Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Oled

Caricato da

Lakshmi KanthDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Oled

Caricato da

Lakshmi KanthCopyright:

Formati disponibili

Abstract

We developed white OLED device with extremely high power efficiency and long Lifetime, in which blue, yellowgreen and red phosphorescent emitters were used. The performance achieved was 64lm/W, and 10000 hours of Lifetime at initial luminance of 1000cd/m2 with light out-coupling technique. New technologies, such as blue phosphorescent materials and sophisticated organic layer structure, were applied to the device. The device also exhibited good durability such as storage stability, which is important performance in practical use. We hope that the development discussed in this paper opens up a course to practical use of OLED in lighting sources for illumination use, backlights and others. (Details of this paper was presented at SID 2007.)

1. Introduction

From a recent environmental problem and energy supply circumstances, light sources of low energy consumption and eco-friendly are demanded. An enormous amount of research effort goes into the field. And inorganic and organic light-emitting diodes attract attention as candidates of this new light source for these past several years. Organic light-emitting diode (OLED) is regarded as a powerful candidate because it is an area light source, can be driven at low voltage such as several voltage, and does not include a material which is harmful to the human body and environment like mercury. As a light source for illumination or backlight, a white light is usually required. To realize a white OLED device, plural light emissive materials such as blue, green, red are used generally. OLED is classified roughly into two types by a difference of mechanism of emission, namely the fluorescent OLED or phosphorescent OLED. It is well known that the phosphorescent OLED is advantageous from an aspect of emission quantum efficiency [1]. For example, Y. Tung et al. reported a phosphorescent white OLED with power efficiency of 18.4lm/W and 16% external emission quantum efficiency (EQE) [2]. However it has been difficult to make a phosphorescent white OLED of a practical performance level because blue phosphorescent materials didnt have enough performance, especially operating stability. Recently, remarkable improvement was achieved about the operating stability of blue phosphorescent material. M. S. Weaver et al. reported blue phosphorescent OLEDs with improved operating stability [3]. And B. W. DAndrade et al. reported a phosphorescent white OLED with 14% EQE and a long Lifetime [4]. Konica Minolta Technology Center, Inc. also pushes forward development of blue phosphorescent materials, and recently succeeded to develop blue phosphorescent dopant and host materials which have superior durability. These materials have 16000 hours of Lifetime from initial luminance to a half at initial luminance of 300cd/m 2. By using these materials and technology of organic layer design, we developed phosphorescent white OLED of performance, such as power efficiency, operating stability and storage stability, at a level of practical use. In this paper, we discuss outline of the technology and major performances of the white OLED developed.

2. Target of Power Efficiency

To replace a conventional light source with a OLED device, it is important to raise power efficiency of OLED to the level that can compete with the level of conventional light sources. Generally, power efficiency is about 10 20lm/W for electric bulbs and 60 - 90lm/W for fluorescent lamps. Therefore, we aimed at 60lm/W as the first step of development of white OLED. It is well known that considerable amount of the emitted light of OLED is confined in the device. Therefore various light out-coupling techniques have been developed to take out the confined light to the outside of the device. The confined light exists as glass mode or waveguide mode, and it is comparatively easy to take out the glass mode. Using light out-coupling technique to take out the glass mode light, 1.6 times increase of the external quantum efficiency could be achieved. Assuming the 1.6 times of the efficiency of light out-coupling, 38lm/W without light out-coupling is necessary to obtain 60lm/W. Then how much EQE and drive voltage of device are necessary to get this power efficiency?

Fig.1 shows the relations with power efficiency and drive voltage, and the dependence on EQE in a case of the OLED device which emits warm white color.

For example, it is shown that the drive voltage less than 3.8V with 20% EQE is necessary to obtain 38lm/W, although these values change to some extent depending on the emission spectrum. If the EQE is 12.5%, the voltage less than 2.5V is necessary, and the voltage less than 1V if it is 5%. The voltage less than 2.5V is less than emission energy of the blue emissive material so that it is impossible to make a device. That is to say, the achievement of EQE of around 20% is required to get 38lm/W. By the way, because the maximum of EQE in fluorescent OLED is generally around 5%, power efficiency of 38lm/W cannot be obtained. It is the reason that we wrestle with the development of phosphorescent OLED. Based on such consideration, we developed organic materials and designed organic layer structure paying attention to achieve 20% EQE and the drive voltage less than 4V.

3. Experimental

Organic layers were evaporated on ITO anode on a glass substrate. Al was used to the cathode. As carrier injection and transport layers across the emission layers, we used materials which had high carrier mobility, and optimized the constitution of layers to decrease the drive voltage. In the electron injection and transport layer, a material developed by Konica Minolta Technology Center, Inc. was used. The emission layers included blue, yellow-green and red phosphorescent dopants and a host material. Blue dopant and host material was developed by Konica Minolta Technology Center, Inc. Yellow-green and red dopants were obtained from Universal Display Corporation. Glass cap encapslation was done by using UV hardening glue in pure dried N2. Absorbents were included in the device. Emission area was 4mm2 or 15cm2. Performance of both device is nearly the same. IVL characteristics and emission spectra were measured by spectrophotometer Konica Minolta Sensing CS1000. In calculation of power efficiency, revision of light population on the device surface was done. Lifetime is defined by time before reaching the luminance reduction by half from the initial luminance under consecutive drive conditions. Storage stability was evaluated in accelerating condition of 85 degrees centigrade.

4. Performance of Efficiency and Lifetime

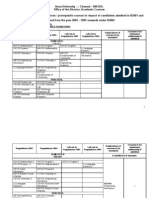

Major performance is shown in Table 1. As for a warm white color device whose color temperature is 4000K and CIE1931 color coordinates of (0.39, 0.43), 20% EQE, drive voltage of 3.7V and power efficiency of 37lm/W were obtained at 1000cd/m2. With light out-coupling technique in which optical film was set up on surface of a glass

substrate, 34% EQE and 64lm/W of power efficiency were achieved at 1000cd/m 2. In addition, CRI value was 76. We can change color temperature and CRI value comparatively by balancing blue, green and red dopants. Table 1 Performances of all phosphorescent white OLED at 1000cd/m 2 without light out-coupling.

Power Efficiency

EQE

Driving Voltage

Color Coordinate

37lm/W

20%

3.7V

0.39, 0.43

Fig.2 shows dependence of EQE on luminance. It shows that 20% EQE was obtained at 1000cd/m 2.. The dependence of EQE on luminance is small although there is a tendency that EQE slightly falls in the high luminance side for a peak at 100cd/m2. Therefore we can assume that the organic layer structure maintains good carrier balance over a wide luminance range. Fig.3 shows dependence of luminance on drive voltage.

Fig.4 shows operating stability under consecutive drive condition. Initial luminance was 3000cd/m 2. Based on the assumption that Lifetime is inverse proportion to luminance-1.5, Lifetime shown was equivalent to Lifetime of 10000 hours at initial luminance of 1000cd/m2 with light out-coupling technique. These performances were achieved by the following technology. Primarily, we use blue phosphorescent dopant and host materials with high emission efficiency and long Lifetime. The performance of these materials was 17% EQE and Lifetime of 16000 hours at initial luminance of 300cd/m 2.

Using these materials developed, realization of the all phosphorescent white OLED device which had high efficiency was enabled. Second, we designed the emission layers to achieve 20% EQE. External quantum efficiencies of the blue,

yellow-green and red dopants in the layer structure which was similar in the white OLED were 17%, 17%, 12% each. It is possible to calculate EQE of white OLED by using these values. If each dopant emits light with above EQE in the white OLED, the calculated EQE of white light becomes only about 15%. This calculated efficiency does not reach to 20% EQE of our target. One possibility to raise the EQE further is to use carrier blocking technique in which carrier blocking layers are set at both sides of the emitting layer. However, this technique is often accompanied with deterioration of Lifetime because of carrier accumulation in emission layer blocking layer interface. We achieved EQE of 20% without using such a technique by optimizing layer structure and dopant distribution in the emission layers. Third, doping technology to the electron transport layer was introduced to achieve low drive voltage. The drive voltage fell 2V - 3V in comparison with a case that Alq3/LiF was used in electron transport and injection layers. It contributes improvement of power efficiency greatly. Although it is known till now about metal doping technique to electron transport layer, there is concern about the durability. We were able to obtain the electron transport layer with superior durability described in the following chapter by developing electron transport materials.

5. Performance of Color Stability

For light sources, especially illumination light sources, color stability while driving a device is an important characteristic and lowering a color change as much as possible is demanded generally. As a result of an effort to suppress a color change while driving a device by optimizing the emission layers design, the color change in the Lifetime period in which luminance becomes half of the initial value was under E 0.03, where E=(x2+y2) and x, y are CIE1931 color coordinates.

6. Performance of Thermal Stability

Storage stability is also as important as color stability in practical use. Storage stability about luminance and color measured by the accelerating condition of 85 degrees centigrade are shown in Fig.5. Change of the luminance is only less than 1%, and color change E is also only less than 0.005. In addition, outbreak of dark spot and decrease of emission area was not seen as shown in photographs in Fig.6.

An accelerating condition of 85 degrees centigrade was used. Measurements were done under a constant electric current at room temperature. The current density used was 2.5mA/cm 2. Open circles ( ) indicate luminance and triangles ( ) indicate color shift.

The left is a photograph before a save at 85 degrees centigrade. The right is a photograph after a save of 520 hours at 85 degrees centigrade.

7. Summary and Conclusion Remarks

We developed the all phosphorescent white OLED device which has power efficiency of 64lm/W, Lifetime of 10000 hours at initial luminance of 1000cd/m 2 with a light out-coupling technique. EQE of 20% and low drive voltage that is near 3.5V was realized. Realization of the performance was due to development of organic materials, such as blue phosphorescent and electron transport materials, and progress of organic layer structure design technology. As shown in Fig.7, performance of the OLED developed surpasses electric bulbs and is reaching a domain of fluorescent lamps. Although further detailed examination will be needed in future, a good characteristic about durability, such as storage stability, which is important in practical use was obtained so far.

For future, further improvement of Lifetime will be necessary while improving power efficiency. If a device of longer Lifetime is realized, the foot of the application spreads out greatly. We hope that the development discussed in this paper opens up a course to practical use of OLED as lighting sources for illumination use, backlights and others.

8. References

[1] M. A. Baldo, S. Lamansky, P. E. Burrows, M. E. Thompson and S. R. Forrest, Very high-efficiency green lightemitting devices based on electrophosphorescence, Appl. Phys. Lett. Vol.75, p. 4, 1999.

[2] Y. Tung, T. Ngo, M. Hack, J. Brown, N. Koide, Y. Nagara, Y. Kato, H. Ito, A high efficiency phosphorescent white OLED for LCD backlight and display applications, SID Symposium Digest, Vol.35, p. 48-51, 2004. [3] M. S. Weaver, Y. J. Tung, B. DAndrade, J. Esler, J. J. Brown, C. Lin, P. B. Mackenzie, R. W. Walters, J. Y. Tsai, C. S. Brown, S. R. Forrest, M. E. Thompson, Advances in Blue Phosphorescent Organic Light-Emitting Devices, SID Symposium Digest, Vol. 37, p. 127-130, 2006 [4] B. W. DAndrade, J-Y. Tsai, C. Lin, M. S. Weaver, P. B. Mackenzie, J. J. Brown, Phosphorescent white organic light-emitting diodes for displays and lighting, Proceedings of The 13th International Display Workshops, p. 469-472, 2006.

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Fundamentals of Control SystemsDocumento18 pagineFundamentals of Control SystemsShiva Sai BuraNessuna valutazione finora

- Worksheet 13 PDFDocumento4 pagineWorksheet 13 PDFVijay Bhaskar50% (2)

- Huawei Data Center Facilities Product Catalog 2Documento32 pagineHuawei Data Center Facilities Product Catalog 2Rizal BachtiarNessuna valutazione finora

- DipDocumento1 paginaDipLakshmi KanthNessuna valutazione finora

- Ieee 1394 (Aka Firewire & Ilink ) : Electus Distribution Reference Data Sheet: Firewire PDFDocumento3 pagineIeee 1394 (Aka Firewire & Ilink ) : Electus Distribution Reference Data Sheet: Firewire PDFLakshmi KanthNessuna valutazione finora

- Warwick Halls Presentation Australian StandardDocumento32 pagineWarwick Halls Presentation Australian StandardLakshmi KanthNessuna valutazione finora

- Using Nanotechnology to Create Perfectly Engineered Concrete AggregatesDocumento10 pagineUsing Nanotechnology to Create Perfectly Engineered Concrete AggregatesLakshmi KanthNessuna valutazione finora

- What Is Passive Solar DesignDocumento21 pagineWhat Is Passive Solar DesignLakshmi KanthNessuna valutazione finora

- Plasma AntenasDocumento4 paginePlasma AntenasLakshmi KanthNessuna valutazione finora

- Antenna in Plasma (AIP) Code: Timothy W. Chevalier Umran S. Inan Timothy F. BellDocumento33 pagineAntenna in Plasma (AIP) Code: Timothy W. Chevalier Umran S. Inan Timothy F. BellLakshmi KanthNessuna valutazione finora

- Lecture5 Chapter2 - Positive and Negative LogicDocumento11 pagineLecture5 Chapter2 - Positive and Negative LogicAyesha HussainNessuna valutazione finora

- SG30 - 33 - 40 - 50CX User ManualDocumento110 pagineSG30 - 33 - 40 - 50CX User ManualAntonio Ruiz JiménezNessuna valutazione finora

- Computer Components Worksheet 1A Processor ComponentsDocumento2 pagineComputer Components Worksheet 1A Processor ComponentsShakila.D Raks PallikkoodamNessuna valutazione finora

- DM CBL 8g PDocumento2 pagineDM CBL 8g Pfaruk604Nessuna valutazione finora

- PD Smart PDFDocumento2 paginePD Smart PDFAriel Leandro Toro MuñozNessuna valutazione finora

- 800xa Outline - IO Systems - S800 IODocumento20 pagine800xa Outline - IO Systems - S800 IOKourosh52Nessuna valutazione finora

- A Review On Recent Progress of Portable Short-Range Noncontact Microwave Radar SystemsDocumento15 pagineA Review On Recent Progress of Portable Short-Range Noncontact Microwave Radar SystemsAhmed HussainNessuna valutazione finora

- ASUS Sound Card GuideDocumento1 paginaASUS Sound Card GuideilabuloNessuna valutazione finora

- Jevi - Junction Boxes For Immersion Heaters - Technical Data SheetDocumento2 pagineJevi - Junction Boxes For Immersion Heaters - Technical Data SheetHasibKaabiNessuna valutazione finora

- Star Rating List For Distribution TransformerDocumento71 pagineStar Rating List For Distribution TransformerSagar SinghNessuna valutazione finora

- General : Group 00EDocumento16 pagineGeneral : Group 00Eopa952ya.ruNessuna valutazione finora

- Detail of Maximum Current - ChillersDocumento3 pagineDetail of Maximum Current - ChillersMohamed RifanNessuna valutazione finora

- Lightning Arrester Modeling Using Atp-Emtp: Trin Saengsuwan and Wichet ThipprasertDocumento4 pagineLightning Arrester Modeling Using Atp-Emtp: Trin Saengsuwan and Wichet ThipprasertgumilarNessuna valutazione finora

- Alto Mistral 6000 PWR SM PDFDocumento33 pagineAlto Mistral 6000 PWR SM PDFmundomusicalmeriaNessuna valutazione finora

- Anna University: : Chennai - 600 025. Office ofDocumento8 pagineAnna University: : Chennai - 600 025. Office ofafzalbaigsa100% (2)

- Degaussing Coil in CRT TelevisionDocumento2 pagineDegaussing Coil in CRT TelevisionSanie D. AbarrientosNessuna valutazione finora

- Applying the commutator transformation C2 for synchronous machinesDocumento8 pagineApplying the commutator transformation C2 for synchronous machinesAli AldesogeNessuna valutazione finora

- Digital Logic Design Course Objectives and UnitsDocumento2 pagineDigital Logic Design Course Objectives and UnitsRameshchandra K ECENessuna valutazione finora

- Sae Ue Ms Csawe ManualDocumento2 pagineSae Ue Ms Csawe Manualvitgahi0% (1)

- 5 Pen PC Technology PDFDocumento8 pagine5 Pen PC Technology PDFNikitha ReddyNessuna valutazione finora

- Conectores CaterpillarDocumento101 pagineConectores Caterpillarwilintonariza100% (7)

- LC 22 Le 320Documento367 pagineLC 22 Le 320Yanto SaeNessuna valutazione finora

- Description and Classification of Electromagnetic Environments - Revision of IEC 61000-2-5Documento5 pagineDescription and Classification of Electromagnetic Environments - Revision of IEC 61000-2-5AAAAANessuna valutazione finora

- Pulse Transfer Function and Block DiagramsDocumento41 paginePulse Transfer Function and Block DiagramsArif HassanNessuna valutazione finora

- Compressor Control Valve Identification: Product BulletinDocumento4 pagineCompressor Control Valve Identification: Product BulletinIgnasiNessuna valutazione finora

- CQI Feedback ModesDocumento6 pagineCQI Feedback ModesravitejagowdaNessuna valutazione finora