Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Lab 1

Caricato da

Edward WangDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Lab 1

Caricato da

Edward WangCopyright:

Formati disponibili

The purpose of this lab is to form 4-cyclohexene-cis-1,2-dicarboxylic anhydride using 3sulfolene and maleic anhyride using microscale reflux.

The product was then characterized by using the melting point set up and IR. The Diers-Alder Reaction is a thermal reaction that forms six-membered rings from a diene and a dienophile. The dienophile (almost any non-conjugated alkene) reacts with the cisdiene (alkene that contains two conjugated pi bonds) through a [4+2] pi cycloaddition. In this addition, the 3 pi bonds of the diene and dienophile are broken, and the six- membered ring is then created when 2 sigma and 1 pi bond is formed from the 6 electrons of the 3 pi bonds broken. The Diers-Alder Reaction occurs as a single step mechanism, occurs only if the diene is in the cis conformation, and proceeds the quickest when the dienophile has more electron- withdrawing substituents. The mass of the 3-sulfolene reactant was that of 0.408g, and the mass of the maleic anhydride reactant was 0.181g. Based of the mass on the reactants, it was determined that the maleic anhydride was the limiting reactant, and since it was the limiting reactant, the theoretical mass of the product was calculated to be 0.281g. The experimental mass of the product, 4- cyclohexane-cis-1,2-dicarboxylic anhydride, was 0.183g. The percent yield was calculated using the equation: [experimental mass/ theoretical mass] * 100%. From the equation, it was determined that the percent yield of the product was 64.9%. The melting point of the product was between 92.0 to 96.0 degrees Celsius. However, the theoretical melting point of 4-cyclohexane- cis- 1,2- dicarboxylic anhydride was 103 degrees Celsius. This lowered melting point indicates impurites in the compound, either from unreacted reactants or from contamination. The IR obtained for the product showed two peaks, a large one at 1760cm-1, and a smaller one at 1830cm-1. These peaks corresponded to the theoretical IR bands, which called for 2 carbonyl peaks between 1880cm-1 and 1780cm-1 to be observed, and indicated the purity of the product obtained. Several sources of error occurred throughout the experiment. Firstly, the transfer of product from the conical vial to the Hirsch funnel resulted in some products left behind in the vial as the spatula could not fully transfer some of the products left in the bottom of the vial. This loss of product would account for the decreased percent yield. Secondly, despite the vacuum filtration, there might have been some water left in the product to contribute to its mass and therefore resulting in a falsely inflated theoretical yield. Lastly, there was contamination from the spin vane used, resulting in the product obtained being slightly brown rather than clear as it was supposed to be. This contamination from the spin vane might have resulted in the lower and broader melting point of 92.0 - 96.0 degrees Celsuis observed, rather than that of the theoretical 103 degrees Celsius.

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Concrete Damaged Plasticity ModelDocumento11 pagineConcrete Damaged Plasticity ModelStructural SpreadsheetsNessuna valutazione finora

- Virtual Lab Report: Name of The SimulationDocumento6 pagineVirtual Lab Report: Name of The Simulationkruyll vlogs0% (1)

- BS EN 12350-7:2000 Concrete Air Content Pressure MethodsDocumento19 pagineBS EN 12350-7:2000 Concrete Air Content Pressure MethodsKayathiri100% (1)

- Sist en 50363 1 2006Documento8 pagineSist en 50363 1 2006Jishnu MmNessuna valutazione finora

- Self-Etching Adhesives Increase Collagenolytic Activity in Radicular DentinDocumento7 pagineSelf-Etching Adhesives Increase Collagenolytic Activity in Radicular DentinPablo BenitezNessuna valutazione finora

- Department of Education: Name: - Grade 9 SectionDocumento3 pagineDepartment of Education: Name: - Grade 9 SectionChai BarcelonNessuna valutazione finora

- Strength & Durability of Pervious Concrete with SCMsDocumento14 pagineStrength & Durability of Pervious Concrete with SCMsAnsar AsrNessuna valutazione finora

- Homework 4Documento7 pagineHomework 4Alferid ShifaNessuna valutazione finora

- Aoc 2 - BiocatalysisDocumento22 pagineAoc 2 - BiocatalysisUsha gowdaNessuna valutazione finora

- Radioactive Waste ManagementDocumento38 pagineRadioactive Waste ManagementLuiejen GasconNessuna valutazione finora

- Exp. 3 Test For The Presence of Carbohydrates Molisch TestDocumento4 pagineExp. 3 Test For The Presence of Carbohydrates Molisch TestClarice Catorce100% (2)

- $RF1EYBQDocumento15 pagine$RF1EYBQLindsey BondNessuna valutazione finora

- 18 - Carbonyl CompoundsDocumento59 pagine18 - Carbonyl CompoundsenderothNessuna valutazione finora

- Super Gasoline 95 RONDocumento1 paginaSuper Gasoline 95 RONxtrooz abiNessuna valutazione finora

- Analytical Chemistry - Unit 2Documento18 pagineAnalytical Chemistry - Unit 2ariel egonNessuna valutazione finora

- Journal of Cleaner Production: Gauri A. Kallawar, Divya P. Barai, Bharat A. BhanvaseDocumento1 paginaJournal of Cleaner Production: Gauri A. Kallawar, Divya P. Barai, Bharat A. BhanvaseSANCHIT BIRENessuna valutazione finora

- Makrolon LED2245 - en - 81038415 00003726 19218403Documento4 pagineMakrolon LED2245 - en - 81038415 00003726 19218403dave judayaNessuna valutazione finora

- Edexcel GCE Biology / Biology (Human) (6101/01) : January 2006Documento10 pagineEdexcel GCE Biology / Biology (Human) (6101/01) : January 2006Mohammad Shahidullah ChowdhuryNessuna valutazione finora

- Steam Distillation - WikipediaDocumento16 pagineSteam Distillation - WikipediaAqsa QureshiNessuna valutazione finora

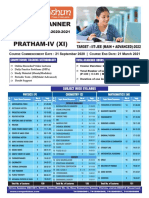

- Course Planner: ACADEMIC SESSION-2020-2021Documento2 pagineCourse Planner: ACADEMIC SESSION-2020-2021dr KNessuna valutazione finora

- SP Log: Saud Qadir Khan 2015-PET-17Documento3 pagineSP Log: Saud Qadir Khan 2015-PET-17Sunny BbaNessuna valutazione finora

- Experiment No. 6: Preparation and Standardization of Naoh and HCL SolutionDocumento3 pagineExperiment No. 6: Preparation and Standardization of Naoh and HCL SolutionJaxon DwyreNessuna valutazione finora

- Grade 8 AutoDocumento14 pagineGrade 8 AutoKariza PugalNessuna valutazione finora

- SepSolve Aroma Profiling of Wine Using Sorptive ExtractionDocumento7 pagineSepSolve Aroma Profiling of Wine Using Sorptive ExtractionDanaNessuna valutazione finora

- A Comparative Clinical Study On The Effect of Mrittika Lepa and Lodhradi Lepa in Yuvanapidika W.S.R To Acne VulgarisDocumento6 pagineA Comparative Clinical Study On The Effect of Mrittika Lepa and Lodhradi Lepa in Yuvanapidika W.S.R To Acne VulgarisIJAR JOURNALNessuna valutazione finora

- Reaction KineticsDocumento19 pagineReaction KineticsParthasarathiNessuna valutazione finora

- Hi Media Price List 2013-14Documento386 pagineHi Media Price List 2013-14kakoli_bhatt9067% (6)

- PerfectPleat SC M8 AFP-1-202Documento2 paginePerfectPleat SC M8 AFP-1-202ROLANDONessuna valutazione finora

- Chemleon Diagnostics Lab ReportsDocumento15 pagineChemleon Diagnostics Lab ReportsDinesh SreedharanNessuna valutazione finora

- An Unusual Intramolecular Halogen Bond Guides Conformational SelectionDocumento6 pagineAn Unusual Intramolecular Halogen Bond Guides Conformational SelectionPedroNessuna valutazione finora