Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Repair, NOTscrap

Caricato da

Than Zaw HtayDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Repair, NOTscrap

Caricato da

Than Zaw HtayCopyright:

Formati disponibili

Sulzer Turbo Services Venlo B.V.

Spikweien 36 NL-5943 AD Lomm, The Netherlands Phone +31 77 473 8666 Fax +31 77 473 2785 www.sulzerts.com

To Whom it my concern

Our ref. Phone direct Fax direct E-Mail direct Document Date +31 77 473 8666 +41 77 473 2785 Peter.vanNeerven@sulzer.com

SULZER TURBO SERVICES VENLO Capabilities: REPAIR, NOT SCRAP !! Rescued from scrap Sulzer Turbo Services Venlo (TS Venlo) has always pushed the boundaries and is a pioneer in the search for new techniques to repair even the worst condition parts. For this we have successfully developed repairs using laser welding and other special processes. We have attached a few examples were we have rescued components from SCRAP were other competitors, including the OEM, were not able to repair. These parts are now running safely in turbines. Lowest price suppliers in many cases scrap or reject many components since these companies are both financially as well as technically not able to effectively refurbish gas turbine hot section parts. TS Venlo however is recognized in the Industry for the low scrap rates and high quality and therefore we have rescued/repaired a lot of parts for customers and prevented the customer to buy very expensive NEW parts from the OEM. If orders would have been evaluated afterwards and not only at the tender opening, TS Venlo would have been the better alternative, taking into account that NO replacement of scrap parts by NEW parts would have been necessary. We at TS Venlo have invested a lot of efforts in the Research & Development for new repair techniques to RESCUE customers parts from being scrapped. We are successfully offering these special repairs to our customers. On the following pages several of many examples are showed to emphasize which parts & developments (processes) we have used to rescue components from scrap. In addition, TS Venlo is able to provide non-OEM new manufacturing of gas turbine components instead of our existing refurbishment technology, if customer wishes. For more information, Please do not hesitate to contact us. Yours sincerely,

Peter van Neerven Regional Sales Manager Sulzer TS Venlo

Sulzer Turbo Services

RESCUED FROM SCRAP

(Few examples out of many repairs)

ABB13E2 stage 1 vane NEW Version A (Meishi , China) scrapped by OEM and UK repair company because of extensive airfoil & platform cracks

ABB13E2 stage 1 vane NEW Version A (Meishi , China) Rescued by coupon repair using laser welding

ABB13E2 stage 1 vane Version 96 (Indonesia / other) Scrapped by OEM and non-OEM Rescued by (several shapes of) coupon repairs using laser welding

Sulzer Turbo Services

X: Area of concern in case of cracks

ABB13E2 stage 1 blade Version 96 (various customers) Scrapped by OEM and non-OEM Rescued by special repair using laser welding

Sulzer Turbo Services

ABB11D/13D3 stage 1 blades (Saudia, Bahrain-ALBA/other) Scrapped by OEM and non-OEM Rescued by coupon repair using laser welding

Before and after coupon repair

Sulzer Turbo Services

Siemens V64.3 stage 1 vanes (Amata, Thailand) Scrapped by others and rescued by coupon repair using laser welding

GE F6 stage 1 nozzle (Oman) Scrapped by OEM and other local repair companies Rescued by heavy coupon repair

Sulzer Turbo Services

GE F9E stage 1 buckets set (SEWA, Sharjah UAE) Scrapped by OEM and others for heavy FOD Rescued by special welding processes and running for > 2 years in GT We also delivered NEW F9E components to SEWA which are fitted in a GT and started up early June 2005 (stage 1-2-3 buckets, stage 2 nozzle, shroud blocks, TPs and C/L)

GE F6B stage 1 buckets set (JinHua P/S China) Scrapped by UK repair company for heavy FOD Rescued by laser welding (April 2005)

Sulzer Turbo Services

GE F9E stage 1 buckets (Iran/other) LE cracks, scrapped by OEM and UK repair company

several sets rescued by Powder laser welding

Sulzer Turbo Services

GE F9E stage 2 Nozzle (Shenzhen Nanshan P/S, China) Scrapped by OEM and others for heavy FOD and overheating Rescued by inserting casted Leading Edge sections and special welding & brazing processes Alternatively we are able to deliver NEW F9E stage 1-2-3 nozzles when necessary

GE F6B stage 1 nozzel (Shaoxing P/S China) Scrapped by OEM and non-OEM repair company for heavy FOD Rescued by inserting new casted trailing edge patches (2005)

Sulzer Turbo Services

GE F9E complete rotor overhaul AES Elsta The Netherlands (Rescued from GE Scrap by machining & powder welding of heavily cracked shaft: Bearing did not get oil for 3 minutes)

ABB13D3 complete rotor overhaul

Pakka Malaysia

(Rescued from OEM Scrap : rotor was heavily damaged and bent as result of a failure)

Sulzer Turbo Services

GE F9FA complete rotor overhaul UK customer (Rescued from GE Scrap ; compressor rotor failed 4 times and Sulzer TS Venlo reverse engineered all compressor blades & vanes and made some modifications to prevent shim migration)

GE F9FA complete rotor overhaul & casing repair UK customer (Rescued from OEM Scrap : GE F-casings suffer from heavy deformations causing compressor blade tip rubbing and finally causing catastrophic failure. Sulzer TS Venlo repaired the casings and bring back to original shape)

Sulzer Turbo Services

Potrebbero piacerti anche

- 08 PawDocumento30 pagine08 PawAnupam KushwahaNessuna valutazione finora

- SPL - PQR-WPS-SWPS SmawDocumento7 pagineSPL - PQR-WPS-SWPS Smawgopuvinu4uNessuna valutazione finora

- Heat Treatment of SteelDocumento3 pagineHeat Treatment of SteelKristine ReyesNessuna valutazione finora

- 24 CalibrationDocumento9 pagine24 CalibrationAdhanom G.Nessuna valutazione finora

- Standard Welding Procedures: by Walter J. SperkoDocumento4 pagineStandard Welding Procedures: by Walter J. SperkoK ArunsiddharthNessuna valutazione finora

- Welding and Heat Treatment Requirements For Equipment and PipingDocumento34 pagineWelding and Heat Treatment Requirements For Equipment and Pipingonur gunesNessuna valutazione finora

- Wopq Format Asme Qw-360Documento1 paginaWopq Format Asme Qw-360Anonymous S33n8gNessuna valutazione finora

- Materials and Qualification Procedures For Ships: Book ADocumento15 pagineMaterials and Qualification Procedures For Ships: Book AJavier del AngelNessuna valutazione finora

- ITP Fuel Fillter (J-1001) Rev10+Documento9 pagineITP Fuel Fillter (J-1001) Rev10+DjokoNessuna valutazione finora

- QW 381Documento1 paginaQW 381Waqas WaqasNessuna valutazione finora

- WI-02 Thermal CuttingDocumento16 pagineWI-02 Thermal CuttingPrakash RajNessuna valutazione finora

- 2.2 - NDEP-C1574-5-6-7-8 - Rev.0 NDE Procedures Book PDFDocumento59 pagine2.2 - NDEP-C1574-5-6-7-8 - Rev.0 NDE Procedures Book PDFGeorge JhonsonNessuna valutazione finora

- 13cr Martensitic Stainless Steel PQR and Wps ReviewDocumento1 pagina13cr Martensitic Stainless Steel PQR and Wps Reviewenels77Nessuna valutazione finora

- SV Engineerings: Work InstructionDocumento5 pagineSV Engineerings: Work InstructionPrakash RajNessuna valutazione finora

- Declaration of Perormance-Le-ZnDocumento4 pagineDeclaration of Perormance-Le-ZnDavid SeeNessuna valutazione finora

- PS 3103Documento9 paginePS 3103JayeshNessuna valutazione finora

- WI-INSP-07 R2 Work Instruction-Inspection of PumpsDocumento5 pagineWI-INSP-07 R2 Work Instruction-Inspection of PumpsRakesh MishraNessuna valutazione finora

- EsscDocumento56 pagineEsscMakwana Mehul100% (1)

- Portfolio Storage&Drying Control ProcedureDocumento4 paginePortfolio Storage&Drying Control Procedurelaz_kNessuna valutazione finora

- Strip CladingDocumento26 pagineStrip Cladingviswamanoj100% (1)

- The New Declaration of Performance (Description)Documento39 pagineThe New Declaration of Performance (Description)Bogdan MuresanNessuna valutazione finora

- RWC Quality Manual 8 JulyDocumento15 pagineRWC Quality Manual 8 JulyVipin Kumar Parashar100% (1)

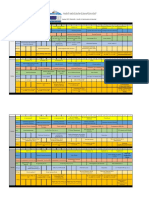

- FG - ASCQ3109 - Welding and Quality Technician - Final - PKG - 01.08.2019 PDFDocumento390 pagineFG - ASCQ3109 - Welding and Quality Technician - Final - PKG - 01.08.2019 PDFJim KaliNessuna valutazione finora

- Calc of NV3BDocumento7 pagineCalc of NV3BpharologstNessuna valutazione finora

- MT Sample ProcedureDocumento7 pagineMT Sample ProcedureAgustine SetiawanNessuna valutazione finora

- VW - TL 4225-2006-05 - (Alloyed Quenched and Tempered Steel 22MnB5 Uncoat or Precoat)Documento11 pagineVW - TL 4225-2006-05 - (Alloyed Quenched and Tempered Steel 22MnB5 Uncoat or Precoat)jorge solisNessuna valutazione finora

- PQR - WPQ Witness ReportDocumento1 paginaPQR - WPQ Witness Reportsdkeskar40Nessuna valutazione finora

- Weld RepireDocumento91 pagineWeld RepireالGINIRAL FREE FIRENessuna valutazione finora

- 1 en 1090 1 QuestionnaireDocumento5 pagine1 en 1090 1 QuestionnaireJohn PirretNessuna valutazione finora

- GMAW FundamentalsDocumento18 pagineGMAW FundamentalsYusup MulyanaNessuna valutazione finora

- ItnDocumento8 pagineItnPaolo FerrarottiNessuna valutazione finora

- IC-000113Documento23 pagineIC-000113hiralronny100% (1)

- Hust WPS Gtaw - Smaw 6GDocumento4 pagineHust WPS Gtaw - Smaw 6GtruongtrungplhdNessuna valutazione finora

- The Quality Standard For The Railway IndustryDocumento15 pagineThe Quality Standard For The Railway IndustryAnkurNessuna valutazione finora

- Ds Universal Wps Migmag enDocumento6 pagineDs Universal Wps Migmag enMarija IvanovskaNessuna valutazione finora

- Hardfacing Solutions For Oil Gas Applications V1Documento25 pagineHardfacing Solutions For Oil Gas Applications V1gacm98100% (1)

- Clarification On CE Marking With en 1090 1Documento5 pagineClarification On CE Marking With en 1090 1Simon KennyNessuna valutazione finora

- Laser Cladding Vs Other TechnologiesDocumento17 pagineLaser Cladding Vs Other Technologiesvenkat200a100% (2)

- VW 50060-1 - 2007-11 - (Cold Rolled-DUAL Phase Steel)Documento5 pagineVW 50060-1 - 2007-11 - (Cold Rolled-DUAL Phase Steel)JORGE SOLISNessuna valutazione finora

- FCAW Unit TestDocumento4 pagineFCAW Unit TestSatish KeskarNessuna valutazione finora

- Taking Your Weld's TemperatureDocumento6 pagineTaking Your Weld's Temperatureweldingheattreatment100% (1)

- Incoloy 800Documento2 pagineIncoloy 800shashi_uit100% (1)

- ASME IX InterpretationDocumento4 pagineASME IX InterpretationPatrick DominguezNessuna valutazione finora

- Asme 9 DatosDocumento47 pagineAsme 9 Datosvichu_villamarNessuna valutazione finora

- 120 PDFDocumento28 pagine120 PDFqczoomenNessuna valutazione finora

- Welder Qualifications ProcedureDocumento32 pagineWelder Qualifications ProcedureghanicwiNessuna valutazione finora

- ASMEDocumento38 pagineASMEshazanNessuna valutazione finora

- Wps & PQR For Valve Installation - XLSX Fix TerbaruDocumento20 pagineWps & PQR For Valve Installation - XLSX Fix TerbarufebriNessuna valutazione finora

- Training Session 5: Gas Turbine Repair: by Scott Hastie / Liburdi Turbine ServicesDocumento42 pagineTraining Session 5: Gas Turbine Repair: by Scott Hastie / Liburdi Turbine Serviceskp pkNessuna valutazione finora

- 06 Advanced Technology OfferingsDocumento27 pagine06 Advanced Technology Offeringsatfrost4638Nessuna valutazione finora

- WI-INSP-04 R0 Work Instruction-Agitator InspDocumento2 pagineWI-INSP-04 R0 Work Instruction-Agitator InspRakesh MishraNessuna valutazione finora

- Painting Report Cd3Documento15 paginePainting Report Cd3sivaNessuna valutazione finora

- Casting DefectsDocumento4 pagineCasting DefectsHamza KayaniNessuna valutazione finora

- KEMPPI Welding Technology Course: R.BanerjeeDocumento78 pagineKEMPPI Welding Technology Course: R.BanerjeeAnoop KushwahaNessuna valutazione finora

- Defects and Discontinuities: Boiler and Mechanical PowerDocumento78 pagineDefects and Discontinuities: Boiler and Mechanical PowerthejusNessuna valutazione finora

- Set-Up Tack Welding Procedure For Drum Long & Cirseam Butt Welds Control No. Revision No.: 0 Date: Page: 1 of 1Documento1 paginaSet-Up Tack Welding Procedure For Drum Long & Cirseam Butt Welds Control No. Revision No.: 0 Date: Page: 1 of 1sbmmlaNessuna valutazione finora

- Low Alloy SteelsDocumento54 pagineLow Alloy SteelsUsha Kiran KumarNessuna valutazione finora

- Repair NOTscrap PDFDocumento10 pagineRepair NOTscrap PDFRaden MasNessuna valutazione finora

- IMSE EU BrochureDocumento14 pagineIMSE EU BrochureDanny TaylorNessuna valutazione finora

- Furn svb08b enDocumento2 pagineFurn svb08b enapi-279886039Nessuna valutazione finora

- EN RFK Interface UniversellDocumento18 pagineEN RFK Interface UniversellIliescu CristianNessuna valutazione finora

- Base Industrial Engine EFI: 1.6-Litre 4-CylinderDocumento2 pagineBase Industrial Engine EFI: 1.6-Litre 4-CylinderTaimoor AhmedNessuna valutazione finora

- I-Smell TechnologyDocumento24 pagineI-Smell Technologyhimmatkanwar100% (3)

- Install Base in R12Documento3 pagineInstall Base in R12Hai Duc NguyenNessuna valutazione finora

- S4 Analytics OptionsDocumento6 pagineS4 Analytics Optionsnewkaox2009Nessuna valutazione finora

- Project Report HateDocumento24 pagineProject Report HateMachine Learning100% (1)

- Washing Machine: Service ManualDocumento66 pagineWashing Machine: Service ManualFernando AlmeidaNessuna valutazione finora

- As 2159 2009 Piling Design and InstallationDocumento9 pagineAs 2159 2009 Piling Design and InstallationKinson LowNessuna valutazione finora

- EL - 5 - Planning and Arranging Transport-37-44Documento8 pagineEL - 5 - Planning and Arranging Transport-37-44Rizky AdiNessuna valutazione finora

- Product Thinking vs. Project ThinkingDocumento8 pagineProduct Thinking vs. Project ThinkingUjwal TickooNessuna valutazione finora

- Plant Maintenance StrategyDocumento8 paginePlant Maintenance Strategymirdza94Nessuna valutazione finora

- Aws Solution Architect Associate DemoDocumento19 pagineAws Solution Architect Associate Demonavin_netNessuna valutazione finora

- 3PDocumento4 pagine3PWookie T BradfordNessuna valutazione finora

- Kerio Connect Adminguide en 7.4.0 7098Documento402 pagineKerio Connect Adminguide en 7.4.0 7098Van NhoNessuna valutazione finora

- Cognitive API Using Neural NetworkDocumento30 pagineCognitive API Using Neural NetworkAnish SNessuna valutazione finora

- What Exactly Is An Information SystemDocumento2 pagineWhat Exactly Is An Information SystemPeir Gen LowNessuna valutazione finora

- 8 Latest Kitchen Chimney Brands in India 2020Documento4 pagine8 Latest Kitchen Chimney Brands in India 2020Sulagna ChowdhuryNessuna valutazione finora

- DWM1001 DatasheetDocumento30 pagineDWM1001 DatasheetJan KubalaNessuna valutazione finora

- Using Avaya Health Check ToolDocumento24 pagineUsing Avaya Health Check ToolkokostNessuna valutazione finora

- Nursing Information System Team Information TechnologyDocumento8 pagineNursing Information System Team Information TechnologyCzarina Mae Quinones TadeoNessuna valutazione finora

- Manual de Reparacion MCR Serie 32-33Documento34 pagineManual de Reparacion MCR Serie 32-33Fernando Tapia Gibson100% (2)

- Q-1. What Is System Boundary? Ans.: Environment and BoundariesDocumento10 pagineQ-1. What Is System Boundary? Ans.: Environment and BoundariesTestNessuna valutazione finora

- Applied Information Processing Systems 2022Documento588 pagineApplied Information Processing Systems 2022Med KH100% (1)

- Time Table Spring 2022-2023 V2Documento3 pagineTime Table Spring 2022-2023 V2moad alsaityNessuna valutazione finora

- Jntuh 4-1 AttendanceDocumento15 pagineJntuh 4-1 Attendancedodda12345Nessuna valutazione finora

- ErewDocumento2 pagineErewKeet WongNessuna valutazione finora

- 1327 Brochure LPKF Protomats S Series enDocumento8 pagine1327 Brochure LPKF Protomats S Series enAlexNessuna valutazione finora

- Correspondence Between OHSAS 18001:2007, ISO 14001:2004 and ISO 9001:2000Documento3 pagineCorrespondence Between OHSAS 18001:2007, ISO 14001:2004 and ISO 9001:2000Deni NoizNessuna valutazione finora

- Even Sem Exam Scedule 2024Documento3 pagineEven Sem Exam Scedule 2024Ankit tutorialNessuna valutazione finora

- Development of An Android-Based Visual ImplementatDocumento8 pagineDevelopment of An Android-Based Visual ImplementatChidera EkeuhieNessuna valutazione finora