Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Fireproofing For Petrochemical Facility

Caricato da

James MurrayDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Fireproofing For Petrochemical Facility

Caricato da

James MurrayCopyright:

Formati disponibili

FIREPROOFING FOR PETROCHEMICAL FACILITIES

Mark S. Schilling Corrosion Probe, Inc.

INTRODUCTION Fireproofing is employed in refineries and petrochemical plants to minimize the escalation of a fire that would occur with the failure of structural supports and the overheating of pressure vessels. The damage that fire could potentially do very early on, could add significant fuel to the fire. The purpose of fireproofing therefore, is to buy time. The traditional method of fireproofing has been poured-in-place concrete or gunite. Other fireproofing materials, such as lightweight cements, prefabricated cementitious board, and intumescent coatings are used to a lesser extent, primarily in areas deemed less critical and where weight reduction is a significant benefit. Typically, fireproofing is designed to protect the structural steel which supports high risk or valuable equipment. The failure point is generally considered to be 1000F, as this is the point where steel has lost approximately 50% of its structural strength. The aim then, is to prevent structural steel from reaching 1000F for some period of time. Tanks, pressure vessels, and heat exchangers may experience a significant cooling effect from liquid contents and so, less fireproofing protection is generally required. Some thermal insulation systems may serve a dual role as fireproofing and this is common with some pressure vessels. Piping may be insulated but it is not generally considered to be fireproofed. Fireproofing needs to be durable to survive the rigors of every day life in the plant so that if and when a fire does occur, the fire endurance properties have been maintained and the fireproofing can be depended on to function satisfactorily. Everyday exposure may involve mechanical abuse, exposure to oil, solvents, and chemicals, and outdoor weathering for prolonged periods of twenty, thirty, forty years or more. As a coating for steel, fireproofing may provide a good measure of corrosion protection. When applied directly to steel, concrete may passivate the steel surface by providing an elevated pH. Experience has shown, however, that passivation is less than certain, especially in coastal marine environments. Corrosion under concrete fireproofing can be significant. Intumescent coatings promise better corrosion protection than concrete by virtue of their low permeability but cases of severe corrosion under fireproofing (CUF) have been reported with these materials. Intumescent epoxies are complex proprietary materials. Concrete and some of the other materials that are used for fire protection are more familiar. The materials themselves may seem simple, but the important details of system design are often overlooked. DISCUSSION Fireproofing is a misnomer because no material is completely fireproof. All construction materials are subject to fire damage. What we really mean is fire resistant - we seek to resist potential fire situations for a given period of time. Fireproofing is passive, built-in protection that buys time to fight the fire, shut off the fires fuel supply and shut down the process. The aim is to minimize the overall damage incurred.

The decision to fireproof is driven by risk-based analysis. One needs to first consider the nature of the fire threat and then make an assessment of the required period of fire endurance for a wide variety of equipment including structural steel, pressure vessels, heat exchangers, pipe supports, LPG spheres and bullets, valves, and cable trays. The location of specific equipment within a process unit is important, as is a units location with regard to neighboring facilities. TEST METHODS AND REQUIRED TIME RATING No fire test method is going to be typical of a real fire situation and so, there is no single correct or "best" fire test method. Standardized testing simply provides a frame of reference for relative comparisons of fireproofing materials and designs. In the 70s, ASTM E119 "Fire Test of Building Construction Materials" was the only internationally accepted standard for investigating the performance of fireproofing materials. This test method, however, was designed to measure the fire performance of walls, columns, floors, and other building members in solid fuel fire exposures. It does not simulate the high intensity of liquid hydrocarbon-fueled fires. The slope of the time/temperature heating curve for the typical solid fuel fire is significantly different than that of the more instantaneous and intense liquid hydrocarbon fire. Wood, for example, burns fairly slowly. Volatilization of the fuel from the surface is slow and wood can form a char which provides some protection. Liquid hydrocarbons volatilize quickly to feed a fire, and there is no protective char formation. In recognition of this, several of the major oil companies developed their own outdoor hydrocarbon pool fire tests. These tests were more representative of the threat posed to refineries and petrochemical plants but reproducibility was not very good. A better test was desired. UL 1709 "Rapid Rise Fire Tests of Protection Materials for Structural Steel" and ASTM E1529 Standard Test Methods for Determining Effects of Large Hydrocarbon Pool Fires on Structural Members and Assemblies, were first issued in the early 90s. Both tests involve a test furnace which develops an average temperature of 2000F (1093C) within the first 5 minutes of the test. The principal difference is that UL 1709 involves a total heat flux of 65,000 BTU/ft2-hr (205 kW/m2), whereas the ASTM E1529 heat flux is only 50,000 BTU/ft2-hr (158 kW/m2). Temperature is an important parameter but heat flux is a better measure of the amount of heat stress being placed on a material (how fast heat works on a material). Although the temperature is the same, the higher heat flux of UL 1709 makes it a more severe test. Where fireproofing is required, the level of fireproofing varies with the application in the plant. Typical protection requirements for a refinery or petrochemical plant might be as follows: For structural steel, a facility may require a fire test rating of two or three hours. Poured-in-place concrete or gunite is most common with a specified minimum thickness of 2.0 to 3.0 inches (50-75 mm). Lightweight cementitious products may also be used. For steel vessels, a facility may require a fire test rating of one to two hours. Gunite applied at 1.5 to 2.0 inches (40-50 mm) may be required. Alternative fireproofing materials that provide a comparable fire resistance rating may be used, including systems that function as both thermal insulation and fireproofing. Plate and frame exchangers are a special concern because of the rubber gasketing material between plates. These exchangers are provided with a protective enclosure designed to prevent the exchanger from exceeding its maximum operating temperature for an hour or so. The maximum operating temperature is vendor specified and typically less than 300oF (150oC). Electrical and pneumatic components (including manual initiators, valve actuators, aboveground wiring, cable, and conduit) essential to emergency isolation, depressurization, and process shutdown are generally fireproofed to achieve a rating of at least 15-20 minutes. This equipment needs to function properly in the first few minutes of a fire.

FIREPROOFING MATERIALS Concrete The excellent fire protection afforded by concrete has been demonstrated time and time again over 90 years of experience in the petrochemical industry. The high mass and low thermal conductivity of concrete make it very effective at reducing heat input to the underlying structure. Poured-in-place concrete, using forms, is common for columns and beams. Gunite is pneumatically applied to spheres and other structures where the use of forms for poured-in-place concrete is impractical. The principal drawback with gunite application is that it can be very messy. Post-fire inspections have shown that concrete spalls to various degrees but the general conclusion is that concrete/gunite performs satisfactorily with the steel structures well protected. Wire reinforcement is commonly used. Reinforcement does not prevent cracking and spalling of the concrete but it does minimize the loss of fractured material during a fire exposure. Excellent Fire Endurance of 30 Year Old Concrete A refinery fire initiated at a gas oil line from a crude distillation unit and burned for about 12 hours. The main pipe rack near the crude tower at the center of the fire was damaged beyond repair. The support structure for the crude tower overhead equipment was severely damaged. The aluminum jacketed thermal insulation on vessels and exchangers was destroyed (aluminum melts at about 660C or 1220F) but most pressure vessels and heat exchangers, showed no visible signs of permanent damage, primarily due to the cooling effect of liquid contents. Gaskets that had been damaged and high strength bolts that had been tempered by the fire exposure, had to be replaced. Thermal expansion and contraction on structural support columns near ground zero caused a good deal of cracking and delamination of the concrete fireproofing; however, no evidence of deep damage to the concrete was found. The main concern was for the support structure of the crude distillation tower as the refinery is located in a seismic zone. The radiant heat and direct fire exposure caused spalling of the 30 year old concrete cover on the exterior of the vessel skirt. Firewater cooling added to the spalling problem. Some rebar was exposed at the crude tower foundation, most notably on the side of the tower that faced the fire. Concrete was removed for inspection of the crude tower skirt and anchor bolts. No heat buckling of the skirt or distortion of the bolt seatings was observed. Bolts were checked for cracks and hardness measurements were made to confirm strength. The concrete fireproofing had prevented any permanent damage to the vessel skirt and anchor bolts. The 30 year old concrete was now a mess but it had served its function. Companies require that their fireproofing systems pass standardized tests, such as UL 1709 or ASTM E1529. The test requirement is only a few hours, at most. Real world experience with concrete fireproofing confirms time and time again (unfortunately), that concrete can provide the needed protection in real fire scenarios, for many hours. Problems with Concrete Concrete is a comparatively simple, well understood commodity item that is readily available around the world. The fact that satisfactory properties can be achieved without specialized skill is a benefit. Still, there is a potential for misuse and misapplication of concrete. All concrete is not created equal. Poor quality water, sand, and/or aggregate have resulted in some notable and much publicized problems. Concrete fireproofing was applied to structural supports at a U.S. Gulf Coast facility. The specification called for 3000 psi (20.9 MPa) compressive strength concrete reinforced with 14 gage galvanized hex-mesh wire on uncoated structural steel. Concrete was applied in a boxed or blocked design to fill the web of the flange on structural beams and columns and to a minimum cover of 2 inches (50 mm). After 20 years, concrete was spalling from the faces of many beams and columns. It was estimated that almost four miles of concrete on structural steel needed repair due to corrosion damage of the underlying steel. An investigation was undertaken to determine the cause and to find a suitable repair. Core samples of the concrete were taken for laboratory chemical analysis and testing which included carbonation, chloride content, permeability, and determination of compressive strength. Some carbonation was

found to a depth of about one inch (25 mm) but it did not correlate well with the overall problem. Chloride content ranged from 0.004 to 0.073 weight percent, a little higher than 0.001 to 0.043 weight percent for concrete fireproofing in other process units. The permeability was in the range of 10-6 cm/sec compared to a normal permeability of 10-10 cm/sec (adapted ASTM D5084). Capillary tests were consistent with the permeability measurements with a 20 mm column of water being drawn into the concrete in less than thirty hours. Eight compression tests gave an average compressive strength of only 2305 psi (16.1 MPa). Five of the eight compression tests gave less than the specified value of 3000 psi. The low value was only 785 psi (5.5 MPa). It was concluded that the concrete was originally placed with inadequate attention to quality. Concrete is a commodity item but its still an engineered material. The high permeability of the concrete and the large surface area of uncoated steel on the structural members prompted rapid consumption of the zinc on the reinforcing wire. With the zinc lost, the thin wire had little remaining life. CUF can be more severe than the corrosion of nearby bare steel because a corrosive electrolyte may be trapped and held in constant contact with the steel. With typical atmospheric corrosion, there is usually some opportunity to dry-out, but with CUF the corrosion process may continue uninterrupted. The build-up of voluminous corrosion products between the steel and the concrete create a stress that may cause cracking and spalling of the concrete, further accelerating corrosion by providing more sites for water entry. Corrosion protection and fire resistance are interrelated. Corrosion of the steel substrate weakens the adhesion of the concrete and renders the concrete fireproofing more susceptible to explosive spalling during a fire exposure. Corrosion of the steel substrate can be insidious and by the time it manifests itself as rust bleed-thru and spalling of the concrete, the fire resistive properties have already been significantly impacted. Lightweight Fireproofing Concrete is heavy. A two inch thickness of concrete weighs approximately 25-30 lb/ft2 (125-150 kg/m2). The added weight may necessitate increased expense to beef-up new structures to be fireproofed. Existing equipment may have limitations on load bearing capacity that precludes the use of concrete. Lightweight cementitious fireproofing materials weigh significantly less, typically 5-10 lb/ft2 (25-50 kg/m2). Intumescent coatings may contribute only 1-5 lb/ft2 (5-25 kg/m2). As the name implies, lightweight fireproofing materials have a distinct weight advantage. The increasing popularity of modular construction has widened the use lightweight fireproofing. Lightweight Cementitious Products Lightweight cementitious fireproofing products employ lightweight aggregates such as vermiculite, perlite, and diatomite in place of the usual sand and stone. The fire resistance is good and there is generally less spalling than with dense concrete. The more porous structure of lightweight cementitious fireproofing materials better enables water to escape. On the other hand, lightweight cementitious fireproofing materials are less durable than concrete, with lower resistance to physical abuse and a greater tendency for water absorption. It was once common to apply these materials directly to steel. Today, most manufacturers no longer rely on the natural alkalinity of the Portland cement to passivate and protect the steel substrate. A primer coating is required for corrosion protection of the steel substrate. Lightweight cementitious fireproofing is often given a sealer coat to improve durability and resistance to moisture intrusion. The main concern is in choosing a product that will have sufficient durability for the everyday non-fire environment. There s a wide range of products to choose from. The materials range in density from about 20 lbs/ft3 to about 55 lbs/ft3. Often, these products are divided into two groups - low strength (20-40 lb density) and intermediate strength (40-55 lb density). This promotes the perception that products in a group are equivalent, when in fact that may not be the case. Lightweight cementitious materials can be designed to pass the standard fire tests but in general, the lower density products are less durable during everyday exposure in the plant. Project engineers are always tempted if two products are equivalent then it s strictly a matter of price. A rule of thumb is that lower density means lower price. Be advised that some lightweights are truly lightweight, and may not meet one s expectations for everyday durability. A bargain isn t a bargain unless the thing does what you need it to do. One needs everyday durability if one is to have fireproofing capability some years down the road.

Intumescent Coatings Intumescent coatings were first patented in 1948 and have been a commercial reality since about 1960. When exposed to sufficient heat, intumescent coatings expand to form a thick, insulating carbonaceous char. The process is similar to that observed with the small black "magic snakes" Fourth of July novelty firework. Anyone who has sat around a campfire knows that poking the fire around every now and then helps keep the fire going, because it disrupts the char. Intumescence is a complex process involving thermal conduction through the coating with the heating rate dependent on the specific conductivity and thickness. The coating and steel substrate heat up until the reaction temperature is reached. The chemical reaction then proceeds from the outer surface down into the thickness of the coating. The thermal conductivity of the coating changes dramatically during this process and ultimately, reliance is on the thermal insulating capability of the char, and the ability of the char to remain adherent and physically intact. Severe corrosion of the steel substrate has been reported beneath seemingly intact coating. In some cases the problem has been tied to hot weather coating applications where chlorinated solvents were used to thin the coating material. It s been reasoned that some of the chlorinated solvent remains trapped in the thick coating and the chlorinated solvent may later degrade to give hydrochloric acid. However, it is possible that other things could go wrong with an intumescent coating. Intumescent coatings are exceedingly complex coating materials. They need to perform all of the functions that other exterior weathering coatings do (adhesion, hardness, toughness, corrosion resistance, etc.) and then, when exposed to sufficient heat, they need to transform and expand to form a thick, insulating, carbonaceous char. The process is acid-driven with derivatives of phosphoric, boric, and sulfuric acid being most common. At elevated temperature, the acid is made available to trigger a chemical reaction with a carbonific component (e.g., starch or other carbohydrate, phenolic or urea resins, penterythritol, etc.) which results in its subsequent charring. A spumific component (e.g., chloroparaffins, melamine) reacts to give the nonflammable gas, typically HCl, NH3, and/or carbon dioxide, that is responsible for expanding the char into a voluminous, cellular mass. The escaping gases also act to cool the matrix and deprive the flame of oxygen at the surface of the char. All of these aspects - acid release, char formation, and gas generation, need to occur in a well coordinated fashion. In the early days, some intumescent coatings were recommended for application direct to steel. Others required a primer. Some products required reinforcement; others did not. The weathering and chemical resistance was purported to be excellent. Some products claimed to activate right at 300F (149C); others started to show some activity at temperatures closer to 150F (65.6C). Generically similar but proprietary products can be very different. Intumescent coatings have natural limits on applied thickness and they need reinforcement in some applications so that expanded char remains intact and doesn t fall off under its own weight. The shape of the structure to be coated is an important factor. For example, intumescents consistently have a lower fire endurance rating on pipe than on I-beams because on pipe, the coatings do not intumesce in the tangential direction and longitudinal fissures develop. On the outside diameter of a tubular, intumescence increases the circumference, creating tensile stresses that are not accommodated by the material. The tensile stress causes cracks. In the case of I-beams, fissures may develop at flange edges but in other areas the developing char is placed in compression. Experience with intumescent epoxies over many years has been mixed. The first consideration is that these are complex proprietary products and there have been a number of formulation changes over the years. The end user is confronted with new and improved products on a periodic basis. The problem for the facility owner is just that it s anew product. It s different, unknown, untested. Newness can be a major hurdle when the bottom line is risk assessment and risk mitigation. The second consideration is that intumescent coatings, like other organic paints and coatings, degrade with prolonged outdoor weathering and exposure to slightly elevated temperatures. The intumescent capability may be degraded by prolonged outdoor weathering or exposure to elevated temperatures. An intumescent coating exposed for ten years on vessels in the U.S. Gulf Coast environment showed delamination, softening, blistering and other signs of deterioration. Samples of the coating were collected for lab

testing. The aged coating was heated in a furnace. It showed no intumescent reaction. It simply burned and disintegrated. A 15 year old intumescent coating on a propane drum at a western U.S. refinery was seen to be chalked and faded but it looked to be otherwise intact. A sample chunk of coating was removed for testing. When heated slowly in a furnace, the intumescent reaction kicked in at about 315C (600F), a little late perhaps, but with good char formation, a volume increase of approximately 50%. An actual fire exposure would be one-sided, with the coating bonded to steel and the steel substrate cooled by the contents of the drum. However, this simple test showed that the 15 year old intumescent coating could still provide reasonably good fire protection. The general industry opinion has been that surface weathering (chalking) is of little consequence for intumescence. If the aged coating is otherwise intact and looks to be in reasonably good condition, it is expected to perform properly in the event of a fire exposure. That may not always be the case. Furnace testing is simple, quick, and inexpensive. If there s any doubt, a quick test is a prudent choice. Thermal Insulation as Fireproofing Fireproofing protects by insulating the substrate from the heat of a fire and so, thermal insulation systems can provide a dual role. Insulation materials for low temperature service typically do not have good fire resistance. Most plastic foams are quickly destroyed by the heat of a fire. To improve fire resistance, polyurethane foam insulation is commonly formulated with flame retardant additives. These are generally organo-phosphorous compounds and/or halogenated organic compounds (chlorinated or brominated). Phosphorous compounds are used to help provide a more stable surface char. Halogenated compounds interrupt flame chemistry. The two approaches are different and synergistic. Fire retardants do slow flame spread but the toxic fumes may contribute to problems. Corrosive residues may remain for months after a fire. In addition, some of the halogenated fire retardant additives may be leached from aging foam insulation over time. Many cases of severe CUI have been reported on tanks, primarily cold tanks (e.g., LPG), beneath polyurethane foam insulation. In such cases, the polyurethane foam is wet or damp, it tests high for chlorides, and may show a surprisingly low pH. Polyurethane foam is an excellent thermal insulation material when dry. It is widely used for cryogenic applications and up to about 500F (482C). The problem is that the formulation routes to improving fire resistance (in terms of smoke and flame spread ratings) bring potentially deleterious side-effects. Cellular glass has many unique properties. In particular, it is lightweight, dimensionally stable, essentially impermeable to moisture, and it is noncombustible (ASTM E136) with a flame spread rating of 5 (ASTM E84) and no smoke. Each cell is an insulating air space containing primarily carbon dioxide and a trace of hydrogen sulfide. Extractable halogens are nil. The tiny amount of hydrogen sulfide has not been shown to be a corrosion concern. In sum, cellular glass is an ideal insulation material for cold service and properly designed, it can provide the dual role of fireproofing. Some folks argue that cellular glass cannot possibly pass the UL1709 or ASTM E1529 fire test protocols for any appreciable period of time. It s simple. Both of these tests provide an exposure temperature of 2000F (1093C) within the first 5 minutes and glass begins to melt near 1700F (927C). A key aspect of fireproofing that is often misunderstood or overlooked is that the performance of the materials is intimately tied to the design of the system. For example, cellular glass may be used with or without an adhesive and it may be used with different types of exterior jacketing. Cellular glass is not resistant to direct flame impingement, and so metal jacketing is required to obtain fire resistance. Aluminum jacketing is common for cold thermal insulation systems but it cannot be used for fireproofing since aluminum melts at about 660C (1220F). Stainless steel jacketing is generally employed to obtain fire resistance. But there are additional details if one wants to achieve fire resistance with cellular glass: A minimum of two layers of cellular glass, each two inches (50 mm) thick for a total minimum thickness of four inches (100 mm). The individual layers are staggered so there are no through-thickness seams.

Each layer needs to be mechanically fastened and supported with stainless steel bands or clips. A polymeric adhesive needs to be used to glue the blocks of glass together and to provide a final surface coating.

It seems counterintuitive that adding a flammable material such as a polymeric adhesive to a noncombustible material such as cellular glass, would improve performance in fire testing but it clearly does (Figure #1). The reason is that the adhesive burns early and forms an insulating char that extends the time it takes to get to the failure point, where the cellular glass begins to slump.

UL 1709 fire testing of cellular glass

1200

Temperature (F)

1000 800 600 400 200 0

with without

10

20

30

40

50

60

70

80

90 100

Time

Figure #1 This plot compares the increase in average steel substrate temperature over time for 4 inches of cellular glass used with and without an asphaltic adhesive. The temperature early in the test was a little higher when the adhesive was used, but the slope then levels out for the duration of the test. The early temperature is lower when the adhesive is not used, but the slope is then steep to the failure point of 1000F. The use of the adhesive effectively doubled the time to failure in this comparative test. Spheres Fireproofing is not always the preferred approach to providing fire protection. Water will not extinguish a hydrocarbon fire but water is a very effective cooling agent due to the combination of high specific heat and large latent heat of evaporation. If enough water is sprayed onto and well distributed over the surface of a vessel, the contents of the vessel stay below 100C (212F), the boiling point of water. (The same is true for a pan of boiling water on the kitchen stove; the pan cannot much overheat until the water is lost to evaporation and the pan goes dry.) The difficulty is being able to apply the water when and where it is needed. For spheres, fire protection is often provided by a water deluge system sized to deliver 0.15 gpm/ft2 or more, to the top of the sphere. This system takes advantage of sphere geometry to distribute the water uniformly. One common factor in CUI/CUF is wet insulation or fireproofing. Water frequently gets behind fireproofing on spheres at the top of the sphere where there are a number of penetrations for piping and for structural steel platform supports. These obstructions make it difficult to install fireproofing. Any gaps need to be well caulked. Although the risk of CUI/CUF is true for any equipment that operates below about 149C (300oF), there are particular risks that should be considered when deciding whether spheres should be covered with passive fireproofing. LPG spheres tend to operate at ambient temperature or below and there is a cooling effect (autorefrigeration) with product draw down that likely drops the surface temperature to below the dew point.

And if that wasnt enough of a threat, spheres are regularly soaked when the water deluge systems are tested. There have been many instances over the years where severe CUI/CUF has resulted as a direct result of local jurisdictions requiring periodic testing of fire water systems. Clean, potable water is often in limited supply. Coastal plants may use seawater for firewater. It may not suffice to prove that a deluge system works or for example, that a water cannon can hit a target, but deliberately miss. No, some facilities have been forced to soak the vessel, just to prove that they can. Fireproofing of spheres is not generally considered mandatory or even necessary. There are a number of reasons; water deluge systems are generally regarded as adequate, the proper application of fireproofing is difficult, fireproofing may promote CUF, and fireproofing hinders external inspection of the steel shell of the vessel. Fireproofing may be deemed necessary for spheres when congestion is a concern. For example, in older plants, the spheres may be too closely spaced according to modern standards. It may also be that a neighboring community has encroached on an older plant. In such cases, fireproofing may be added to further reduce the risk of a BLEVE (boiling liquid expanding vapor explosion). Fireproofing is not just a simple materials issue. Fireproofing is an important part, but it s just one part of a larger effort in risk assessment and risk mitigation. A Novel Lightweight Design A refining company required concrete for structural steel, and a minimum two hour fire test rating. A contoured design, in which the minimum concrete thickness of two inches followed the shape of beams was allowed in some cases, but their standard practice was a boxed design, in which the web of the flange is filled with concrete. The boxed or blocked design required a minimum concrete thickness of two inches over the outside of the beam but the concrete thickness over the web of the flange was of course, much greater than 2 inches. Savings on weight, constructability and cost, are important project concerns. On a construction project for this refinery, an engineering firm provided a novel design. The fireproofing system for smaller columns and beams was to be the solid boxed concrete design but for larger columns and beams there would be two inches of concrete cover over Styrofoam block filling the web of the flange (Figure #2):

Concrete 2" Thickness Minimum Cover Steel Wire Reinforcement Styrofoam Filler Steel I-Beam

The Styrofoam blocks were approximately four feet long and individual blocks of Styrofoam were separated with a four inch wide band of concrete (Figure #3):

Steel Beam

4" Concrete typical

4 0" typ

Styrofoam

Fireproofing

Side View W21 or Greater Fireproofed Beams

This novel fireproofing design had somehow slipped under the radar during the planning stage of the project. It wasn t discovered until a refinery engineer walked through the lay-down area and saw the Styrofoam blocks and how they were being used. Knowing that that just couldn t be right, the engineer brought the novel design to the attention of the project engineers. The work ground to a halt. This needed to be sorted out. The engineering firm argued that this novel design met the refinery s requirements because (1) it was essentially a boxed or "blocked" design and, (2) the cover material was concrete at the required minimum thickness of two inches. The refinery s materials engineers quickly countered that the refinery s requirements were for concrete, period not concrete and whatever else someone might want to use. The refinery could not be expected to keep a long list of all the things one could not use. Certainly, Styrofoam can t be used for fireproofing!

The engineering firm then argued that they had installed this novel design at other refineries. One of their fireproofing specialists proceeded to explain that the fire resistance of concrete was dependent on the water content. Concrete was said to function by maintaining a temperature at about 100C (212F) until all of the water had been boiled away. Two inches of concrete was known to be sufficient for the required two hours, so this novel design will work. This seemed like a convincing argument but it was very wrong and it was no surprise that the required fire test data was not forthcoming. The water content of concrete is important but it doesnt take long in a fire exposure to loose the free water. Water of hydration is not the same as free water. It is lost more slowly and at more elevated temperatures. Consequently, concrete does not maintain a temperature near the boiling point of water for very long. Fire test data for a concrete boxed beam shows a small plateau in the time-temperature curve near 100C (212F) at about the 20 minute mark but thereafter the temperature rise is slow and uniform (Figure #4). It s primarily the high mass and low thermal conductivity of concrete that make it effective at reducing the heat input to the steel.

UL 1709 fire testing of concrete box design on 10W49 beam

Temperature (F)

1000 800 600 400 200 0

20

40

60

80

100 120 140 160 180 200 220

Time

Figure #4 This shows the increase in average steel substrate temperature over time for the concrete box or blocked design, with a minimum two inch cover over the outside. The web of the flange is filled with concrete so the thickness there is much more than the 2 inch minimum requirement. The initial temperature spikes and then levels off for several minutes near the boiling point of water. Then there is a smooth slope all the way out to the failure point of 1000F. The data provided by Figure #4 is for a boxed design in which the web of the flange is filled with concrete, so the concrete thickness is much greater than two inches over the web. A two inch concrete cover of the web is certainly less protective, whether it is two inches directly on the steel (contour design), two inches over Styrofoam blocks, or two inches over void space (air). Polystyrene melts at about 340F. In a fire situation, one should expect that with the novel design, the Styrofoam would soon melt and flow. And polystyrene burns, adding fuel to the fire, and it would do so from within this novel fireproofing system. A clear-thinking engineer can immediately see that this novel fireproofing design has no chance in Hell of surviving a two hour UL 1709 test. But that didn t stop the engineering firm from selling it, and then defending it when confronted. The structure had been designed with significant weight savings. Steel had been delivered. A solid concrete box design was no longer an option. The project continued with concrete applied in a contour design. Fortunately, the problem was identified early and corrected on this particular project. However, one should take note of the fact that in defending this novel design, the engineering firm was quick to point out that they had installed this novel design at other refineries. Somebody has a built-in problem.

CONCLUSION Each type of fireproofing material offers a different combination of physical and chemical properties, and each has its own application requirements. As with any protective coating, the quality of the applied fireproofing is a function of the surface preparation, the materials used, and the care with which it is applied. Poorly designed, installed, and/or maintained fireproofing will not likely provide the expected level of protection during a fire, and may promote corrosion of the underlying steel substrate.

References 1. 2. 3. 4. ACI 222R-89, Corrosion of Metals in Concrete, 1989 API Publication 2218, "Fireproofing Practices in Petroleum and Petrochemical Processing Plants" ASTM E119, "Fire Tests of Building Construction and Materials ASTM E1529, Standard Test Methods for Determining Effects of Large Hydrocarbon Pool Fires on Structural Members and Assemblies, NACE RP0198 "The Control of Corrosion Under Thermal Insulation and Fireproofing Materials - A Systems Approach" NACE Publication 6H189 A State-of-the Art Report of Protective Coatings for Carbon Steel and Austenitic Stainless Steel Surfaces Under Thermal Insulation and Cementitious Fireproofing Underwriters Laboratories UL 1709, "Standard for Rapid Rise Fire Tests for Protection Materials for Structural Steel" Walker, A.G., Flame-Retardant Paints, Progress in Organic Coatings, 7 (1979) pgs. 279-287 Blake, Melvyn, Fireproofing Structural Steel in the Hydrocarbon Processing Industry, Journal of Protective Coatings & Linings, January 1986 Lazar III, Peter, "Conference on Corrosion and Infrastructure," November 28-30, 1995, Baltimore, MD Papa, Anthony J., Reactive Flame Retardants for Polyurethane Foams, Ind. Eng. Chem. Prod. R es. Develop., Vol. 9, No. 4, 1970 Papa, Anthony J., Flame Retardation of Polyurethane Foams in Practice, Ind. Eng. Chem. Prod. Res. Develop., Vol. 11, No. 4, 1972 Katzier, J., Tank Insulation Costs Up? Use Polyurethane Foam, Hydrocarbon Processing, May 1980 Schilling, Mark S., Development of a Company Standard on Fireproofing NACE Corrosion 2000

5.

6.

7.

8. 9.

10.

11.

12.

13. 14.

Potrebbero piacerti anche

- New Yellow Book 01-07-2014Documento115 pagineNew Yellow Book 01-07-2014scegts100% (2)

- KDIGO 2023 CKD Guideline Public Review Draft 5 July 2023Documento339 pagineKDIGO 2023 CKD Guideline Public Review Draft 5 July 2023oscar coreaNessuna valutazione finora

- Fire Protection For Structural Steel in Buildings (Yellow Book)Documento162 pagineFire Protection For Structural Steel in Buildings (Yellow Book)Alexandra Daramus100% (2)

- Wrestling Strength and ConditioningDocumento12 pagineWrestling Strength and ConditioningTintin BilatbatNessuna valutazione finora

- G21 Fire and Blast Databook Panels2.0Documento149 pagineG21 Fire and Blast Databook Panels2.0Lakshmi Binoy MenonNessuna valutazione finora

- NPK (10.26.26) PDFDocumento1 paginaNPK (10.26.26) PDFJames MurrayNessuna valutazione finora

- International Sales Commission Agreement TemplateDocumento6 pagineInternational Sales Commission Agreement TemplateJames MurrayNessuna valutazione finora

- UL 1709 Ed 2017Documento43 pagineUL 1709 Ed 2017frgonzalezc100% (1)

- Blast Resistant Building Design CriteriaDocumento51 pagineBlast Resistant Building Design Criteriahrol31060100% (2)

- Steel Stacks Desing GuideDocumento23 pagineSteel Stacks Desing GuideKhaled Eid100% (5)

- Kapil Bhaskar Chapter 1 To DownloadDocumento16 pagineKapil Bhaskar Chapter 1 To DownloadJames Murray100% (1)

- Blake PastoralDocumento4 pagineBlake PastoralSanya AhmedNessuna valutazione finora

- Passive Fire Protection Case Study PDFDocumento6 paginePassive Fire Protection Case Study PDFkharlos.romero1409Nessuna valutazione finora

- Steel Structure Subjected To Fire and FatigueDocumento12 pagineSteel Structure Subjected To Fire and Fatigueakhlaq_hssainkotaNessuna valutazione finora

- 1.4 Advanced PFP Seminar 11 2011 PDFDocumento94 pagine1.4 Advanced PFP Seminar 11 2011 PDFfredo405Nessuna valutazione finora

- Epoxy Intumescent Coating Systems For The Corrosion Protection and Fire Protection of Structural Steel IfjDocumento4 pagineEpoxy Intumescent Coating Systems For The Corrosion Protection and Fire Protection of Structural Steel IfjAnonymous B7pghhNessuna valutazione finora

- Industrial Fire ProofingDocumento20 pagineIndustrial Fire Proofingkenoly123100% (3)

- GP 52-20 - Passive Fire Protection Fireproofing - 0900a866801074adDocumento26 pagineGP 52-20 - Passive Fire Protection Fireproofing - 0900a866801074adMichael Moore67% (3)

- Fire Protection For Structural SteelDocumento8 pagineFire Protection For Structural SteelcheckshinlNessuna valutazione finora

- 2218 E3 PADocumento3 pagine2218 E3 PAtonytrujillo0% (1)

- DEP 34.19.20.11-Gen PASSIVE FIRE PROTECTION FOR ONSHORE FACILITIESDocumento24 pagineDEP 34.19.20.11-Gen PASSIVE FIRE PROTECTION FOR ONSHORE FACILITIESmahesh100% (2)

- FireproofingDocumento15 pagineFireproofingDubey Deepak100% (1)

- A-320 - Fire Proofing of Steel StructureDocumento11 pagineA-320 - Fire Proofing of Steel StructurePoorvi Bhave75% (4)

- Fireproofing From 2020chevron PDFDocumento25 pagineFireproofing From 2020chevron PDFArmin MnNessuna valutazione finora

- Spec. Safety and Fire Protection - SJBDocumento16 pagineSpec. Safety and Fire Protection - SJBRizaldi Riz100% (2)

- Review of The Robustness of Epoxy Passive Fire Protection Tech PaperDocumento19 pagineReview of The Robustness of Epoxy Passive Fire Protection Tech Paperuserscribd2011100% (1)

- Rapid Rise Fire Tests of Protection Materials For Structural SteelDocumento43 pagineRapid Rise Fire Tests of Protection Materials For Structural Steelmuleacidic100% (1)

- Fire Resistance of Steel StructuresDocumento21 pagineFire Resistance of Steel StructuresCan AydoğmuşNessuna valutazione finora

- Passive Fire Protection NorimaxDocumento8 paginePassive Fire Protection NorimaxMehman NasibovNessuna valutazione finora

- Design of Self Supported Steel ChimneyDocumento27 pagineDesign of Self Supported Steel ChimneyAlok JhaNessuna valutazione finora

- Fireproofing For Hydrocarbon ExposuresDocumento7 pagineFireproofing For Hydrocarbon ExposuresN P SrinivasaraoNessuna valutazione finora

- LNG Water CurtainDocumento20 pagineLNG Water CurtainDera ChoanjiNessuna valutazione finora

- BYBU - XR701 Fire Resistance Ratings - ANSI/UL 1709Documento2 pagineBYBU - XR701 Fire Resistance Ratings - ANSI/UL 1709FPA InspectorNessuna valutazione finora

- Guideline On Structural Fire Engineering Part I - Fire Scenarios and Calculation of Temperature Under Fire Struct PDFDocumento92 pagineGuideline On Structural Fire Engineering Part I - Fire Scenarios and Calculation of Temperature Under Fire Struct PDFLeung LiangNessuna valutazione finora

- Passive Fire ProtectionDocumento13 paginePassive Fire ProtectionAzmi SuhardiNessuna valutazione finora

- Fire Design of Steel StructuresDocumento28 pagineFire Design of Steel StructuresDaliborStevic100% (2)

- 331615-Water Storage Steel TanksDocumento14 pagine331615-Water Storage Steel TanksinstrengNessuna valutazione finora

- Fireproofing From ChevronDocumento25 pagineFireproofing From ChevronAnonymous pH3jHscX983% (6)

- Historical Beam SectionsDocumento77 pagineHistorical Beam SectionsMohammed Hafiz100% (1)

- Industrial Fire Protection BasicsDocumento83 pagineIndustrial Fire Protection BasicsHakan Şahinoğlu100% (1)

- Compressed Gases and Cryogenic Fluids CodeDocumento5 pagineCompressed Gases and Cryogenic Fluids Codesudarshan jalluriNessuna valutazione finora

- 9 Seperation DistancesDocumento26 pagine9 Seperation DistancesmetaslaNessuna valutazione finora

- Specification Philosophy Passive Fire Protection OnshoreDocumento16 pagineSpecification Philosophy Passive Fire Protection OnshoreagaricusNessuna valutazione finora

- UL 1709 V ISO Hydrocarbon FireDocumento5 pagineUL 1709 V ISO Hydrocarbon FirevikaspisalNessuna valutazione finora

- Corrosion by Concentrated Sulfuric Acid Steel Pipes and Tanks I21319914Documento8 pagineCorrosion by Concentrated Sulfuric Acid Steel Pipes and Tanks I21319914carlos sotoNessuna valutazione finora

- An Introduction To Structural Fire EnginDocumento63 pagineAn Introduction To Structural Fire EnginkushNessuna valutazione finora

- BYBU - XR711 - Fire-Resistance Ratings - ANSI - UL 1709 - UL Product Iq AVI 2020 PDFDocumento3 pagineBYBU - XR711 - Fire-Resistance Ratings - ANSI - UL 1709 - UL Product Iq AVI 2020 PDFCIAKNessuna valutazione finora

- Wind Turbine API RP2 SeriesDocumento8 pagineWind Turbine API RP2 SeriesBona_VentureNessuna valutazione finora

- UL1709 ScopeDocumento2 pagineUL1709 ScopeSaravanan PanduranganNessuna valutazione finora

- RCC Chimney - CICIND CommentaryDocumento65 pagineRCC Chimney - CICIND CommentaryVasanth KumarNessuna valutazione finora

- Ip 19 PDFDocumento240 pagineIp 19 PDFparry1701Nessuna valutazione finora

- 7.3 Calculation of PFP ThicknessDocumento10 pagine7.3 Calculation of PFP ThicknessFrancisco Javier Martinez Burgo100% (3)

- Blast Proof BuildingsDocumento35 pagineBlast Proof BuildingsAnonymous I1tOPIZSkNessuna valutazione finora

- Blast DesignDocumento45 pagineBlast DesignM Refaat FathNessuna valutazione finora

- Abbbdgget 155667Documento15 pagineAbbbdgget 155667Wan Ah-LunNessuna valutazione finora

- Whatever Is Updated and RevisedDocumento14 pagineWhatever Is Updated and RevisedWan Ah-LunNessuna valutazione finora

- NEvereverever PDFDocumento15 pagineNEvereverever PDFWan Ah-LunNessuna valutazione finora

- Tank Fire FightingDocumento5 pagineTank Fire FightingT. LimNessuna valutazione finora

- A Case of Choice of Passive Fire Protection (PFP) in An Oil & Gas EPC Project - Part2Documento1 paginaA Case of Choice of Passive Fire Protection (PFP) in An Oil & Gas EPC Project - Part2potatoteddyNessuna valutazione finora

- Understanding The Fire Resistance of Structural SteelDocumento9 pagineUnderstanding The Fire Resistance of Structural SteelChris TongNessuna valutazione finora

- Lecture 4B.4: Practical Ways of Achieving Fire Resistance of Steel StructuresDocumento14 pagineLecture 4B.4: Practical Ways of Achieving Fire Resistance of Steel StructuresЧавдар Пенелов100% (1)

- Статья по созданию и тесту печиDocumento7 pagineСтатья по созданию и тесту печиДенис БакланNessuna valutazione finora

- Jawapan JM (Soalan H N I)Documento4 pagineJawapan JM (Soalan H N I)Nurul Izzati Raihan RamziNessuna valutazione finora

- Present Trend On Refractory Uses For Reheating Furnaces: G. D. SinghDocumento6 paginePresent Trend On Refractory Uses For Reheating Furnaces: G. D. SinghmmkattaNessuna valutazione finora

- Refractory Materials PDFDocumento18 pagineRefractory Materials PDFadi nugroho100% (2)

- Rakic - Type of Fireproofing Materials PDFDocumento3 pagineRakic - Type of Fireproofing Materials PDFbehrouzbehnam100% (1)

- Notice To Creditors Re ApplicationDocumento2 pagineNotice To Creditors Re ApplicationJames MurrayNessuna valutazione finora

- YajnaprocedureDocumento15 pagineYajnaprocedureJames Murray0% (1)

- Bosiet With CA Ebs Huet With CA Ebs and Foet With CA Ebs Rev 0 Amendment 8 Available From 1st November 2018Documento78 pagineBosiet With CA Ebs Huet With CA Ebs and Foet With CA Ebs Rev 0 Amendment 8 Available From 1st November 2018James MurrayNessuna valutazione finora

- Unclaimed Accounts Identified As Per Senior Citizen Welfare Fund Rules 2016Documento10 pagineUnclaimed Accounts Identified As Per Senior Citizen Welfare Fund Rules 2016James MurrayNessuna valutazione finora

- Nri News Bulletin May 18 AdvDocumento11 pagineNri News Bulletin May 18 AdvJames MurrayNessuna valutazione finora

- Nri News Bulletin June 18Documento10 pagineNri News Bulletin June 18James MurrayNessuna valutazione finora

- Chakras and Beeja MantrasDocumento57 pagineChakras and Beeja MantrasGeorgegeorgeb100% (2)

- NPK (10.26.26) PDFDocumento1 paginaNPK (10.26.26) PDFJames MurrayNessuna valutazione finora

- Loan - Roi W.E.F 01.08.2018Documento2 pagineLoan - Roi W.E.F 01.08.2018James MurrayNessuna valutazione finora

- Mantra Rahasya DR Narayan Datt ShrimaliDocumento384 pagineMantra Rahasya DR Narayan Datt ShrimaliJames Murray100% (1)

- Tantric Mantra Book PDFDocumento68 pagineTantric Mantra Book PDFJames Murray100% (2)

- Chakras and Beeja MantrasDocumento1 paginaChakras and Beeja MantrasJames MurrayNessuna valutazione finora

- Chakras and Beeja MantrasDocumento57 pagineChakras and Beeja MantrasGeorgegeorgeb100% (2)

- 3 100e Unersal Silicone Tds enDocumento1 pagina3 100e Unersal Silicone Tds enJames MurrayNessuna valutazione finora

- 2 100e Universal Licone Tds enDocumento1 pagina2 100e Universal Licone Tds enJames MurrayNessuna valutazione finora

- Band On 10Documento1 paginaBand On 10James MurrayNessuna valutazione finora

- 1 100e Universal Silicone Tds enDocumento1 pagina1 100e Universal Silicone Tds enJames MurrayNessuna valutazione finora

- GR1 HSE Improvement Workshop M & P 07-02-2015Documento12 pagineGR1 HSE Improvement Workshop M & P 07-02-2015James MurrayNessuna valutazione finora

- Turbo Lab 1Documento10 pagineTurbo Lab 1Seng SoonNessuna valutazione finora

- Membrane AutopsyDocumento2 pagineMembrane AutopsyBiljana TausanovicNessuna valutazione finora

- Motivational Interviewing (MI) Refers To ADocumento5 pagineMotivational Interviewing (MI) Refers To AJefri JohanesNessuna valutazione finora

- How Condensing Boilers WorkDocumento1 paginaHow Condensing Boilers WorkBrianNessuna valutazione finora

- Biecco Lawrie Ece Gec Reyrolle Burn Jyoti SwitchgearDocumento18 pagineBiecco Lawrie Ece Gec Reyrolle Burn Jyoti SwitchgearSharafat AliNessuna valutazione finora

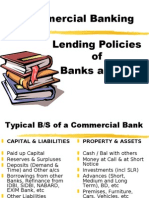

- Lending Policies of Indian BanksDocumento47 pagineLending Policies of Indian BanksProf Dr Chowdari Prasad80% (5)

- Pressure MeasurementDocumento293 paginePressure MeasurementGlen Lauren PerezNessuna valutazione finora

- TDS-PE-102-UB5502H (Provisional) 2019Documento2 pagineTDS-PE-102-UB5502H (Provisional) 2019Oktaviandri SaputraNessuna valutazione finora

- UntitledDocumento8 pagineUntitledapi-86749355Nessuna valutazione finora

- Peritoneal Dialysis Unit Renal Department SGH PD WPI 097 Workplace InstructionDocumento10 paginePeritoneal Dialysis Unit Renal Department SGH PD WPI 097 Workplace InstructionAjeng SuparwiNessuna valutazione finora

- Business Proposal New VentureDocumento18 pagineBusiness Proposal New VentureBramhananda ReddyNessuna valutazione finora

- Importance of The On Board Crew Trainings and Drills For The Improvement of The Vessels' SafetyDocumento8 pagineImportance of The On Board Crew Trainings and Drills For The Improvement of The Vessels' SafetyilgarNessuna valutazione finora

- Reviewer Crim 3 FinalsDocumento6 pagineReviewer Crim 3 FinalsMaria Rafaella P. DadoNessuna valutazione finora

- Improving Communication Skills of Pharmacy StudentDocumento13 pagineImproving Communication Skills of Pharmacy StudentAbdul QadirNessuna valutazione finora

- 9ha Power PlantsDocumento2 pagine9ha Power PlantsGaurav DuttaNessuna valutazione finora

- Doppler EffectDocumento47 pagineDoppler EffectLouies UngriaNessuna valutazione finora

- BRSM Form 009 - QMS MDD TPDDocumento15 pagineBRSM Form 009 - QMS MDD TPDAnonymous q8lh3fldWMNessuna valutazione finora

- Decompensated Congestive Cardiac Failure Secondary To No1Documento4 pagineDecompensated Congestive Cardiac Failure Secondary To No1Qi YingNessuna valutazione finora

- Standard DetailsDocumento168 pagineStandard DetailsMurathan Paksoy100% (1)

- Bradycardia AlgorithmDocumento1 paginaBradycardia AlgorithmGideon BahuleNessuna valutazione finora

- ENG 110-Task 4 (Unintended Messages)Documento2 pagineENG 110-Task 4 (Unintended Messages)Erika Noreen Dela RosaNessuna valutazione finora

- Refuse Chute PPT 01Documento11 pagineRefuse Chute PPT 01sanika shindeNessuna valutazione finora

- Aahaa Puttu Flour ProjectDocumento53 pagineAahaa Puttu Flour ProjectApple ComputersNessuna valutazione finora

- 200 State Council Members 2010Documento21 pagine200 State Council Members 2010madhu kanna100% (1)

- Standard Practice For Magnetic Particle Testing For AerospaceDocumento16 pagineStandard Practice For Magnetic Particle Testing For AerospaceSaul RuizNessuna valutazione finora

- Chan vs. ChanDocumento2 pagineChan vs. ChanMmm GggNessuna valutazione finora

- HD Management Brochure - Final PDFDocumento2 pagineHD Management Brochure - Final PDFVanzari RBMNessuna valutazione finora