Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Flange Design Mmcobc 1.1 2010

Caricato da

bakellyCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Flange Design Mmcobc 1.1 2010

Caricato da

bakellyCopyright:

Formati disponibili

24-March-2012

ASME BPVC-VIII-1 (2010)

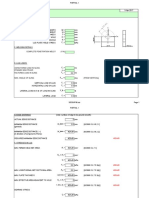

DESIGN OF CIRCULAR STEEL FLAT-FACE FLANGE WITH METAL-TO-METAL CONTACT OUTSIDE THE B OLT CIRCLE - INTEGRAL TYPE FLANGE WITH SELF-SEALING GASK ET REFERENCE DRAWINGS: DESIGN CONDITIONS: DESIGN CODE =

ASME BPVC SECT. VIII - DIV. 1 [2010] [CLASS 1 ASSEMBLY / CATEGORY 1 FLANGE] C MPa

DESIGN TEMPERATURE DESIGN PRESSURE FLANGE MATERIAL DATA: FLANGE MATERIAL DESIGN TENSILE STRENGTH @ AMBIENT DESIGN TENSILE STRENGTH @ DESIGN TEMP. HUB MATERIAL: DESIGN TENSILE STRENGTH @ AMBIENT DESIGN TENSILE STRENGTH @ DESIGN TEMP. MODULUS OF ELASTICITY @ OPERATING TEMP. B OLT/STUD DATA: MATERIAL PROOF STRENGTH DESIGN TENSILE STRENGTH @ AMBIENT DESIGN TENSILE STRENGTH @ DESIGN TEMP. MODULUS OF ELASTICITY @ OPERATING TEMP. NOMINAL DIAMETER AREA NO. OF THREADED ENDS (BOLT = 1 STUD = 2) FLANGE DIMENSIONS (REFER FIG. Y-3.2 FOR NOTATION): OUTSIDE DIAMETER INSIDE DIAMETER BOLT CIRCLE DIAMETER THICKNESS OF HUB @ SMALL END THICKNESS OF HUB @ BACK OF FLANGE HUB LENGTH (h > 0) NO. OF BOLTS BOLT HOLE DIAMETER OUTSIDE DIAMETER OF SPACER (=A, IF NONE) GASK ET DATA: MATERIAL DIAMETER GASKET FACTOR MIN DESIGN SEATING STRESS OUTSIDE DIAMETER INSIDE DIAMETER DIA. @ LOCATION OF GASKET LOAD REACTION B OLT-FORCES / MOMENT ARMS (REFER FIG. Y-3.2 FOR NOTATION): HYDROSTATIC END-FORCE H'STATIC END FORCE ON AREA I/S OF FLANGE GASKET LOAD HYDROSTATIC END FORCE MOMENT ARM MOMENT ARM MOMENT ARM FLANGE MOMENTS: MOMENT MOMENT MOMENT MOMENT

= P=

= Sf = Sf = = Sn = Sn = EI =

MPa MPa MPa MPa MPa

SECT II-D T (1A) SECT II-D T (1A) SECT II-D T (1A) SECT II-D T (1A) SECT II-D T (TM-1)

= Fy = Sa = Sb = E= db = A b/n = =

MPa MPa MPa MPa mm mm

SECT II-D T (3) SECT II-D T (3) SECT II-D T (TM-1)

A= B= C= go = g1 = h= n= D= =

mm mm mm mm mm mm mm mm

F (Y-3.2) F (Y-3.2) F (Y-3.2)

C (Y.3(a)) F (Y-3.2)

= = m= y= = = G=

mm MPa mm mm 0.0 mm T (2-5.1) T (2-5.1)

F (Y-3.2)

H= HD = HG = HT = hD = hG = hT =

0 N 0 0 0 0.0 0.0 0.0 N N N mm mm mm

C (Y.3(a)) C (Y.3(a)) C (Y.3(a)) C (Y.3(a)) T (2.6) T (2.6) T (2.6)

MD = MG = MT = M P=

0 N.mm 0 N.mm 0 N.mm 0 N.mm

C (Y.3(a)) C (Y.3(a)) C (Y.3(a)) C (Y.3(a))

89796855.xls.ms_office

Page 1

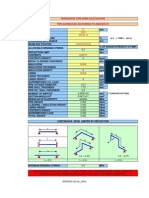

SUGGESTED TRIAL VALUES: FLANGE THICKNESS BOLT AREA SUGGESTED TRIAL FLANGE THICKNESS SUGGESTED TOTAL AREA OF BOLTS SUGGESTED AREA OF BOLT RADIAL DIST. FROM B.C.D. TO BEARING CIRCLE SELECTED VALUES: SELECTED FLANGE THICKNESS SELECTED AREA OF BOLT RADIAL DIST. FROM B.C.D. TO BEARING CIRCLE

ta = A b' = t= Ab = A b/n = hC =

#DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

mm mm mm mm mm 0 mm

E (39) E (42) T (Y-9.1) T (Y-9.1)

C Y-4(a)(2)

t= A b/n = hC = h Cmax = ts = =

mm 0 mm mm 0 mm mm mm

C (Y.3(a)) C (Y.3(a))

THICKNESS OF SPACER THICKNESS OF W ASHERS, ETC MISCELLANEOUS CALCULATIONS:

g 1/g o = ho = h/h o = K= T= U= Y= Z= F= V= f= e= d= L= B1 = SHAPE FACTOR SHAPE FACTOR BOLT HOLE ASPECT RATIO a= = AR = rB = Jp = Js = CALCULATED STRAIN LENGTH OF BOLT ELASTICITY FACTOR l= rE = F' = FLANGE MOMENT DUE TO FLANGE-HUB INTERACTION: Ms = SLOPE OF FLANGE AT DIAMETER B TIMES E: E qB = SLOPE #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

#DIV/0! 0.0 #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

C Y.3(a) F 2-7.1 F 2-7.1 F 2-7.1 F 2-7.1 F 2-7.1 T 2-7.1 T 2-7.1 T 2-7.1 C Y.3(a) C Y.3(a) C Y.3(a) C Y.3(a) C C C C (Y.3(a)) (Y.3(a)) (Y.3(a)) (Y.3(a))

C (Y.3(a)) C (Y.3(a)) 0.0 mm C (Y.3(a)) C (Y.3(a)) E (5a)

N-mm

E (7)

MPa rad deg

E (8)

qB =

=

CONTACT FORCE B ETWEEN FLANGES AT h C: HC = #DIV/0! N E (9)

89796855.xls.ms_office

Page 2

B OLT LOAD AT OPERATING CONDITIONS: REQUIRED BOLT-FORCE B OLT AREAS: REQUIRED BOLT-AREA TOTAL BOLT-AREA OPERATING B OLT STRESS: OPERATING BOLT STRESS DESIGN PRESTRESS IN B OLTS: DESIGN PRESTRESS IN BOLTS PERCENTAGE OF YIELD STRESS TYPE OF LUBRICANT NUT FACTOR (TORQUE CO-EFFICIENT) BOLT PRELOAD BOLT TORQUE RADIAL FLANGE STRESS AT B OLT CIRCLE:

W m1 =

#DIV/0!

E (10)

Am = Ab =

#DIV/0!

mm 0 mm

C (Y-4(b))

sb =

#DIV/0!

MPa

E (11)

Si = = = = = =

#DIV/0! #DIV/0!

MPa %

E (12)

#DIV/0! #DIV/0!

kN N-m

SR = RADIAL FLANGE STRESS AT INSIDE DIAMETER: SR = TANGENTIAL FLANGE STRESS AT INSIDE DIAMETER: ST = LONGITUDINAL HUB STRESS: SH = (S H+S R)/2 = (S H+S T)/2 = ALLOWAB LE FLANGE DESIGN STRESSES: BOLTS: Sb FLANGE: SR ST SH (S H+S R)/2 (S H+S T)/2 DESIGN SUMMARY: FLANGE STRESSES BOLT STRESS = = = = = =

#DIV/0!

MPa

E (13)

#DIV/0!

MPa

E (14a)

#DIV/0!

MPa

E (15a)

#DIV/0! #DIV/0! #DIV/0!

MPa MPa MPa

E (16a)

0.0 MPa

C (Y-7(a))

0.0 0.0 0.0 0.0 0.0

MPa MPa MPa MPa MPa

C C C C C

(Y-7(c)) (Y-7(d)) (Y-7(b)(1)) (Y-7(e)) (Y-7(e))

S act/S all = sb/S b =

#DIV/0! #DIV/0!

89796855.xls.ms_office

Page 3

A = C =

#DIV/0! #DIV/0!

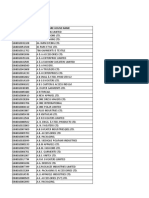

C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C C

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37

= = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = =

#DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

E E E E E E

1 2 3 4 5 6

= = = = = =

#DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

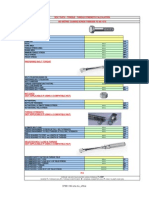

- Metric Bolt Torque - Thread StrengthDocumento7 pagineMetric Bolt Torque - Thread StrengthbakellyNessuna valutazione finora

- Bolt Torque ASME B16.5 Flanges - Sheet Gaskets 02Documento26 pagineBolt Torque ASME B16.5 Flanges - Sheet Gaskets 02bakelly100% (7)

- Bolt Torque ASME B16.5 Flanges - Sheet Gaskets 02Documento26 pagineBolt Torque ASME B16.5 Flanges - Sheet Gaskets 02bakelly100% (7)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Client:-Visa Power Limited: Released For ConstructionDocumento36 pagineClient:-Visa Power Limited: Released For Constructionraj sekharNessuna valutazione finora

- Pipe Pressure RatingDocumento1 paginaPipe Pressure RatingbakellyNessuna valutazione finora

- Design of Flanges - Loose Type 2010Documento53 pagineDesign of Flanges - Loose Type 2010bakellyNessuna valutazione finora

- Design of Flanges - Welded-On Integral Type 2010Documento59 pagineDesign of Flanges - Welded-On Integral Type 2010bakellyNessuna valutazione finora

- Monorail Beam Design 07Documento5 pagineMonorail Beam Design 07bakellyNessuna valutazione finora

- Design of Flanges - Weld Neck Type 2010Documento58 pagineDesign of Flanges - Weld Neck Type 2010bakellyNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Lifting Lug Design B 01Documento22 pagineLifting Lug Design B 01bakellyNessuna valutazione finora

- Bolt Torque ASME B16.5 Flanges - Spiral Wound GasketsDocumento31 pagineBolt Torque ASME B16.5 Flanges - Spiral Wound Gasketsbakelly100% (5)

- Youngs Modulus b3 2010Documento2 pagineYoungs Modulus b3 2010bakellyNessuna valutazione finora

- Flange Design Mmcobc 3.1 2010Documento6 pagineFlange Design Mmcobc 3.1 2010bakellyNessuna valutazione finora

- Design of Flanges - Optional Type 2010Documento59 pagineDesign of Flanges - Optional Type 2010bakellyNessuna valutazione finora

- Horizontal Cylindrical Pressure Vessvessel Zick 03Documento12 pagineHorizontal Cylindrical Pressure Vessvessel Zick 03bakelly0% (1)

- Design of Flanges - Full-Face Gasket 2010Documento29 pagineDesign of Flanges - Full-Face Gasket 2010bakelly100% (2)

- Design PhilosophiesDocumento23 pagineDesign PhilosophiesTeju AshuNessuna valutazione finora

- IPIMS Background Learning - Drillstring, Drill Bits and Drilling FluidDocumento14 pagineIPIMS Background Learning - Drillstring, Drill Bits and Drilling Fluidfebry_rfNessuna valutazione finora

- Expansion Loop Flexibility Analysis (Weaver)Documento3 pagineExpansion Loop Flexibility Analysis (Weaver)bakelly100% (1)

- Asme BPVC II Part D Material Strengths 01Documento7 pagineAsme BPVC II Part D Material Strengths 01bakellyNessuna valutazione finora

- Corrective Action Report March 2013Documento14 pagineCorrective Action Report March 2013Jaijeev Pali50% (2)

- Yield Strength 01Documento2 pagineYield Strength 01bakellyNessuna valutazione finora

- Flange Design Mmcobc 3.3 2010Documento3 pagineFlange Design Mmcobc 3.3 2010bakellyNessuna valutazione finora

- 777D 3PR Senr6910Documento2 pagine777D 3PR Senr6910Putra Jawa100% (1)

- Linear Thermal Expansion b4 2010Documento2 pagineLinear Thermal Expansion b4 2010bakellyNessuna valutazione finora

- Metric Bolt Data - Torque - Thread StrengthDocumento10 pagineMetric Bolt Data - Torque - Thread StrengthbakellyNessuna valutazione finora

- Metric Bolt Data - Torque - Thread StrengthDocumento10 pagineMetric Bolt Data - Torque - Thread StrengthbakellyNessuna valutazione finora

- PenstockDocumento7 paginePenstockmodest_dhuNessuna valutazione finora

- Design of Flanges - Loose Hub Type 2010Documento58 pagineDesign of Flanges - Loose Hub Type 2010bakellyNessuna valutazione finora

- Pipe Span Without Point LoadsDocumento36 paginePipe Span Without Point Loadsbakelly100% (4)

- Pipe Span Without Point LoadsDocumento36 paginePipe Span Without Point Loadsbakelly100% (4)

- Vendors (Supplies Provider)Documento257 pagineVendors (Supplies Provider)Nawair Ishfaq33% (3)

- Product Mix NotesDocumento9 pagineProduct Mix NotesAANessuna valutazione finora

- Wedge Wire ScreensDocumento6 pagineWedge Wire Screenscumpio425428Nessuna valutazione finora

- Project Report On Self Compacting ConcreteDocumento94 pagineProject Report On Self Compacting ConcreteSunilkumar Ce100% (3)

- GB-T 11263-2010Documento17 pagineGB-T 11263-2010shankarmech04@gmail.comNessuna valutazione finora

- Chemrite 303 SPDocumento3 pagineChemrite 303 SPICPL-RWPNessuna valutazione finora

- Philippine Green Building CodeDocumento64 paginePhilippine Green Building CodeTina Cruz100% (1)

- ASME B16.5 Class 150 & 300 Flanges Studbolt LengthDocumento3 pagineASME B16.5 Class 150 & 300 Flanges Studbolt LengthbakellyNessuna valutazione finora

- App 710Documento20 pagineApp 710Sueli E FranciscoNessuna valutazione finora

- Updated Paving Notice For Leghorn AvenueDocumento2 pagineUpdated Paving Notice For Leghorn AvenueAlexis TarraziNessuna valutazione finora

- Allectra 12 KF IsoDocumento20 pagineAllectra 12 KF Isomsyan1965Nessuna valutazione finora

- Foam Performance of A New HMS-PP-paperDocumento5 pagineFoam Performance of A New HMS-PP-paperDebabrata MukhopadhyayNessuna valutazione finora

- 13 Chapter 2Documento36 pagine13 Chapter 2Ibtisam SaidNessuna valutazione finora

- The Wolf of Wall StreetDocumento20 pagineThe Wolf of Wall StreetBoris PopovNessuna valutazione finora

- ME6402 MT-II - by Civildatas - Com 12Documento14 pagineME6402 MT-II - by Civildatas - Com 12Muhammed SalmanNessuna valutazione finora

- Material Specification Slab: Second Floor Design Criteria (NSCP 2015, TABLE 204-2)Documento4 pagineMaterial Specification Slab: Second Floor Design Criteria (NSCP 2015, TABLE 204-2)hhhh0% (1)

- hp26 Eng HandbookDocumento58 paginehp26 Eng HandbookxbinfluxNessuna valutazione finora

- Boitier de Commande PDFDocumento4 pagineBoitier de Commande PDFAnonymous oDi9mLNessuna valutazione finora

- 40S Be 0258Documento89 pagine40S Be 0258Saleh HassanNessuna valutazione finora

- 9 Health and SafetyDocumento2 pagine9 Health and SafetyHéctorNessuna valutazione finora

- nrcs142p2 - 024468 (Autoguardado)Documento1 paginanrcs142p2 - 024468 (Autoguardado)Luis RamirezNessuna valutazione finora

- SSCWG7 Repan3 Convers Fact Solar CollectorsDocumento3 pagineSSCWG7 Repan3 Convers Fact Solar CollectorsMeng SunNessuna valutazione finora

- Verbal Reasoning Test1 SolutionsDocumento3 pagineVerbal Reasoning Test1 SolutionsmaheshprabhumnmNessuna valutazione finora

- P 340 SDocumento190 pagineP 340 SPera PericNessuna valutazione finora

- Warehouse CodeDocumento348 pagineWarehouse CodeSaddamHossain100% (1)