Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Derrick Pipe Handling

Caricato da

John RongDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Derrick Pipe Handling

Caricato da

John RongCopyright:

Formati disponibili

Derrick Pipe Handling

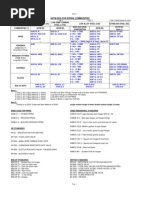

Robotic Motion Control (RMC)

RMC makes it possible to move huge and complex machines safely and efficiently using only one hand. RMC moves the machines along paths. RMC is available for the following pipe handlers: Vertical Pipe handling (Bridge Crane System and 2-Arm System) - Synchro control system Eagle / Eagle Light Pipe Racking Machine Triplex Crane Advantages RMC features the following advantages: Easy to use; one hand operated Efficient and safe movement Minimal crew training required Movement in narrow areas is done fast and safely All cylinders and motors move in an optimal way Controlled oil consumption Vertical Pipe handling: The two racking arms and fingerboard are one-man operated allowing for simultaneous Roughneck operation. User interface RMC is integrated into the user interface of the control system. Technology RMC utilises mathematics from the world of robot control to calculate the optimal movement of pipe handling systems. Cylinders and motors are equipped with absolute position sensors and the RMC uses these sensors to achieve the correct positioning. The RMC controlled machines move along calculated 6 axis paths. The first three axes (X,Y,Z) define the position of the load. The last three axes (a,b,l) define the orientation of the load. This gives a great flexibility with respect to requirements given by the rig layout. Safety

RMC ensures that no cylinders or motors are moved

in such a manner that load can be dropped: The path that is calculated takes into account all hindrances along the way to the destination The load is kept as low as possible above deck Running pattern repeated Vertical Pipe handling: The two machines are synchronised, hence safer operation Eagle / Eagle Light moves outside working area of travelling assembly/top drive when transporting tubulars to vertical position Triplex Crane: The yoke is under full control and is kept horizontal and correctly aligned at all times

RMC contains continuous monitoring of all sensors and of the control system itself. This well-proven system detects and reacts to a large number of critical situations: Sensor failures Valve failures Computer failures Calculation failures Operator failures RMC can easily be included in a zone management system to ensure inter-machine safety.

Typical RMC screen picture

Typical RMC screen picture

www.marhyd.com

maritime hydraulics

39

Derrick Pipe Handling

Drill Floor Manipulator Arm (DFMA)

The DFMA is designed for guiding/ handling of various tubular sizes including risers and other items. The DFMA can be prepared for mounting underneath the Topdrive Guiderails or pedestal mounted on Drillfloor. The DFMA can be prepared for hydraulic/ electrical/ radio remote control panel.

Technical data Tubular range Push/pull force Max. l/min. working out-reach Slewing Tilt Hydraulic power consumption

3 " to 60" 30 kN (6700 lb) 10m/2.8m (32ft/9ft) 360 o 10o up /45o down 140 bar/160 l/min (2030psi/42 gallon/min)

Drillfloor Manipulator Arm

DFMA Controls

Access Basket

The Access Basket is designed for safe access when performing maintenance and / or working tasks in places that are hard to reach. The basket can easily be installed in the derrick, moonpool area or other areas, either directly with the mounting bracket, or by means of various optional interface kits. All the basket controls, including emergency stops, can be operated from inside the basket and / or Remote Control Stand.

Casing stabbing boards are also available Special version can be delivered for BOP maintenance Rail mounting

Technical data Max. free working height Max. permitted load Hydraulic power consumption 17.2m (56.4 ft) 300 kg (660 lb) 207 bar, 50 l/min (3000 psi/ 13 gal./min) +- 60 degrees +- 90 degrees 4000 kg (8800 lb) 3400 mm (11.2 ft) 4600 mm (15.1 ft) 5600 mm (18.4 ft)

Access Basket

Tilting, up/down Rotating Max. weight Telescoping

The Access basket can be supplied with one or two-man basket.

One-man Basket

40

maritime hydraulics

www.marhyd.com

Derrick Pipe Handling

Pipe Racking Machine

The Pipe Racking Machine is designed for safe handling of tubulars in singles and as 60 & 90stands. The machine operates between the setback, well centre and the catwalk machine. The machine consists of one guiding arm and one lifting arm which are connected to a single closed column. The arms can be operated in a synchronous or independent mode (RMC). The column is attached to a lower and an upper carriage for rail travel and slewing up to 270 degrees. The large hoisting range for the lifting arm and a specially designed gripping head with integrated stabbing function gives the Pipe Racking Machine a fully integrated HTV-function. The unique gripper head arrangement has three rotational axes and pick up pipes from arbitrary angles. The Pipe Racking Machine can change from HTV-mode to VPHmode without manual interruption. The machine can build stands offline while drilling, and handle miscellaneous equipment within the drill-floor area. Because of the simple geometry of the arms, the machine is controlled by one operator, either manually or automated through a control system. The machine is suitable for XY- and parallel racking configuration.

VPH-mode; retracted

Technical data Tubular range Racking capacity Lifting capacity Hoist stroke Installed weight Overall height Slewing sector Slewing speed Time for 90 Travel speed

2 7/8 to 20 4.6 m (15 ft) x 2 11.0 mT (12 tons) 20.0 m (65 ft) 35.0 mT (incl. rails) (38.5 tons) 32.0 m (104 ft) 270 5 rpm 4 sec. 0.5 m/s (1.6 ft/sec)

VPH-mode; extended

HTV-mode; hoisting

Pipe Racking Crane close up

www.marhyd.com

maritime hydraulics

41

Derrick Pipe Handling

Cabins

MH supplies quality Cabins for various drilling and pipe handling operations. These are: Derrickmans Cabin Assistant Drillers Cabin Both Cabins are designed and built as optimal, safe and comfortable workplaces to suit various operations. They are selfsupported steel structures with suitable lifting arrangements. The operator is situated in an ergonomic chair with unobstructed view to all necessary equipment and operations. All main windows have efficient wiper and washer facilities. The windows are made of tinted, laminated safety glass for optimal view and safety. The Cabin interior is heated and ventilated with an efficient defrost / demist function on the windows. Both Cabins are designed to meet the most stringent noise level requirements. MH can deliver Cabins for location in both safe and hazardous areas.

Derrickmans Cabin

Derrickmans Cabin

The Derrickmans Cabin is, during normal operation, the main operation control position for the Upper Racking Arm or Bridge Crane and the fingerboards.

Derrickmans Cabin

Assistant Drillers Cabin

The Assistant Drillers Cabin is normally used as the secondary operating position for the pipe handling in the upper part of the Derrick. It can also be used for operation of singular machinery such as a Multi Manipulator Arm or equal.

Assistant Drillers Cabin

42

maritime hydraulics

www.marhyd.com

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Design of SpindleDocumento36 pagineDesign of SpindleAMIT SOLANKI0% (1)

- Lateral Earth Pressure Due To Vibratory Rollers PDFDocumento11 pagineLateral Earth Pressure Due To Vibratory Rollers PDFchutton681Nessuna valutazione finora

- 6 Pile GroupDocumento29 pagine6 Pile GroupAnonymous nwByj9LNessuna valutazione finora

- Manufacturing MMMMMMMMMMMMM and Assembling of Drill RodsDocumento24 pagineManufacturing MMMMMMMMMMMMM and Assembling of Drill RodsGoturi KAMALAKAR REDDYNessuna valutazione finora

- Astm Nos For PipingDocumento6 pagineAstm Nos For PipingJessica HerringNessuna valutazione finora

- GPG291 Designer's Guide To The Options For Ventilation and Cooling 2001Documento40 pagineGPG291 Designer's Guide To The Options For Ventilation and Cooling 2001IppiNessuna valutazione finora

- Shipbuilding Process 1Documento53 pagineShipbuilding Process 1tiwaripur100% (1)

- ENERGY SAVINGS FROM SWIMMING POOL COVERSDocumento11 pagineENERGY SAVINGS FROM SWIMMING POOL COVERSdanateoNessuna valutazione finora

- HERCULESDocumento6 pagineHERCULESJohn Rong100% (3)

- Ship Hull Design-420Documento2 pagineShip Hull Design-420lgbrangelNessuna valutazione finora

- Large Diameter Diaphragm Wall ShaftsDocumento7 pagineLarge Diameter Diaphragm Wall ShaftsmeñoxNessuna valutazione finora

- Ship Structure DesignDocumento215 pagineShip Structure DesignHashem GamNessuna valutazione finora

- Ship Constructor Autodesk Proposal To Canadian Gov NavyDocumento12 pagineShip Constructor Autodesk Proposal To Canadian Gov NavyJohn RongNessuna valutazione finora

- Philosophy For Old AgeDocumento20 paginePhilosophy For Old AgeJohn RongNessuna valutazione finora

- Navtech Proposal To Canandian Gov NavyDocumento12 pagineNavtech Proposal To Canandian Gov NavyJohn RongNessuna valutazione finora

- PEX Vs PB Comparison 2-03Documento1 paginaPEX Vs PB Comparison 2-03John RongNessuna valutazione finora

- Workboats or Warships A National Shipbuilding Strategy For CanadaDocumento10 pagineWorkboats or Warships A National Shipbuilding Strategy For CanadaJohn RongNessuna valutazione finora

- UntitledDocumento128 pagineUntitledapi-61200414Nessuna valutazione finora

- Mid Fatigue Plastic Water Pipe 01-12-12Documento44 pagineMid Fatigue Plastic Water Pipe 01-12-12John RongNessuna valutazione finora

- T I 83 GuidebookDocumento446 pagineT I 83 GuidebookMarcelo AndradeNessuna valutazione finora

- 2011 Heritage CalendarDocumento28 pagine2011 Heritage CalendarJohn RongNessuna valutazione finora

- I DogDocumento16 pagineI Doghuxley2378Nessuna valutazione finora

- Anna Kostenko Paintings Not Photographs 11Documento24 pagineAnna Kostenko Paintings Not Photographs 11John RongNessuna valutazione finora

- Science Cyclic Creep1Documento7 pagineScience Cyclic Creep1John RongNessuna valutazione finora

- User'S Guide: MFC-5460CNDocumento151 pagineUser'S Guide: MFC-5460CNJohn RongNessuna valutazione finora

- Pinniped Deterrents at Bonneville Dam 2005-2006: Fisheries Field UnitDocumento27 paginePinniped Deterrents at Bonneville Dam 2005-2006: Fisheries Field UnitJohn RongNessuna valutazione finora

- Columbia River Inside StoryDocumento80 pagineColumbia River Inside StoryArvind SrivastavaNessuna valutazione finora

- Philosophy For Old AgeDocumento20 paginePhilosophy For Old AgeJohn RongNessuna valutazione finora

- Science-Fem Water HamerDocumento14 pagineScience-Fem Water HamerJohn RongNessuna valutazione finora

- 41 547Documento16 pagine41 547John RongNessuna valutazione finora

- HTTP://WWW Slides Co Il/zoom Php?id 9628Documento36 pagineHTTP://WWW Slides Co Il/zoom Php?id 9628www.slides.co.ilNessuna valutazione finora

- 28 CountriesDocumento1 pagina28 CountriesJohn RongNessuna valutazione finora

- Asme - Journal of Vibration and Acoustics - July 2003Documento165 pagineAsme - Journal of Vibration and Acoustics - July 2003Johan Graffman100% (1)

- Gavric 1993Documento15 pagineGavric 1993John RongNessuna valutazione finora

- 41 371Documento26 pagine41 371John RongNessuna valutazione finora

- A Simulation Approach For Prediction and Reduction of Radiated Noise of An Air Cleaner SnorkelDocumento17 pagineA Simulation Approach For Prediction and Reduction of Radiated Noise of An Air Cleaner SnorkelJohn RongNessuna valutazione finora

- 41 351Documento20 pagine41 351John RongNessuna valutazione finora

- Mesurement and Inspection SheetDocumento3 pagineMesurement and Inspection SheetSaifur RahmanNessuna valutazione finora

- ALLSTYLE CatalogwebDocumento48 pagineALLSTYLE CatalogwebjorgegalezoNessuna valutazione finora

- GSE EnVision ProcessFund Sim IDocumento2 pagineGSE EnVision ProcessFund Sim IFungky KingNessuna valutazione finora

- Kenr7125kenr7125-01 Sis PDFDocumento2 pagineKenr7125kenr7125-01 Sis PDFHector Dongo ArrayanNessuna valutazione finora

- Razvodni VentilDocumento17 pagineRazvodni VentilalexkeserNessuna valutazione finora

- Strain Modeling of Transpressional and Transtensional DeformationDocumento12 pagineStrain Modeling of Transpressional and Transtensional Deformationmehenna ouidjaNessuna valutazione finora

- Physics formulas cheat sheetDocumento2 paginePhysics formulas cheat sheetBOT NigmaNessuna valutazione finora

- Aircraft Major Structural Stresses Copy of DiscussionDocumento34 pagineAircraft Major Structural Stresses Copy of DiscussionangeloNessuna valutazione finora

- Man B&W: Main BearingDocumento72 pagineMan B&W: Main BearingRobert LuuNessuna valutazione finora

- Ashok LeylandDocumento1 paginaAshok LeylandDileep Mannath100% (1)

- General Ventilation RequirementsDocumento19 pagineGeneral Ventilation RequirementsNelson VargasNessuna valutazione finora

- Atp 2000 4016tag2a Lsa 52.3S6Documento2 pagineAtp 2000 4016tag2a Lsa 52.3S6Is LamNessuna valutazione finora

- NUST Machine Design Lecture on Stress, Strength and UncertaintyDocumento19 pagineNUST Machine Design Lecture on Stress, Strength and UncertaintyMuhammad Zun Nooren BangashNessuna valutazione finora

- IP Ratings Chart V3 PDFDocumento1 paginaIP Ratings Chart V3 PDFsuprakashpaul93Nessuna valutazione finora

- Cebora Bravo MIG2235 ManualDocumento5 pagineCebora Bravo MIG2235 Manualradu_3g6573100% (1)

- Finite Element Analysis On Lateral Torsional BucklDocumento5 pagineFinite Element Analysis On Lateral Torsional BucklPraneeth VenkatNessuna valutazione finora

- Series Low Pressure Centrifugal PumpDocumento4 pagineSeries Low Pressure Centrifugal PumpDaniel CortezNessuna valutazione finora

- COMPRESOR Powerex Scroll Sed-Set-Seq (1) Sistema ExistenteDocumento2 pagineCOMPRESOR Powerex Scroll Sed-Set-Seq (1) Sistema ExistenteCAROLINA MONGUINessuna valutazione finora

- Pressure Vessel RT TestDocumento3 paginePressure Vessel RT TestAriq FauzanNessuna valutazione finora

- Fluid Machinery Syllabus PDFDocumento3 pagineFluid Machinery Syllabus PDFBajajNessuna valutazione finora

- Fluid Mechanics, Lecture 4Documento27 pagineFluid Mechanics, Lecture 4Jagruti Patel100% (1)

- Daewoo - DWD m8041 m8042 m8043 DWD m1041 m1042 m1043 DWD m1241 m1242 m1243Documento32 pagineDaewoo - DWD m8041 m8042 m8043 DWD m1041 m1042 m1043 DWD m1241 m1242 m1243Mihai LunguNessuna valutazione finora

- Rock Stress AnalysisDocumento30 pagineRock Stress Analysissamwel juliusNessuna valutazione finora