Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

AD IFC090 IFC090i PROFIBUS e 72

Caricato da

luis_h_t_79Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

AD IFC090 IFC090i PROFIBUS e 72

Caricato da

luis_h_t_79Copyright:

Formati disponibili

KROHNE 07/2000

Supplementary Installation and Operating Instructions IFC 090, IFC 090 i

KROHNE Messtechnik GmbH & Co. KG Ludwig-Krohne-Str. 5 D-47058 Duisburg Tel.: 0203-301 309 Fax: 0203-301389 e-mail: krohne@krohne.de

1/7

Supplementary Documentation IFC 090, IFC 090 i with PROFIBUS-PA

GENERAL .......................................................................................................................................................................3 ITEMS INCLUDED WITH SUPPLY ................................................................................................................................3 SOFTWARE HISTORY ...................................................................................................................................................3 1. PROFIBUS-PA ............................................................................................................................................................3 1.1 GSD........................................................................................................................................................................4 1.2 PROFIBUS-PA PROFILE .........................................................................................................................................4 1.3 MEANING OF MEASUREMENT AND STATUS INFORMATION .............................................................................................4 2. ELECTRICAL CONNECTION (SEE SECTION 2 IN THE INSTALLATION AND OPERATING INSTRUCTIONS) ...................................6 2.1 INTERCONNECTION OF DEVICES IN THE HAZARDOUS LOCATION....................................................................................6 2.2 BUS CABLE...............................................................................................................................................................6 2.3 SHIELDING AND GROUNDING......................................................................................................................................6 2.4 PROFIBUS-PA CONNECTION ..................................................................................................................................6 3. MENU SETTINGS FOR PROFIBUS-PA (SEE SECTION 4 IN THE INSTALLATION AND OPERATING INSTRUCTIONS).............7 4. TECHNICAL DATA, PROFIBUS IDENT-NO. F401 ...................................................................................................7

KROHNE Messtechnik GmbH & Co. KG Ludwig-Krohne-Str. 5 D-47058 Duisburg Tel.: 0203-301 309 Fax: 0203-301389 e-mail: krohne@krohne.de

2/7

Supplementary Documentation IFC 090, IFC 090 i with PROFIBUS-PA

General

These Instructions are supplementary to the Installation and Operating Instructions IFC 090 K / F dated 12/96. The details given there, in particular the Safety Information, are valid and should be observed. These Supplementary Instructions provide only additional information for device operation and connection to a PROFIBUS-PA fieldbus. Attention: Please set the controller to manual mode before changing parameters of the IFC 090.

Items included with supply

In addition to the standard scope of supply, these Supplementary Instructions for the IFC 090 with PROFIBUS-PA interface, plus a diskette with all available GSD files of KROHNE devices.

Software history

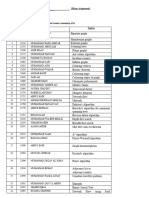

Issued month/year 09/98 Signal converter Hardware Firmware PROFIBU S-PA Module PROFIBU S-PA Module PROFIBU S-PA Module 1.00 User program Hard- Operating Software system ware Instructions Device 12/96+Supplement 01/99 Windows 95, 98, NT 4.0 Windows 95, 98, NT 4.0 PDM V 4.1.1 PDM V 4.1.1 12/96+Supplement 05/99 + 08/99, 03/00 12/96+Supplement 07/00 User program

05/99

2.00/99050 PC 5 2.00/ PC

07/00

1. PROFIBUS-PA

Control system (PLC) Class 1 master

Engineering or operation control tool Class 2 master

PROFIBUS-DP, up to 12 Mbit/s

Analog I/O module Power Supply Segment coupler/link

PROFIBUS-PA

Segment coupler/link

K ROHNE

kg/h

1000 900

kg

78 6320

586 677/ 01-0 3 H 50/RR/ M9/K2/ ESK-Z 2 K2 5.2 1 .457 1 C V 25 1 .4571 I 1997

800 700 600 500 400 300 200 100 RP

KROHN E H250

SN MC C F MD

C2H50H

D V T P 0.93 2.5 23.5 0.4 kg/ l mPa.s C MPa

FIA 1025

PROFIBUS-PA

K ROHN E

4-20 mA HART device

The above diagram shows a typical instrumentation with PROFIBUS-PA devices in hazardous and non-hazardous locations, including connection of conventional devices (e.g. with 4-20mA signals) to the PROFIBUS-PA. The PROFIBUS-PA is normally connected to a segment coupler which, among other things, carries out conversion to the PROFIBUS-DP. Here, it needs to be noted in particular that the segment coupler is normally set to a fixed baud rate on the DP side.

KROHNE Messtechnik GmbH & Co. KG Ludwig-Krohne-Str. 5 D-47058 Duisburg Tel.: 0203-301 309 Fax: 0203-301389 e-mail: krohne@krohne.de 3/7

Supplementary Documentation IFC 090, IFC 090 i with PROFIBUS-PA

Further information on the planning and operation of PROFIBUS-PA networks is to be found in the KROHNE brochure PROFIBUS-PA networks.

1.1 GSD

All available GSD files of KROHNE devices including those of the IFC 090, of course - are supplied together with each device. The GSD contains information that is needed for project planning of the PROFIBUS-DP/PA communication network. The relevant data files must be loaded into the project planning system/master system before start-up of the bus system. For example, the following applies to COMET 200 or COM PROFIBUS from Siemens: all GSD files (*.GSD) into the directory of the GSD files, e.g. *\GSD all BMP files (*.BMP) into the directory of the bit maps, e.g. *\BITMAPS In STEP7, the GSD file is automatically copied into the respective directory with install new GSD (in the HW-Config Menu: EXTRAS). After that, the bit map must be copied into the directory *\SIEMENS\STEP7\S7data\Nsbmp. Following catalog updating the device can be placed in the project. This will then enable the cyclic communication (measured values and status).

1.2 PROFIBUS-PA profile

The IFC 090 supports the PROFIBUS-PA Profile Version 2.0. Additionally, all relevant parameters in the device are offered via the PROFIBUS-PA interface. The IFC 090 defines the following blocks: Three Function Blocks (FB): One Analog Input-FB for flow and two Totalizer-FBs for totalizers. During configuration of the network you can distinguish between two different kind of totalizers. First the temporary Profibus totalizers (PA-Tot.1/2) which will be resetted after power on. These totalizers are according Profil 2.0. You also can choose the permanently stored device totalizers (Device-Tot.1/2). These device totalizers will be mapped to the totalizer function blocks whereas limits and the unit of this block can be used together with the device totalizers. Reset function is possible as well. One transducer block for electromagnetic flow measurement. This block provides the parameters defined in Profile 2.0. One physical block. This block contains the parameters defined in Profile 2.0, and also all device-specific parameters in the form of an appendix.

1.3 Meaning of measurement and status information

During integration of the KROHNE device into the PROFIBUS master you can choose which values should be transfered via PROFIBUS. This can be done by using the GSD file. Each value which is a 4 Byte Float Format according IEEE Standard 754 Short Real Number a status byte follows. That means each measurement value consists of 4 byte value plus 1 byte status. Other measurement values will directly follow as 5 Byte pakage if configured during integration. Below the meaning of the status byte is described: Float Format

Byte n

Bit7 Bit6 Bit7 Bit6

Byte n+1

VZ 27 26 25 24 23 22 21 20 2-1 2-2 2-3 2-4 2-5 2-6 Exponent Mantissa

Byte n+2 Byte n+3 Bit7 Bit7 2-7 2-8 2-9 2-10 2-11 2-12 2-13 2-14 2-15 2-16 2-17 2-18 2-19 2-20 2-21 2-22 2-23 Mantissa Mantissa

Example: Calculation:

40 F0 00 00 (hex) = 0100 0000 1111 0000 0000 0000 0000 0000 (binary) VZ (Exponent - 127) Value = (-1) * 2 * (1 + Mantissa) 0 (129 - 127) -1 -2 -3 Value = (-1) * 2 * (1 + 2 + 2 + 2 ) Value = 1 * 4 * (1 + 0,5 + 0,25 + 0,125) = 7,5

KROHNE Messtechnik GmbH & Co. KG Ludwig-Krohne-Str. 5 D-47058 Duisburg Tel.: 0203-301 309 Fax: 0203-301389 e-mail: krohne@krohne.de

4/7

Supplementary Documentation IFC 090, IFC 090 i with PROFIBUS-PA

The meaning of the status byte is as following:

Quality Gr Gr 27 26 0 0 0 1 1 0 1 1 Quality-Substatus QS QS QS QS 25 24 23 22 Limits Qu Qu 21 20 = bad = uncertain = good (Non Cascade) = good (Cascade) - not supported

Status = bad 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 1 1 1 1

0 0 1 1 0 0 1 1

0 1 0 1 0 1 0 1

= non-specific = configuration error = not connected = device failure = sensor failure = no communication (last usable value) = no communication (no usable value) = out of service

Status = uncertain 0 1 0 0 0 1 0 0 0 1 0 0 0 1 0 0 0 1 0 1 0 1 0 1 0 1 0 1 0 1 0 1

0 0 1 1 0 0 1 1

0 1 0 1 0 1 0 1

= non-specific = last usable value = substitute-set = initial value = sensor conversion not accurate = engineering unit violation (unit not in the valid set) = sub-normal = configuration error

Status = good (Non-Cascade) 1 0 0 0 0 0 1 0 0 0 0 1 1 0 0 0 1 0 1 0 0 0 1 1 1 0 0 1 0 0 1 0 0 1 0 1 1 0 0 1 1 0 1 0 1 0 0 0 1 0 1 0 0 1 Status = Limits 0 0 1 1 0 1 0 1

= ok = active block alarm = active advisory alarm (priority < 8) = active critical alarm (priority > 8) = unacknowledged block alarm = unacknowledged advisory alarm = unacknowledged critical alarm = initiate fail safe = maintenance required

= ok = low limited = high limited = constant

Check the first two quality bits in order to get the quality information of the measurement value: Good (non Cascade) measurement value is ok and can be used without restrictions Uncertain measurement value can be used but the accuracy can not be guaranteed (e.g. measurement value has been frozen or A/D converter is saturated) Bad measurement value is bad dont use it Good (Cascade) not supported because its not applicable for measurement devices Diagnostics If the device has been detected an error additional diagnostic information will be send to the master. The meaning of the additional information is described within the GSD file under UNIT_DIAG_BIT(i).

KROHNE Messtechnik GmbH & Co. KG Ludwig-Krohne-Str. 5 D-47058 Duisburg Tel.: 0203-301 309 Fax: 0203-301389 e-mail: krohne@krohne.de

5/7

Supplementary Documentation IFC 090, IFC 090 i with PROFIBUS-PA

2. Electrical connection (see Section 2 in the Installation and Operating Instructions)

2.1 Interconnection of devices in the hazardous location

We recommend that a PROFIBUS-PA network in the hazardous location be projected in accordance with PTBs FISCO model (see KROHNE brochure PROFIBUS-PA networks). The FISCO-Model may be used, if: all electrical components which should be connected to the bus must be approved according the FISCO model (even the termination), the maximum cable length does not exceed 1000 m, the values of the cable are within the following ranges R=15...150W/km; L=0,4...1mH/km; C=80...200nF/km, the approved input values of the field devices (Uo, Io, Po) are matchable with the output values of the power supply (e.g. segmment coupler) which menas UI Uo, II Io und PI Po.

2.2 Bus cable

Further limitations to the cable than the FISCO limitations are not existent. Nevertheless a twisted pair and shielded cable is strongly recommended. The good quality cable could have the following data: 44W/km, <90nF/km, <3dB attenuation at 39kHz and 100 Ohm impedance at 31,25kHz.

2.3 Shielding and grounding

For optimum electromagnetic compatibility of systems it is extremely important that the system components, and particularly the bus cables connecting the components, be shielded and that such shields - if possible - form an unbroken cover, electrically speaking. Hence it follows that, for use in non-hazardous duty systems , the cable shield should be grounded as often as possible. In Ex systems an adequate equipotential bonding in the hazardous and non-hazardous location along the entire fieldbus installation is strongly recommended. Multiple grounding of the shield is also of advantage. Note: The use of twisted and shielded cables is strongly recommended, otherwise EMC protection of the IFC 090 cannot be assured.

2.4 PROFIBUS-PA connection

Connect the bus cable as shown in the figure. Connect the cable cores to terminals D and D . Polarity reversal will not have any effect. The cable shield should be connected with minimum length to the FE functional ground. The equipotential bonding conductor must be connected to the device by connecting it to FE functional ground.

KROHNE Messtechnik GmbH & Co. KG Ludwig-Krohne-Str. 5 D-47058 Duisburg Tel.: 0203-301 309 Fax: 0203-301389 e-mail: krohne@krohne.de

6/7

Supplementary Documentation IFC 090, IFC 090 i with PROFIBUS-PA

PROFIBUS-PA with current output Non Ex version

fieldbus current output powersupply FE

PROFIBUS-PA with pulse/switching output Non Ex version

fieldbus switching output powersupply FE

D D

FE busconnection

I

4-20mA

I

U min = 8V

D D

FE busconnection

B1 B1

U max = 30V

Ex version current output

Ex version

fieldbus power supply

switching output

fieldbus

power supply

I

4-20mA

U min = 8V

I D D

busconnection

B1 B1 D D

busconnection

U max = 30V

3. Menu settings for PROFIBUS-PA (see Section 4 in the Installation and Operating Instructions)

The following settings need to be made for operation of the IFC 090 on a PROFIBUS-PA network. Note that the address can be set by the service set slave address as well.

Function (Fct.)

3.8 3.9 TAG NO. COM

Description

Text, measuring-point tag (max. 10 characters) Characters assignable to each place: A-Z,a-z, 0-9 or "_" (blank character) Select function for the communication port OFF HART PROFI PA Press key to transfer to subfunction "ADDRESS". Set address Range: 00-15 for HART (default 00) 00-126 for PROFI PA (default 126) Press key to return to Fct. 3.9 COM

ADDRESS

4. Technical data, PROFIBUS Ident-No. F401

Hardware Physical Bus characteristics Base current FDE Fault current Starting current Ex approval Connection to IEC 61158-2 and the FISCO model 9... 30 V; 0.3 A max.; 4.2 W max. 10 mA yes: separate fault clearance electronics provided 6 mA; (fault current = max. continuous current base current) lower than the base current EEx ia IIC T6 or EEx ib IIC/IIB T6 in conformity with the FISCO model independent of polarity Software GSD all KROHNE GSD files supplied on diskette Device profile complete implementation of Profile B, V2.0 Functional blocks flow [m3/h], totalizer1[m3], totalizer2 [m3] mentioned units are default units Address range 0-126, default 126, set slave address supported Operator control local display and operator interface at device SAP`s 1; typically the number of service access points is equal to the number of class 2 masters (operating tools) 7/7

KROHNE Messtechnik GmbH & Co. KG Ludwig-Krohne-Str. 5 D-47058 Duisburg Tel.: 0203-301 309 Fax: 0203-301389 e-mail: krohne@krohne.de

Potrebbero piacerti anche

- Networked Control System: Fundamentals and ApplicationsDa EverandNetworked Control System: Fundamentals and ApplicationsNessuna valutazione finora

- Krohne Ufc030 (Ufc 3 Beam) (Ing)Documento17 pagineKrohne Ufc030 (Ufc 3 Beam) (Ing)Richard KNessuna valutazione finora

- AD IFC300 Profibus PA V0200 en PDFDocumento24 pagineAD IFC300 Profibus PA V0200 en PDFCesar GuidoNessuna valutazione finora

- CX9000 HWenDocumento61 pagineCX9000 HWenDmitry VasilevNessuna valutazione finora

- E500 FD Rel11 Part1 OverviewDocumento35 pagineE500 FD Rel11 Part1 OverviewЖорж КаназирскиNessuna valutazione finora

- TC230 Expert IEC60870-5-103Documento22 pagineTC230 Expert IEC60870-5-103Manish RandhawaNessuna valutazione finora

- CP 443-1Documento28 pagineCP 443-1Jacob KalloorNessuna valutazione finora

- Amendments: Chapter/Section DescriptionDocumento28 pagineAmendments: Chapter/Section DescriptionLeonardLapatratNessuna valutazione finora

- 452 840 840C 880 PLC 135WB 135WB2 Package 7 Code CarriersDocumento110 pagine452 840 840C 880 PLC 135WB 135WB2 Package 7 Code CarriersООО ЛантисNessuna valutazione finora

- Abbauto 50xm100n ManualDocumento165 pagineAbbauto 50xm100n ManualBromax DandanNessuna valutazione finora

- Siprotec: Communication Module Profibus-Dp Bus MappingDocumento46 pagineSiprotec: Communication Module Profibus-Dp Bus MappingFuturo InocenteNessuna valutazione finora

- ABB ProconticDocumento591 pagineABB ProconticJuan LugoNessuna valutazione finora

- PALL Technical DescriptionDocumento8 paginePALL Technical Descriptionoscar alfredoNessuna valutazione finora

- HIMAP A1 Communication EDocumento51 pagineHIMAP A1 Communication Emaronnam100% (1)

- RS 485 Clock Manual V1 PDFDocumento8 pagineRS 485 Clock Manual V1 PDFTaharat HussainNessuna valutazione finora

- BSS OAM BSC Architecture v4Documento109 pagineBSS OAM BSC Architecture v4dattarajrfNessuna valutazione finora

- Catalogo PLC Wago PDFDocumento402 pagineCatalogo PLC Wago PDFEdison Benjamin Consuegra ChalenNessuna valutazione finora

- Truyenthong CPNet FC, FBDocumento334 pagineTruyenthong CPNet FC, FBNguyễn Anh TúNessuna valutazione finora

- BK9000 Ethernet CouplerDocumento58 pagineBK9000 Ethernet CouplerAlainNessuna valutazione finora

- GE D60 Relay ManualDocumento704 pagineGE D60 Relay ManualdmjbooksNessuna valutazione finora

- Siemens S7 PLC ConnectionDocumento15 pagineSiemens S7 PLC ConnectionkiciorNessuna valutazione finora

- TR 0199-27-1215-1-EnDocumento6 pagineTR 0199-27-1215-1-Enls-huntingNessuna valutazione finora

- WAGO Conect - A202201eDocumento16 pagineWAGO Conect - A202201eDaniel Marques SilvaNessuna valutazione finora

- Optiflex 2200 C/F Optiflex 2200 C/F Optiflex 2200 C/F Optiflex 2200 C/FDocumento24 pagineOptiflex 2200 C/F Optiflex 2200 C/F Optiflex 2200 C/F Optiflex 2200 C/FMuhammad AdreesNessuna valutazione finora

- GE - d60 Line Distance ProtectionDocumento668 pagineGE - d60 Line Distance ProtectionPhil KerrNessuna valutazione finora

- Distance Relay D60Documento630 pagineDistance Relay D60nadalllabeedNessuna valutazione finora

- Release Notes DTM Library Manuial E+HDocumento8 pagineRelease Notes DTM Library Manuial E+HSILVA VILA FERNANDO ALEXISNessuna valutazione finora

- How Is The Assignment of The MPI DP Interface DefinedDocumento10 pagineHow Is The Assignment of The MPI DP Interface Definedwww.otomasyonegitimi.com100% (1)

- HY-eVision2 7.0 User ManualDocumento50 pagineHY-eVision2 7.0 User ManualEmerson GomesNessuna valutazione finora

- Huong Dan Tao Ket Noi ProfibusDocumento24 pagineHuong Dan Tao Ket Noi ProfibusThien NguyenngocNessuna valutazione finora

- Manual Instalacion RTUDocumento25 pagineManual Instalacion RTUlmbkn2013Nessuna valutazione finora

- CX9000 / CX9010: Hardware DocumentationDocumento60 pagineCX9000 / CX9010: Hardware DocumentationAbdel MUNDENNessuna valutazione finora

- Modulos Familia MoellerDocumento61 pagineModulos Familia Moellermagwolff86Nessuna valutazione finora

- H 1157 GDocumento93 pagineH 1157 GFelipe StassunNessuna valutazione finora

- STULZ WIB8000 G67C 1118 enDocumento52 pagineSTULZ WIB8000 G67C 1118 enOctavio Farid Rossi YumhaNessuna valutazione finora

- PNIO DKSW Description V300Documento30 paginePNIO DKSW Description V300Fabio MachadoNessuna valutazione finora

- PI PCS7TM-EA V31 enDocumento21 paginePI PCS7TM-EA V31 enginoaikido3420Nessuna valutazione finora

- Protocolo Profibus MEAGDocumento116 pagineProtocolo Profibus MEAGGillSport33% (3)

- Rexroth VisualMotion 10 - Project Planning ManualDocumento152 pagineRexroth VisualMotion 10 - Project Planning Manualicisternas icisternasNessuna valutazione finora

- MV 3000 Getting Started ManualDocumento160 pagineMV 3000 Getting Started ManualterranohrNessuna valutazione finora

- Avinocs MilBusDocumento2 pagineAvinocs MilBussakthisriniNessuna valutazione finora

- Datachief C20 Remote Operator Station: Doc - No.: Au-0662-B/14-Dec-99Documento78 pagineDatachief C20 Remote Operator Station: Doc - No.: Au-0662-B/14-Dec-99FENGNessuna valutazione finora

- Simatic Advanced PDFDocumento268 pagineSimatic Advanced PDFFelipe Emc SegoviaNessuna valutazione finora

- Profibus DP Pressure Transmitter User Manual - 20121112 PDFDocumento42 pagineProfibus DP Pressure Transmitter User Manual - 20121112 PDFLuis CristóbalNessuna valutazione finora

- Types Profibus CommunicationDocumento23 pagineTypes Profibus CommunicationAhmed ElsayedNessuna valutazione finora

- Summary of Corrections and EnhancementsDocumento7 pagineSummary of Corrections and EnhancementsEliana Negron LauraNessuna valutazione finora

- Remote IO Modules and IO Expansion Units 20120815Documento196 pagineRemote IO Modules and IO Expansion Units 20120815Pedro BortotNessuna valutazione finora

- GPS Din 0200 PDFDocumento117 pagineGPS Din 0200 PDFFernando ParedesNessuna valutazione finora

- Cambium PTP 670 Series 03-65 System Release NotesDocumento6 pagineCambium PTP 670 Series 03-65 System Release Notesinhouserepair23Nessuna valutazione finora

- GE Protection Relay B90 ManualDocumento460 pagineGE Protection Relay B90 ManualShirosh Ayeshmantha100% (1)

- DS0000101 User's Manual - X-View2 SoftwareDocumento56 pagineDS0000101 User's Manual - X-View2 SoftwareShay TonyNessuna valutazione finora

- PCS-996S-A - PMU - DataSheet - EN - Overseas General - X - R1.00Documento37 paginePCS-996S-A - PMU - DataSheet - EN - Overseas General - X - R1.00mackayaboloaudesteavenNessuna valutazione finora

- Configuration A Profibus-DP Node Using Step7 and WAGO-I/O ComponentsDocumento18 pagineConfiguration A Profibus-DP Node Using Step7 and WAGO-I/O ComponentsJose LunaNessuna valutazione finora

- Siemens PLC With TIA Portal V12 Prof SP1 enDocumento52 pagineSiemens PLC With TIA Portal V12 Prof SP1 enernesto antonioNessuna valutazione finora

- TC1291 Oxe r9.1Documento20 pagineTC1291 Oxe r9.1Humberto Ochoa MendezNessuna valutazione finora

- Profibus Datalink Description Supplement: Single and Dual Input AnalyzersDocumento12 pagineProfibus Datalink Description Supplement: Single and Dual Input AnalyzersPauloNessuna valutazione finora

- M517-E235F (DR300 Installation Manual Remote Maintenance Option)Documento68 pagineM517-E235F (DR300 Installation Manual Remote Maintenance Option)Izzeldin ZakiNessuna valutazione finora

- MicomDocumento220 pagineMicomMurty GuttulaNessuna valutazione finora

- Simatic Net: S7-Cps For Industrial EthernetDocumento34 pagineSimatic Net: S7-Cps For Industrial EthernetObby AryasuciNessuna valutazione finora

- JW1991C/D/E: Integrated 500V MOS Non-Isolated Buck LED DriverDocumento1 paginaJW1991C/D/E: Integrated 500V MOS Non-Isolated Buck LED Driverluis_h_t_79Nessuna valutazione finora

- 5ik40gn AulDocumento5 pagine5ik40gn Aulluis_h_t_79Nessuna valutazione finora

- MBR10150CTDocumento3 pagineMBR10150CTluis_h_t_79Nessuna valutazione finora

- Bit 3267Documento1 paginaBit 3267Franklin Jimenez90% (10)

- Datasheet PDFDocumento8 pagineDatasheet PDFmcr16986Nessuna valutazione finora

- Bit 3267Documento1 paginaBit 3267Franklin Jimenez90% (10)

- 2SK790 1Documento5 pagine2SK790 1luis_h_t_79Nessuna valutazione finora

- A 3150 OptocouplerDocumento2 pagineA 3150 Optocouplerluis_h_t_79Nessuna valutazione finora

- Bit 3267Documento1 paginaBit 3267Franklin Jimenez90% (10)

- 2 SK 3747Documento4 pagine2 SK 3747luis_h_t_79Nessuna valutazione finora

- 700hrc Rel TimerDocumento14 pagine700hrc Rel Timerluis_h_t_79Nessuna valutazione finora

- Simatic S5: System Manual CPU 100/102/103Documento550 pagineSimatic S5: System Manual CPU 100/102/103Felipe Savieto AcorsiNessuna valutazione finora

- Diodos ZenerDocumento3 pagineDiodos Zenerremanuel18Nessuna valutazione finora

- 2 SK 2225Documento10 pagine2 SK 2225luis_h_t_79Nessuna valutazione finora

- Simatic S5Ć115U/H/F: GeneralDocumento94 pagineSimatic S5Ć115U/H/F: GeneralAzizul AgNessuna valutazione finora

- 1.5ke6.8 CADocumento4 pagine1.5ke6.8 CAluis_h_t_79Nessuna valutazione finora

- 2N3904Documento7 pagine2N3904zabroma1717Nessuna valutazione finora

- 20090722181006914108-西门子 SIMATIC S5 S5-DOS ST使用手册Documento108 pagine20090722181006914108-西门子 SIMATIC S5 S5-DOS ST使用手册luis_h_t_79Nessuna valutazione finora

- Pas740 e (Search Manual Online - Com)Documento22 paginePas740 e (Search Manual Online - Com)luis_h_t_79Nessuna valutazione finora

- TD IFC090 e 72Documento14 pagineTD IFC090 e 72luis_h_t_79Nessuna valutazione finora

- S5-100U Reference Guide 6ES5 997-8MA21 - eDocumento40 pagineS5-100U Reference Guide 6ES5 997-8MA21 - erayleihNessuna valutazione finora

- S5 100U Closed Loop ControlDocumento154 pagineS5 100U Closed Loop Controlluis_h_t_79Nessuna valutazione finora

- 59 Siemens S5 Timer CounterDocumento21 pagine59 Siemens S5 Timer CounterjaimeasisaNessuna valutazione finora

- 1n4728 Thru 1n4764Documento4 pagine1n4728 Thru 1n4764snoothieNessuna valutazione finora

- PB Fms s7 s5 RWDocumento51 paginePB Fms s7 s5 RWluis_h_t_79Nessuna valutazione finora

- PB Fdl-Sda s7 s5Documento41 paginePB Fdl-Sda s7 s5luis_h_t_79Nessuna valutazione finora

- PB FDL s7 s5Documento40 paginePB FDL s7 s5luis_h_t_79Nessuna valutazione finora

- Steam BookDocumento66 pagineSteam Bookdekate_manoj100% (1)

- Ie SR s7 s5 IsoDocumento37 pagineIe SR s7 s5 Isoluis_h_t_79Nessuna valutazione finora

- Method Statement For FDTDocumento7 pagineMethod Statement For FDTMs UndergroundNessuna valutazione finora

- Newton's Three Law of MotionDocumento6 pagineNewton's Three Law of MotionRey Bello MalicayNessuna valutazione finora

- Faiscp MK2 Om Eng 44311D PDFDocumento60 pagineFaiscp MK2 Om Eng 44311D PDFJiso JisoNessuna valutazione finora

- HP SMART ARRAY 641 USER GUIDEDocumento69 pagineHP SMART ARRAY 641 USER GUIDEMichele BarbaNessuna valutazione finora

- PYTHONBOOKDocumento32 paginePYTHONBOOKJyotirmay SahuNessuna valutazione finora

- Fabrication of Mortar Mixer and CHB Filler PumpDocumento15 pagineFabrication of Mortar Mixer and CHB Filler PumpRenjo Kim VenusNessuna valutazione finora

- Mini Test PBD - SpeakingDocumento4 pagineMini Test PBD - Speakinghe shaNessuna valutazione finora

- Sales Presentation of K&N ChickenDocumento25 pagineSales Presentation of K&N ChickensanahansmukhNessuna valutazione finora

- Balberan, Julliene Paula Gozon, Aleha Ann Macabalang, Mary Jomelane Manzano, JakeDocumento9 pagineBalberan, Julliene Paula Gozon, Aleha Ann Macabalang, Mary Jomelane Manzano, JakeJake ManzanoNessuna valutazione finora

- UntitledDocumento30 pagineUntitledGauravNessuna valutazione finora

- Injection Machine RobotDocumento89 pagineInjection Machine Robotphild2na250% (2)

- Angular With Web ApiDocumento32 pagineAngular With Web ApiAnonymous hTmjRsiCp100% (1)

- Listening - Cot4thDocumento6 pagineListening - Cot4thmichel.atilanoNessuna valutazione finora

- Researchpaper Parabolic Channel DesignDocumento6 pagineResearchpaper Parabolic Channel DesignAnonymous EIjnKecu0JNessuna valutazione finora

- OP-COM Fault Codes PrintDocumento2 pagineOP-COM Fault Codes Printtiponatis0% (1)

- Transport Modelling Guidelines Volume 5 Intersection Modelling June 2020Documento198 pagineTransport Modelling Guidelines Volume 5 Intersection Modelling June 2020Amul ShresthaNessuna valutazione finora

- Walter BenjaminDocumento15 pagineWalter BenjaminAndrea LO100% (1)

- 7.IITD 2012 Theory of VibrationDocumento9 pagine7.IITD 2012 Theory of Vibrationlaith adnanNessuna valutazione finora

- Transportation Impact Handbook 2010Documento246 pagineTransportation Impact Handbook 2010Enrique Márquez100% (1)

- Els2204 Sinsis 1718 CepDocumento7 pagineEls2204 Sinsis 1718 CepChristian MarpaungNessuna valutazione finora

- Graph Theory (B)Documento2 pagineGraph Theory (B)Waqar RoyNessuna valutazione finora

- EVMDocumento4 pagineEVMSimNessuna valutazione finora

- NOLS 2014 Fall Catalog PDFDocumento60 pagineNOLS 2014 Fall Catalog PDFcoldflame81Nessuna valutazione finora

- Ontologies For Location Based Services Quality Enhancement: The Case of Emergency ServicesDocumento8 pagineOntologies For Location Based Services Quality Enhancement: The Case of Emergency Serviceskhairul_fajar_3Nessuna valutazione finora

- A Comprehensive Guide To Oracle Partitioning With SamplesDocumento36 pagineA Comprehensive Guide To Oracle Partitioning With SamplesSreenivasa Reddy GopireddyNessuna valutazione finora

- DCR-DVD810: DVD Handycam® Camcorder NEWDocumento2 pagineDCR-DVD810: DVD Handycam® Camcorder NEWraynaldoNessuna valutazione finora

- Practice For The CISSP Exam: Steve Santy, MBA, CISSP IT Security Project Manager IT Networks and SecurityDocumento13 paginePractice For The CISSP Exam: Steve Santy, MBA, CISSP IT Security Project Manager IT Networks and SecurityIndrian WahyudiNessuna valutazione finora

- The Role of Youth in ForthDocumento17 pagineThe Role of Youth in ForthSamuel EmmanuelNessuna valutazione finora

- Notes On Guenter Lee PDEs PDFDocumento168 pagineNotes On Guenter Lee PDEs PDF123chessNessuna valutazione finora

- Construction Management Plan TemplateDocumento15 pagineConstruction Management Plan TemplatePrasad Ghorpade100% (2)

- Arizona, Utah & New Mexico: A Guide to the State & National ParksDa EverandArizona, Utah & New Mexico: A Guide to the State & National ParksValutazione: 4 su 5 stelle4/5 (1)

- New York & New Jersey: A Guide to the State & National ParksDa EverandNew York & New Jersey: A Guide to the State & National ParksNessuna valutazione finora

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptDa EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptValutazione: 5 su 5 stelle5/5 (1)

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensDa EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensNessuna valutazione finora

- The Bahamas a Taste of the Islands ExcerptDa EverandThe Bahamas a Taste of the Islands ExcerptValutazione: 4 su 5 stelle4/5 (1)

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoDa EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoValutazione: 5 su 5 stelle5/5 (1)