Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Item 9000-5005 - Repair 5 Repair Concrete Pedestal S-31231

Caricato da

Ammar A. AliDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Item 9000-5005 - Repair 5 Repair Concrete Pedestal S-31231

Caricato da

Ammar A. AliCopyright:

Formati disponibili

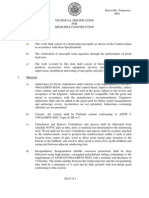

ITEM 9000-5005 REPAIR 5, REPAIR CONCRETE PEDESTAL, S-31231 -----------------------------------------------------------DESCRIPTION This work is replacing concrete pedestals with Class

ss A Cement Concrete as indicated. MATERIAL o Class A Cement Concrete Section 704, except use AASHTO No. 8 Coarse Aggregate. o Reinforcement Bars Section 709.1, epoxy coated. o Concrete Bonding Compound Section 706. o Annealed Iron Wire ASTM A684. o Non-Shrink Grout Section 1001.2(e). CONSTRUCTION (a) General. 1. Perform the work when the bridge is jacked-up, and the existing bearing is removed. 2. Provide safe access to concrete pedestals to permit the Representative to delineate the limits of repair. 3. Provide safe access for performance of the work. 4. Perform work in accordance with applicable parts of Section 1001.3 and as indicated. (b) Removal. 1. Provide satisfactory shielding below or adjacent to all areas of removal of concrete to protect areas below from falling debris. 2. Remove concrete as indicated. minimum clearance all around. Provide exposed reinforcement bars with a

3. Do not use pneumatic hammers heavier than nominal 30-pound class. 4. Use hand tools, such as hammers and chisels or small air chisels, to remove loose particles of unsound concrete or to provide necessary clearances around reinforcement bars. (c) Reinforcement. 1. Blast clean all exposed reinforcement to white metal. Remove and replace all portions of damaged or heavily corroded reinforcement bars (reinforcement with 25% loss or more) with the same size epoxy coated reinforcement. Splice new epoxy coated bars to the existing reinforcement. If sufficient splice length is not available, drill new dowel holes and place dowel bars as directed. 2. Place reinforcement within the repair area and tie to existing reinforcement bars and dowel bars as indicated. (d) Concrete Placement. 1. Set forms to original surface and maintain all chamfers, joints, and grooves. If clear concrete cover to the reinforcement bars is less than 2", set forms to

provide 2" of clear cover by adjusting the forms. Provide adequate ports for applying concrete bonding compound and placement of repair concrete. Use removable forms. 2. Blow-clean all removal areas with oil-free compressed air and protect against any contaminant detrimental to the bond of the new concrete. 3. Immediately prior to placing new concrete, apply concrete bonding compound to the area of existing concrete that is in contact with the new concrete. Place concrete against the bonding compound while it is still sufficiently tacky to provide a proper bond. Recoat bonding compound that is no longer tacky. Wirebrush or abrasive blast bonding compound that has hardened before recoating. 4. Place concrete in accordance with applicable parts of Section 1001.3. 5. Use water cure in accordance with Section 1001.3. permitted. MEASUREMENT AND PAYMENT Each Removal of existing concrete and placement of all repair materials are included in this item. Providing safe access for the Representative to determine limits of repair and inspect the work is incidental to this item. Membrane curing is not

Potrebbero piacerti anche

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDa Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsValutazione: 4 su 5 stelle4/5 (1)

- Technical ProposalDocumento6 pagineTechnical ProposalMark Sinclair100% (1)

- Domestic Water Standard Specifications Technical Conditions-20170825 - Complete - 201708251747350216Documento112 pagineDomestic Water Standard Specifications Technical Conditions-20170825 - Complete - 201708251747350216PankajNessuna valutazione finora

- Appendix 6.1 Structural Repairs To RCC Columns, Beams and SlabsDocumento4 pagineAppendix 6.1 Structural Repairs To RCC Columns, Beams and SlabsNirmal KishorNessuna valutazione finora

- Technical Specification For Micropile ConstructionDocumento9 pagineTechnical Specification For Micropile ConstructionFFerideKochanNessuna valutazione finora

- 2700 Wearings Coat and AppurtenancesDocumento5 pagine2700 Wearings Coat and Appurtenancesdhamu_i4uNessuna valutazione finora

- Optional Precast Reinforced Concrete (2-14-04) Box Culvert at StationDocumento5 pagineOptional Precast Reinforced Concrete (2-14-04) Box Culvert at StationSayed Moussa El-KellawyNessuna valutazione finora

- Item 03100 Concrete FormworkDocumento6 pagineItem 03100 Concrete FormworkNurLelyHardiantiZendratoNessuna valutazione finora

- Procurement of Infrastructure Projects: Hilippine Idding OcumentsDocumento6 pagineProcurement of Infrastructure Projects: Hilippine Idding OcumentsAlmira RoblesNessuna valutazione finora

- Precast Concrete CurbsDocumento3 paginePrecast Concrete Curbsgskodikara2000Nessuna valutazione finora

- Cutting, Coring and Patching - MSTDocumento3 pagineCutting, Coring and Patching - MSTwafikmh4Nessuna valutazione finora

- Drain PipeDocumento4 pagineDrain PipeNur HaryatiNessuna valutazione finora

- Manholes - MSTDocumento8 pagineManholes - MSTwafikmh4Nessuna valutazione finora

- Sequatchie Concrete Service: Precast Prestressed Hollow Core Concrete Floor and Roof Systems Design ManualDocumento31 pagineSequatchie Concrete Service: Precast Prestressed Hollow Core Concrete Floor and Roof Systems Design ManualNirmal KishorNessuna valutazione finora

- ManholesDocumento20 pagineManholesA.K.A. HajiNessuna valutazione finora

- Methodology For PIpe Culvert, Box-Culvert, Slab Drain, Minor Bridge & Major Bridge.Documento57 pagineMethodology For PIpe Culvert, Box-Culvert, Slab Drain, Minor Bridge & Major Bridge.Abhi100% (1)

- Division 5: Masonry SpecificationsDocumento9 pagineDivision 5: Masonry SpecificationsKae MoNessuna valutazione finora

- Cast in Place ConcreteDocumento16 pagineCast in Place ConcreteabdouNessuna valutazione finora

- Crakes (2) Segregation (6) Erosion: Mistakes in ConcreteDocumento23 pagineCrakes (2) Segregation (6) Erosion: Mistakes in ConcreteVishakha PatelNessuna valutazione finora

- Piling ProcedureDocumento7 paginePiling ProcedureimranNessuna valutazione finora

- Retrofitting For The Slab of An Existing Warehouse On PLOT L.R NO.11880/11 - NAIROBIDocumento9 pagineRetrofitting For The Slab of An Existing Warehouse On PLOT L.R NO.11880/11 - NAIROBImusiomi2005Nessuna valutazione finora

- SECTION 02605 Manholes: Part 1. GeneralDocumento11 pagineSECTION 02605 Manholes: Part 1. GeneralDaniel KariukiNessuna valutazione finora

- PCC P Thin White TopDocumento5 paginePCC P Thin White Topdemonfry69Nessuna valutazione finora

- BT 4Documento9 pagineBT 421-03606Nessuna valutazione finora

- Part S16 Cast in Place Concrete Piles (2008)Documento3 paginePart S16 Cast in Place Concrete Piles (2008)CK TangNessuna valutazione finora

- Pipe CoatingDocumento51 paginePipe CoatingAndy ChongNessuna valutazione finora

- Wearing CoatDocumento5 pagineWearing Coatnandi_scrNessuna valutazione finora

- Size Cased (If Contract Documents Specify The Cased Method.)Documento7 pagineSize Cased (If Contract Documents Specify The Cased Method.)jmpkumaraNessuna valutazione finora

- PSP024 - Precast Reinforced Concrete Box Culvert at Station PDFDocumento5 paginePSP024 - Precast Reinforced Concrete Box Culvert at Station PDFHpeso EmohseNessuna valutazione finora

- Masonry Works: HEO Architects Technical SpecificationDocumento6 pagineMasonry Works: HEO Architects Technical SpecificationDk MariNessuna valutazione finora

- PileDocumento5 paginePileSuman NakarmiNessuna valutazione finora

- Section 334110 - Storm Drainage: TA1056 MBI Sampang Agung Brewery ExtensionDocumento3 pagineSection 334110 - Storm Drainage: TA1056 MBI Sampang Agung Brewery Extensionery achjariNessuna valutazione finora

- Pipe Culverts MethodologyDocumento11 paginePipe Culverts MethodologyAbhiNessuna valutazione finora

- Section 5-Part 12-JointsDocumento6 pagineSection 5-Part 12-JointsAdamNessuna valutazione finora

- Specifications For Repair Work of ChimneyDocumento2 pagineSpecifications For Repair Work of ChimneyAkshay AmbadeNessuna valutazione finora

- SPC Occ 221423 MeDocumento4 pagineSPC Occ 221423 Metarekhisham1234Nessuna valutazione finora

- Marriot Grand Ballroom Concrete Works: Project Title: Contract Package No. Document TitleDocumento10 pagineMarriot Grand Ballroom Concrete Works: Project Title: Contract Package No. Document TitleImho TepNessuna valutazione finora

- Size, Height or Special. "AE" Denotes Air-Entrained Concrete. No Entry Denotes Concrete Without AirDocumento3 pagineSize, Height or Special. "AE" Denotes Air-Entrained Concrete. No Entry Denotes Concrete Without AirGeeta RamsinghNessuna valutazione finora

- ConstructionDocumento8 pagineConstructionGaspar Lig-ang TolomiaNessuna valutazione finora

- METHOD STATEMENT FOR EARLY WORKS PACKAGE Rev-3 - Emaar The ViewsDocumento6 pagineMETHOD STATEMENT FOR EARLY WORKS PACKAGE Rev-3 - Emaar The Viewsaliengineer953Nessuna valutazione finora

- Division 3 Concrete WorksDocumento9 pagineDivision 3 Concrete WorksMa Monica M. MuncadaNessuna valutazione finora

- Rock BoltDocumento5 pagineRock BoltMuhammad Noufal AchyarNessuna valutazione finora

- Specifications PDFDocumento30 pagineSpecifications PDFRivaiNessuna valutazione finora

- Casting Box Girder Segments - tcm45-342871Documento3 pagineCasting Box Girder Segments - tcm45-342871AuYongTheanSengNessuna valutazione finora

- 06 Specification Section036000 GroutingDocumento4 pagine06 Specification Section036000 GroutingOtceliban SarlNessuna valutazione finora

- SpecificationsDocumento10 pagineSpecificationsSilendrina MishaNessuna valutazione finora

- Hill Country StoneDocumento3 pagineHill Country StoneAJAYSINGLABTINessuna valutazione finora

- Steps For StrentheningDocumento2 pagineSteps For StrentheningsehikmatNessuna valutazione finora

- Method of State-WPS OfficeDocumento8 pagineMethod of State-WPS OfficeAsif SafiNessuna valutazione finora

- Construction of Rajive Gandhi Urja Bhawan, Ongc Energy Center & Corporate OfficeDocumento23 pagineConstruction of Rajive Gandhi Urja Bhawan, Ongc Energy Center & Corporate OfficeDevendra SharmaNessuna valutazione finora

- 03 Steel WedgeDocumento1 pagina03 Steel WedgeJay CeeNessuna valutazione finora

- MS For Reinforcement Cement ConcretingDocumento6 pagineMS For Reinforcement Cement ConcretingShan THALANessuna valutazione finora

- Division 3 Specs WrittingDocumento16 pagineDivision 3 Specs WrittingJaymar Palomares OrilloNessuna valutazione finora

- Mr. Pioc General SpecificationsDocumento11 pagineMr. Pioc General SpecificationsErick Anopol Del MonteNessuna valutazione finora

- Annex A - SpecificationsDocumento5 pagineAnnex A - SpecificationsDesigners Eng'gConsultancyNessuna valutazione finora

- ASTM Specs For Precast Concrete ProductsDocumento9 pagineASTM Specs For Precast Concrete ProductsPrateek Mody100% (1)

- Reinforced Concrete Buildings: Behavior and DesignDa EverandReinforced Concrete Buildings: Behavior and DesignValutazione: 5 su 5 stelle5/5 (1)

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringDa EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringValutazione: 4 su 5 stelle4/5 (5)

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionDa EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNessuna valutazione finora

- VSL (2464)Documento2 pagineVSL (2464)Ammar A. AliNessuna valutazione finora

- Thermal Stresses: Jake Blanchard Spring 2008Documento11 pagineThermal Stresses: Jake Blanchard Spring 2008Muhammad NaveedNessuna valutazione finora

- 5704 Ca 14 Ae 380Documento4 pagine5704 Ca 14 Ae 380Ammar A. Ali100% (1)

- Section Adequacy:: For Solid Section: For Hollow SectionDocumento1 paginaSection Adequacy:: For Solid Section: For Hollow SectionAmmar A. AliNessuna valutazione finora

- Thermal Stresses: Jake Blanchard Spring 2008Documento11 pagineThermal Stresses: Jake Blanchard Spring 2008Muhammad NaveedNessuna valutazione finora

- Jce 67 2015 1 1 1136 enDocumento9 pagineJce 67 2015 1 1 1136 enAmmar A. AliNessuna valutazione finora

- Two-Way Slab Design Using The Coefficient MethodDocumento7 pagineTwo-Way Slab Design Using The Coefficient MethodJason Edwards97% (66)

- 1 571 4Documento15 pagine1 571 4Ammar A. AliNessuna valutazione finora

- 1 s2.0 S1877705816327643 MainDocumento7 pagine1 s2.0 S1877705816327643 MainAmmar A. AliNessuna valutazione finora

- Two-Way Slab Design Using The Coefficient MethodDocumento7 pagineTwo-Way Slab Design Using The Coefficient MethodJason Edwards97% (66)

- 1 571 4Documento15 pagine1 571 4Ammar A. AliNessuna valutazione finora

- Steel Structures, Multi Storey Building AnalysisDocumento6 pagineSteel Structures, Multi Storey Building AnalysisIk Einstein OjoganNessuna valutazione finora

- Jce 67 2015 1 1 1136 enDocumento9 pagineJce 67 2015 1 1 1136 enAmmar A. AliNessuna valutazione finora

- Prof. Connor Section 5: Non-Linear Analysis of Members 5.1 Deformation AnalysisDocumento17 pagineProf. Connor Section 5: Non-Linear Analysis of Members 5.1 Deformation AnalysisAmmar A. AliNessuna valutazione finora

- 190 2 PDFDocumento10 pagine190 2 PDFAmmar A. AliNessuna valutazione finora

- Supplemented Companies As: Memo To Designers APRIL 1989 17-130Documento3 pagineSupplemented Companies As: Memo To Designers APRIL 1989 17-130Ammar A. AliNessuna valutazione finora

- 1 s2.0 S1877705816327643 MainDocumento7 pagine1 s2.0 S1877705816327643 MainAmmar A. AliNessuna valutazione finora

- 1 s2.0 S1877705816327643 MainDocumento7 pagine1 s2.0 S1877705816327643 MainAmmar A. AliNessuna valutazione finora

- Supplemented Companies As: Memo To Designers APRIL 1989 17-130Documento3 pagineSupplemented Companies As: Memo To Designers APRIL 1989 17-130Ammar A. AliNessuna valutazione finora

- 2007 SEM Ann Conf s04p01 Investigations Static Dynamic Performance Railway PrestressedDocumento11 pagine2007 SEM Ann Conf s04p01 Investigations Static Dynamic Performance Railway PrestressedAmmar A. AliNessuna valutazione finora

- 1 s2.0 S1877705816327643 MainDocumento7 pagine1 s2.0 S1877705816327643 MainAmmar A. AliNessuna valutazione finora

- Supplemented Companies As: Memo To Designers APRIL 1989 17-130Documento3 pagineSupplemented Companies As: Memo To Designers APRIL 1989 17-130Ammar A. AliNessuna valutazione finora

- 1 s2.0 S1877705816327643 MainDocumento7 pagine1 s2.0 S1877705816327643 MainAmmar A. AliNessuna valutazione finora

- 08 Plasticity 01 Introduction PDFDocumento11 pagine08 Plasticity 01 Introduction PDFAmmar A. AliNessuna valutazione finora

- 2007 SEM Ann Conf s04p01 Investigations Static Dynamic Performance Railway PrestressedDocumento11 pagine2007 SEM Ann Conf s04p01 Investigations Static Dynamic Performance Railway PrestressedAmmar A. AliNessuna valutazione finora

- 02 Actual Applications and Potential of Textile-Reinforced ConcreteDocumento11 pagine02 Actual Applications and Potential of Textile-Reinforced ConcreteAmmar A. AliNessuna valutazione finora

- Supplemented Companies As: Memo To Designers APRIL 1989 17-130Documento3 pagineSupplemented Companies As: Memo To Designers APRIL 1989 17-130Ammar A. AliNessuna valutazione finora

- Sol Assign2Documento2 pagineSol Assign2Ammar A. AliNessuna valutazione finora

- Plastic eDocumento125 paginePlastic eChandrakanta MishraNessuna valutazione finora

- 1 s2.0 S1877705816327643 MainDocumento7 pagine1 s2.0 S1877705816327643 MainAmmar A. AliNessuna valutazione finora

- Melange YarnDocumento2 pagineMelange YarnKingson_786100% (3)

- HDPE Material of PipeDocumento6 pagineHDPE Material of PipeAnggi Gusti RizaNessuna valutazione finora

- Boba Fett Helmet TutorialDocumento109 pagineBoba Fett Helmet Tutorialstaticfactory92810% (1)

- Monarch Epoxy Flooring - Floor Coating - For Industrial & Domestic UseDocumento2 pagineMonarch Epoxy Flooring - Floor Coating - For Industrial & Domestic UsegangadevimgmNessuna valutazione finora

- Tubes and SdfspipesDocumento19 pagineTubes and SdfspipesScumfucOutlawNessuna valutazione finora

- Wall Structures: After The Foundations Have Been Completed The Walls Are Set Out and Construction CommencesDocumento16 pagineWall Structures: After The Foundations Have Been Completed The Walls Are Set Out and Construction CommencesMirza Waqar BaigNessuna valutazione finora

- Building Construction WoodDocumento30 pagineBuilding Construction WoodDaryl Gomez Timatim100% (1)

- Graco Husky 515 Diaphragm Pump Data SheetDocumento8 pagineGraco Husky 515 Diaphragm Pump Data SheetMROstop.comNessuna valutazione finora

- Road Marking Paint - AlkydDocumento2 pagineRoad Marking Paint - AlkydCharith LiyanageNessuna valutazione finora

- Reactive Powder ConcreteDocumento15 pagineReactive Powder ConcreterishinathnehruNessuna valutazione finora

- Service RegisterDocumento60 pagineService RegisternikunjNessuna valutazione finora

- Hand Lay UpDocumento29 pagineHand Lay UpRavendran Krishnan100% (2)

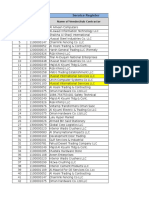

- Technical ProgrammeDocumento60 pagineTechnical ProgrammeAmy FitzgeraldNessuna valutazione finora

- 9 FtestDocumento4 pagine9 Ftest박찬우100% (2)

- Premium Quality Synthetic Rotary Vacuum Pump Oil: SV-77Documento9 paginePremium Quality Synthetic Rotary Vacuum Pump Oil: SV-77supervacoilsNessuna valutazione finora

- AWJMDocumento43 pagineAWJMgajendra2010Nessuna valutazione finora

- Lecture 13 Processing of PlasticsDocumento45 pagineLecture 13 Processing of PlasticsSilentxpireNessuna valutazione finora

- Integra Kitchen Design by Pedini San FranciscoDocumento68 pagineIntegra Kitchen Design by Pedini San FranciscoPedinisfNessuna valutazione finora

- Fairmate Guide For Your HomeDocumento8 pagineFairmate Guide For Your HomefairmatechemicalNessuna valutazione finora

- TCN-01 B1206Documento23 pagineTCN-01 B1206Riya AgarwalNessuna valutazione finora

- Plastocrete RT6 PlusDocumento2 paginePlastocrete RT6 PlusElricaSyaukaniNessuna valutazione finora

- Cast-In Place ConcreteDocumento217 pagineCast-In Place ConcreteFarid ObandoNessuna valutazione finora

- Brochure Dramix For Concrete ReinforcementDocumento15 pagineBrochure Dramix For Concrete ReinforcementVincentNessuna valutazione finora

- Hytrel Product Reference GuideDocumento4 pagineHytrel Product Reference GuideashkansoheylNessuna valutazione finora

- Peppers A2LCF GlandDocumento2 paginePeppers A2LCF GlandBob JohnsonNessuna valutazione finora

- 11-02-24r Glaverbel-SunergyDocumento16 pagine11-02-24r Glaverbel-SunergydatanotionNessuna valutazione finora

- Raychem e CatalogDocumento99 pagineRaychem e Catalogarifayee-1Nessuna valutazione finora

- Weber Dry 110 FX: Flexible High-Performance Cement-Based Waterproof CoatingDocumento2 pagineWeber Dry 110 FX: Flexible High-Performance Cement-Based Waterproof CoatingRamzi MusthafaNessuna valutazione finora

- TTT DiagramDocumento31 pagineTTT DiagramEducated SmugglerNessuna valutazione finora