Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Final Work

Caricato da

Mujaahiid BheekharryDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Final Work

Caricato da

Mujaahiid BheekharryCopyright:

Formati disponibili

The UTM accessories and wears shop

PROJECT CHARTER Project Name: UTM accessories and wears shop Project Start Date: 15/01/2009 1.0 INTRODUCTION

University of Technology, Mauritius is a tertiary educational institute situated at La Tour Koenig, Pointes aux Sables. UTM has started its operation since January 2000 and has now become one of the leading tertiary educational institute in Mauritius. UTM has about 2500 students studying with both full time and part time courses.

Project End Date: 31/12/2011

1.1

PROBLEM STATEMENT

We have noticed that in the recent years, there has been a lack of facilities in terms of educational materials for the student such as printing, photocopy service and educational accessories.

1.2

PROPOSED SOLUTION

Having analysed the situation with the help of conducting a market survey, we are proposing to open a shop on the UTM campus to meet the needs of all the students coming to this university.

2.0

PROJECT DEFINITION

This is our project on the opening of a shop selling accessories and wears for the students at the University of Technology, Mauritius. The project will last for 3 years.

3.0

PROJECT GOALS AND OBJECTIVES

The UTM accessories and wears shop

3.1

GOALS

Provide a variety of educational accessories at a reasonable price Provide wears and badge which has UTM logo Provide better customer service to student Improve the branding of UTM in Mauritius

3.2

SCOPE

The scope can be divided into 2 main parts: Activities Requirements

3.2.1 ACTIVITIES

Tender Patent & Registration of Company Building Market Survey Furniture Internal decoration Supplier

3.2.2 REQUIREMENTS

Student wears T-shirt / Track Suit / Cap / Badge Educational accessories o A4 Paper o Copybook o Pendrive o Pocket file o CD / DVD o Printing / Scanning machine o Binding machine

The UTM accessories and wears shop

4.0

BUDGET

The estimated cost for the project is Rs 1,500,000. Each of us (3 persons) will contribute Rs 500,000 as agreed.

5.0

STAKEHOLDERS

Owner Durbarry Mitish Alleesaib Zaynab Bheekharry S Mujaahiid El Registrar of UTM Students of UTM Suppliers Government

6.0

FEASIBILITY

The feasibility of a project can be ascertained in terms of technical factors, operational factors and economical factors. A feasibility study is documented with a report showing all the ramifications of the project. In project finance, the prefinancing work (sometimes referred to as due diligence) is to make sure there is no "dry rot" in the project and to identify project risks ensuring they can be mitigated and managed in addition to ascertaining "debt service" capability. We have chosen the 3 different types of feasibility to work out our project: Technical Operational Economical

6.1

TECHNICAL FEASIBILITY

Technical feasibility refers to the ability of the process to take advantage of the current state of the technology in pursuing further improvement. The technical capability of the personnel as well as the capability of the available technology 3

The UTM accessories and wears shop should be considered. Technology transfer between geographical areas and cultures needs to be analyzed to understand productivity loss (or gain) due to differences. Technical components related to the UTM accessories and wears shop are as follows: Building 20 * 20 feet size o Fitting room 5 * 5 feet size Furniture o 2 Office tables 8 * 2.5 feet o 2 Shelves 13 * 1 feet 11 * 1 feet o 3 Rack 9 * 4 feet o 3 Office chairs o 1 Bench 6 * 1.5 feet 1 Computer o Windows and Software integrated 1 Binding machine 1 Counter Machine 1 Integrated Scanner / Printing / Photocopy machine Painting and decoration Finish goods o A4 Paper 20 boxes o Copybook 4000 dozen o Pendrive 2GB 1500 o Pocket file A4 1000 o CD / DVD 5000 each Curtain twice (10 * 5 feet) Mirror 8 * 3 feet Fittings

The UTM accessories and wears shop o Track suit 250 small size 500 medium size 500 large size o T-shirt 500 small size 1000 medium size 1000 large size o Cap 1500 o Metal badge 1000 Notes: All the finish goods like copybook, pocket file, track suit, t-shirt, cap and badge will all have UTM logo on it.

6.1.1 ASSUMPTIONS

Room UTM will provide us the room B0.05 to do the shop. Electricity The room in which we are going to open the shop will have all the electricity connection available in it with socket and lighting already fixed. Water and toilets We will use the UTM toilet and water facilities. Air-conditioning The room in which we are going to do the shop will already have 2 air-conditioning fixed in it. Telephone & internet wire The room will also have rapid internet facilities and telephone cable.

The UTM accessories and wears shop

6.1.2 PLAN OF THE SHOP

13 feet 20 feet 5 feet

1 feet

A B

5 feet

20 feet 8 feet

H I N O P

11 feet

C

KEY MAPS 6

The UTM accessories and wears shop

A: Shelves of size 13 ft by 1 ft B: Fitting room of size 5 ft by 5 ft C: Shelves of size 11 ft by 1.5 ft D: Windows E: Door F: Bench of size 6 ft by 1.5 ft G: Counter machine H: Computer I: Table of size 8 ft by 2.5 ft J, K and L: Chairs M: Photocopy/Scanner/Printing machine N, O and P: Stand (tag) 9 ft by 4 ft

6.2

OPERATIONAL FEASIBILITY

Define the urgency of the problem and the acceptability of any solution; if the system is developed, will it be used? It includes people-oriented and social issues: internal issues, such as manpower problems, labour objections, manager resistance, organizational conflicts and policies; also external issues, including social acceptability, legal aspects and government regulations. In view to the current environment the project is operationally feasible. The current characteristics are as follows: Manpower Legal framework Resources

In view of the fact that the location chosen to open the shop will be on the UTM campus for both full time and part time students, there would not have any adverse effect on the society. Instead, it will be a positive advancement for all the students studying in this university. The project is in line with all legal requirements because the municipality itself is providing facilities in getting government permits such as patent and other permit to 7

The UTM accessories and wears shop operate. For the shop to operate normally it requires 3 staffs to work; 1 as a cashier and 2 sales representatives. Assumptions: As we will owe the shop, we will occupy the different available job. We will work in a profit sharing ratio. Supplier of furniture: TFP Courts (Selected Supplier) Neel industry

Supplier of wears: Allports Ltd Citizen Sports Swaze International Ltd (Selected Supplier)

Supplier of computer and related materials: ACD Computer Ltd Jacey Computer Services Task Computer (Selected Supplier)

Supplier of UTM badge: Metal Casting Ltd (Selected Supplier) Beryl Rose Ltd

Supplier of paints: Mauvilac Permoglaz (Selected Supplier)

Supplier of paper: Ramtoola

The UTM accessories and wears shop Marcello MWT (Selected Supplier)

6.3

ECONOMICAL FEASIBILITY

This involves the feasibility of the proposed project to generate economic benefits. A benefit-cost analysis and a breakeven analysis are important aspects of evaluating the economic feasibility of new industrial projects. The tangible and intangible aspects of a project should be translated into economic terms to facilitate a consistent basis for evaluation.

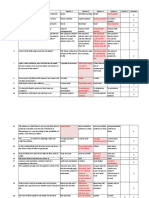

6.3.1 CAPITAL COST

Capital Cost for the shop

Unit Cost COMPANY REGISTRATION Permit FITTING ROOM Curtain 10 * 5 feet Mirror 8 * 3 feet Fittings FURNITURE Office tables Shelves 13 * 2 feet 11 * 2 feet Rack Stand for clothing hanger Chairs (Standard) Bench 8 * 2 feet Rs 1000 Rs 100 Rs 300 Rs 150 Rs 1500 Rs 10,000 Rs 7000 Rs 500 Rs 750 Rs 500 2 Quantity Total Cost Rs 1000 Rs 200 Rs 300 Rs 150 Rs 3000 Rs 10,000 Rs 7000 Rs 1500 Rs 2250 Rs 500 Rs 16,000

2 1 1 3 3 1 1

COMPUTER PC - Windows and Software Rs 16,000 integrated Counter machine Binding machine Rs 1500 Rs 750

1 1 1

Rs 1500 Rs 750 Rs 5000

Printing / Scanning / Photocopy Rs 5000 Machine

The UTM accessories and wears shop PAINTING & DECORATION Paints & other decorations FINISH GOODS A4 Paper Copybook Pendrive 2 GB A4 Pocket file 30 folder CD DVD Track suit (Small Size) (Medium Size) T-Shirt (Large Size) (Small Size) (Medium Size) (Large Size) Cap Badge Total Cost

Rs 1000 Rs 1875 Rs 30 Rs 150 Rs 7.50 Rs 0.25 Rs 1 Rs 150 Rs 225 Rs 275 Rs 50 Rs 75 Rs 100 Rs 50 Rs 25 20 Box 4000 dozen 1500 1000 5000 5000 250 500 500 500 1000 1000 1500 1000

Rs 1000 Rs 37,500 Rs 120,000 Rs 225,000 Rs 7500 Rs 1250 Rs 5000 Rs 37,500 Rs 112,500 Rs 137,500 Rs 25,000 Rs 75,000 Rs 100,000 Rs 75,000 Rs 25,000 Rs1,033,900

6.3.2 RECURRENT COST

Recurrent Cost for the shop

Monthly Cost BUILDING B0.05 Room SALARY Sales Representatives Cashier Rs 5000 Rs 7500 Rs 8000 2 1 Quantity Total Cost Rs 5000 Rs 15,000 Rs 8000

Recurrent detail cost

January Rent Rs 2500 Salary Rs 23000 Telephone Rs 300 Electricity Rs 300

10

The UTM accessories and wears shop February March April May June July August September October November December Total Gross Total Rs 5000 Rs 5000 Rs 5000 Rs 5000 Rs 2500 Rs 5000 Rs 5000 Rs 5000 Rs 2500 Rs 42500 Rs 280500 Rs 23000 Rs 23000 Rs 23000 Rs 23000 Rs 23000 Rs 23000 Rs 23000 Rs 23000 Rs 23000 Rs 230000 Rs 300 Rs 300 Rs 300 Rs 300 Rs 100 Rs 100 Rs 300 Rs 300 Rs 300 Rs 300 Rs 300 Rs 3200 Rs 500 Rs 500 Rs 500 Rs 500 Rs 200 Rs 200 Rs 300 Rs 500 Rs 500 Rs 500 Rs 300 Rs 4800

6.3.3 SALES REVENUE

Month January February March April May June July August September October November December Total

Revenue from sales

Rs 90,000 Rs 110,000 Rs 110,000 Rs 110,000 Rs 35,000 Rs 120,000 Rs 110,000 Rs 110,000 Rs 90,000 Rs 35,000 Rs 920,000

Benefits:

The Registrar of UTM has granted us to pay a halfly rental payment for the month of January, August and December as we will work for only 15 days during these months. There will be no rental payment for the month of June and July as the university will be closed for holidays.

11

The UTM accessories and wears shop On buying 20 boxes of A4 Paper from supplier MWT, 5 additional boxes were obtained freely. For pendrive, we have got 25 spare ones from Task Computer Ltd.

6.3.4 TECHNIQUES FOR ECONOMIC APPRAISAL OF THE PROJECT

Year 0 (1,033,900) (1,033,900) (1,033,900) (1,033,900) Year 1 (280,500) 920,000 639,500 (394,400) 581,363.6 Year 2 (280,500) 920,000 639,500 245,100 528,512.4 Year 3 (280,500) 920,000 639,500 884,600 480,465.8

Cost Revenue Net Cash Flow Cumulative Cash Flow Discounted Cash Flow (10%)

6.3.5 PAYBACK PERIOD

Payback period is a simple method of investment appraisal which looks at how quickly the cash flows arising from the project exactly equal to the amount of the original investment. We are considering to invest Rs 1,500,000 in the opening of the shop. The project will recover initial investment after two years.

6.3.6 RETURN ON INVESTMENT (ROI)

Average Annual Profit = = = ROI = = Total Net Cash Flow Investment / 3 1,918,500 1,033,900 / 3 Rs 294,866.7

(294,866.7 / 1,033,900) * 100 28.5%

It has an average annual profit of 28.5%.

6.3.7 NET PRESENT VALUE (NPV)

NPV = Total Discounted Cash Flow - Investment 12

The UTM accessories and wears shop

= =

(581,363.6 + 528,512.4 + 480,465.8) 1,033,900 1,590,341.8 1,033,900

= Rs 556,441.80 The project has a positive NPV, so the project is feasible.

7.0

WORK BREAKDOWN STRUCTURE

A complex project is made manageable by first breaking it down into individual components in a hierarchical structure, known as the work breakdown structure, or the WBS. Such a structure defines tasks that can be completed independently of other tasks, facilitating resource allocation, assignment of responsibilities, and measurement and control of the project.

UTM Shop

7.1

WBS DICTIONARY

Duration (week) 4 1 3 Dependency 1.2

Component 1.1 1.2 1.3

13

The UTM accessories and wears shop 1.4 1.5 6 1 1.1 1.2

7.2

GANTT CHART

10

8.0

CONCLUSION

For the UTM accessories and wears shop project, we have covered the project charter which includes the goals, scope, estimated budget, stakeholders and the general time-frame. We have also covered the feasibility study including the technical, operational, and economical. The overall project is feasible since the initial payback investment is recovered in a short period of 2 years, the average annual profit rate is 28.5% and the net present value is positive. The project will meet its goals as it will provide a competitive price for all the materials, better customer care and improve the branding of the UTM.

14

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Estimation Eirr 2014Documento11 pagineEstimation Eirr 2014M iqbalNessuna valutazione finora

- Finance BDM 04Documento88 pagineFinance BDM 04FrancisDrakeNessuna valutazione finora

- SSRN Id1282952Documento12 pagineSSRN Id1282952byakunomaureen3Nessuna valutazione finora

- IFM Methodology v2.0 - Final - 7.7.22Documento61 pagineIFM Methodology v2.0 - Final - 7.7.22Juan Manuel Cardona GrandaNessuna valutazione finora

- Scasher Mgmt471w Sbu Strategic Plan FinalDocumento33 pagineScasher Mgmt471w Sbu Strategic Plan FinalwerfsdfsseNessuna valutazione finora

- Banana Production (Lakatan) Project: A Business Plan of Ecleo FarmDocumento20 pagineBanana Production (Lakatan) Project: A Business Plan of Ecleo Farmmarkgil1990Nessuna valutazione finora

- Chapter 20 Corporate FinanceDocumento37 pagineChapter 20 Corporate FinancediaNessuna valutazione finora

- Chapter Six SlidesDocumento19 pagineChapter Six SlidesMohammad Jamal Al-AwamlehNessuna valutazione finora

- Pavement Type Selection For Developing Countries Applying Life Cycle Cost AnalysisDocumento7 paginePavement Type Selection For Developing Countries Applying Life Cycle Cost AnalysisIJAR JOURNALNessuna valutazione finora

- Mid-Semester Examinations Project Management MBAWPDocumento5 pagineMid-Semester Examinations Project Management MBAWPSujit ThiruNessuna valutazione finora

- Project Appraisal EMBA-524Documento18 pagineProject Appraisal EMBA-524Nasin BabuNessuna valutazione finora

- Investment DecisionDocumento26 pagineInvestment DecisionToyin Gabriel AyelemiNessuna valutazione finora

- Chapter 2 RDLDocumento16 pagineChapter 2 RDLStanley T. VelascoNessuna valutazione finora

- Accept Less - Reject Greater: IRR Is The Interest Rate That Makes The NPV 0: 0 +$200 - $2501+IRR Solving For IRRDocumento10 pagineAccept Less - Reject Greater: IRR Is The Interest Rate That Makes The NPV 0: 0 +$200 - $2501+IRR Solving For IRRAtheer Al-AnsariNessuna valutazione finora

- Pmba 6313 Week 2 HomeworkDocumento1 paginaPmba 6313 Week 2 HomeworkLucyNessuna valutazione finora

- MoS Porcini Assignment - Group3 - Sec ADocumento5 pagineMoS Porcini Assignment - Group3 - Sec AAshish Chauhan100% (1)

- Introduction To Asset Valuation and Discounting: Mathias SchmitDocumento38 pagineIntroduction To Asset Valuation and Discounting: Mathias SchmitPhương Phan Thị LanNessuna valutazione finora

- FM (3 Files Merged)Documento43 pagineFM (3 Files Merged)Priyanka MahajanNessuna valutazione finora

- Capital Budgeting ProcessDocumento19 pagineCapital Budgeting ProcessAbhishek GoelNessuna valutazione finora

- Evans TB Businessanalytics03 9781292339009Documento334 pagineEvans TB Businessanalytics03 9781292339009Nazia EnayetNessuna valutazione finora

- Chapter 1 Feasibility Study For Dance StudioDocumento9 pagineChapter 1 Feasibility Study For Dance StudioAlexander100% (1)

- PPP Financial Model ToolDocumento310 paginePPP Financial Model Toolniranjanchou100% (1)

- FIN5203 Midterm Exam 2 FL22 ReviewDocumento46 pagineFIN5203 Midterm Exam 2 FL22 Reviewmerly chermonNessuna valutazione finora

- Logistics 25 FreeDocumento11 pagineLogistics 25 FreeCassandra StapelbergNessuna valutazione finora

- Fin 202Documento28 pagineFin 202herueuxNessuna valutazione finora

- Lecture 03 - Project Risk AnalysisDocumento40 pagineLecture 03 - Project Risk AnalysisDanila GallaratoNessuna valutazione finora

- 03-PMP Project Charter - TestDocumento5 pagine03-PMP Project Charter - TestIRVINNessuna valutazione finora

- BDP ResortDocumento30 pagineBDP ResortRitesh GhimireNessuna valutazione finora

- Mcom Sem IV FM MCQ For Collage Web1Documento4 pagineMcom Sem IV FM MCQ For Collage Web1Avi DVNessuna valutazione finora

- Capital Budgeting TechniquesDocumento11 pagineCapital Budgeting Techniquesnaqibrehman59Nessuna valutazione finora