molten salt possesses high thermal conductivity allowing temperatures to reach 600C (1100F). As a leading provider of molten salt pumps for more than 60 years, Flowserve understands the detrimental effects of heat distortion on a vertical pump. Thats why Flowserve engineers utilize advanced thermal mapping software to ensure heat dissipation is adequate and distortion is mitigated.

Key Features and Benefits of the Molten Salt VTP Pump

Low pump submergence allows for greater energy generation. Low NPSHR allows for enhanced suction performance. Excellent heat dissipation design. prevents distortion at high temperatures. Advanced fluid sealing system protects against fluid leakage and reduces heat conduction. Materials are engineered to equalize thermal growth and forestall distortion.

Vertical Turbine Pumps for Primary Molten Salt Service

Single or multistage diffuser designs Operating Parameters Flows to 13 600 m3/h (60 000 gpm) Heads to 530 m (1740 ft) Pressures to 100 bar (1450 psi) Temperatures to 600C (1100F) Settings to 20 m (65 ft)

CPXV

Vertical Lineshaft and Cantilever Pumps for Auxiliary Molten Salt Services

Operating Parameters Flows to 2700 m3/h (12 000 gpm) Heads to 100 m (325 ft) Pressures to 14 bar (200 psi) Temperatures to 600C (1100F)

FRBHJC 6 VTP

flowserve.com

Heat Transfer Fluid Pumps

Regardless of the HTF used, Flowserve pumps can really take the heat.

Radially Split, Double-Suction API Pumps for Primary HTF Circulation

Key Features and Benefits of the HDX Pump

Centerline mounted design ensures proper alignment and minimizes pipe stresses at high temperatures. Between bearings design provides outstanding shaft stability for long bearing and seal life. Double-suction impeller compensates for low NPSHA. Custom engineered mechanical seal prevents shaft leakage and corrosion.

ISO 13709/API 610 (BB2); engineered for reliable, efficient operation at elevated temperatures and pressures Operating Parameters Flows to 4100 m3/h (18 000 gpm) Heads to 450 m (1500 ft) Pressures to 100 bar (1500 psi) Temperatures to 455C (850F)

API Process Pumps for Auxiliary Service

Centerline mounted, single-stage, overhung pumps; available for auxiliary HTF services such as secondary recirculation, overflow, makeup and storage Operating Parameters Flows to 2000 m3/h (9000 gpm) Heads to 350 m (1100 ft) Pressures to 80 bar (1160 psi) Temperatures to 455C (850F)

HDX

HPX 7

Flowserve has repeatedly proven it builds the highest quality, most reliable boiler feed pumps.

Boiler Feed Water Pumps

Boiler feed pumps are among the most critical pieces of rotating equipment in the steam cycle. Regardless of the type of power plant, Flowserve has repeatedly proven it builds the highest quality, most reliable boiler pumps available. Flowserve has several radially and axial split, multistage, between bearings pump models with single- or double-suction, first-stage impellers to meet application needs.

Key Features and Benefits of the WXH and DMX Feed Pumps

Centerline mounted design ensures proper alignment and minimizes pipe stresses at high temperatures. Between bearings design provides outstanding shaft stability for long bearing and seal life. Optional double-suction first-stage impeller compensates for low NPSHA. Mechanical seals with integral pumping ring maintain optimal sealing temperatures.

Multistage, Segmental Ring Diffuser Pumps

Between bearings, radially split designs Operating Parameters Flows to 1160 m3/h (5100 gpm) Heads to 2750 m (9000 ft) Pressures to 310 bar (4500 psi) Temperatures to 205C (400F)

Multistage, Horizontal Split Case Volute Pumps

WXH

Between bearings, axially split, double volute case, side suction, side discharge Operating Parameters Flows to 2950 m3/h (13 000 gpm) Heads to 2130 m (7000 ft) Pressures to 275 bar (4000 psi) Temperatures to 205C (400F)

DMX

flowserve.com

Circulating Water Pumps

Flowserve offers several vertical and horizontal pump models for reliable and extended operation in circulating water service. Pumps are available in a wide range of configurations, hydraulics and materials to maximize efficiency while meeting site requirements.

Vertical, Wet-Pit Pumps

Mixed flow, pullout and non-pullout designs Operating Parameters Flows to 170 000 m3/h (750 000 gpm) Heads to 110 m (350 ft) Pressures to 10 bar (150 psi) Temperatures to 95C (200F)

VCT

VTP

Horizontal, Between Bearings, Single-Stage Pumps

Heavy-duty, axially split, double volute, double-suction Operating Parameters Flows to 51 000 m3/h (225 000 gpm) Heads to 300 m (985 ft) Pressures to 30 bar (435 psi) Temperatures to 150C (300F)

LNN 9

No other pump company has the systems knowledge, hydraulic expertise or application know-how Flowserve possesses.

Condensate Extraction Pumps

Flowserve has a long and proven performance record in condensate extraction. Its versatile line of vertical condensate extraction pumps has unsurpassed hydraulic coverage and a broad range of available options to address system requirements.

Vertical, Multistage, Canned Pumps

Multistage, mixed flow designs with single- or doublesuction first-stage impeller to fit NPSH requirements, mechanically sealed, optional spacer coupling APKD VPC

Operating Parameters Flows to 4550 m3/h (20 000 gpm) Heads to 500 m (1650 ft) Pressures to 50 bar (700 psi) Temperatures to 95C (200F)

Vertical Turbine, Canned Pumps

Multistage, diffuser casing designs with large eye first-stage impeller for enhanced suction characteristics, mechanically sealed, optional spacer coupling Operating Parameters Flows to 13 600 m3/h (60 000 gpm) Heads to 670 m (2200 ft) Pressures to 65 bar (950 psi) Temperatures to 230C (450F)

10

flowserve.com

Auxiliary Services Pumps

Flowserve pumps come in a wide variety of materials and configurations to satisfy virtually all plant-wide needs.

Durco Mark 3

ANSI, ISO and DIN Process Pumps

Many designs available, low-flow/high-head, selfpriming, dynamic sealing, recessed impeller and in-line Operating Parameters Flows to 4540 m3/h (20 000 gpm) Heads to 300 m (1000 ft) Pressures to 31 bar (450 psi) Temperatures to 370C (700F)

Durco Mark 3 ISO

LR

Axially Split, Single-Stage Pumps

Operating Parameters Flows to 2000 m3/h (8800 gpm) Heads to 170 m (560 ft) Pressures to 21 bar (300 psi) Temperatures to 150C (300F)

Heavy-duty, broad hydraulic range, high-efficiency MEN

Segmental Ring Section Pumps

Multistage, radially split Operating Parameters Flows to 850 m3/h (3740 gpm) Heads to 700 m (2300 ft) Pressures to 60 bar (870 psi) Temperatures to 140C (285F)

NM

11

USA and Canada Flowserve Corporation 5215 North OConnor Blvd. Suite 2300 Irving, Texas 75039-5421 USA Telephone: +1 937 890 5839 Europe, Middle East, Africa Flowserve Corporation Parallelweg 13 4878 AH Etten-Leur The Netherlands Telephone: +31 76 502 8100 Latin America Flowserve Corporation Martn Rodriguez 4460 B1644CGN-Victoria-San Fernando Buenos Aires, Argentina Telephone: +54 11 4006 8700 Telefax: +54 11 4714 1610 Asia Pacific Flowserve Pte. Ltd. 10 Tuas Loop Singapore 637345 Telephone: +65 6771 0600 Telefax: +65 6862 2329

Bulletin FPD-16c (E) Printed in USA. July 2011. Flowserve Corporation To find your local Flowserve representative: For more information about Flowserve Corporation, visit www.flowserve.com or call +1 937 890 5839.

flowserve.com

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Auditorium case study reveals sound absorption strategiesDocumento16 pagineAuditorium case study reveals sound absorption strategiesAshi Chandak0% (1)

- Units Offered S1 2015 Engineering DegreeDocumento4 pagineUnits Offered S1 2015 Engineering DegreescytheVSNessuna valutazione finora

- Ebook t357 Block1 Part3-4 E2i1 n9780749252670 l1Documento96 pagineEbook t357 Block1 Part3-4 E2i1 n9780749252670 l1Bobby extramoneyguyNessuna valutazione finora

- M 236 ContentDocumento103 pagineM 236 ContentgeetanandnNessuna valutazione finora

- Cu-Psha A Matlab Software For PshaDocumento26 pagineCu-Psha A Matlab Software For PshaPartha Sarathi ParhiNessuna valutazione finora

- CHP 4, SolutionsDocumento4 pagineCHP 4, SolutionsJacko CrestNessuna valutazione finora

- S275 S355 Data Sheet 2021Documento1 paginaS275 S355 Data Sheet 2021CarloNessuna valutazione finora

- 01 Chap 1 ChemF4 Bil 2018 (CSY3p) PDFDocumento20 pagine01 Chap 1 ChemF4 Bil 2018 (CSY3p) PDFalanislnNessuna valutazione finora

- Repol® C015Eg: Reliance Industries LimitedDocumento2 pagineRepol® C015Eg: Reliance Industries LimitedCamilo ObandoNessuna valutazione finora

- Aluminum A413Documento2 pagineAluminum A413Fabio Miguel RodriguesNessuna valutazione finora

- Seismic Performance of Buckling Restrained Braced Frames in A Chilean BuildingDocumento12 pagineSeismic Performance of Buckling Restrained Braced Frames in A Chilean BuildingSebastian Contreras ContrerasNessuna valutazione finora

- Closed-Book Practice-Ch 03 (2016!12!10)Documento8 pagineClosed-Book Practice-Ch 03 (2016!12!10)JuanNessuna valutazione finora

- Reinforced Concrete Chapter 3 SolutionsDocumento5 pagineReinforced Concrete Chapter 3 SolutionsFofer Fofe100% (1)

- Experimental and Numerical Investigation of Lower Limb Prosthetic Foot Made From Composite Polymer Blends1Documento12 pagineExperimental and Numerical Investigation of Lower Limb Prosthetic Foot Made From Composite Polymer Blends1Jawad K. OleiwiNessuna valutazione finora

- Thermo Mid Term 2022-RevisedDocumento4 pagineThermo Mid Term 2022-RevisedJeet VyasNessuna valutazione finora

- Astm D-6432Documento18 pagineAstm D-6432Lorenzo CampaniniNessuna valutazione finora

- Flare - Reduced Purge Rates in StacksDocumento13 pagineFlare - Reduced Purge Rates in StacksGary JonesNessuna valutazione finora

- Sample Wps Multi ProcessDocumento1 paginaSample Wps Multi ProcessMohammed Elmodathir Ali100% (1)

- Electromagnetic Wave Propagation in Sea WaterDocumento12 pagineElectromagnetic Wave Propagation in Sea WaterKaren Gordillo RamosNessuna valutazione finora

- Integrated Rate Laws DPP-03Documento3 pagineIntegrated Rate Laws DPP-03ShanksNessuna valutazione finora

- RCC DesignDocumento71 pagineRCC Designsirfmein100% (1)

- How fiber addition affects properties of low cement castablesDocumento4 pagineHow fiber addition affects properties of low cement castablesAndrian Hadiana100% (1)

- Diffraction Property of WavesDocumento4 pagineDiffraction Property of Wavessaed cabdiNessuna valutazione finora

- Asme Sec Viii Div-2Documento31 pagineAsme Sec Viii Div-2Yash Rami100% (3)

- International Temperature Scale of 1990 PDFDocumento4 pagineInternational Temperature Scale of 1990 PDFSamNessuna valutazione finora

- Sealeze APH Brush Seals BrochureDocumento2 pagineSealeze APH Brush Seals BrochureMurilo Camisão SchwindenNessuna valutazione finora

- Physics Form 4 Yearly Lesson Plan 2010Documento26 paginePhysics Form 4 Yearly Lesson Plan 2010Mohd Khairul AnuarNessuna valutazione finora

- Review Jurnal ALD - Adella Fahdarina P-02511740000046Documento4 pagineReview Jurnal ALD - Adella Fahdarina P-02511740000046Samuel ArelianoNessuna valutazione finora

- Chapter13 - Acids and BasesDocumento44 pagineChapter13 - Acids and BasesXiaohan TangNessuna valutazione finora

- MEMS (Micro-Electro-Mechanical System) TECHNOLOGYDocumento25 pagineMEMS (Micro-Electro-Mechanical System) TECHNOLOGYMonika PanghalNessuna valutazione finora